Regional control method for additive manufacturing of in-situ self-generated TiC reinforced titanium-based composite material

A titanium-based composite material and additive manufacturing technology, which is applied in the field of zonal control of in-situ self-generated TiC-reinforced titanium-based composite materials in additive manufacturing, can solve the problem of difficult control of distribution uniformity, difficulty in meeting technical requirements, limited size, etc. problem, to achieve the effect of uniform size distribution of the reinforcement phase and optimized regional performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] This embodiment includes the following steps:

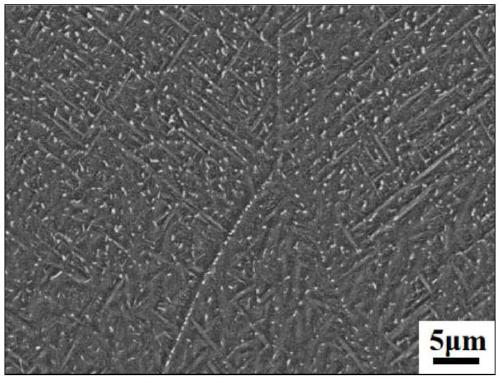

[0034] Step 1: Add 79.2g of pure titanium powder with a size of 15 μm to 45 μm and a mass purity of 99.5% and 0.8g of nano-carbon powder with an average size of 40nm into 20mL of absolute ethanol, and then place it in a ball mill. Under the conditions of 100r / min and ball-to-material ratio of 1:1.5, perform ball milling treatment for 5 hours, then dry once at 60°C for 6 hours to obtain ball mill powder, and then spray 0.8g into the ball mill powder with a volume fraction of 2.7% The polyvinyl alcohol aerosol was stirred evenly, and the temperature was 100°C for secondary drying for 3 hours to obtain a C / Ti composite powder with a nano-carbon mass content of 1%;

[0035] Step 2. Replace the mass of pure titanium powder in step 1 with 78.4g, 77.6g, 76.8g, 76g, 75.2g, 74.4g, 73.6g, 72.8g, 72g, 71.2g, 70.4g, corresponding to nano carbon The quality of the powder is changed to 1.6g, 2.4g, 3.2g, 4.0g, 4.8g, 5.6g, 6.4g, 7.2g, 8....

Embodiment 2

[0060] This embodiment includes the following steps:

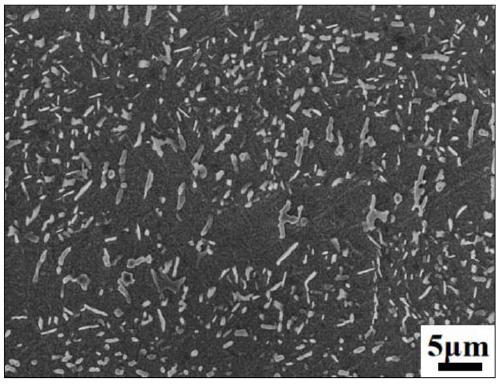

[0061] Step 1. Add 79.4g of pure titanium powder with a size of 75 μm to 100 μm and a mass purity of 99.5% and 0.6g of nano-carbon powder with an average size of 40nm into 60mL of absolute ethanol, and then place it in a ball mill. Under the conditions of 300r / min and ball-to-material ratio of 1:3, perform ball milling treatment for 2 hours, then dry once at 100°C for 3 hours to obtain ball mill powder, and then spray 2.4g of aerosol into the ball mill powder and stir evenly. Carrying out secondary drying for 1 hour at a temperature of 120°C to obtain a C / Ti composite powder with a nano-carbon mass content of 0.75%;

[0062] Step 2. Replace the quality of the pure titanium powder in step 1 with 79.2g, 78.4g, 77.6g, 78.4g, 79.2g, 79.4g, and replace the corresponding nano-carbon powder with 0.8g, 1.6g, 2.4 g, 1.6g, 0.8g, 0.6g, according to the process of preparing C / Ti composite powder in step 1, the obtained nano-carbon ma...

Embodiment 3

[0068] This embodiment includes the following steps:

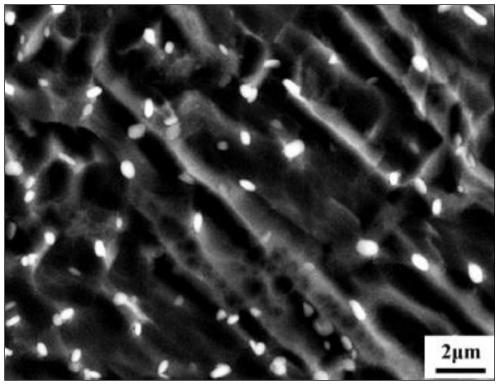

[0069] Step 1: Add 77.6g of Ti60 powder with a size of 100μm to 200μm and a mass purity of 99.5% and 2.4g of nano-carbon powder with an average size of 40nm into 40mL of absolute ethanol, and then place it in a ball mill at a speed of 200r / min and ball-to-material ratio of 1:2, ball milling was carried out for 3 hours, and then dried once at 85°C for 4.5 hours to obtain ball milling powder, and then 1.6g of aerosol was sprayed into the ball milling powder and stirred evenly. Carrying out secondary drying for 2 hours at a temperature of 110°C to obtain a C / Ti composite powder with a nano-carbon mass content of 3%;

[0070] Step 2. Replace the quality of the Ti60 powder in step 1 with 76.8g, 79.2g, 77.2g, 78.8g, 77.6g, 78.4g, 78g, 80g, and replace the corresponding nano-carbon powder with 1.6g, 0.8 g, 0.6g, 0.4g, 0.6g, 0.8g, 1.6g, 2.4g, according to the process of preparing C / Ti composite powder in step 1, the mass content...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com