Preparation method of gold nanoparticles

A gold nanoparticle and gold nanoparticle technology are applied in the field of preparing gold nanoparticles with controllable morphology, which can solve the problems of complex preparation process and conditions, unfavorable precise control of gold nanoparticles, etc., and achieve the effect of reducing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0012] The embodiment of the present invention provides a method for preparing gold nanoparticles. The method includes the following steps:

[0013] S1, to provide a gold ion-containing solution and a carboxylic acid solution containing at least two carboxyl groups as a reducing agent and a stabilizer, and

[0014] S2, mixing the gold ion-containing solution and the carboxylic acid solution to form a mixed solution, and reacting at 20°C to 60°C to form a gold nanoparticle colloidal solution.

[0015] In the above step S1, the gold ion-containing solution includes a solvent and a gold source dissolved in the solvent. The solvent includes one or more of water, ethanol, acetone, and chloroform, preferably water or ethanol. The embodiment of the present invention uses water as the solvent. The gold source is preferably chloroauric acid (HAuCl 4 ), gold chloride (AuCl 3 ) And potassium chloroaurate (KAuCl 4 ) One or more of. The embodiment of the present invention uses HAuCl 4 As the so...

Embodiment 1

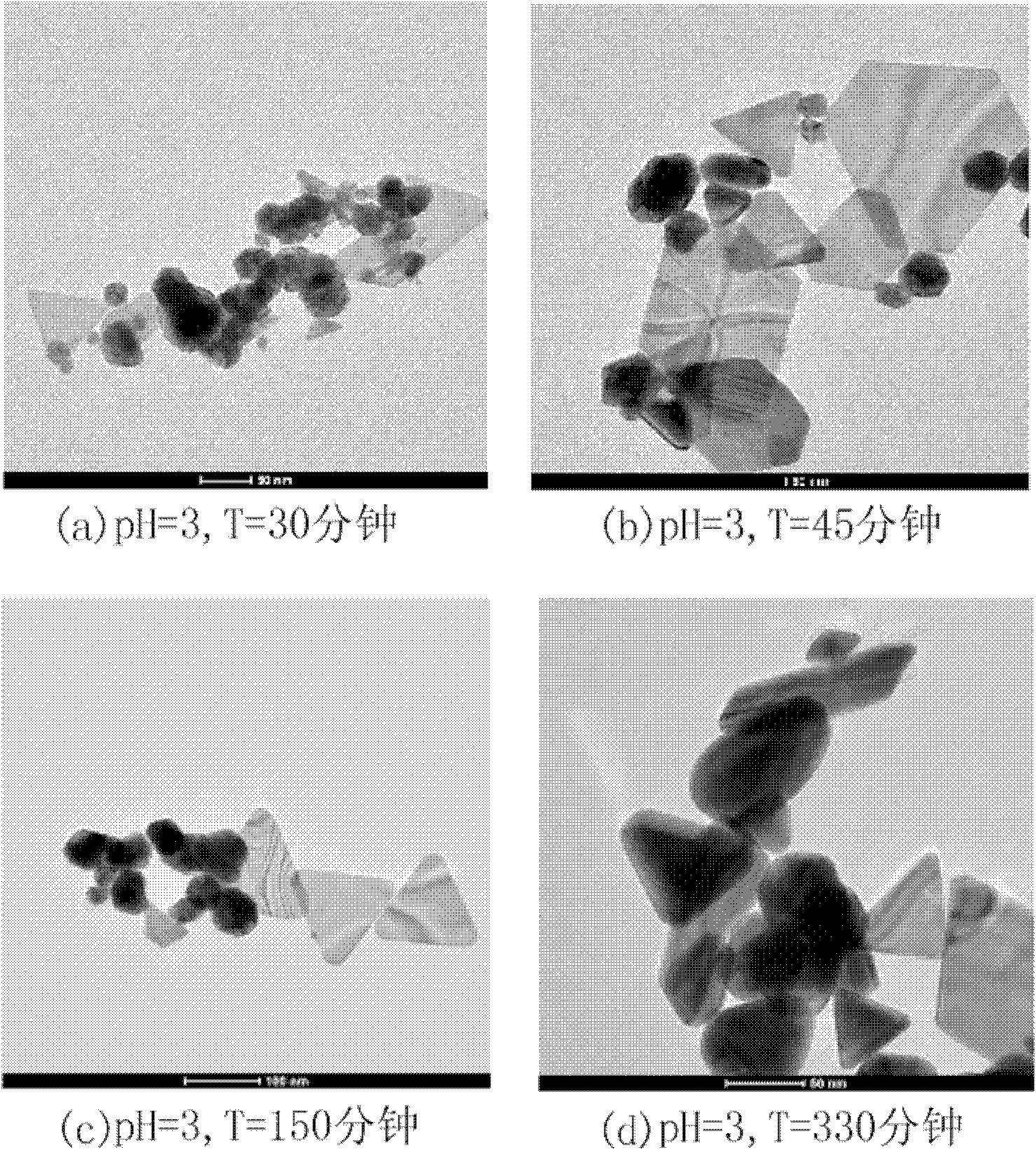

[0035] Preparation of gold nanosheets

[0036] The reactor was immersed with aqua regia, and washed with deionized water several times to remove the residual aqua regia in the reactor. The reactor was heated in a water bath at 50°C, and then the C was added at the molar ratio of the gold ion to the carboxylic acid 1:1. 6 H 8 O 7 Add HAuCl to the solution at once 4 A mixed solution is formed in the aqueous solution, and the pH of the mixed solution is adjusted to 3 with a hydrochloric acid solution, and the colloidal solution of gold nano particles produced by the reaction is obtained by sampling at different times. The sampling time is T = 30 minutes, T = 45 minutes, T = 150 minutes and T = 330 minutes. The sampled sample is immediately cooled with 4°C cold water to stop the reaction, and placed for 2 days before taking a TEM photo, please refer to figure 1 (a)~(d).

Embodiment 2

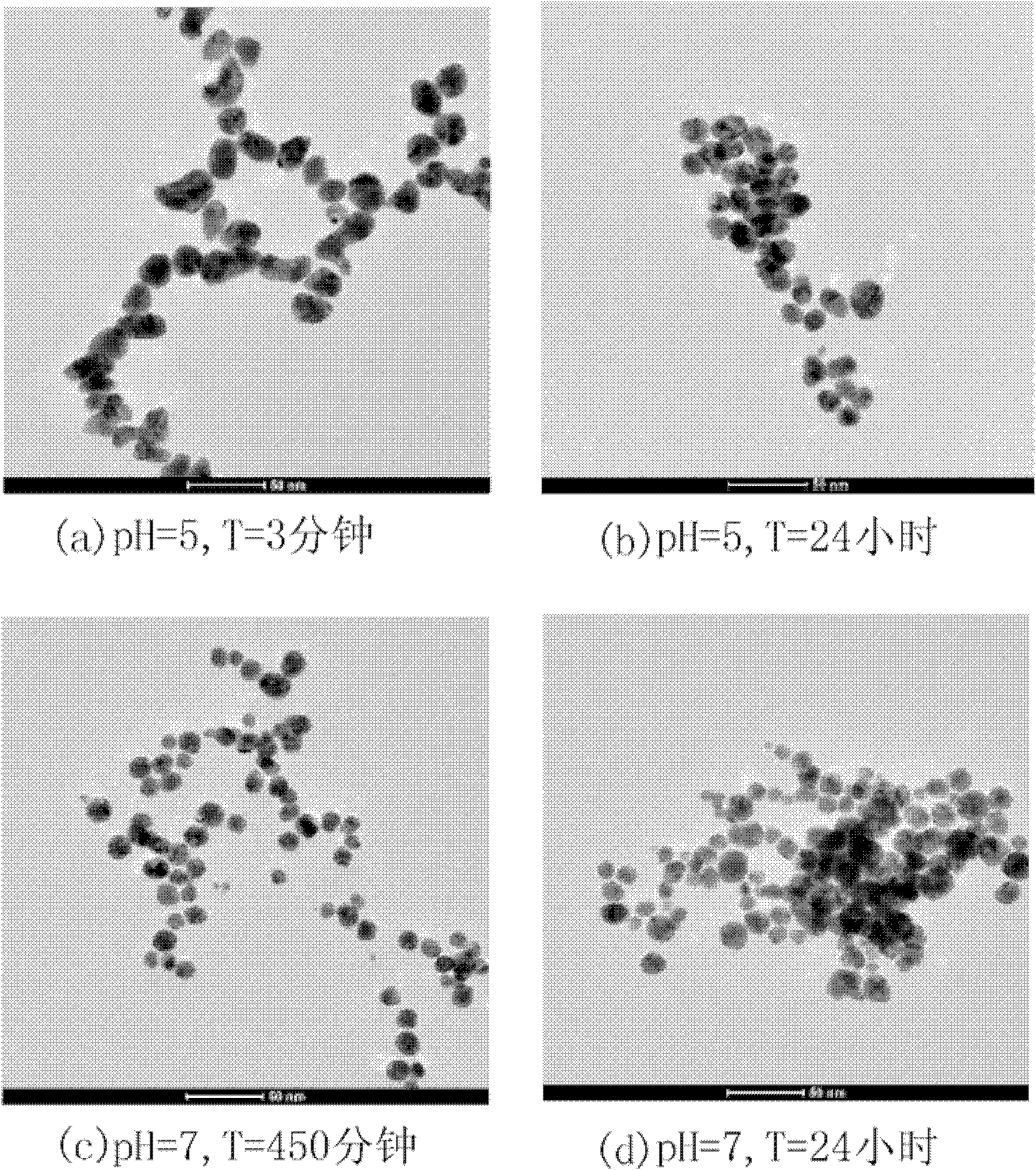

[0038] Preparation of gold nano mesh

[0039] The preparation process of the gold nano-mesh is the same as that of the above-mentioned embodiment 1, except that the pH of the mixed solution is adjusted to 5 with hydrochloric acid solution. The sampling time is T=3 minutes and T=24 hours. The sampled sample is immediately cooled with 4°C cold water to stop the reaction, and placed for 2 days before taking a TEM photo, please refer to figure 2 (a) and figure 2 (b).

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com