Linkage structure for drawer type three-dimensional material warehouse

A material library and drawer type technology, which is applied in the field of linkage structure for drawer type three-dimensional material library, can solve the problems of high working intensity, waste of manpower and easy damage of the rotating shaft of the rotating friction wheel, so as to ensure continuous production and processing and improve support stability Sexual, effort-reducing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

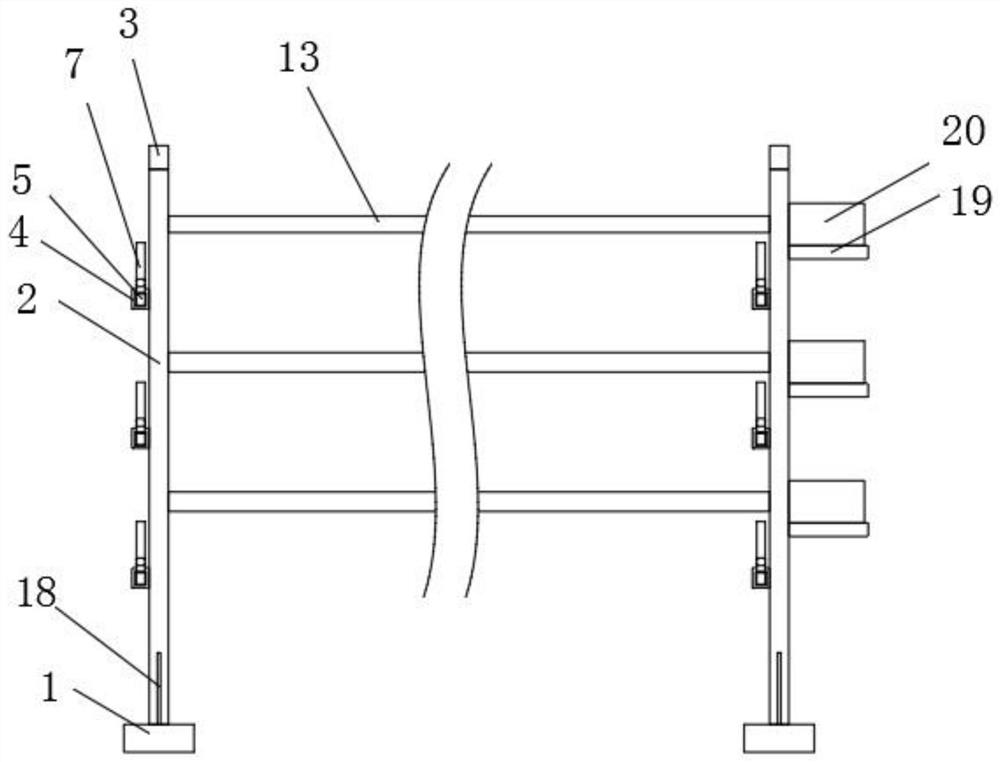

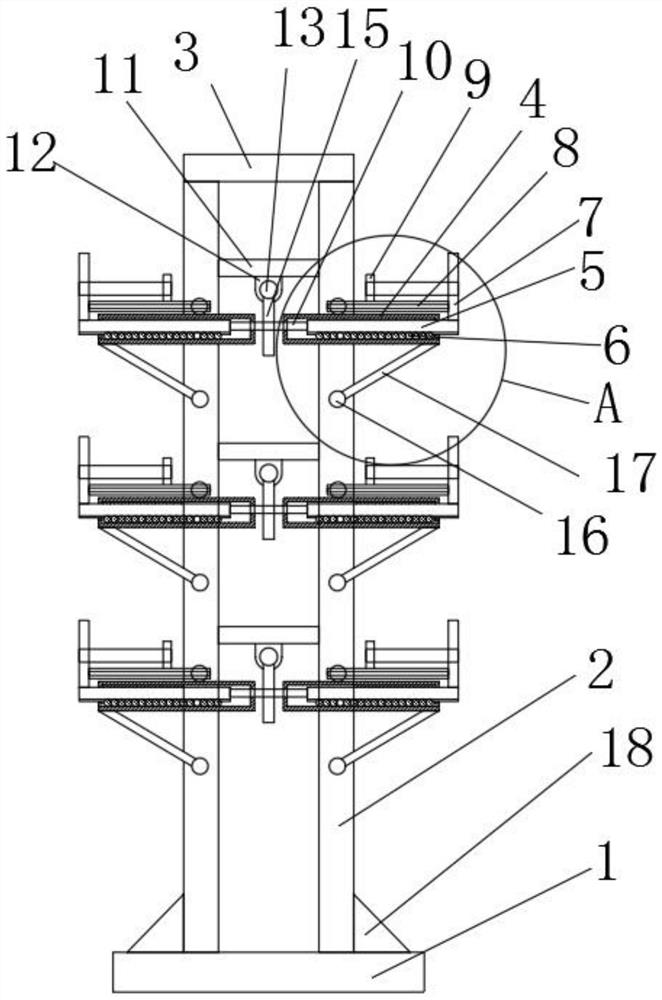

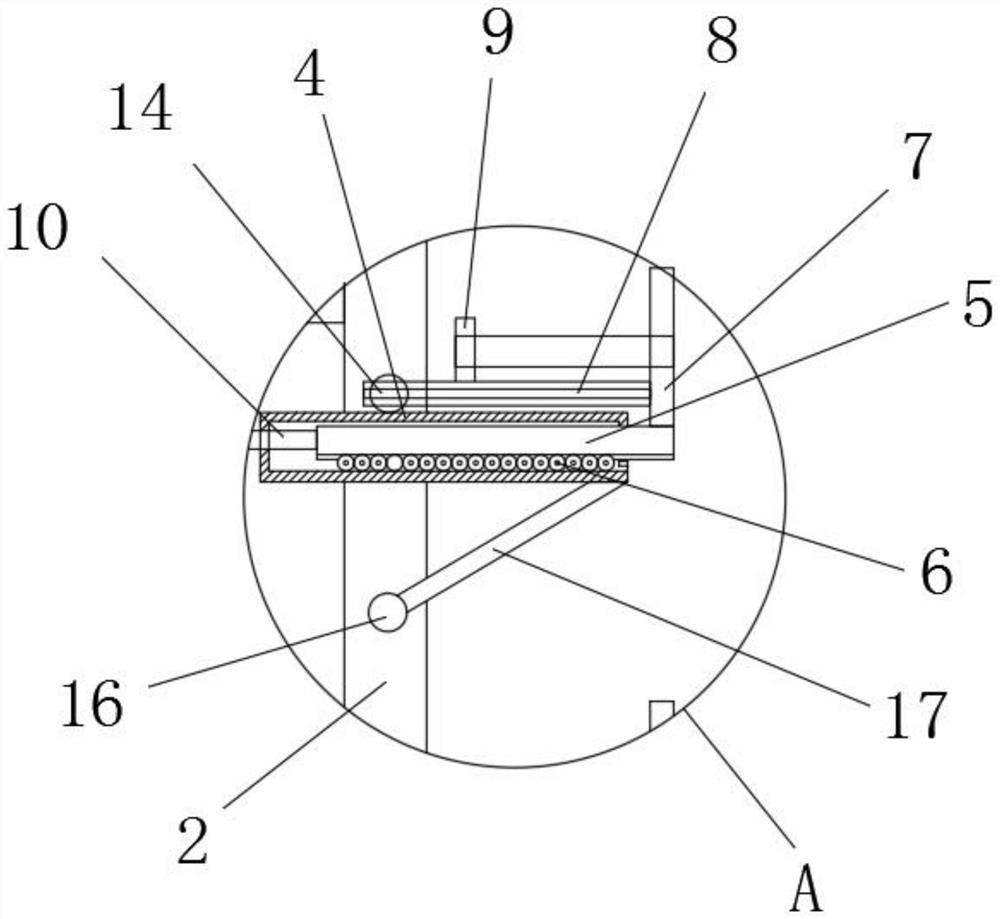

[0032] see Figure 1-3, a linkage structure for a drawer-type three-dimensional material warehouse, including a base 1, the number of bases 1 can be arranged side by side according to the length of the stored materials, and the worm gears 15 on the same layer on the multiple bases 1 are engaged with the same worm 13 for transmission , the setting of a plurality of bases 1 can be assembled arbitrarily to adapt to the storage of different material lengths. Among the bases 1 arranged side by side, one side facing outwards without a fixed drawer slide 4 is fixedly connected with a motor fixing frame 19, and the motor fixing frame 19 is fixedly connected with a drive motor 20, the output shaft of the drive motor 20 is fixedly connected to one end of the worm screw 13 through a coupling, and the drive motor 20 is connected to the mains power supply, and the drive motor 20 can drive the worm screw 13 to rotate, thereby achieving the control of the drawer. The effect of pulling out re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com