Hollow spherical mesoporous PtAu nanomaterial and preparation method and application thereof

A technology of hollow spherical and nano-materials, applied in the field of materials, can solve the problems of slow oxidation of methanol and limit the development of methanol fuel cells, etc., and achieve the effects of good carrier stability, realization of preparation methods, and simple and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] 1)

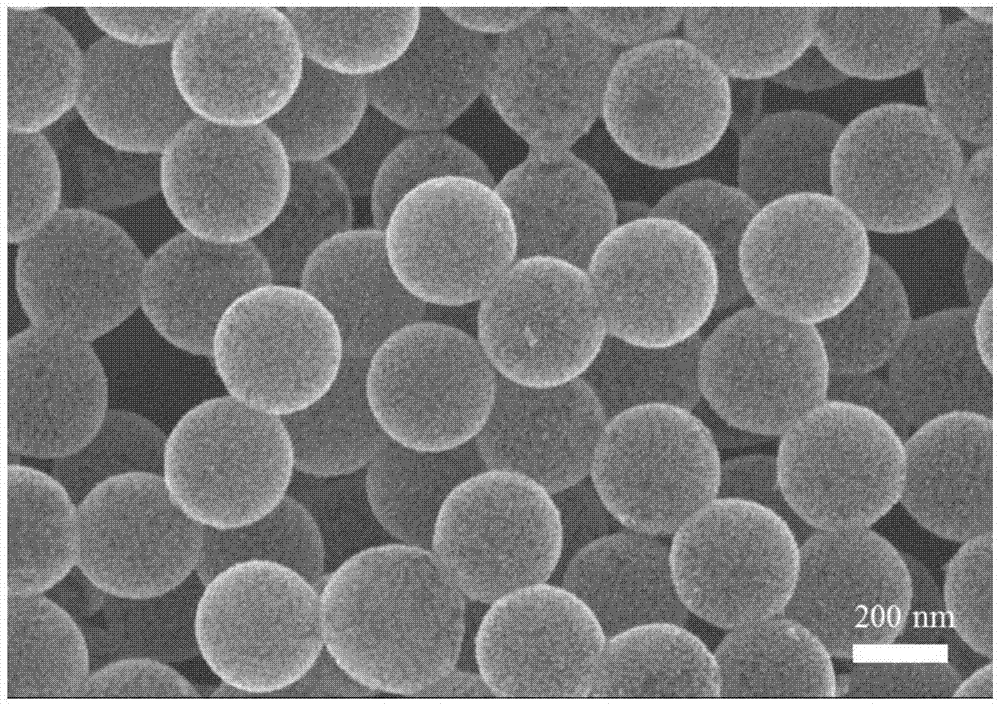

[0055] Preparation of PEI-modified polystyrene spherical template with a particle size of 260nm:

[0056] Add 1mL of 2mM aqueous solution of polystyrene microspheres into 0.5% polyethyleneimine (PEI) aqueous solution and mechanically stir for 50min, then centrifuge 3 times at a speed of 9000rpm, each centrifugation time is 25min. Redisperse in water for later use.

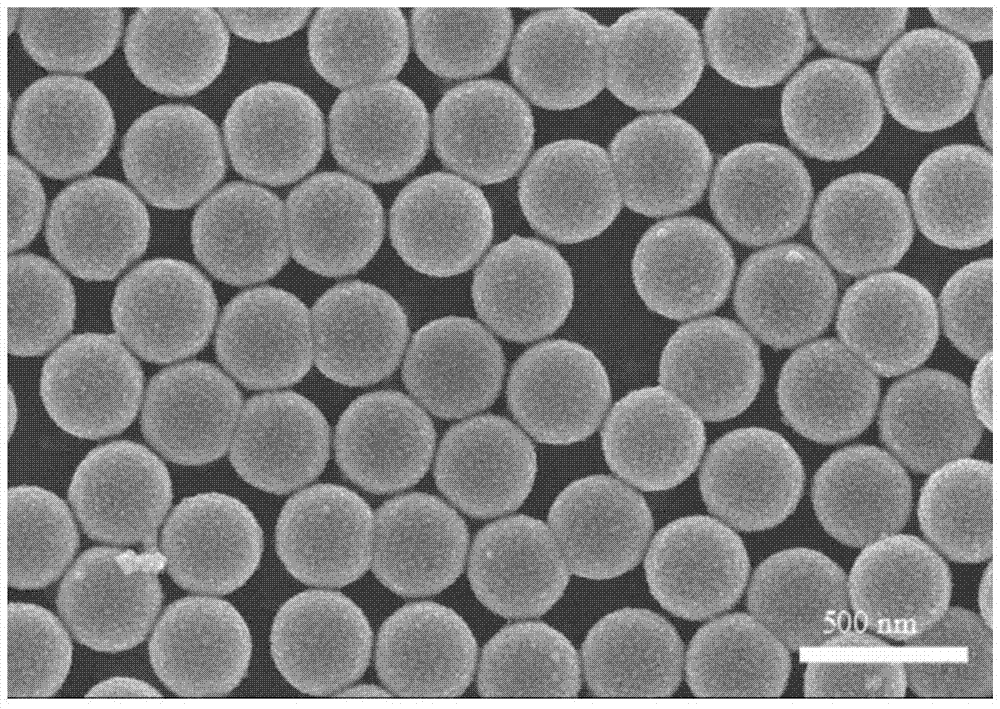

[0057] Preparation of gold sol-modified template dispersion:

[0058] Mix the aqueous solution of PEI-modified template agent microspheres with the nano-gold sol obtained above at a volume ratio of 1:5, stir for 20 minutes, and centrifuge 3 times at a speed of 4000 rpm, and the time of each centrifugation is 10 minutes. Nano gold sol modified template dispersion PS@Au seeds.

[0059] 2)

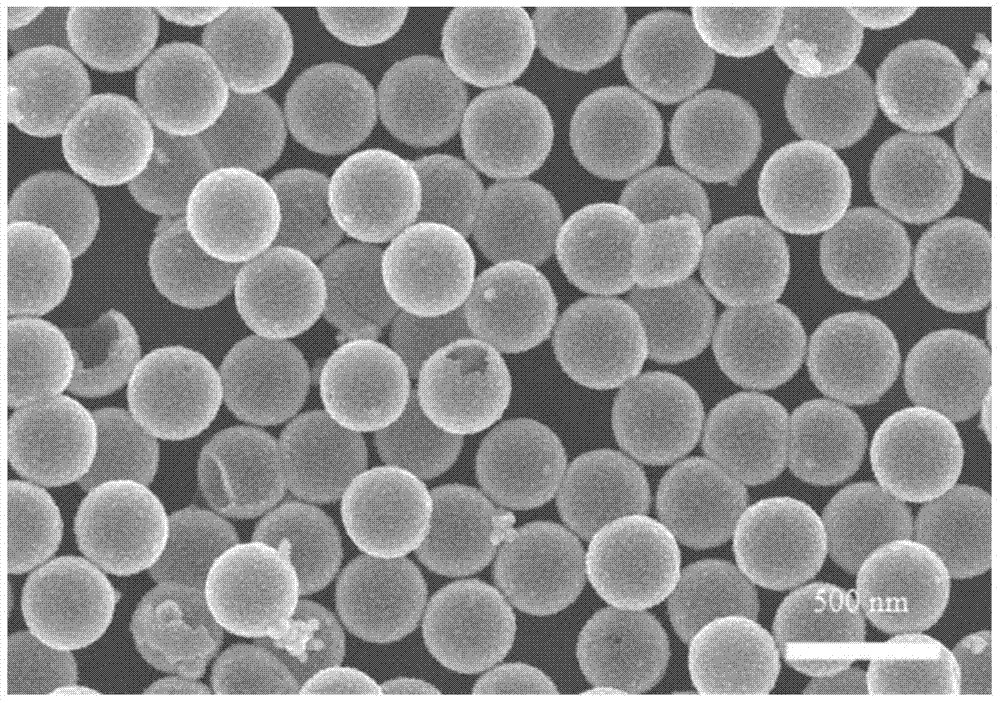

[0060] React with an aqueous solution of chloroauric acid, a growth solution containing a gold source:

[0061] Add 2 mL of template dispersion liquid PS@Au seeds modified by nano-gold sol obtained in step 2) into 2...

Embodiment 2

[0067] Embodiment 2, electrocatalytic methanol oxidation test

[0068] Take 5 μL of the hollow spherical nanomaterial dispersion (2mg / mL) obtained in Example 1 with a pipette and drop-coat it on the surface of a clean glassy carbon electrode. After drying, take 5 μL and apply nafion ethanol solution (0.5%) drop-coated on the electrode surface. The glassy carbon electrode modified by the hollow spherical nanomaterial is obtained, which is dried and used for later use.

[0069] A conventional three-electrode system was used to test the electrocatalytic performance of the hollow spherical nanomaterial obtained in Example 1. The glassy carbon electrode modified by the hollow spherical nanomaterial was used as a working electrode, the platinum wire electrode was used as a counter electrode, and the saturated KCL silver / silver chloride electrode was used as a reference. Electrodes, the test temperature is 25°C. The composition of the electrolyte is 0.5M sulfuric acid solution, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com