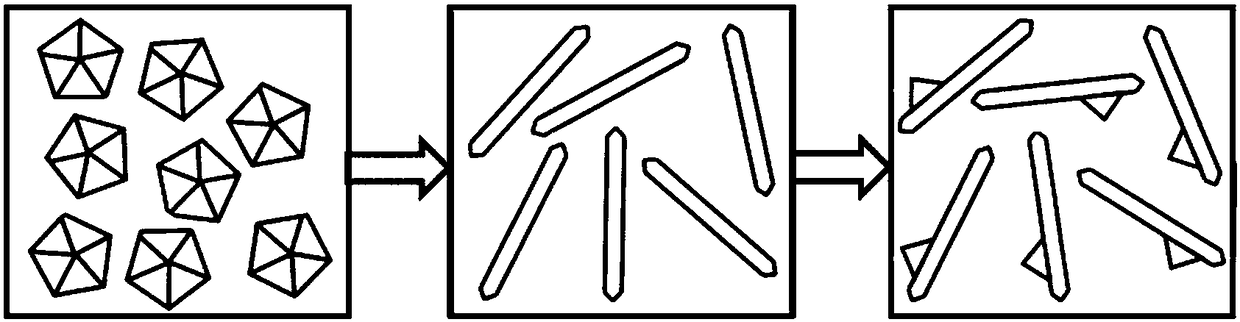

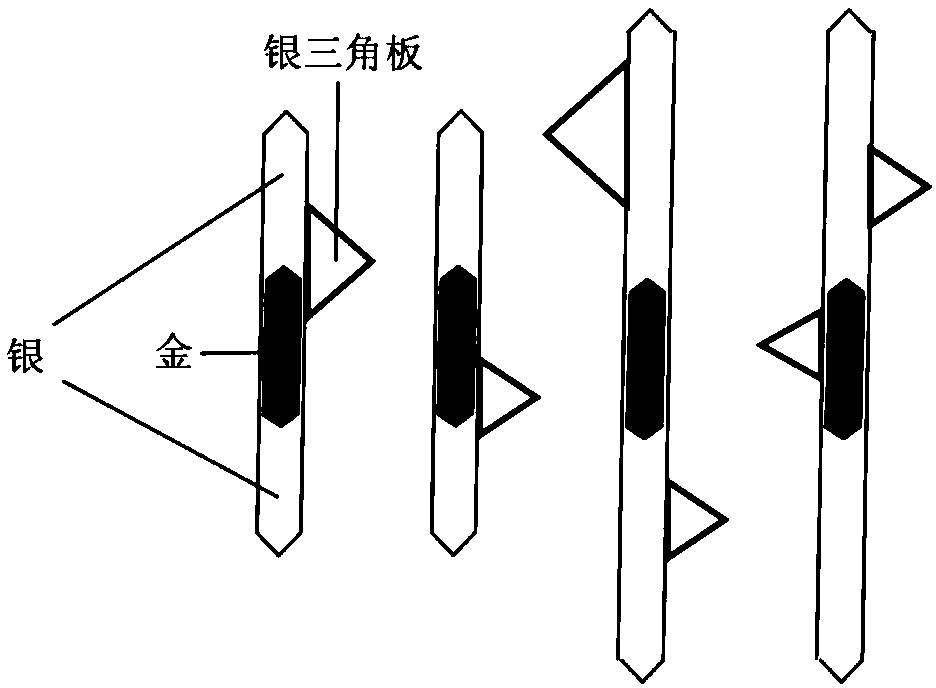

Large-scale controllable preparation method of surface plasmon nanonail structure

A technology of surface plasmons and nano-nails, applied in separation methods, nanotechnology for materials and surface science, chemical instruments and methods, etc., can solve problems such as narrow-spectrum resonance effects, reduce production costs, and achieve realization shape-controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

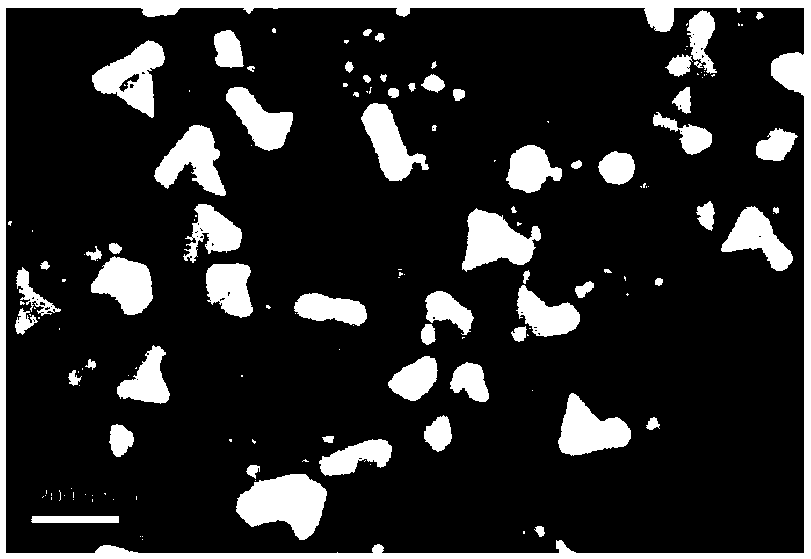

Examples

Embodiment 1

[0069] 1. Synthesis of silver nanonails whose backbone is silver nanorods:

[0070] (1) Illumination-induced growth of decahedral nuclei

[0071] Add 0.52ml 0.5M sodium citrate, 15ul 0.5M PVP (molecular weight 40k), 0.05ml 0.05M L-arginine and 0.4ml 0.05M silver nitrate to 150ml water, stir for 5min and then add 2ml 0.1M Sodium borohydride, continue to stir for 45 minutes, add a small amount of hydrogen peroxide solution, stir for 25 minutes, and irradiate the mixed solution with light for 2 hours to obtain a silver decahedron solution.

[0072] (2) Chemical reduction growth of silver nanorods

[0073] Add 0.72ml 0.5M sodium citrate and 0.135ml 0.5M PVP to 60ml water, heat and stir at 115°C for 10min, add 0.4ml 0.05M silver nitrate, and add the silver decahedron prepared in step (1) at the same time, stop heating after 10min , to obtain a silver nanorod solution.

[0074] (3) Ingot epitaxial growth into nano-nails

[0075] Centrifuge the nanorod solution prepared in step (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| q value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com