A method for forming a composite material tubular member

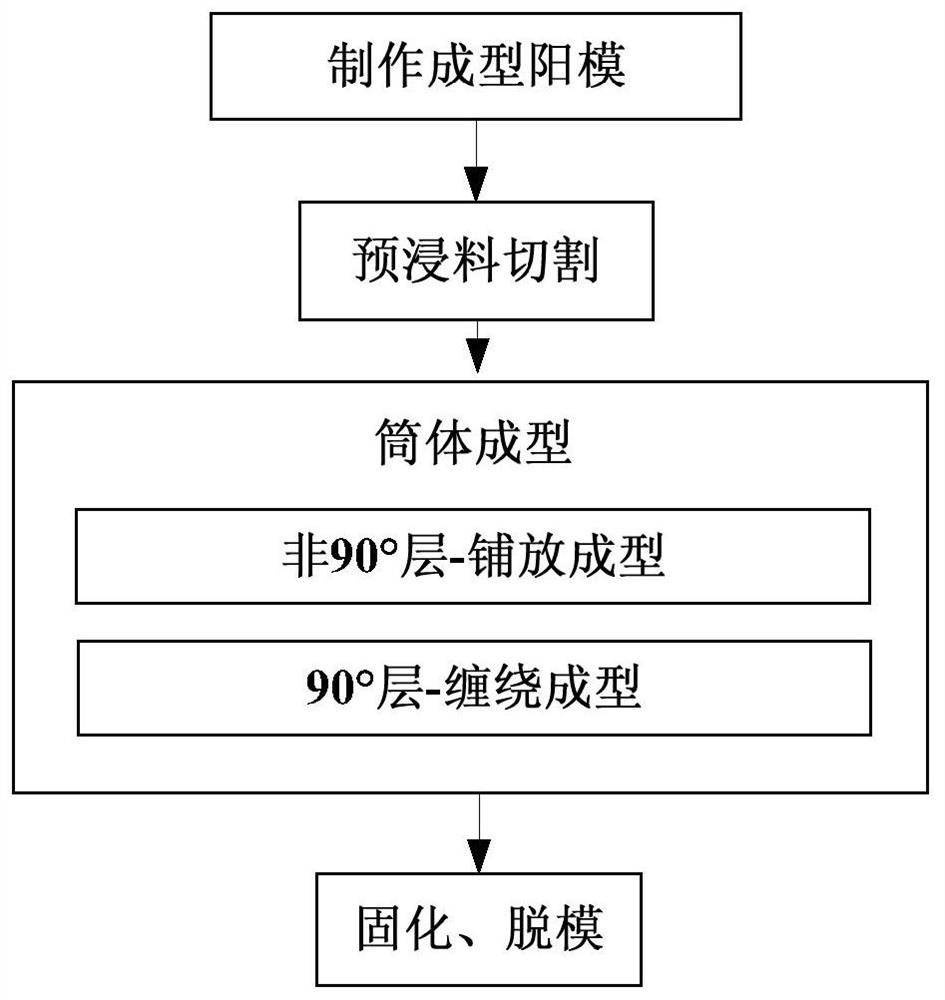

A composite material and molding method technology, which is applied in the field of composite material preparation technology, can solve the problems of high loss rate of prepreg, inability to perform local winding, unstable layup quality, etc., and achieve molding speed and molding quality advantages, matching methods Reasonable and feasible to ensure the compactness of the ply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

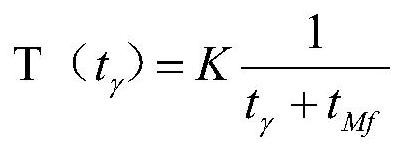

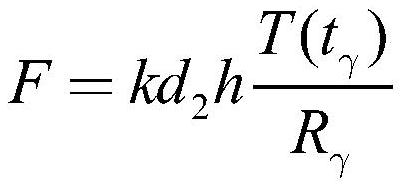

[0060]A cylindrical member with a length of 7m, a radius of 2m, and a thickness of 18mm was formed using this forming process. The first 5 layers of the cylindrical structure are laid in the order [90 / 0 / 90 / 0 / 90]. 90° layer uses winding forming method, the width of winding tape d1=50mm, the actual winding angle is 89.5°, and the tape forming method is used at 0°, the width of the tape is d2= 150mm, 90° winding tension is 9.2N / mm, 9N / mm, 8.8N / mm, 0° layup pressure is 19.8N and 19.4N. The molding cycle of the cylindrical component is 12 days, which is nearly half shorter than the original manual molding cycle of 23 days.

[0061]Ultrasonic non-destructive testing method was used to test the whole cylinder after forming. The test results showed that there were no defects such as delamination, looseness, pores, etc. on the whole of the component. Partial sampling of the component was carried out and the metallographic test was made. The porosity of the component is less than 0.3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com