A Method for Determining Local Surface Normal Vectors Based on Dual Infrared Sensors

A determination method and sensor technology, applied in instruments, measuring devices, optical devices, etc., can solve problems such as the inability of measuring technology to be realized, and achieve the effect of overcoming errors and inefficiencies, avoiding measuring equipment, and processing efficiently.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

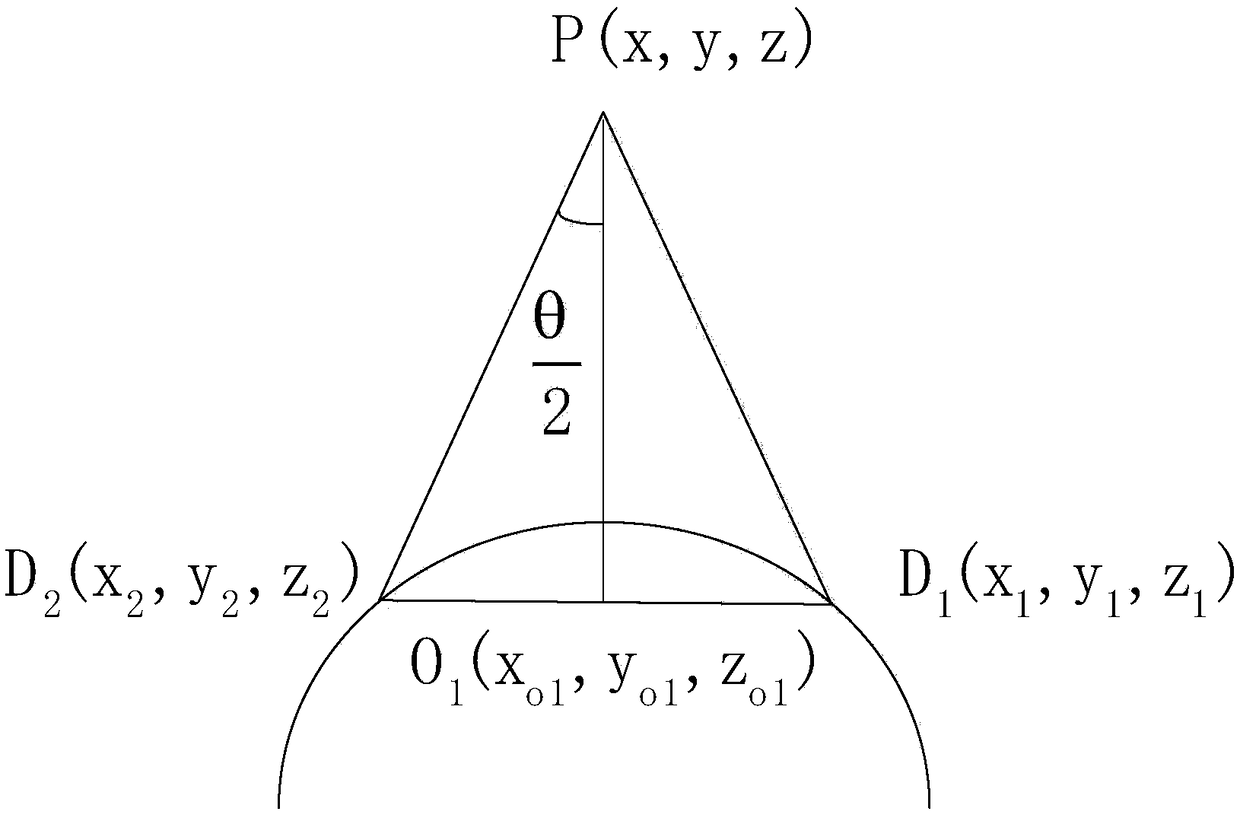

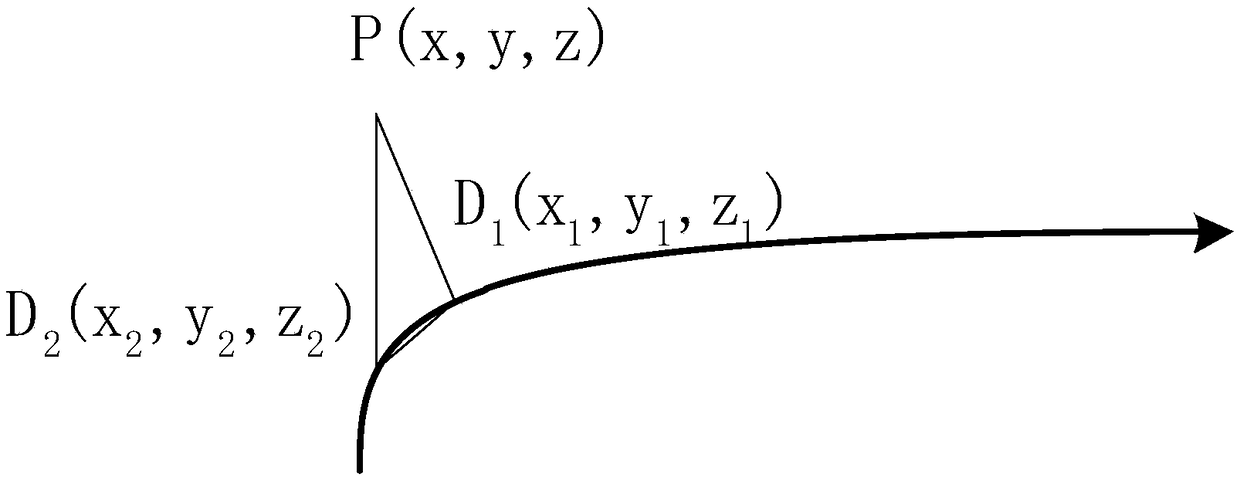

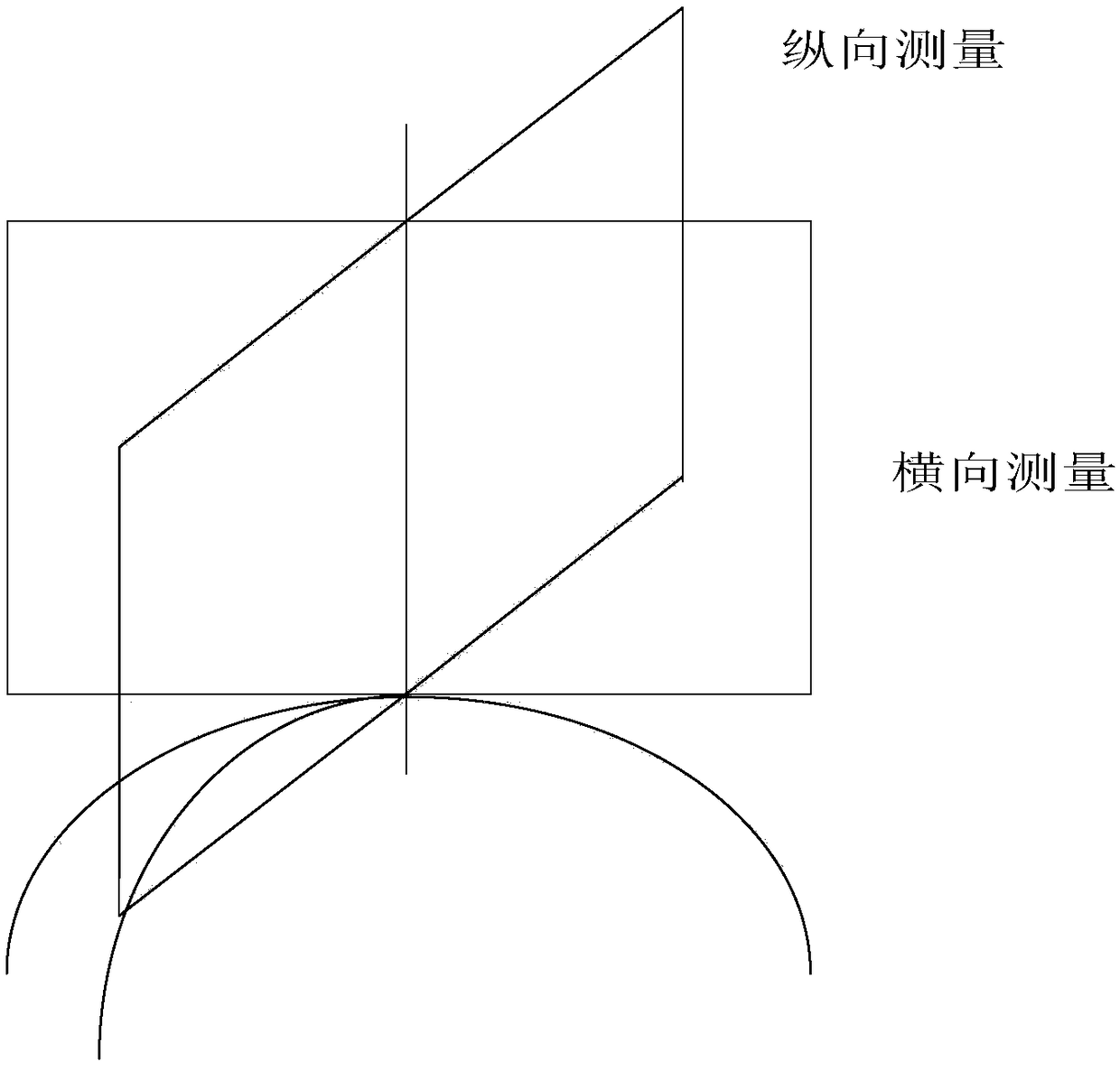

[0039] Specific implementation mode one: combine figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 To illustrate this embodiment, a method for determining local surface normal vectors based on dual infrared sensors in this embodiment includes two parts: lateral measurement and longitudinal measurement;

[0040] 1. The implementation steps of the longitudinal measurement method are as follows:

[0041] Step 11: After the robot nozzle moves to the position of the curved surface of the workpiece to be sprayed, obtain the coordinates of the robot nozzle in the earth coordinate system and set it as P(x,y,z), (x,y,z conform to the right-hand rule) ;

[0042] Step 1 and 2: According to the angle θ between the two infrared ranging sensors set on the edge of the robot nozzle, and the distance d between the two infrared sensors and the curved surface of the workpiece to be sprayed measured by the infrared sensor 1 、d 2 , the two points D on the surface of the workpiece to...

specific Embodiment approach 2

[0060] Specific implementation mode two: the difference between this implementation mode and specific implementation mode one is: in the step one or two, D 1 (x 1 ,y 1 ,z 1 ), D 2 (x 2 ,y 2 ,z 2 ) The specific formula is:

[0061]

[0062]

[0063] Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0064] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is: the intersection point O in the step 1 and 31 (x o1 ,y o1 ,z o1 ) The specific formula is:

[0065]

[0066] Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com