Femtosecond laser ablation-surface coating combined processing method for super-hydrophobic surface

A super-hydrophobic surface and femtosecond laser technology, applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of time-consuming, weak stability, single function of super-hydrophobic structure, etc., to achieve strong stability, High processing precision, fast and efficient preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific implementation manner and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

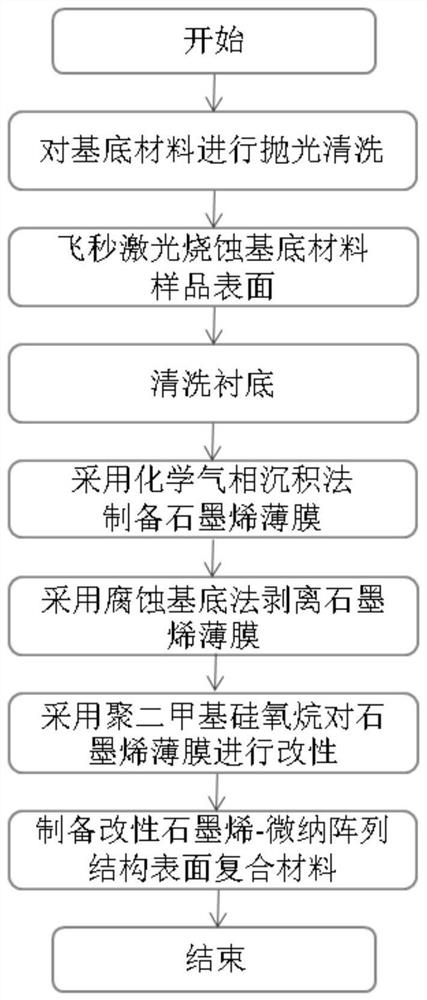

[0033] A composite processing method of femtosecond laser ablation-surface coating on a super-hydrophobic surface, the flow chart of which is as follows figure 1 shown.

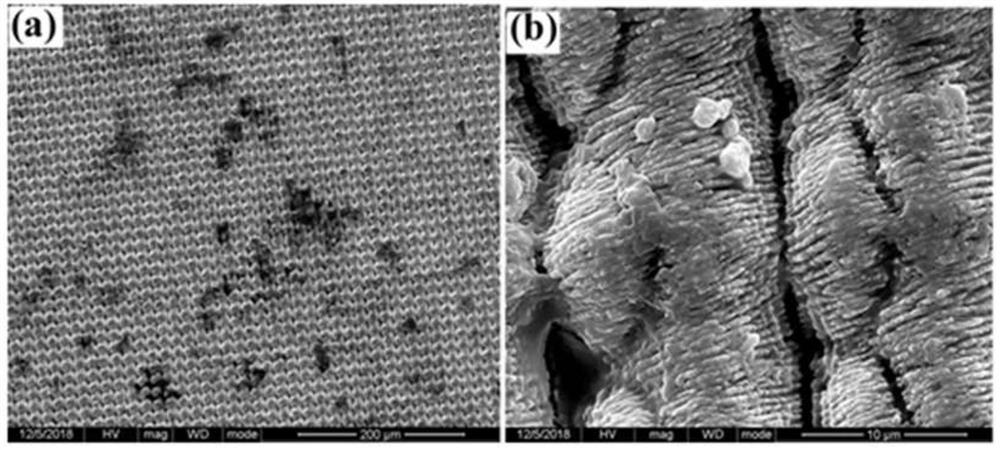

[0034] First, through FDTD software simulation, parameters such as femtosecond laser energy density, laser polarization state, and laser scanning distance are determined. In the actual processing process, as the laser pulse energy increases, the contact angle first increases and then decreases; therefore, the optimal pulse energy range for processing superhydrophobic surfaces is between 275 μJ and 325 μJ. Under the condition of the most suitable laser pulse energy, the change of the contact angle caused by changing the scanning speed and laser polarization state is not obvious. When the scanning speed is 0.8mm / s, the surface contac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com