The craft of making paper tube furniture and the small square stool made by this craft

A production process and technology of paper tubes, which are applied in the field of paper tube furniture production process and small square stools produced by this process, can solve the problems of high cost, poor dynamic load stability, unattractive appearance, etc., and achieve convenient transportation and dynamic stability Good performance and cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

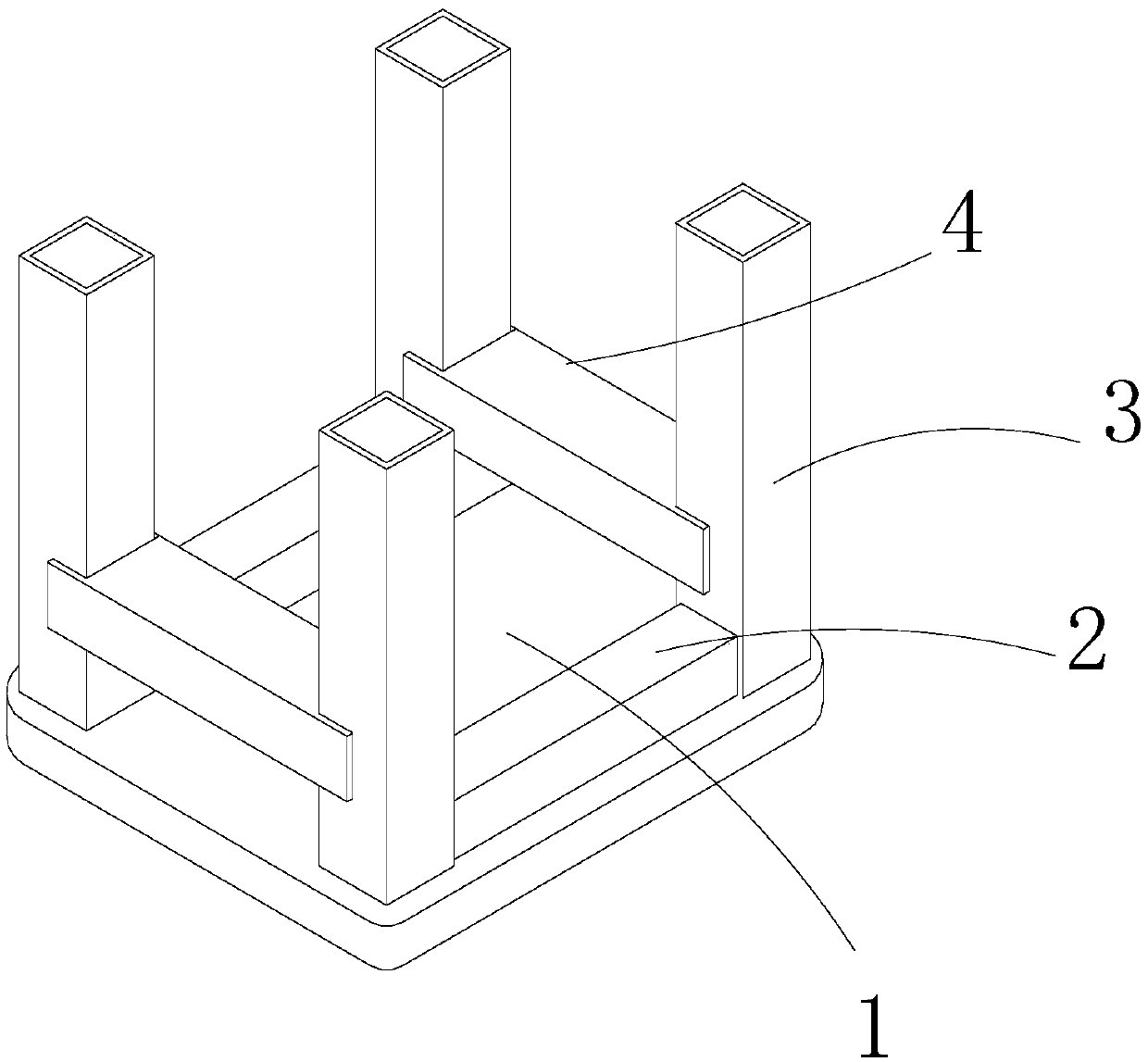

[0053] Such as figure 1 The small square stool shown includes a panel 1, two blind grooves parallel to each other are opened on the lower surface of the panel 1, a connecting pipe 2 is fixed in the blind groove, a tenon groove is opened on the wall of the connecting pipe 2, and two hollow legs 3 It is inserted into both ends of a connecting pipe through a tenon and groove, and a beam pipe is connected between two adjacent legs that are not on a connecting pipe. The bottom end of the leg is inserted with a The outrigger plug-in 5.

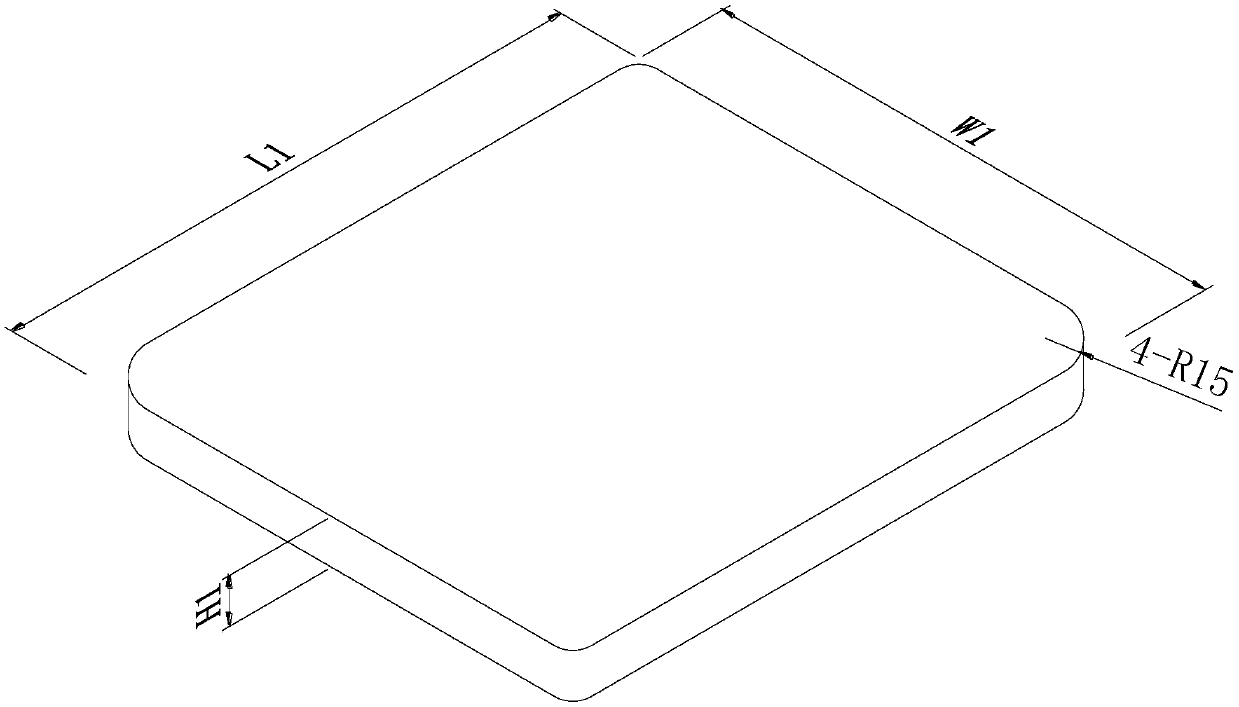

[0054] Such as Figure 1-3 As shown, the length of the panel is 250mm, the width is 220mm, and the thickness is 20mm. The blind grooves are parallel to each other, divided into two sides of the panel, each close to and parallel to a long side of the panel.

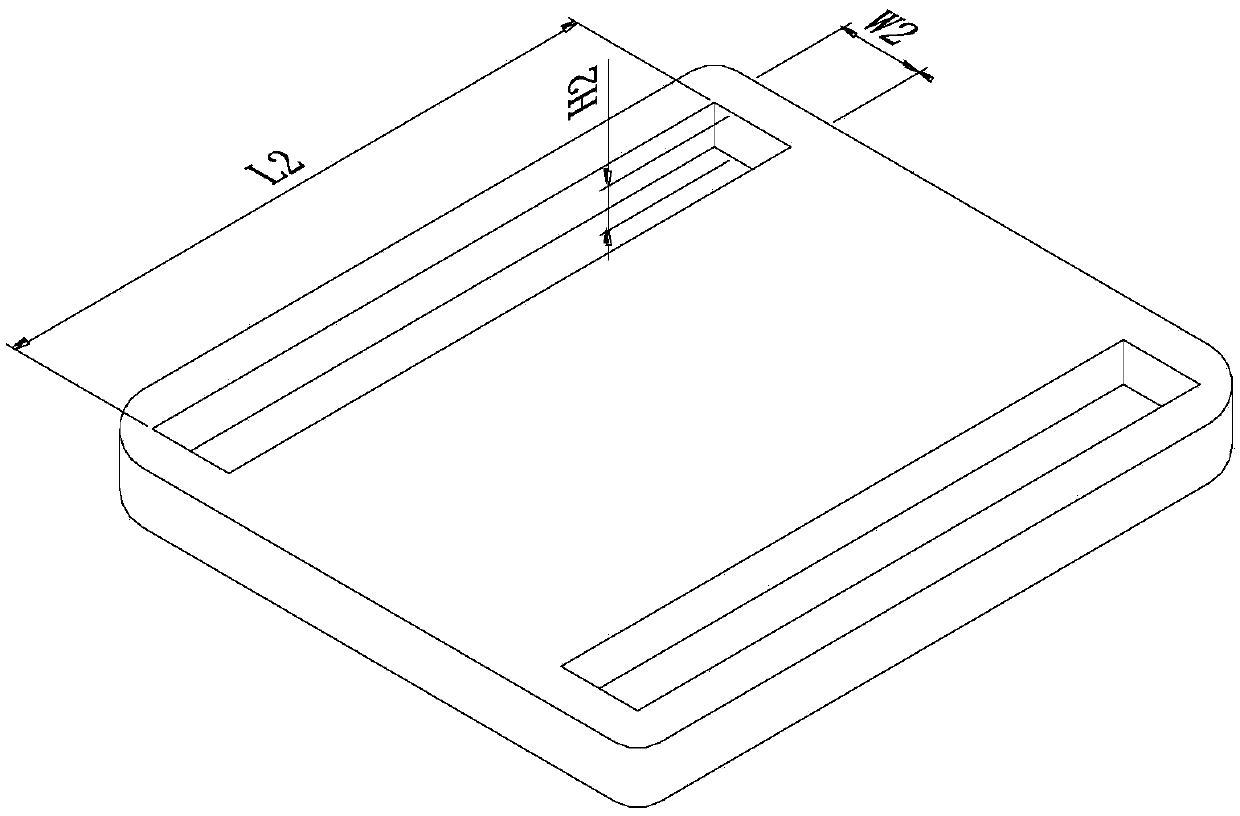

[0055] Among them, the length of the blind groove is 220mm, the depth is 15mm, and the width is 30mm; the depth of the blind groove is less than or equal to half the thickness of the panel. ...

Embodiment 2

[0066] As the assembly process of the small square stool in embodiment 1:

[0067] (1) The connection method between the small square bench panel and the paper tube

[0068] First, select the panel material, and cut two blind slots on the panel that match the paper tube, see the attached figure 2 , 3 .

[0069] Secondly, choose a suitable square paper tube and solid filler (the filler should be environmentally friendly and have the function of sawing), put the solid filler into the paper tube, and then make a groove on the paper tube covered with the filler to obtain the stool surface connecting tube. see attached Figure 4 , 5 . The purpose of slotting is for embedding other paper tubes.

[0070] Finally, apply glue in the blind groove of the panel, and insert the finished connecting pipe of the stool surface into the blind groove of the panel. see attached figure 1 .

[0071] (2) The method of making the pipe-to-pipe connection. This is the connection method betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com