Hybrid welding continuous welding method and device, welded product, car body

A welding method and hybrid welding technology, applied in welding equipment, laser welding equipment, metal processing equipment, etc., can solve the problem of difficulty in escaping welding pores, and achieve the effects of reducing power density, reducing hydrogen holes, and increasing diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

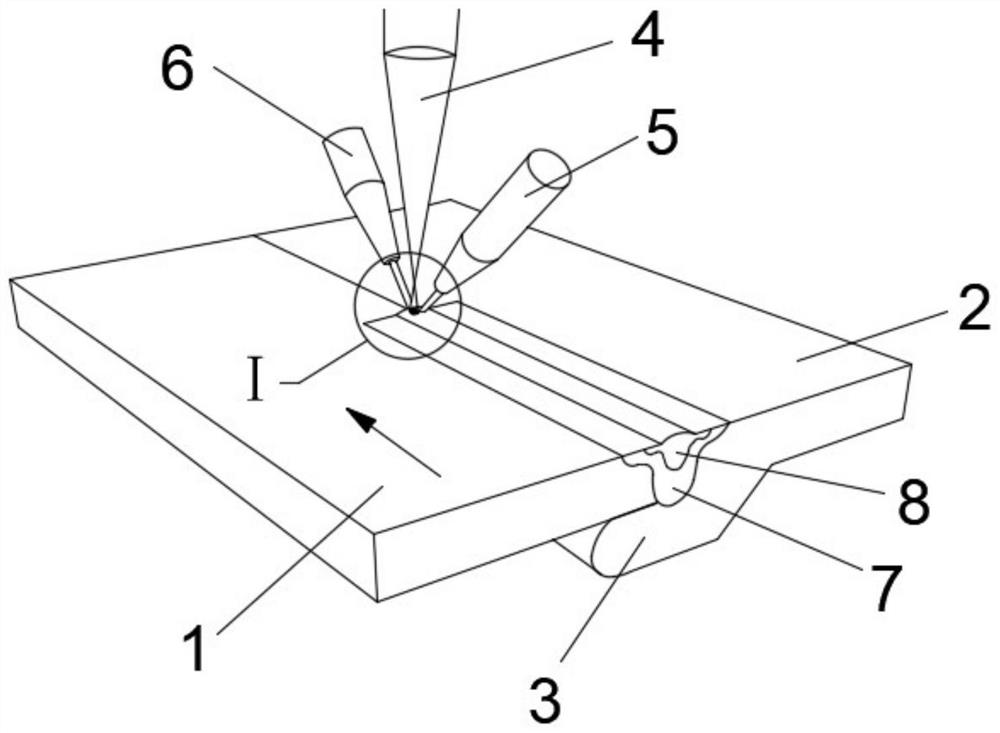

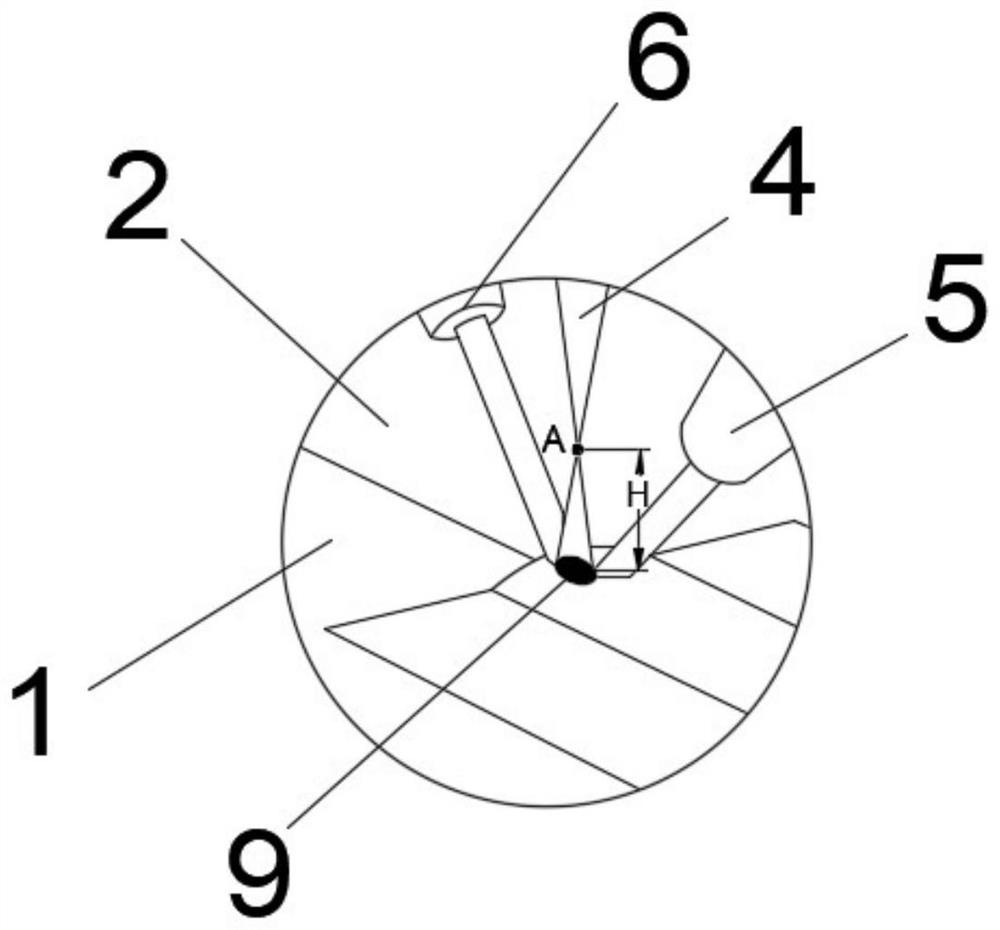

[0042] Such as figure 1 with figure 2 As shown, the hybrid welding continuous welding method provided in this embodiment includes: performing hybrid welding on the groove of the weldment by coupling laser and polarity-changing arc. Among them, the defocus amount H of the laser is not less than the Rayleigh length Z of the laser R. This method can use laser-polarity variable hybrid welding to realize continuous welding of the weldment to be welded, and use the energy coupling effect of hybrid welding to ensure welding stability, and at the same time expand the defocus of the laser beyond the range of the Rayleigh length of the laser, thereby It solves the problem that the welding pores are difficult to escape in the prior art, and effectively improves the welding stability and reliability.

[0043] In the traditional laser arc hybrid welding, the laser generated by it has no defocus or the defocus amount H is very small, so the laser spot 9 falling on the workpiece surface...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com