Piercing method and laser processing apparatus

A laser processing machine and processing method technology, applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problem that the workpiece cannot function effectively, and achieve the effect of effective penetration processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

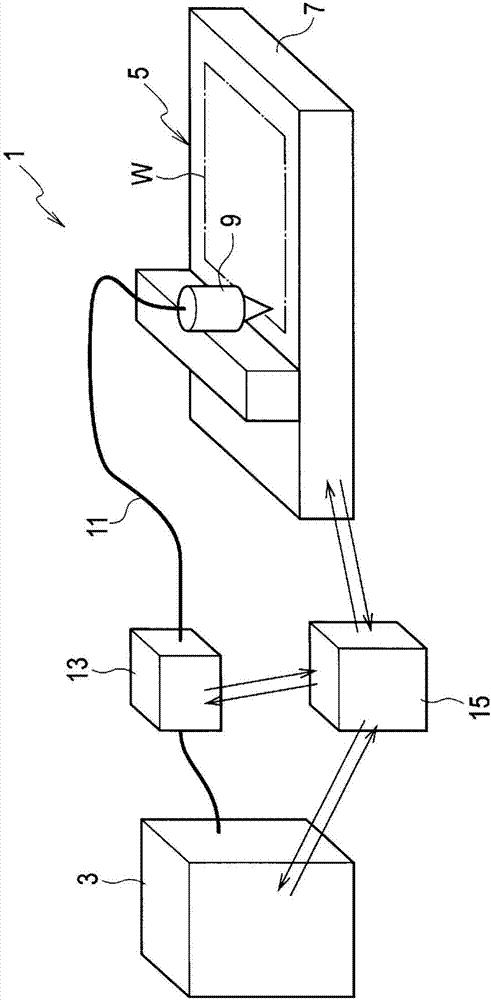

[0027] Such as figure 1 Conceptually and schematically shown, a laser processing machine (laser processing system) 1 according to an embodiment of the present invention includes a laser oscillator 3 and a processing machine main body 5 . The above-mentioned laser oscillator 3 is a laser oscillator such as a fiber laser oscillator that emits laser light having a wavelength in the 1 μm band. In addition, the above-mentioned laser oscillator 3 may use the semiconductor laser beam having the seed light having a wavelength of less than 1 μm as direct diode laser light. The processing machine main body 5 includes a laser processing cutting head 9 relatively movable and positioned in the X, Y, and Z axis directions with respect to a thick plate-shaped workpiece W such as a mild steel plate placed on the table 7 . A condensing lens (not shown) is arranged on the laser processing cutting head 9 . In addition, since the above-mentioned laser oscillator 3 and the processing machine mai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com