Preparation method of microcarrier

A technology of microcarriers and macromolecular polymers, applied in the field of preparation of microcarriers, can solve the problems of limiting the application of microcarriers, different sizes of microcarriers, low efficiency, etc., shortening the solvent removal time, and accurately regulating the size and shape. Appearance, simple installation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] The invention discloses a preparation method of a microcarrier, and those skilled in the art can learn from the content of this article and appropriately improve the process parameters to achieve. In particular, it should be pointed out that all similar replacements and modifications are obvious to those skilled in the art, and they are all deemed to be included in the present invention. The method and application of the present invention have been described through the preferred embodiments. It is obvious that relevant persons can modify or appropriately change and combine the methods and applications described herein without departing from the content, spirit and scope of the present invention to achieve and Apply the technology of the present invention.

[0048] The raw materials, auxiliary materials or instruments used in the preparation method of the microcarrier provided by the present invention can all be purchased from the market.

Embodiment 1

[0050] Example 1 The influence of different preparation parameters on microcarriers

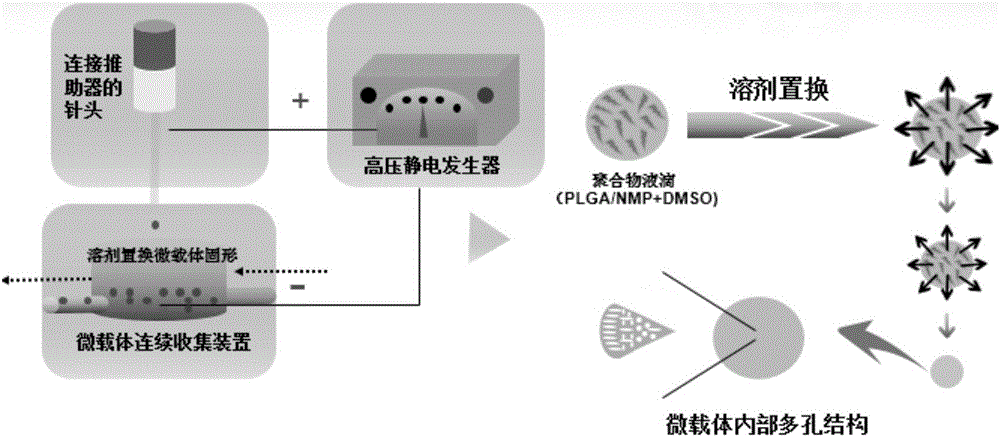

[0051] 1. Preparation method of PLGA microcarrier

[0052] This method uses high-polarity solvents such as DMSO and NMP to dissolve the PLGA solution made by PLGA, and then uses a high-voltage electrostatic field to charge the PLGA solution to overcome its surface tension. The surface of the Taylor cone at the end of the nozzle is sprayed at high speed with controllable particle size and good monodispersity. PLGA droplets, the droplets enter the replacement solution (water / ethanol mixture), and the organic solvent in the PLGA droplets is extracted by the principle of mutual solubility of polar solvents and water / ethanol mutual solutions to achieve the purpose of rapid solidification of the microcarriers. The specific method is as follows: Dissolve PLGA in a mixed solvent of DMSO and NMP (NMP:DMSO=10:0~0:10) to make a PLGA solution (PLGA concentration: 5%, 7%), and instill the PLGA solution through...

Embodiment 2

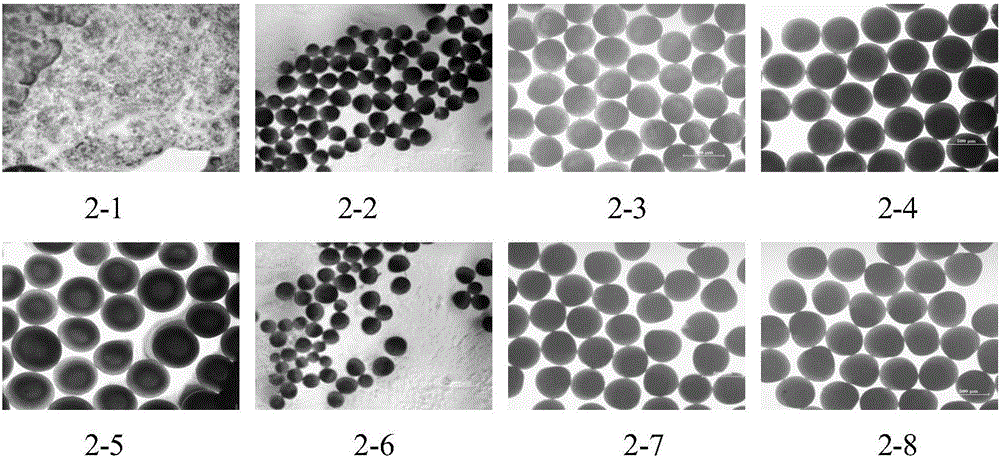

[0098] Example 2 Preparation of PLGA microcarriers

[0099] Use a mixed solvent of DMSO and NMP (NMP:DMSO=7:3) to dissolve PLGA to make a 5% PLGA solution, and add the PLGA solution through a needle by electrostatic instillation (voltage intensity 5kv, needle inner diameter 0.25mm) In the replacement solution, the replacement solution is an ethanol aqueous solution (water:ethanol=1:1), which is collected through a pipeline in the collection device. The prepared PLGA microcarriers were washed three times with water and ethanol solution respectively, and dried in vacuum for use. Observed under the electron microscope, the prepared microcarriers are regular spherical ( Picture 9 ), the surface morphology is smooth.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| percent by volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com