Tentering shaping conveying device for magnetic suspension functional fabric

A tenter setting and conveying device technology, which is applied in the direction of fabric elongation, fabric surface trimming, textile and papermaking, etc., can solve the problems of inability to realize linear and circular feeding motion at the same time, small feeding range, low running speed, etc. , to achieve the effect of extending the maintenance cycle, high movement precision and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

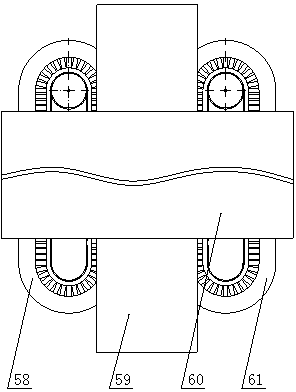

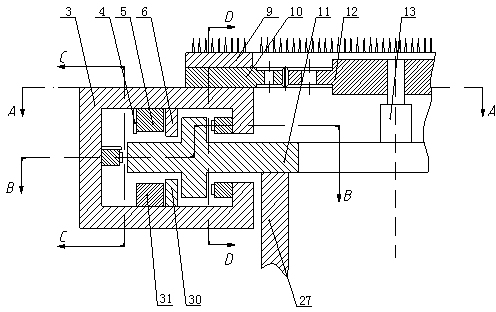

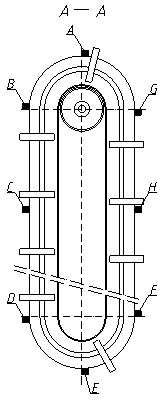

[0028] See attached figure 1 , 2 , 3, 4, a kind of magnetic levitation function coated fabric tentering setting conveying device, comprises a pair of conveying device 58,61 and oven 60, during work, under the joint action of conveying device 58,61, will be coated with coating Fabric 59 is brought into drying oven 60 for drying. Each conveying device comprises support block 27, and raceway type static guide rail 11 is installed on support block 27, and several maglev moving guide rails 3 are set on static guide rail 11, and gear belt 10 is installed on the maglev moving guide rail, and a plurality of mutually spaced guide rails are installed on gear belt 10. Needle felt 9, a rotating motor 13 is installed at the circular arc end on one side of the static guide rail 11, a gear plate 12 is installed on the rotating motor 13, the gear plate 12 meshes with the gear belt at the arc end, and the inner side of the magnetic levitation moving guide rail 3 is vertically symmetrical A p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com