Bearing film for 3D product, composite film comprising bearing film and film laminating method

A carrier film and composite film technology, applied in the direction of layered products, chemical instruments and methods, synthetic resin layered products, etc., can solve the problems of low product production efficiency, low product pass rate, OCA damage, etc., to achieve good film sticking , The overall structure is simple, the effect of avoiding corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

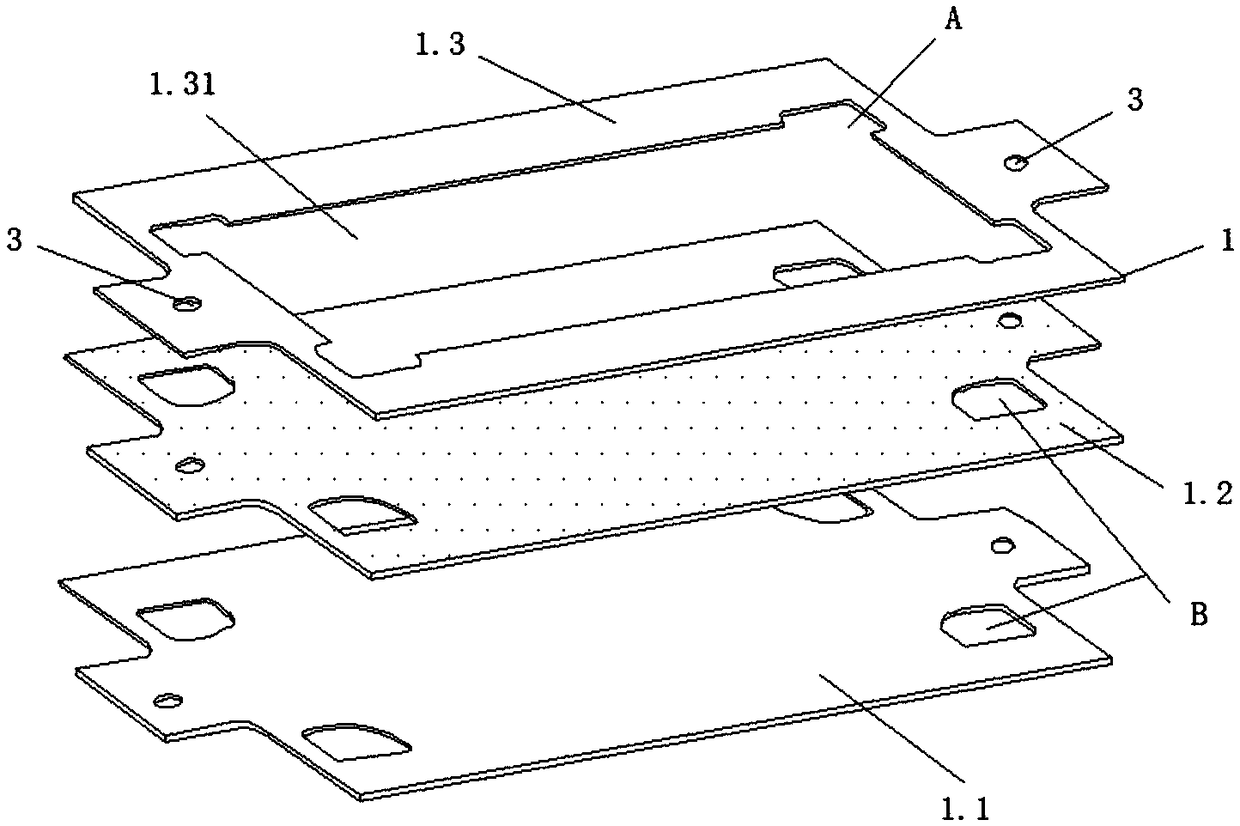

[0036] see figure 1 , a carrier film for 3D products, comprising a carrier film body 1, the carrier film body 1 includes a first film layer 1.1, an adhesive layer 1.2 and a second film layer 1.3 stacked in sequence, the first film layer 1.1 , the outer dimensions of the adhesive layer 1.2 and the second film layer 1.3 are the same.

[0037] The middle position of the second film layer 1.3 is provided with a hollow part 1.31 that matches the outline of the 3D product to be pasted after unfolding (the area of the hollow part is slightly larger than that of the 3D product after unfolding, for example, the surrounding area of the hollow part is larger than that of the 3D product. The four sides are 0.10-0.15mm wide, and the four corners are larger, these parameters are determined according to the actual situation).

[0038] The material of the first film layer 1.1 and the second film layer 1.3 is polyethylene terephthalate; the material of the adhesive layer 1.2 is acid-free ...

Embodiment 2

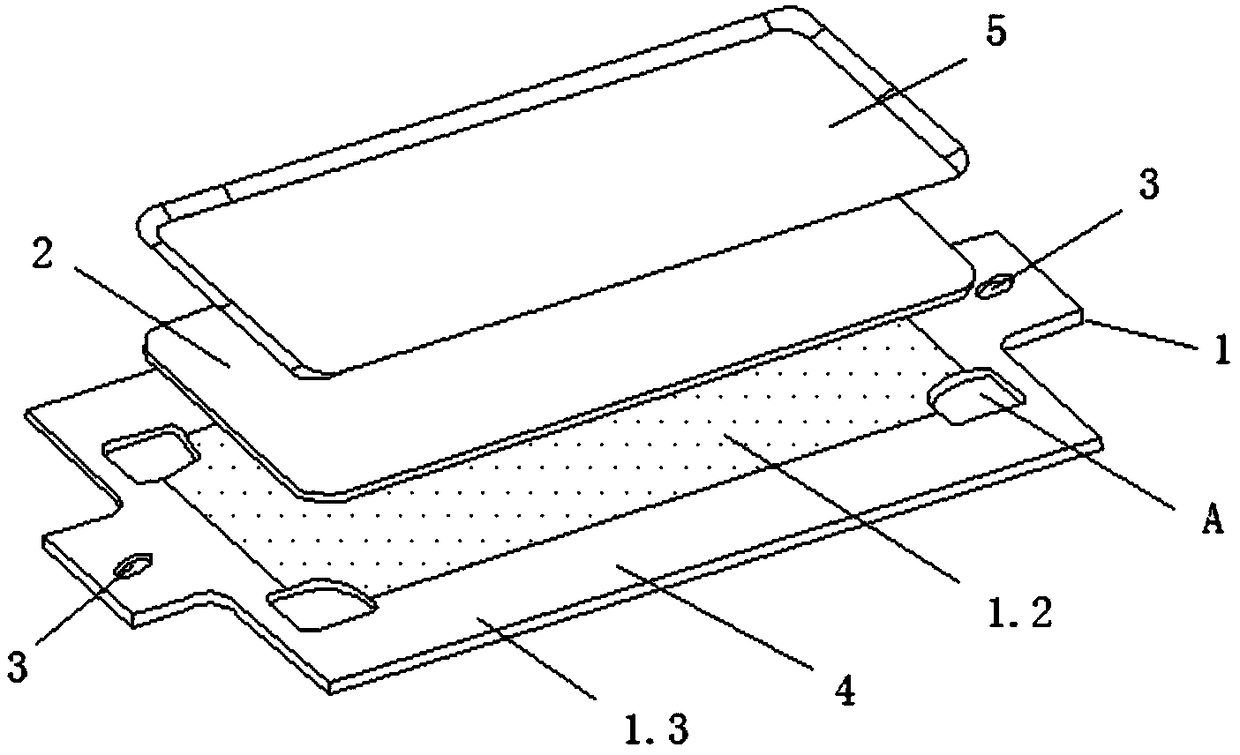

[0044] A composite film for 3D products, see details figure 2 , this composite film includes the carrier film for 3D products in Example 1 and the independently set diaphragm 2 .

[0045] The membrane 2 is arranged in the hollow part 1.31 of the second membrane layer 1.3, the back of the membrane 2 is attached to the adhesive layer 1.2, and the front of the membrane 2 is provided with a protective layer.

[0046] The specific process of applying the above-mentioned composite film for 3D products to film includes the following steps:

[0047] The first step, making a carrier film for 3D products; laminating the diaphragm 2 with the carrier film for 3D products to obtain a composite film for 3D products;

[0048] The second step is to position the 3D product with the composite film through the positioning through hole 3 on it and the positioning column on the fixture;

[0049] The third step is to fix the 3D product on the fixture with a composite film (here it can be fixed b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com