Preparation method for nanometer composite metal oxide

A nano-composite and composite metal technology, which is applied in the preparation of oxides/hydroxides, rare earth metal oxides/hydroxides, rare earth metal compounds, etc. Commercial application of the system, complex preparation equipment or process flow, etc., to avoid impure components and difficult to control microstructure, reduce pollutant emissions and production costs, reduce equipment costs and operational difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] One embodiment of the present invention provides a method for preparing a nano-composite metal oxide, comprising: using nano-metal oxide, one of the main metal components of the composite metal oxide, as a nano-template, and uniformly dispersing the nano-template in In the aqueous solution of water-soluble salts of other metal components in the composite metal oxide to obtain a mixed dispersion, the main metal component refers to a metal component whose molar content accounts for more than 30% of the molar content of all metal components; Dry the mixed dispersion by spray drying or vacuum drying to obtain a powder mixture; heat-treat the powder mixture so that the oxides generated by the decomposition of the water-soluble salt combine with the nano-metal oxides to form The nanocomposite metal oxide.

[0050] The scheme of the present invention uses nano-oxides of main metal elements as templates, and soluble salts (such as inorganic salts) added to the aqueous solution ...

Embodiment 1

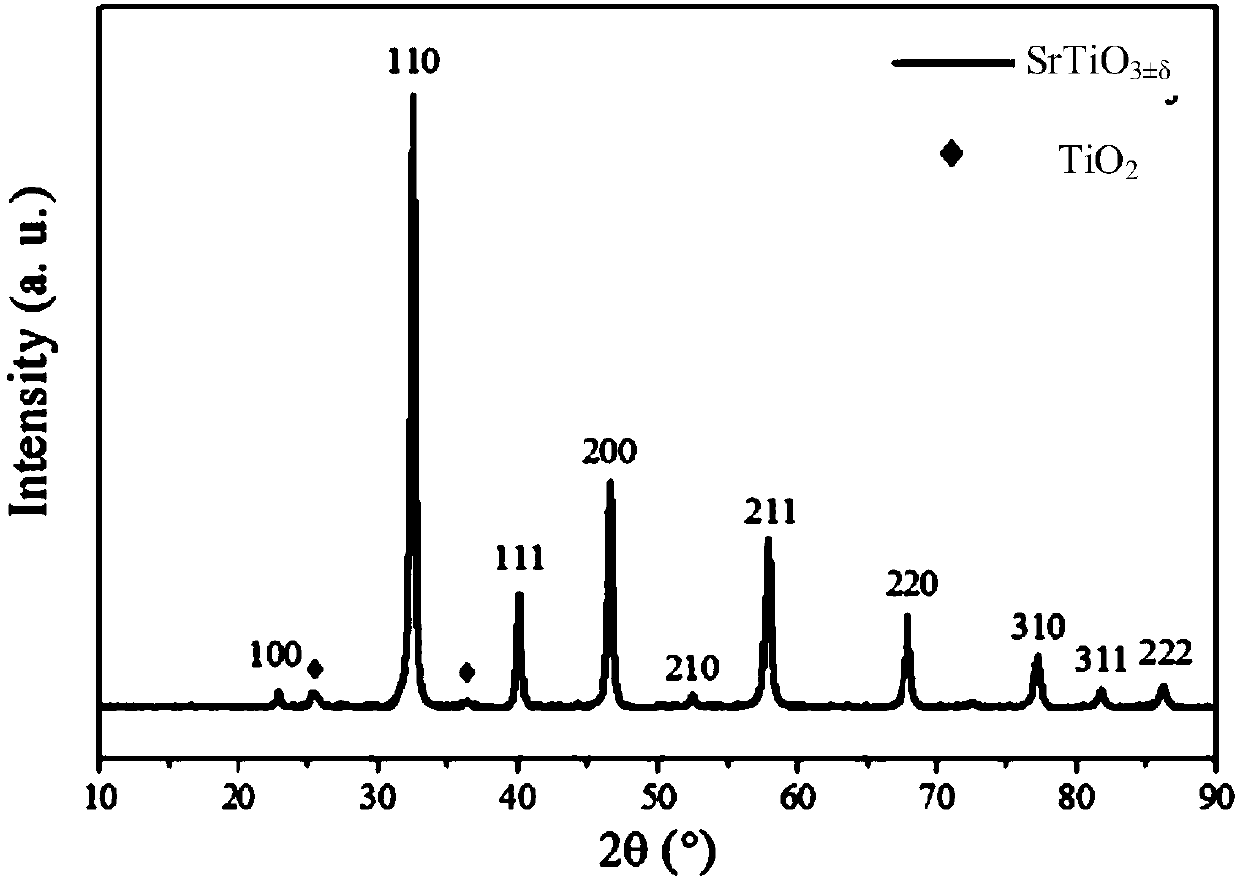

[0068] SrTiO 3±δ preparation of

[0069] 1. Weigh 0.2 mol of TiO with a particle size of about 15 nm 2 Put the particles in a beaker, add 100mL deionized water and stir to form a suspension, set as A;

[0070] 2. Weigh 0.2mol Sr(NO 3 ) 2 , add 800mL deionized water to dissolve, set as B;

[0071] 3. Slowly pour B into A, stir and mix evenly; add a small amount of surfactant (P123, PVP, Triton-100 or PEG400-2000) to form a stable suspension.

[0072] 4. Transfer the suspension in step 3 to a spray dryer for spray drying. The inlet air temperature is set to 150-180°C, the air flow is 120-200L / min, and the residence time is 1-4s;

[0073]5. After drying the powder at 120°C in a blast drying oven for 2 hours, take out the powder and pour it into a crucible, place the crucible in a muffle furnace, raise the temperature to 350°C at a heating rate of 1°C / min and keep it warm After cooling for 1 hour, place the crucible in the middle of the tube furnace, seal it and feed nitroge...

Embodiment 2

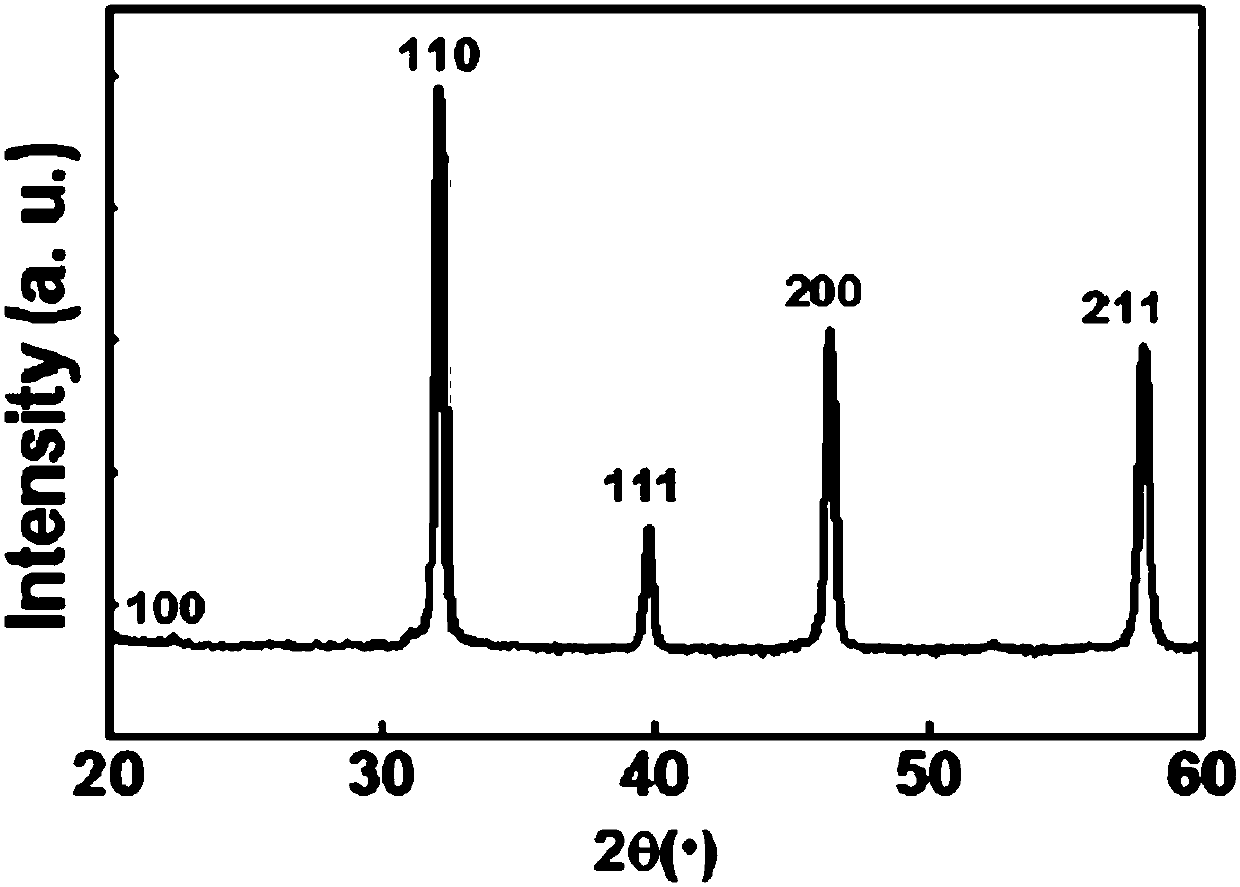

[0076] Sr 0.95 Ti 0.9 Nb 0.1 o 3±δ preparation of

[0077] 1. Weigh 0.18 mol of TiO with a particle size of 60 nm 2 Put the particles in a beaker, add 700mL deionized water and stir to form a suspension, set as A;

[0078] 2. Weigh 0.19mol Sr(NO 3 ) 2 Add 800mL deionized water to dissolve and set it as B; slowly pour B into A, stir and mix evenly to form solution C;

[0079] 3. Weigh 0.02mol C 4 h 4 NbO 9 , into C, stir rapidly, and add a small amount of surfactant (P123, PVP, Triton-100 or PEG400-2000) to form a stable suspension.

[0080] 4. Transfer the suspension in step 3 to a vacuum freeze dryer, quickly freeze it into a solid state at -10 to -50°C, and then directly sublimate the water into a gaseous state under a vacuum of 1.3 to 13Pa to remove it.

[0081] 5. Put the powder in the muffle furnace, raise the temperature to 350°C at a heating rate of 1°C / min and keep it warm for 1 hour. After cooling, place the crucible in the middle of the tube furnace, and a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com