Method for preparing mark stamp based on femtosecond laser ablation composite induction

A technology of femtosecond laser and femtosecond laser, applied in laser welding equipment, welding equipment, manufacturing tools, etc. Part processing and other issues, to achieve the effect of improving processing efficiency and recognition rate, good consistency, and reducing reflectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1, a method for preparing marks based on femtosecond laser ablation composite induction, comprising the following steps:

[0023] 1) Use an area of 2×2cm 2 , a TC4 metal sheet with a thickness of 2mm (the composition of the titanium alloy TC4 material is Ti-6Al-4V, containing the remainder of titanium (Ti), iron (Fe) ≤ 0.30, carbon (C) ≤ 0.10, nitrogen (N) ≤ 0.05 , hydrogen (H) ≤ 0.015, oxygen (O) ≤ 0.20, aluminum (Al) 5.5 ~ 6.8, vanadium (V) 3.5 ~ 4.5) as the processing object;

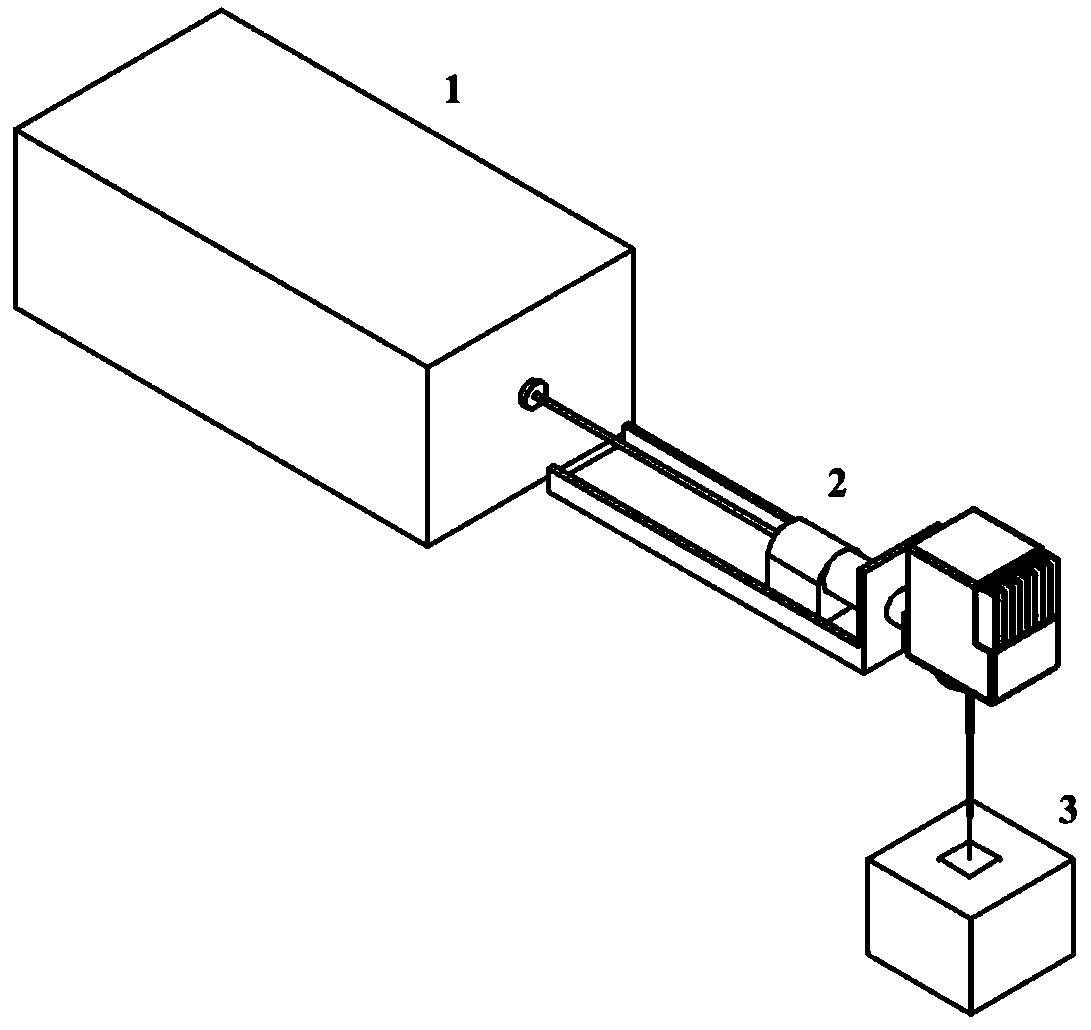

[0024] 2) Build an optical path, such as figure 1 As shown, the output light of the femtosecond laser 1 is focused on the scissor lift table 3 through the two-axis scanning galvanometer system 2, and the femtosecond laser 1 and the two-axis scanning galvanometer system 2 are connected to the computer;

[0025] 3) Using a computer to adjust the output laser of the femtosecond laser 1, the laser wavelength is 1030nm, the pulse width is 240fs, the repetition frequency is 50kHz, and...

Embodiment 2

[0029] In Example 2, the laser ablation parameters in Example 1 were set to scan speed 80 mm / s and groove spacing 10 μm, and the laser induction parameters were laser power 650 mW, scanning speed 30 mm / s and groove spacing 10 μm.

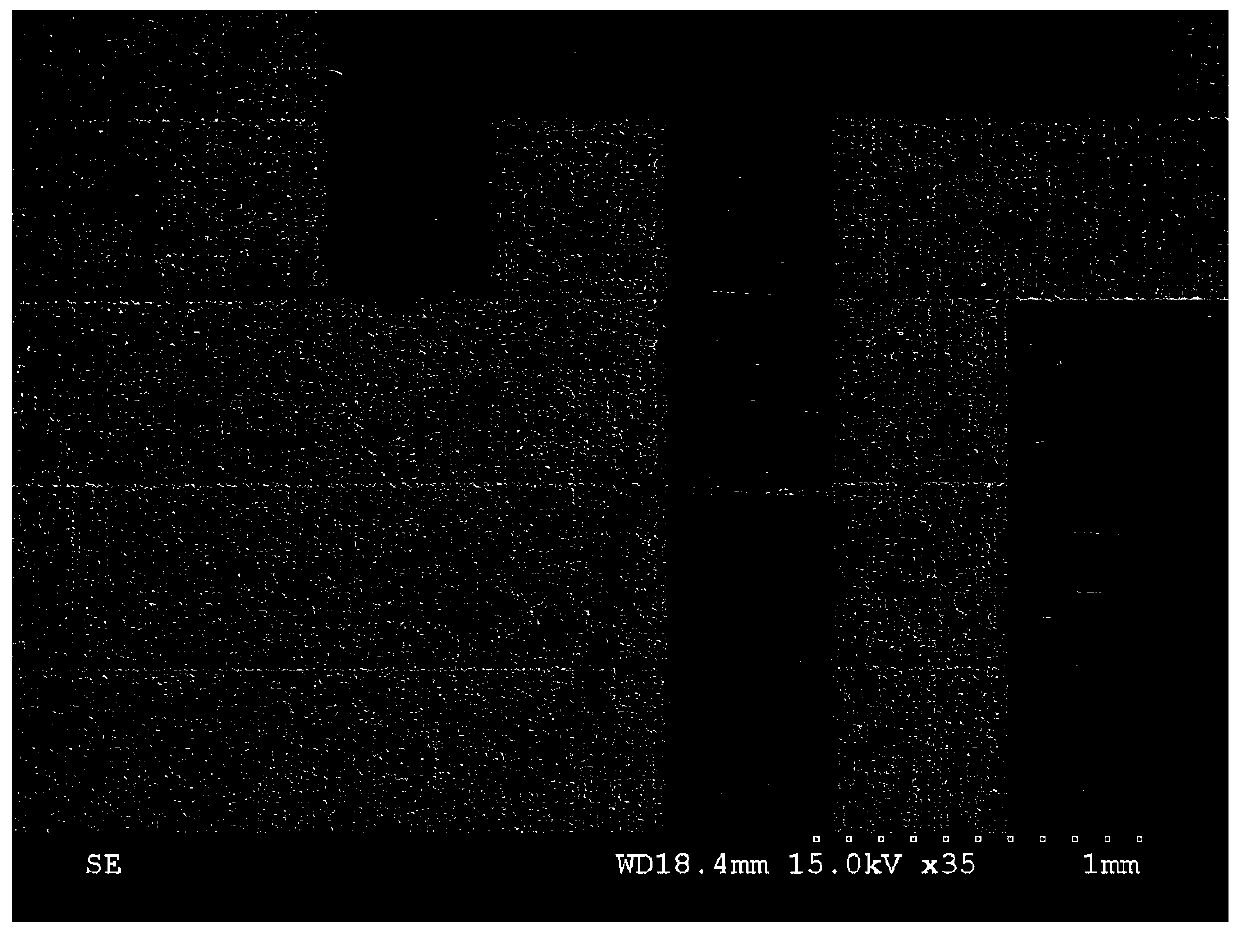

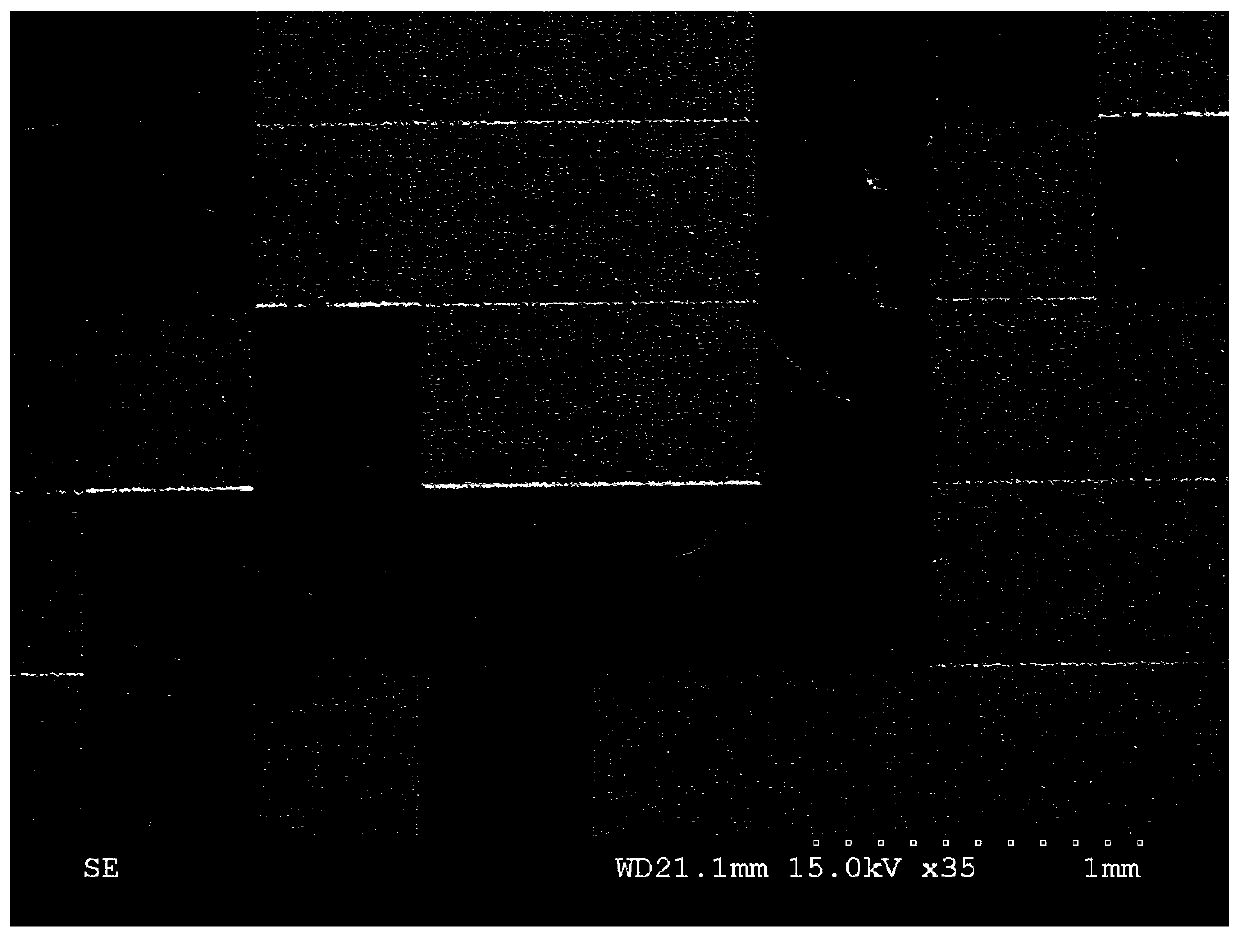

[0030] The beneficial effects of this embodiment are: image 3 , the melting of the marking unit obtained in this example is significantly reduced, the roughness is small, and the edge quality and consistency are better; the size of the marking unit is set to 500 μm, and the marking can be adjusted according to the amount of information carried and actual needs. Size, and this marking unit can be completed within 1.15s, with high efficiency; marking can be recognized by barcode equipment. refer to Figure 4 , Figure 4 for image 3 The zoom-in results of the marking unit show that micro-nano-scale structures are induced on its surface, thereby reducing the reflectivity of the marking pattern and effectively improving the recognition rate of the m...

Embodiment 3

[0031] Embodiment 3, the material among the embodiment 1 is selected as nickel base alloy GH4169 sheet metal (nickel base alloy GH4169 material is composed of nickel (Ni)≤56.02, iron (Fe)≤20.55, chromium (Cr)≤20.22, niobium ( Nb)≤3.21) as the processing object, the laser ablation parameters were set to scan speed 70mm / s and groove spacing 10μm, and the laser induction parameters were laser power 650mW, scanning speed 40mm / s and groove spacing 5μm.

[0032] The beneficial effects of this embodiment are: Figure 5 In this example, the marking unit was prepared by laser ablation compound induction on nickel-based alloy GH4169, and the overall quality was as good as that of titanium alloy TC4: the melting of the marking unit was significantly reduced, the roughness was small, and the edge quality was consistent Good performance; the size of the marking unit is set to 500μm, and the size of the marking can be adjusted according to the amount of information carried and the actual ne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com