Ball screw assembly precision retaining ability testing device

A ball screw pair, precision maintenance technology, applied in the direction of machine gear/transmission mechanism testing, etc., can solve the problems of blank in the research and development field, lack of simulation of various actual working conditions in the precision maintenance testing machine, etc., to achieve continuous change, Guaranteed compatibility and stability, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

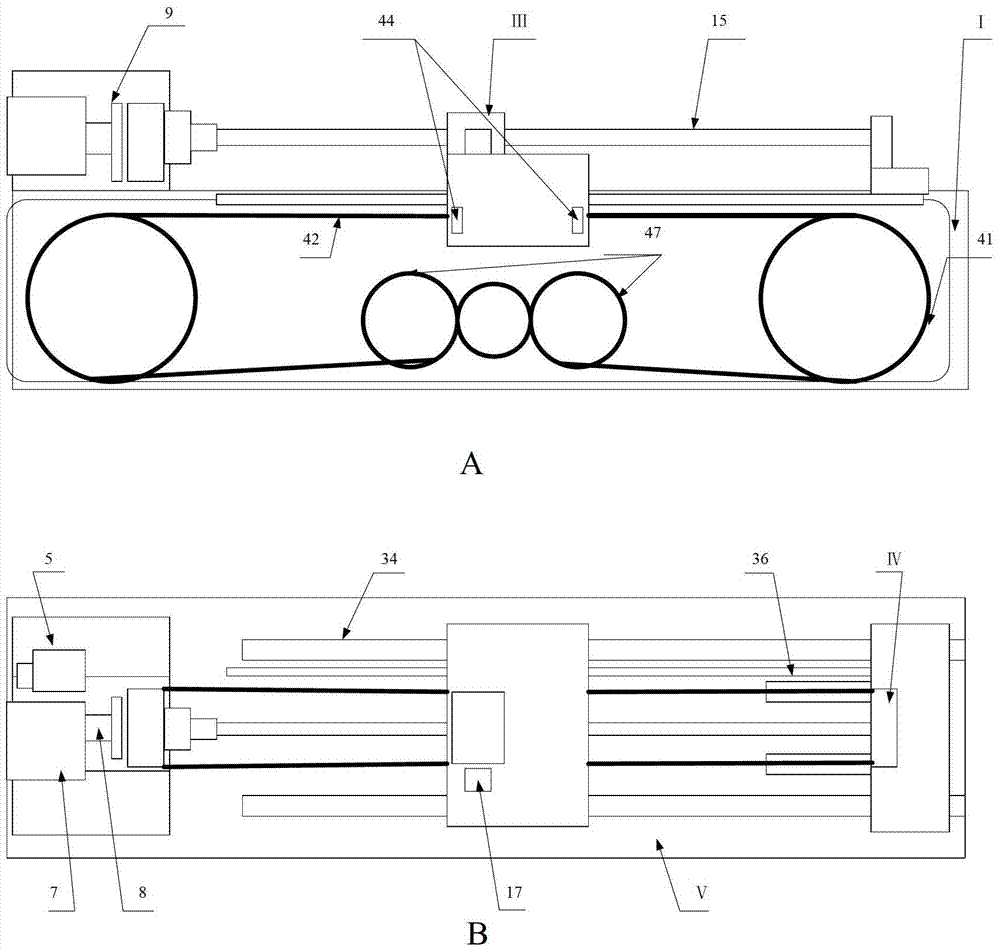

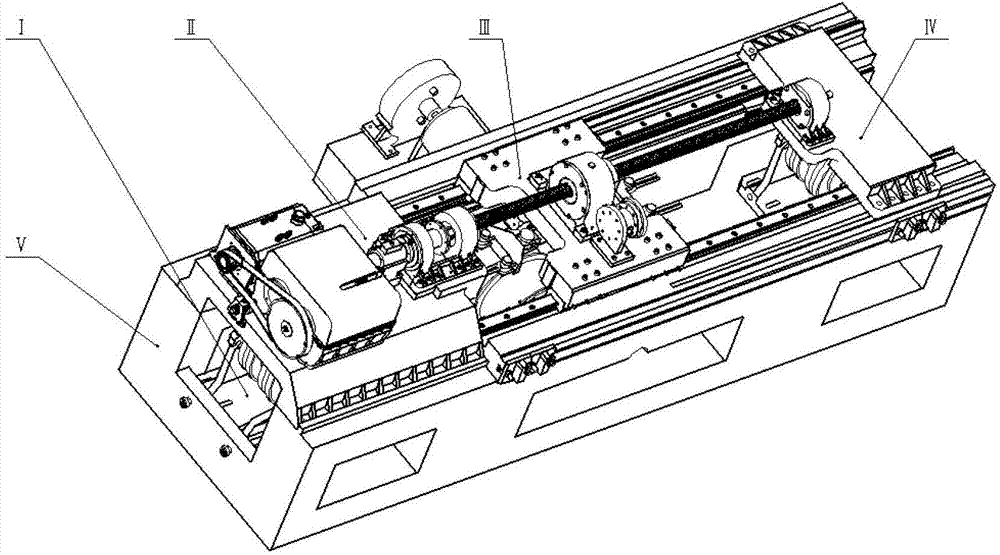

[0019] combine figure 1 , figure 2 , a ball screw pair accuracy maintenance test device of the present invention, comprising a loading part I, a headstock dragging part II, a working table part III, a tailstock supporting part IV and a bed V, wherein the headstock dragging part II and the tailstock supporting part IV are located on the bed V, the worktable part III is located between the headstock dragging part II and the tailstock supporting part IV, and the loading part I is located in the groove in the middle of the bed V;

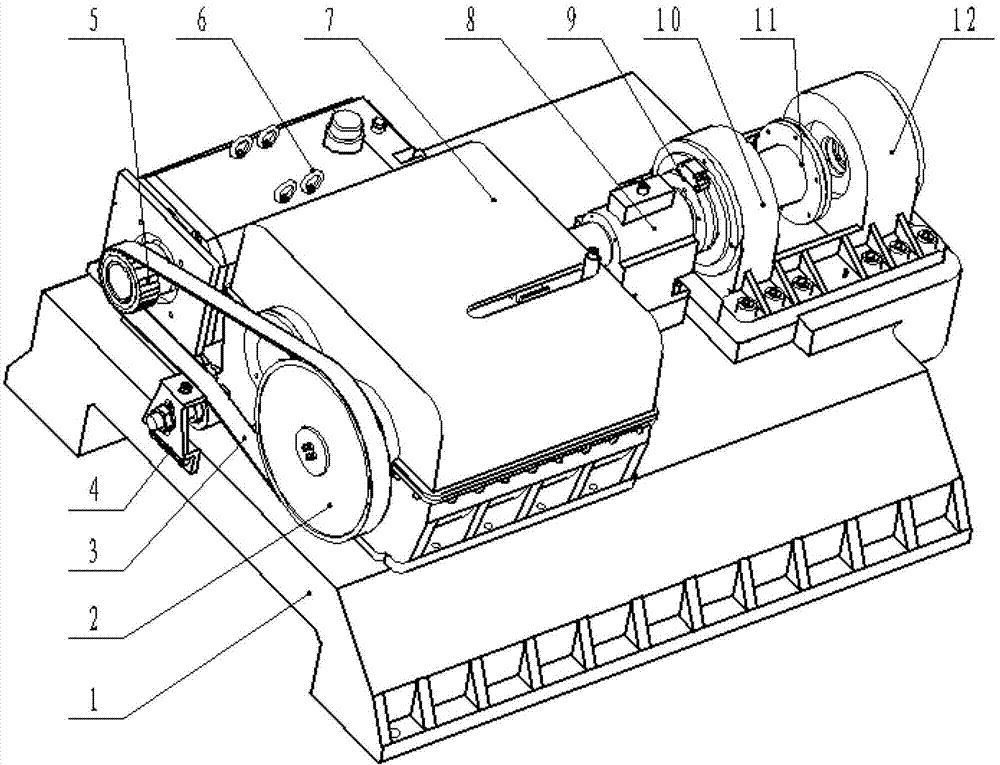

[0020] combine image 3 , the head frame dragging part II includes a head frame support plate 1, a driven pulley 2, a synchronous belt 3, a tension pulley 4, a drive pulley 5, a motor 6, a gearbox 7, a dynamic torque sensor 8, a circular magnet Grid 9, first head frame support unit 10, second head frame support unit 12, motor 6 and gearbox 7 are arranged on the head frame supporting plate 1, driving pulley 5 is arranged on the output shaft of motor 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com