Spinning technique of pulley

A spinning process and pulley technology, which is applied in the production process of spinning pulleys, can solve the problems of small thickness of the tooth bottom, wrinkles, and influence on the strength of the pulley, and achieve the effect of improving the qualification rate, large force area and uniform force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

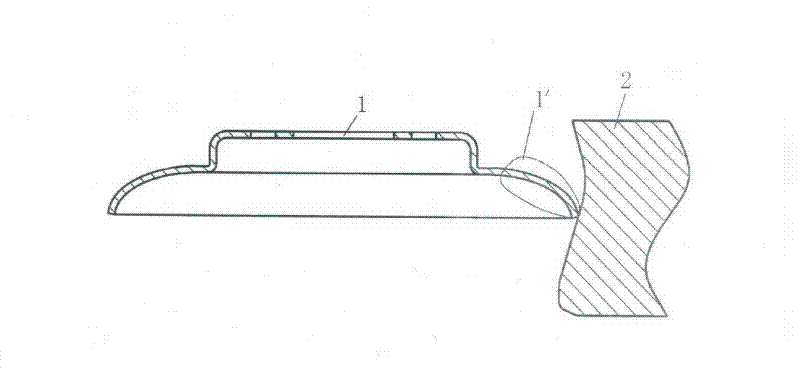

[0027] A kind of pulley spinning process, as attached figure 1 As shown, 1 is the blank to be processed, and 1' is the transition part of the large arc of the blank. The large arc transition can avoid the formation of fracture and wrinkle defects in the spinning process; the spinning machine is equipped with a mandrel clamp, and the blank 1 Installed on the mandrel fixture; Install the pre-forming rotary wheel 2 on the spinning machine, so that the working surface of the pre-forming rotary wheel 2 is in contact with the outer edge of the blank 1.

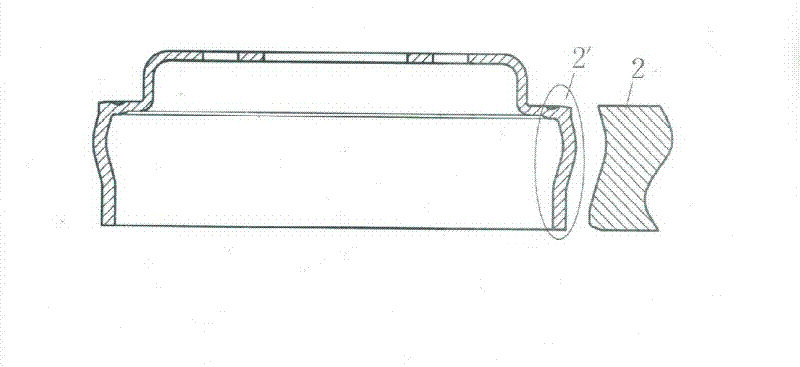

[0028] as attached figure 2 As shown, the main shaft of the spinning machine rotates, driving the mandrel fixture and the blank 1 to rotate; the preforming rotary wheel 2 is rotated and moved horizontally to spin the blank 1, and the large arc transition part 1' of the blank is spun into a The preformed part 2' is a primary semi-finished product.

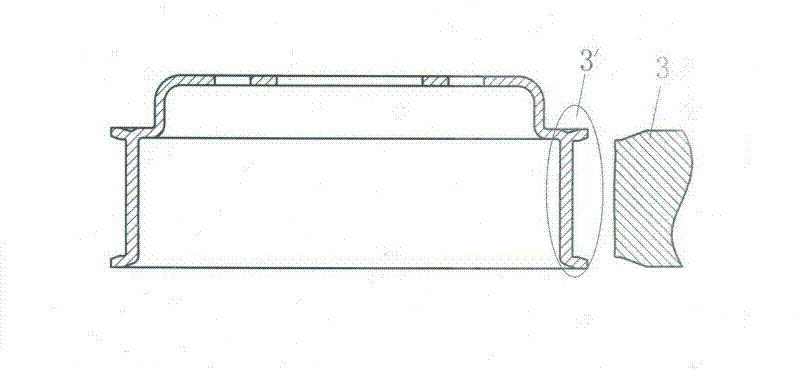

[0029] as attached image 3 As shown, the primary forming rotary wheel 3 is inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com