Double-wheel rotor engine

A rotary engine and two-wheel technology, applied to combustion engines, machine/engines, internal combustion piston engines, etc., can solve the problems of not being widely used in civilian vehicles, high manufacturing costs of complete machines, immature technology, etc., and achieve simple structure, compact size Small, easy-to-manufacture effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

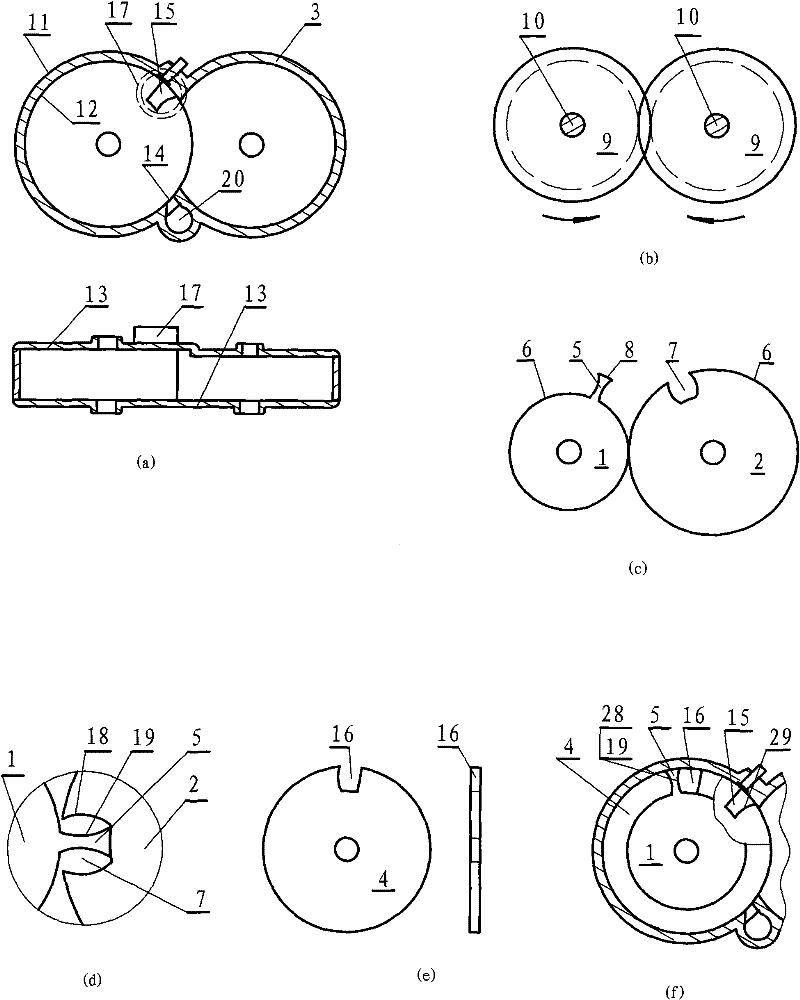

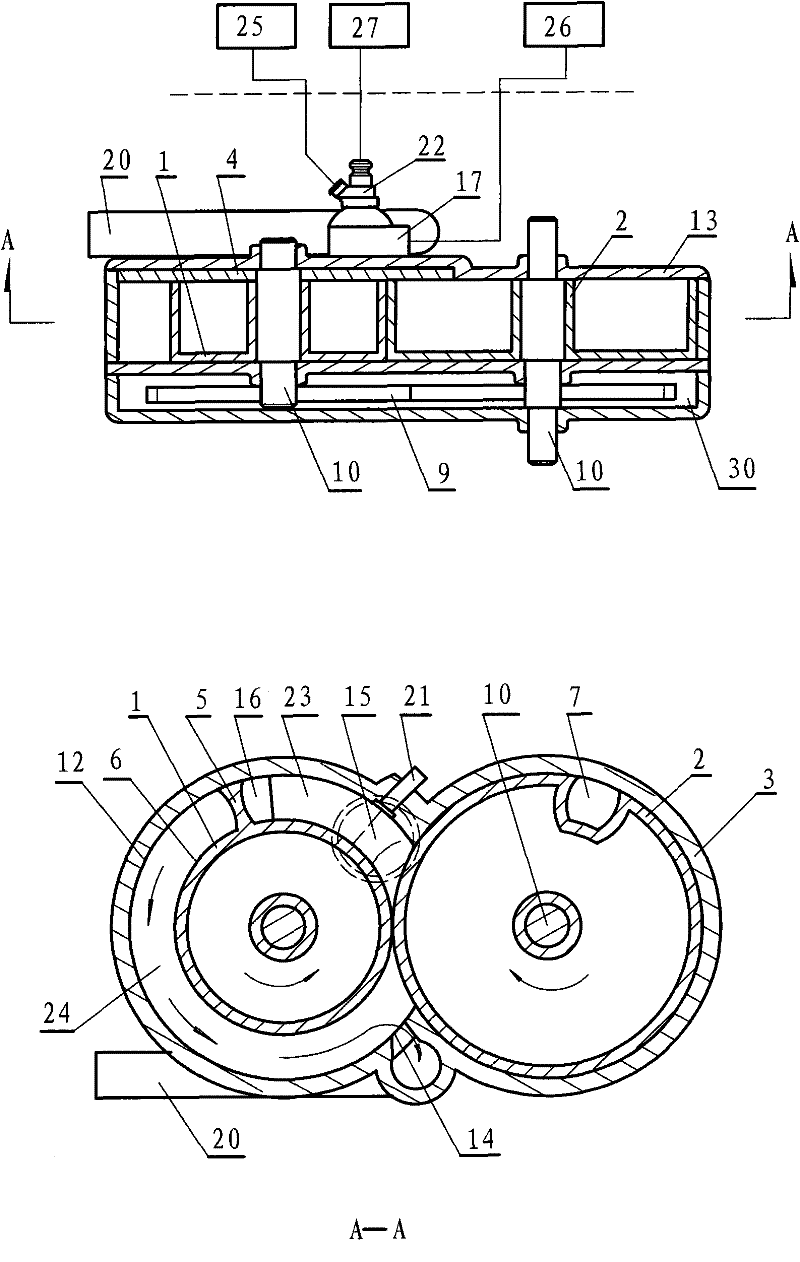

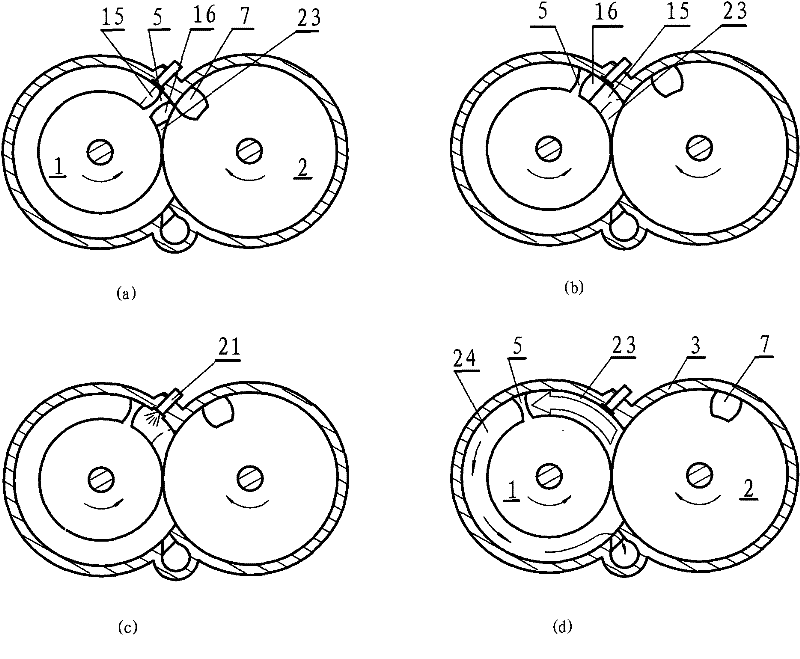

[0019] combine figure 1 , first of all, some terms involved in the present invention are defined. Cylinder block diagram a, a combination composed of two intersecting cylinders and two parallel planes perpendicular to the axes of the two intersecting cylinders, because the shape is similar to the symbol "∞", it is called ∞-shaped cylinder 3, referred to as cylinder body 3. The two parallel planes of the cylinder block 3 are called the cylinder block plane 13 , the inner arc surface of the cylinder block 3 is called the cylinder wall 12 , and the outer arc surface of the cylinder block 3 is called the cylinder surface 11 . An arc-shaped intake port 15 is opened on the plane 13 of the cylinder block, and a rectangular exhaust port 14 is opened on the cylinder wall 12 . The intake port 15 is connected to the intake pipe 17 outside the cylinder block 3 , and the exhaust port 14 is connected to the exhaust pipe 20 outside the cylinder block 3 . Synchronous gears and parallel sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com