Efficient, intelligent and safe petroleum drilling winch system and control method thereof

A technology of oil drilling and drawworks, which is applied in the direction of hoisting device and clockwork mechanism, etc. It can solve the problems of long drilling cycle, low efficiency of tripping and tripping, and poor interchangeability, so as to improve power utilization and fast tripping Drilling, the effect of improving drilling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

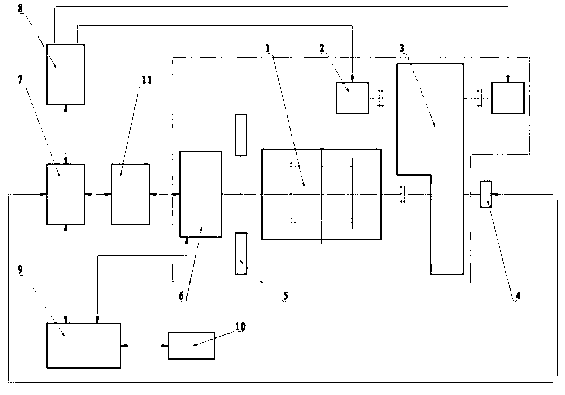

[0039] see figure 1 : A high-efficiency, intelligent and safe oil drilling winch system, including a winch structure part and a winch control part, said winch structure including electromagnetic turbine brake 6, disc brake 5, drum shaft assembly 1, double-speed gearbox 3, said The dual-speed gearbox 3 is connected to the AC variable frequency motor 2 through a clutch, and there are two AC variable frequency motors, which are respectively arranged on both sides of the double-speed gearbox, and the dual-speed gearbox 3 is connected to the drum shaft assembly 1 through a clutch , the drum shaft assembly 1 is connected to the electromagnetic vortex brake 6 through a spline, and the disc brake 5 is connected between the drum shaft assembly 1 and the electromagnetic vortex brake 6 through a spline; the winch control part includes a silicon controlled rectifie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com