Method of producing a micro- or nano-mechanical part, comprising a femto-laser-assisted ablation step

A mechanical part, micron-level technology, used in the production of transmission parts, those transmission parts in clock/watch manufacturing, can solve problems such as difficulty in control, limit the accuracy of the ablation zone, limit the shape, etc., to achieve the effect of short duration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

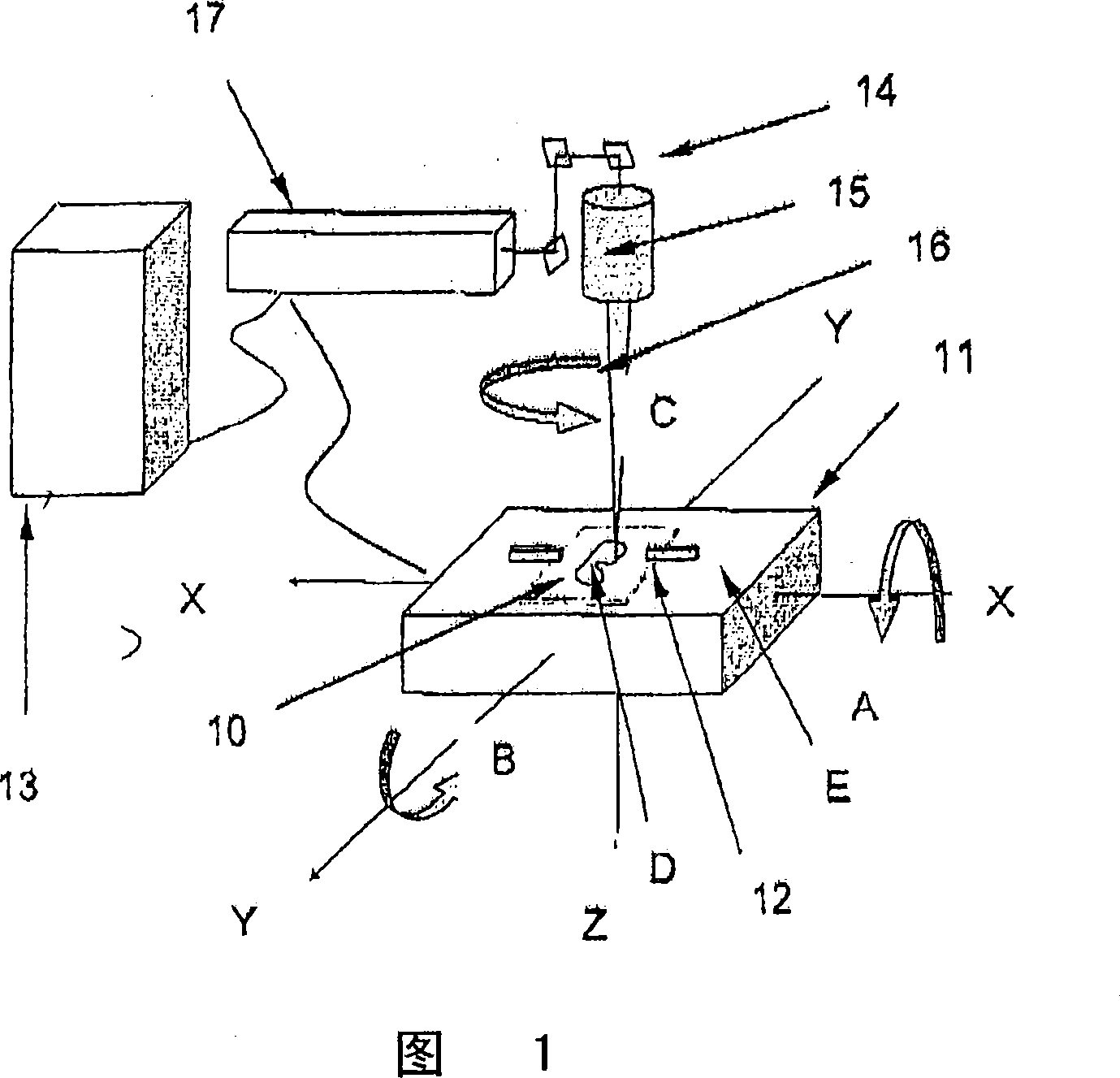

[0055] The device shown in Figure 1 is used to produce parts 10, this device is a synchronous or asynchronous transmission device, is used for transmitting motion or power, and it comprises:

[0056] Working surface 11, in this example 6 programmable axes (A, B, C, X, Y, Z) and holding device 12 (e.g. fastening splints, adhesives, magnets, vacuum, etc. system). The above-mentioned axes are controlled by the micron-level automatic machining program executed by the information processor 17 by means of compensation or updating means.

[0057] The information processor 13 mainly has a three-dimensional model software, such as a three-dimensional CAD system.

[0058] A femtosecond-type ultrashort pulse laser 14 with an optical head 15 for concentrating the emission of a laser beam 16 in a focal area.

[0059] Displacement control / manipulation information processor 17

[0060] Machining method

[0061] The information processor 13 can be constituted by such as a personal computer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com