Method for accurately controlling overall morphology and performance of shallow trench isolation

A precise control, shallow trench technology, used in semiconductor/solid-state device manufacturing, electrical components, circuits, etc. groove morphology and other issues, to achieve the effect of improving development efficiency and product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

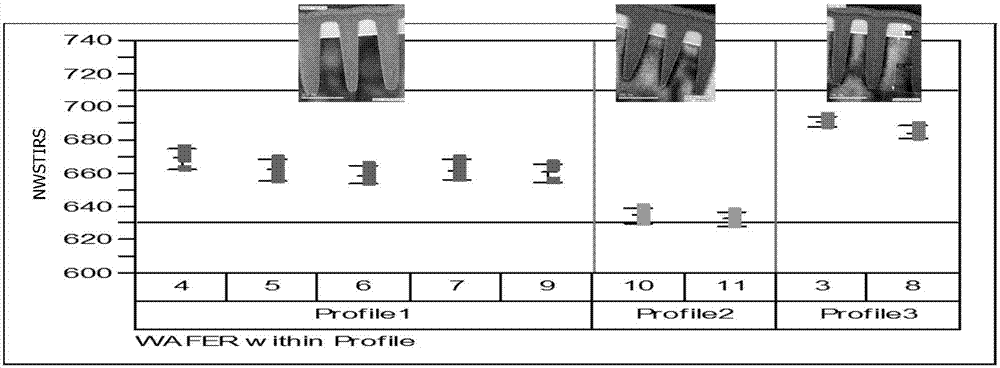

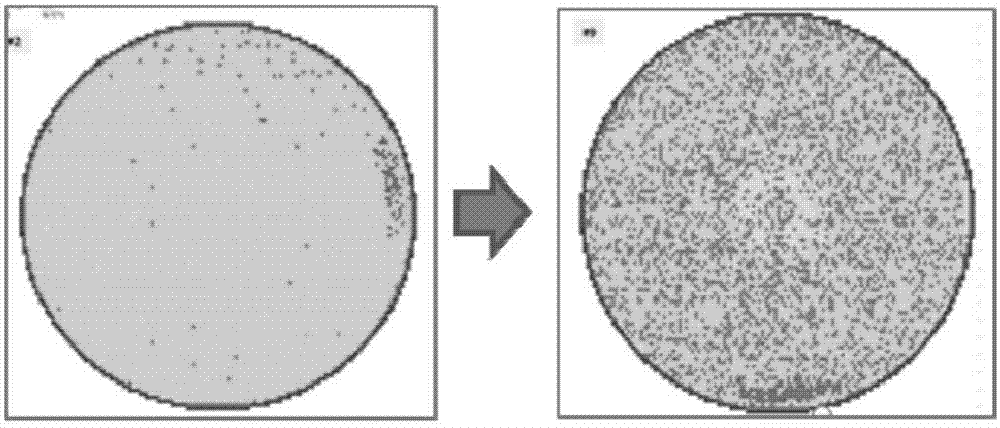

[0029] This embodiment 1 provides a method for accurately controlling the overall shape and performance of shallow trench isolation, using an optical linewidth measuring instrument to detect and quantify the three-dimensional waist shape parameters of shallow trench etching under different light transmittances, so that according to the shallow The three-dimensional waist shape parameters of trench etching are used to define the light transmittance range suitable for etching menu, so as to precisely control the overall shape and performance of shallow trench isolation.

[0030] In the first embodiment, the optical line width measuring instrument is used to accurately measure the three-dimensional waist shape of the shallow groove under the same etching condition and different light transmittance conditions, and the relationship between the three-dimensional waist shape parameters and the light transmittance is established. The relational model to define the transmittance interva...

Embodiment 2

[0036] The second embodiment provides a method for precisely controlling the overall shape and performance of shallow trench isolation, using an optical linewidth measuring instrument to detect and quantify the shallow trench etching under different light transmittances, including the three-dimensional waist shape parameters. Two or more three-dimensional topography parameters, so that the light transmittance range suitable for the etching menu can be defined according to the two or more three-dimensional topography parameters of shallow trench etching, including the three-dimensional waist topography parameters, and the shallow trench isolation can be precisely controlled overall shape and performance.

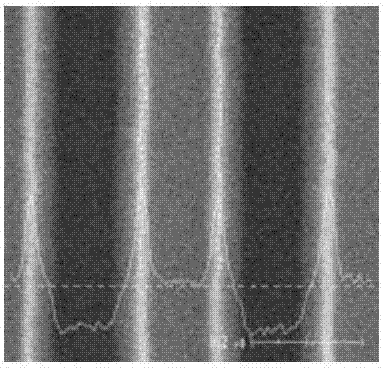

[0037] Figure 6 It is a schematic diagram of the cross-sectional structure of the optical line width measuring instrument measuring the shape parameters of the shallow groove. Please refer to Figure 6, the three-dimensional shape parameters in the present embodiment two i...

Embodiment 3

[0040] The third embodiment provides a method for accurately controlling the overall shape and performance of shallow trench isolation, including the step of using trenches instead of shallow trenches, that is, using an optical line width measuring instrument to detect and quantify the trench engraving under different light transmittances. According to the three-dimensional waist shape parameters etched by the groove or two or more three-dimensional shape parameters including the three-dimensional waist shape parameters, the three-dimensional waist shape parameters or two or more three-dimensional waist shape parameters The three-dimensional shape parameters are used to define the transmittance range suitable for the etching menu, so as to precisely control the overall shape and performance of the trench isolation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com