Janus particles with compatibility and preparation method thereof

A technology of biocompatibility and granules, which is applied in the field of Janus granules and its preparation, can solve problems such as limited applications, and achieve good biocompatibility, good biodegradability, and simple and easy methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Example 1: Preparation of biocompatible Janus particles with a particle size of about 400 nm

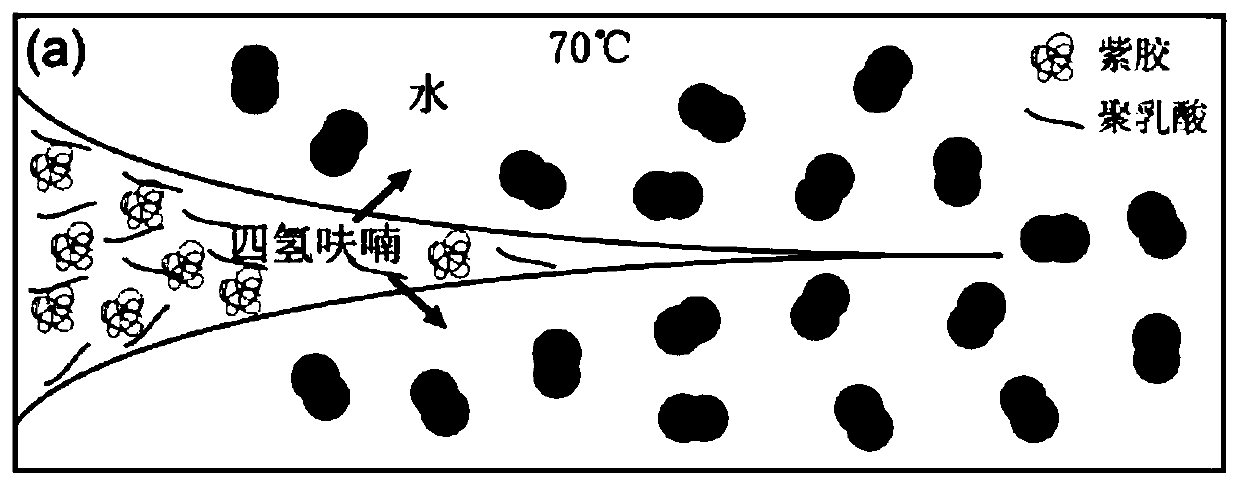

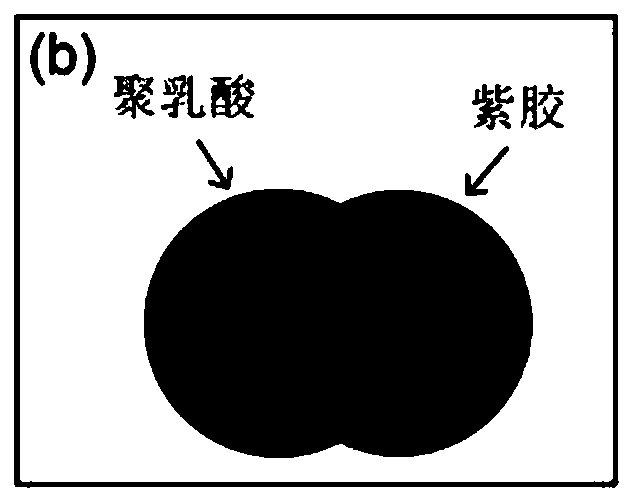

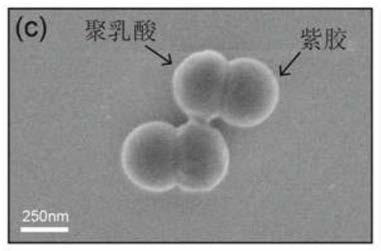

[0048]With reference to accompanying drawing 1 (a), adopt the method of the present invention to prepare the Janus particle with biocompatibility, concrete steps are as follows:

[0049] (1) Dissolve 120mg of shellac in 5ml of tetrahydrofuran, put it into the rotor and stir on a magnetic stirring table until the shellac is completely dissolved to obtain a shellac solution with a concentration of 24mg / ml; then dissolve 120mg of polylactic acid in the shellac solution , ultrasonically dispersed to obtain a mixed solution with a shellac concentration of 24 mg / ml and a polylactic acid concentration of 24 mg / ml. Add 1ml of Tween 80 to 100ml of deionized water, ultrasonically disperse in an ultrasonic cleaner, and then filter with a disposable syringe filter (specification: Φ25mm*0.45μm) to obtain an aqueous solution of Tween 80.

[0050] (2) Heat the mixed solution prepared in ste...

Embodiment 2

[0052] Embodiment 2: Janus particles in the particle shape change process in alkaline solution

[0053] (1) Dissolve 150mg of shellac in 5ml of tetrahydrofuran, put it into the rotor and stir on a magnetic stirring table until the shellac is completely dissolved to obtain a shellac solution with a concentration of 30mg / ml; then dissolve 150mg of polylactic acid in the shellac solution , ultrasonically dispersed to obtain a mixed solution with a shellac concentration of 30 mg / ml and a polylactic acid concentration of 30 mg / ml. Add 1ml of Tween 80 to 100ml of deionized water, ultrasonically disperse in an ultrasonic cleaner, and then filter with a disposable syringe filter (specification: Φ25mm*0.45μm) to obtain an aqueous solution of Tween 80.

[0054] (2) Heat the mixed solution prepared in step (1) and 3ml of Tween 80 aqueous solution in a constant temperature water bath, set the temperature of the water bath to 70°C, heat for 15min, and take 100 μl of the mixed solution prep...

Embodiment 3

[0058] Embodiment 3: Regulate the size of Janus particle by changing the initial concentration of material

[0059] (1) According to the steps of Example 1, change the concentration of shellac and polylactic acid in tetrahydrofuran, but keep the concentration of shellac and polylactic acid the same, set the following groups of concentrations: 2mg / ml, 6mg / ml, 12mg / ml ml, 18mg / ml, 24mg / ml, and 30mg / ml were used to prepare Janus particles with the same volume as the shellac hemisphere and the polylactic acid hemisphere, but the overall size of the particle changes within the range of hundreds of nanometers, as shown in the attached image 3 shown.

[0060] (2) the Janus particles of different sizes prepared in step (1) are used to measure particle size distribution by DLS method, and the results are as follows:

[0061] When the concentrations of shellac and PLA are both 2mg / ml, the average particle size of Janus particles is about 230nm;

[0062] When the concentrations of she...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com