Patents

Literature

81 results about "Miller cycle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

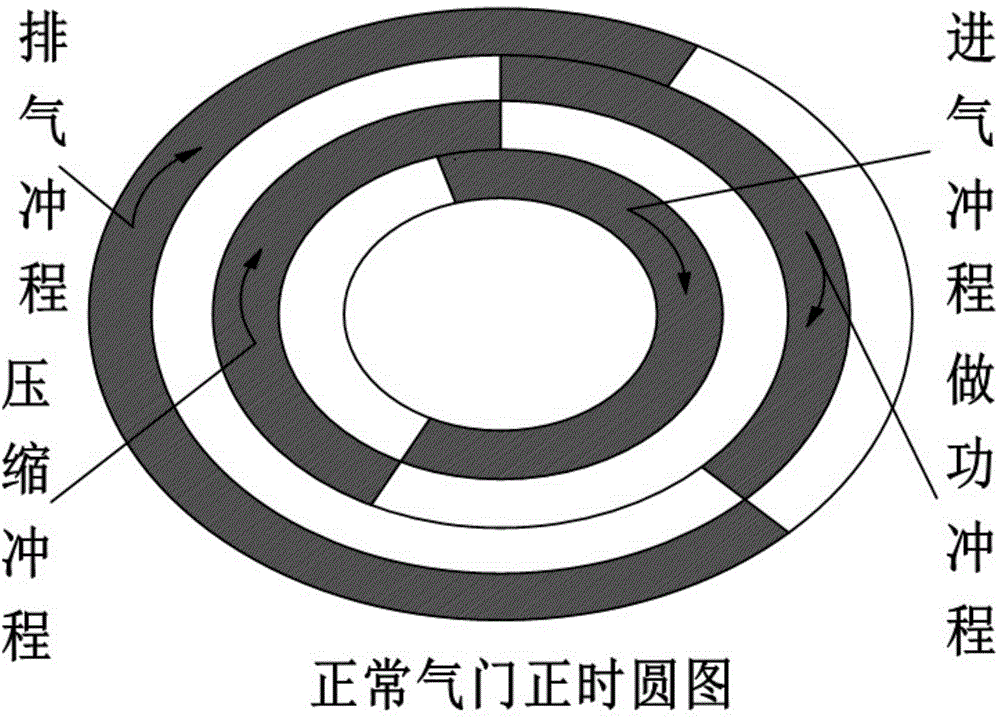

In engineering, the Miller cycle is a thermodynamic cycle used in a type of internal combustion engine. The Miller cycle was patented by Ralph Miller, an American engineer, US patent 2817322 dated Dec 24, 1957. The engine may be two- or four-stroke and may be run on diesel fuel, gases, or dual fuel.

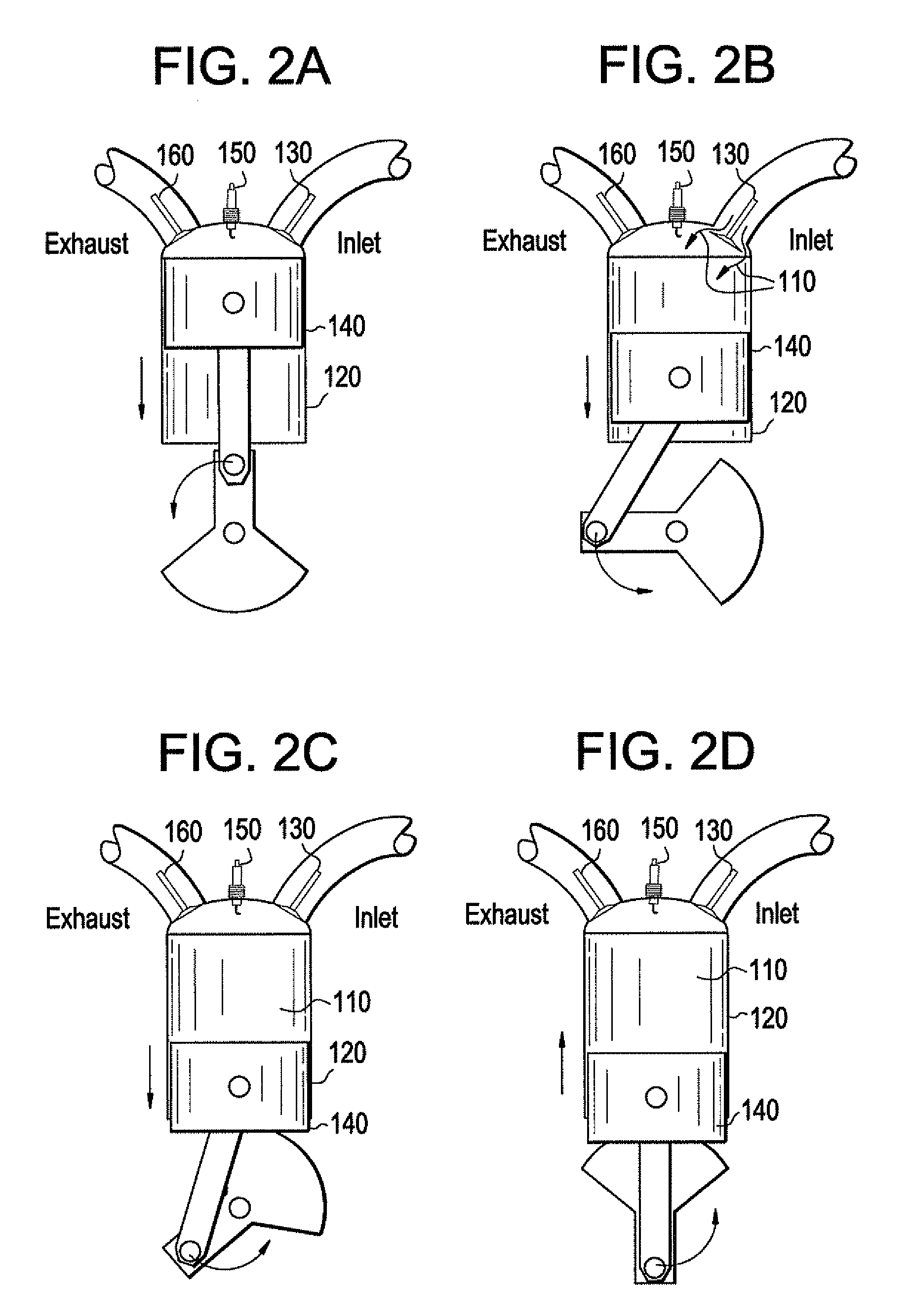

Compound cycle rotary engine

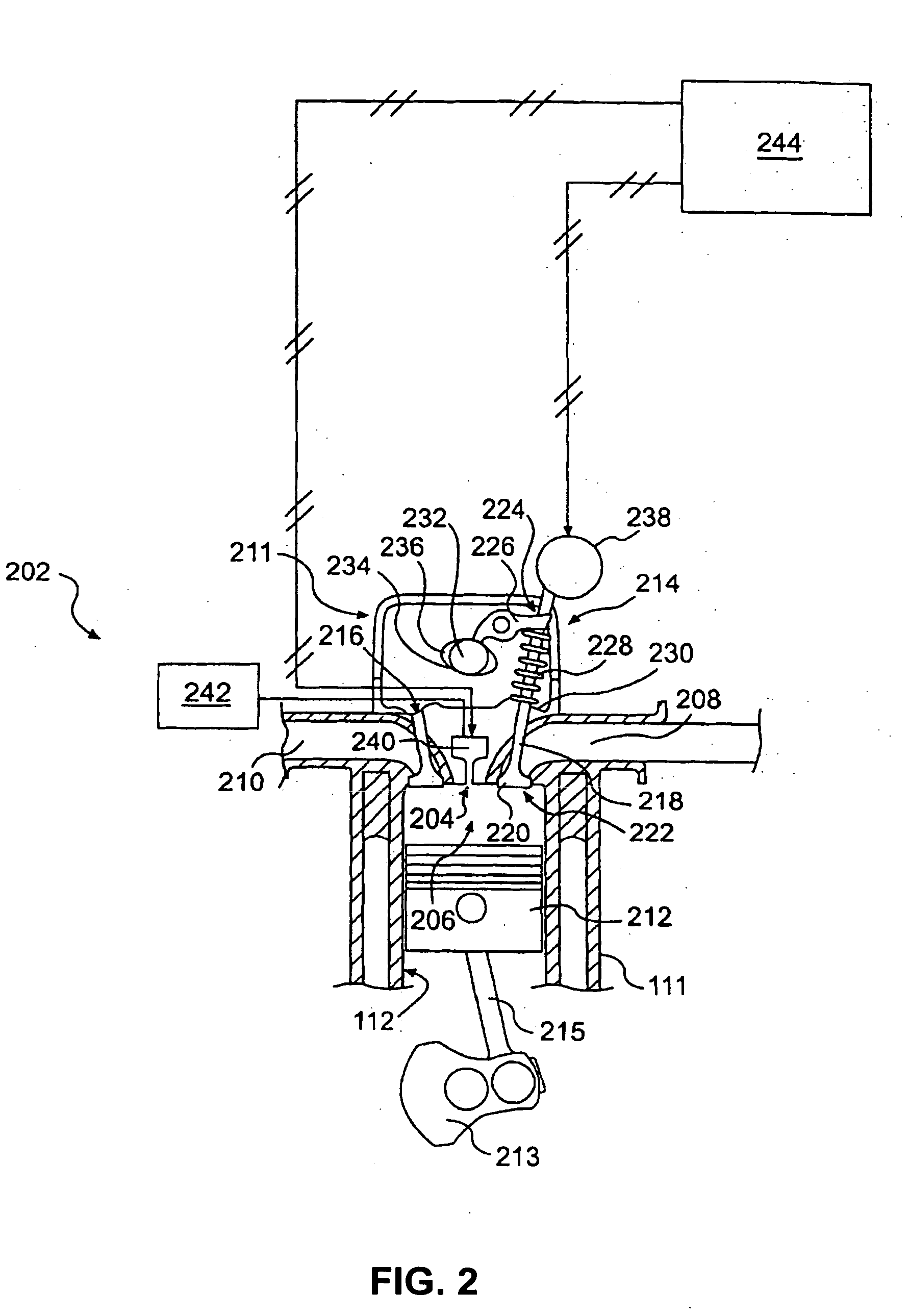

ActiveUS7753036B2High power to weightReduce fuel consumptionInternal combustion piston enginesCombination enginesRotary engineIntercooler

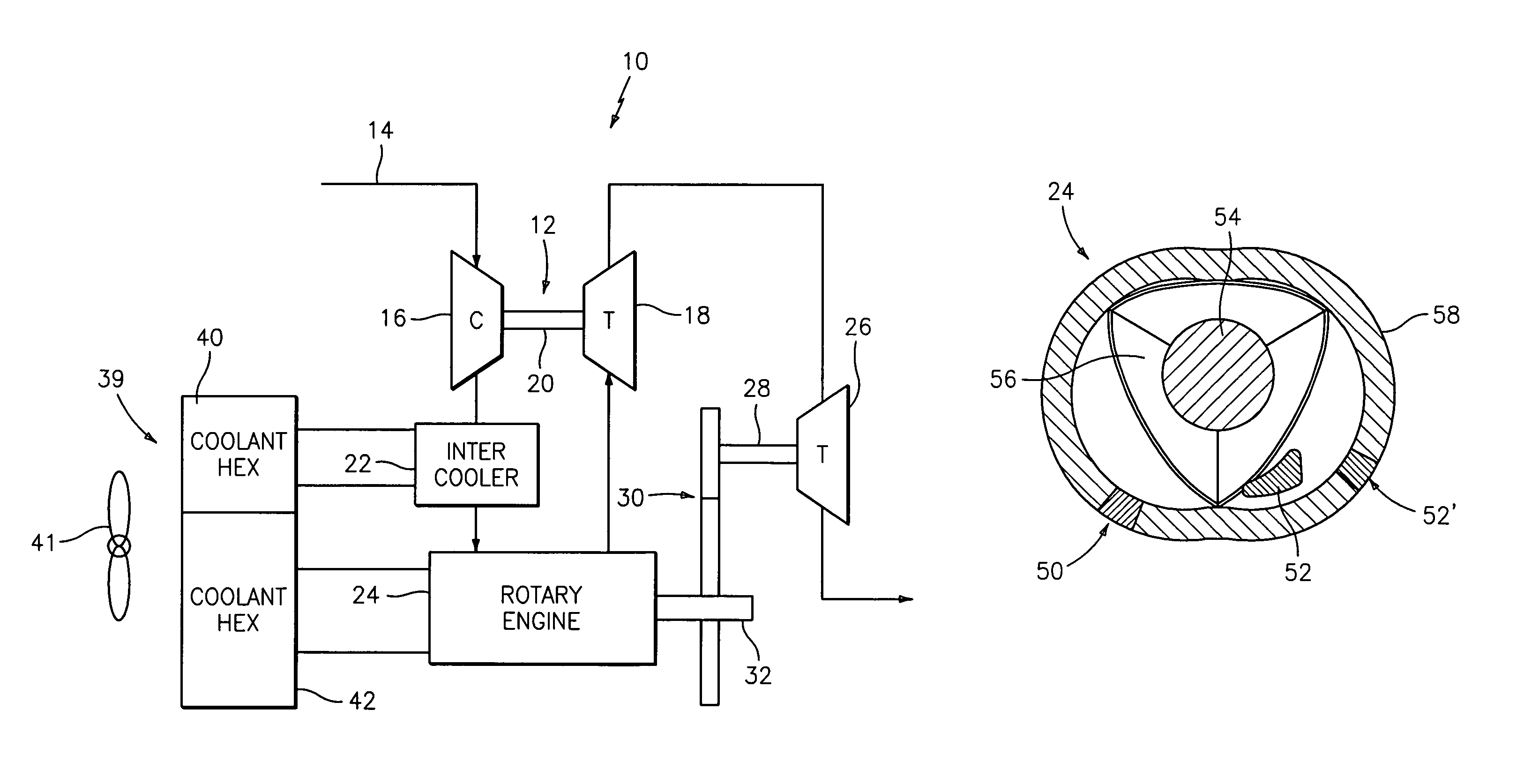

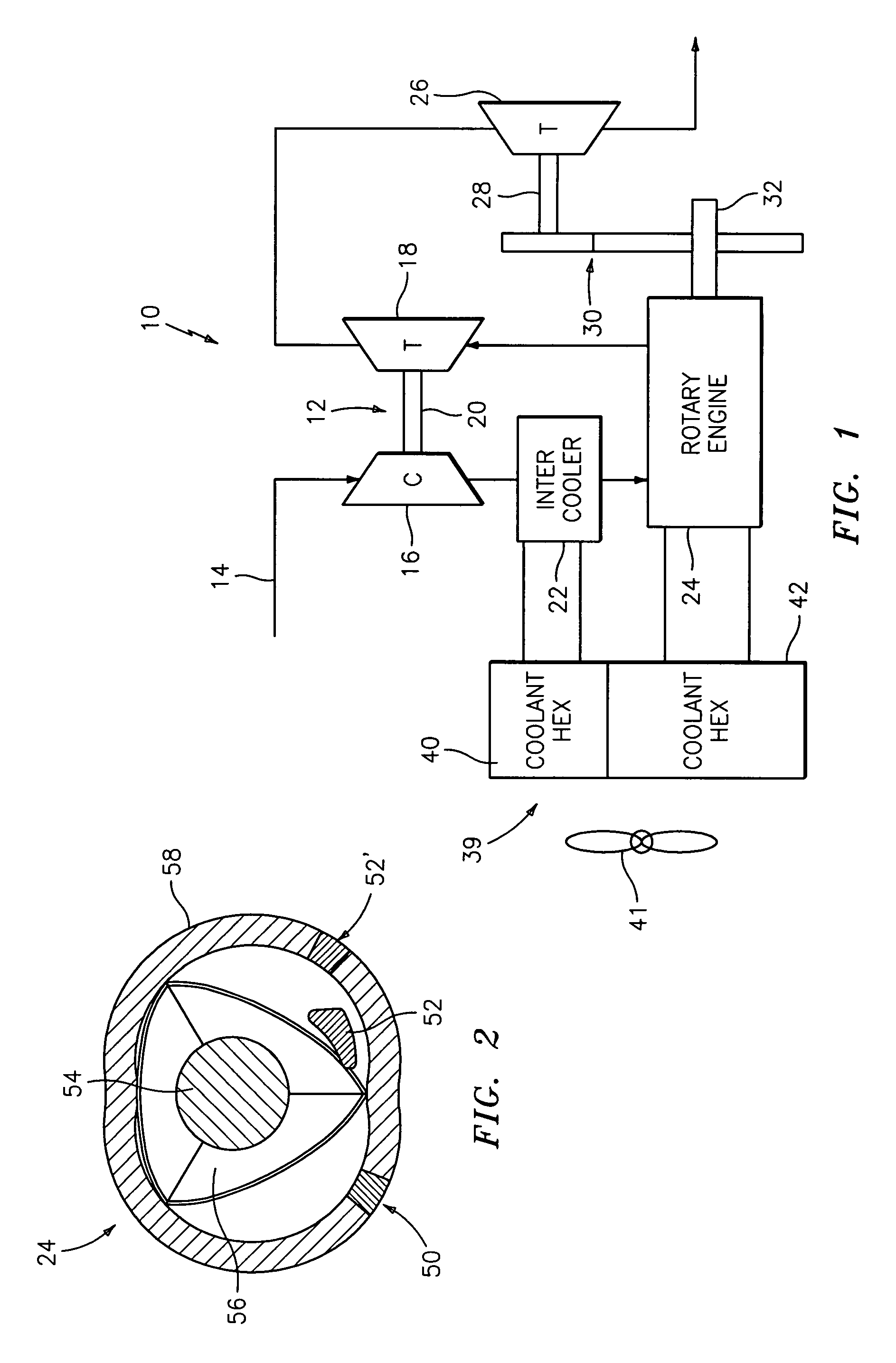

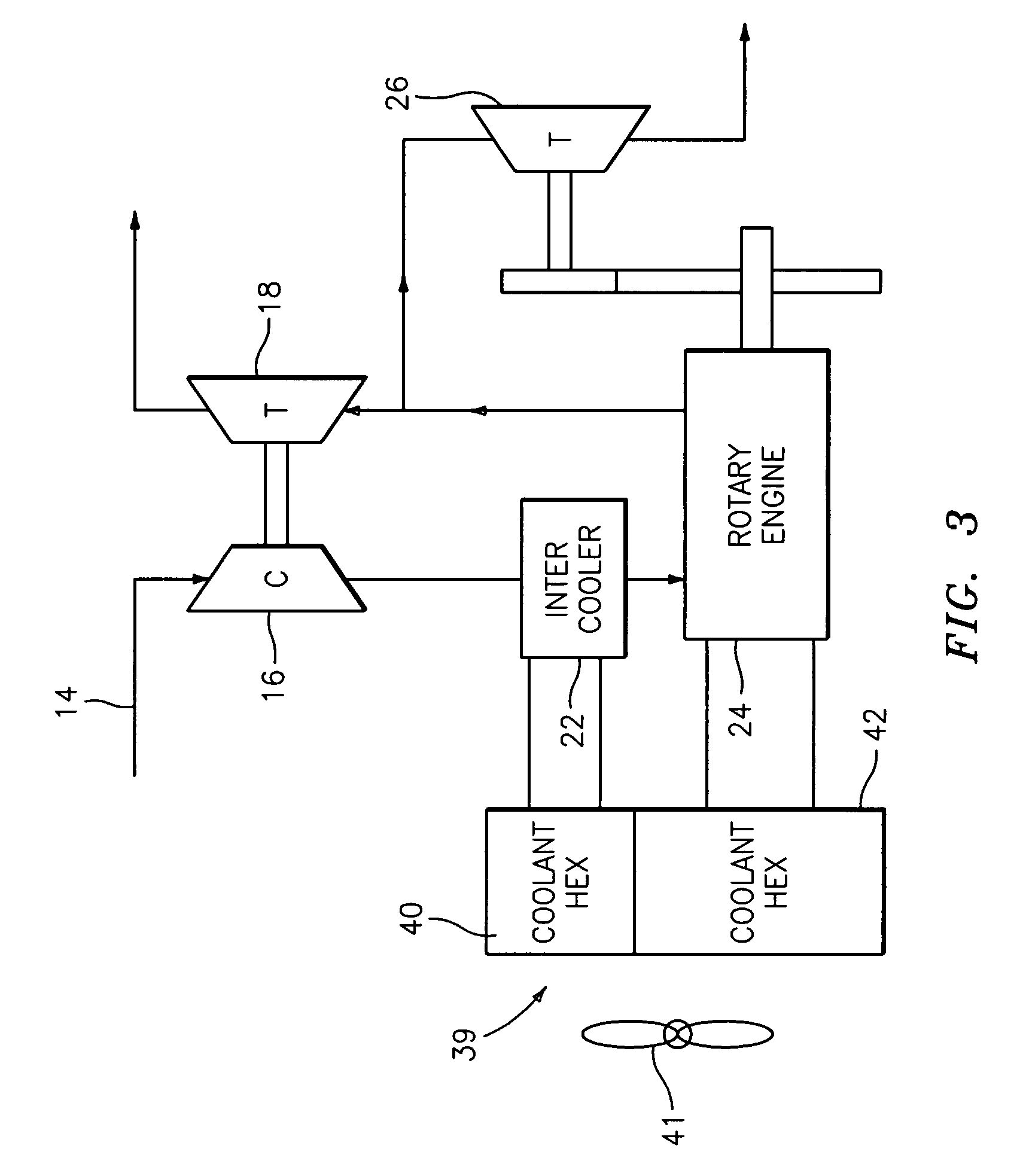

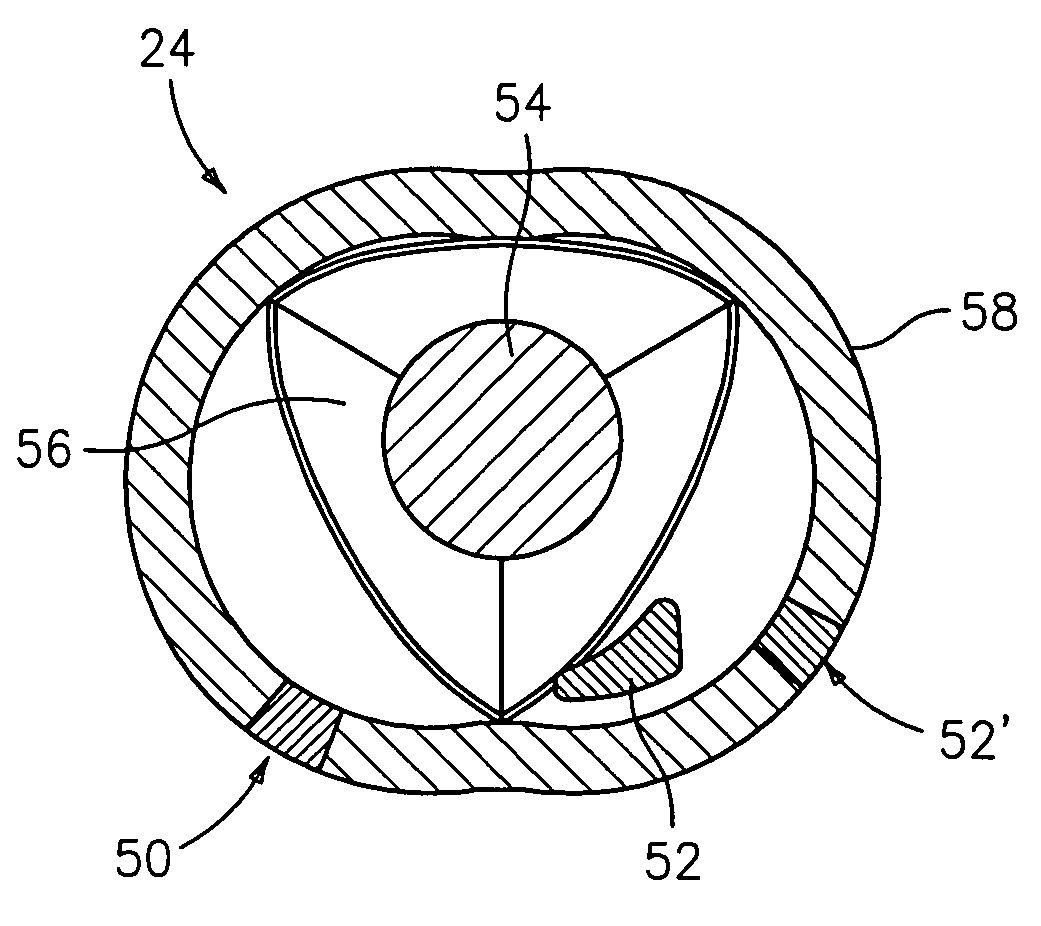

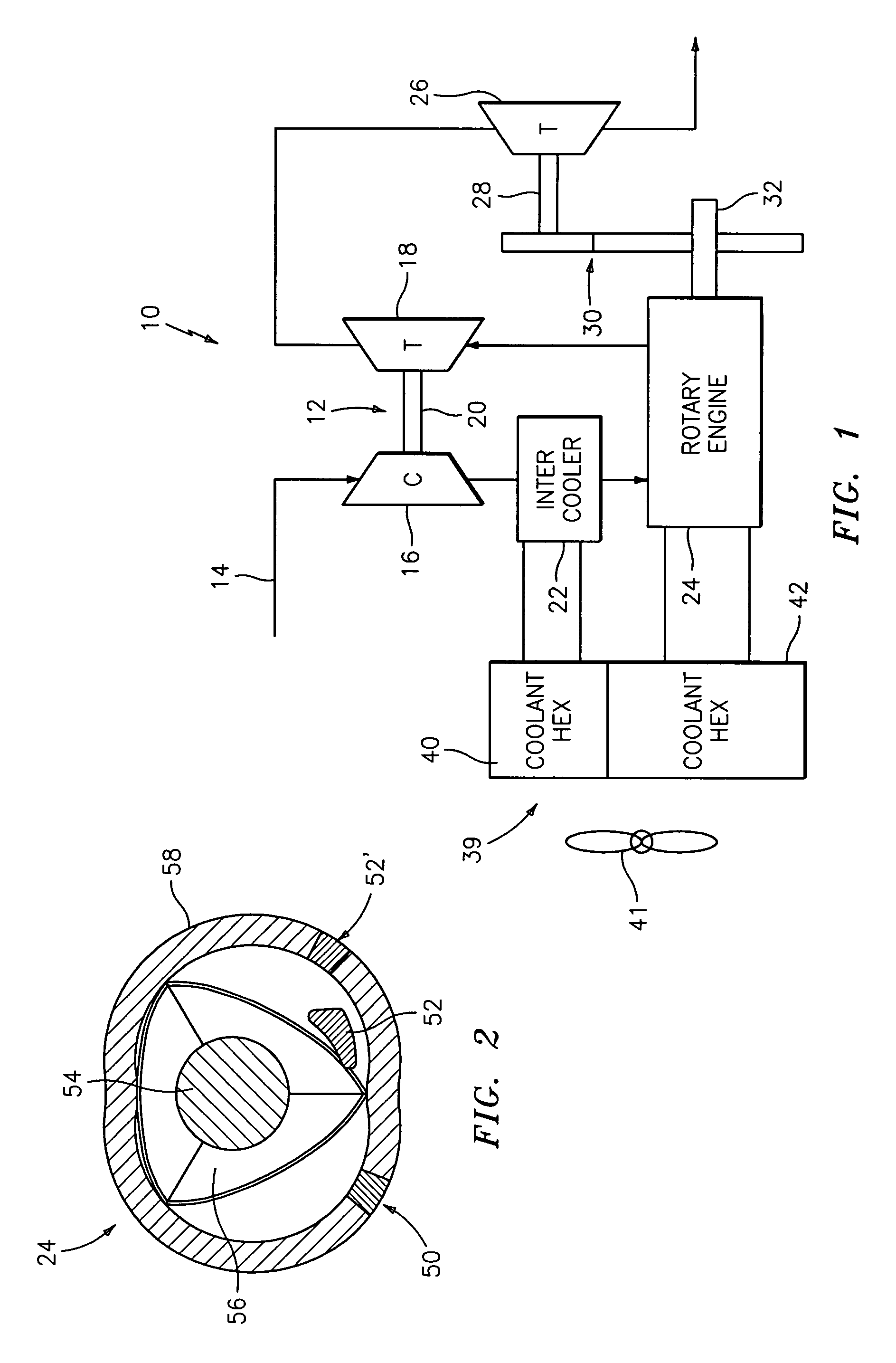

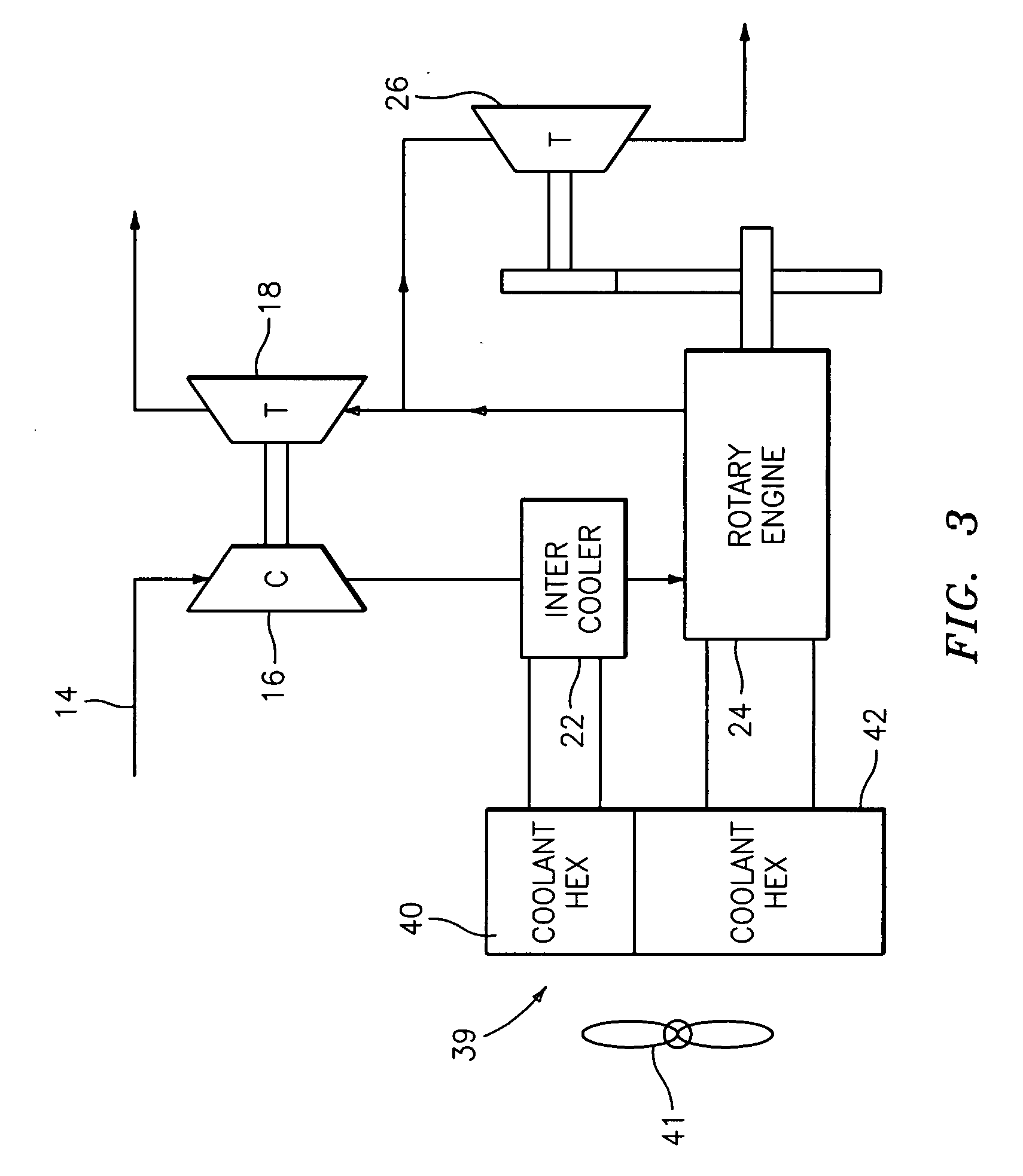

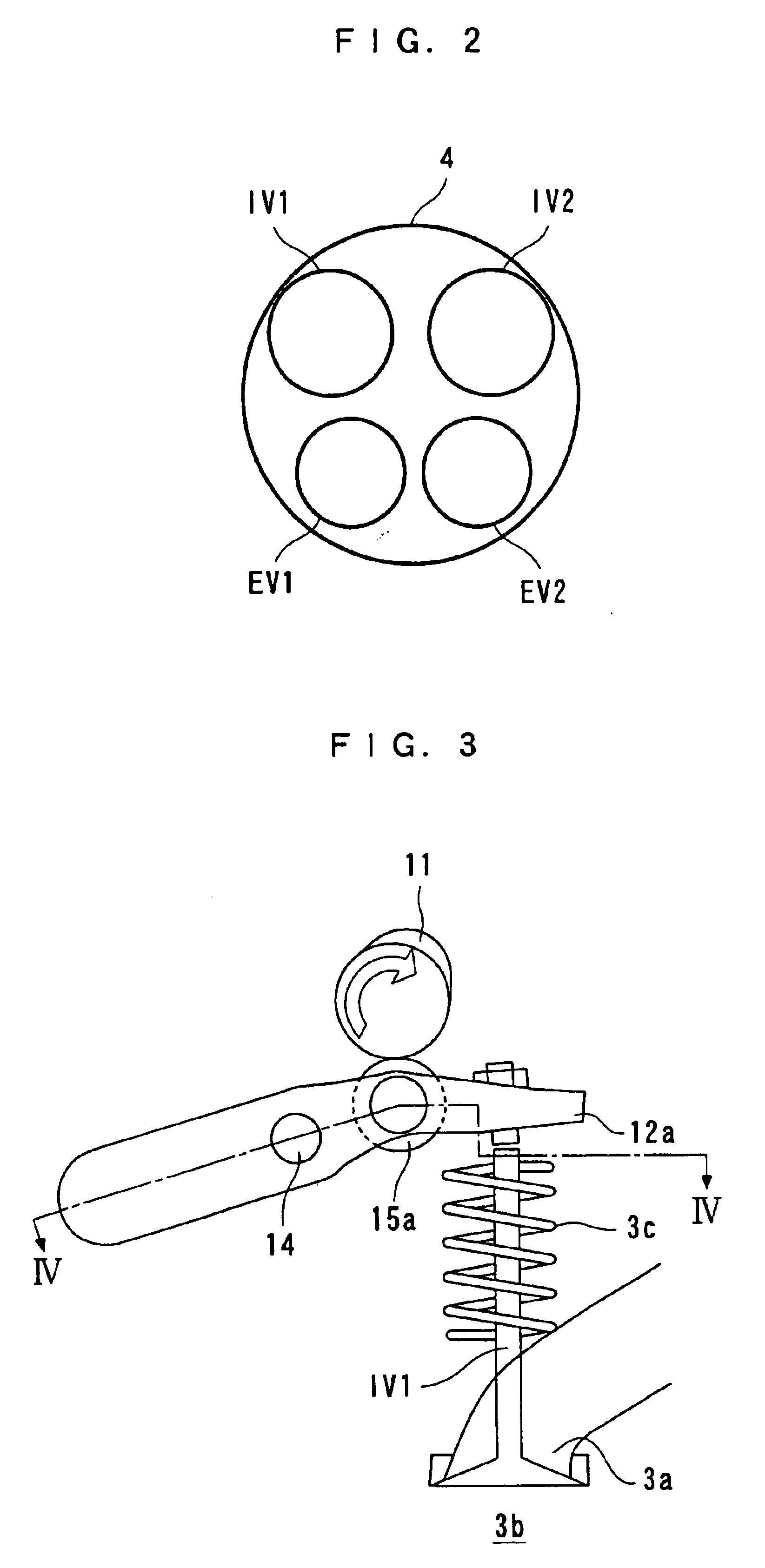

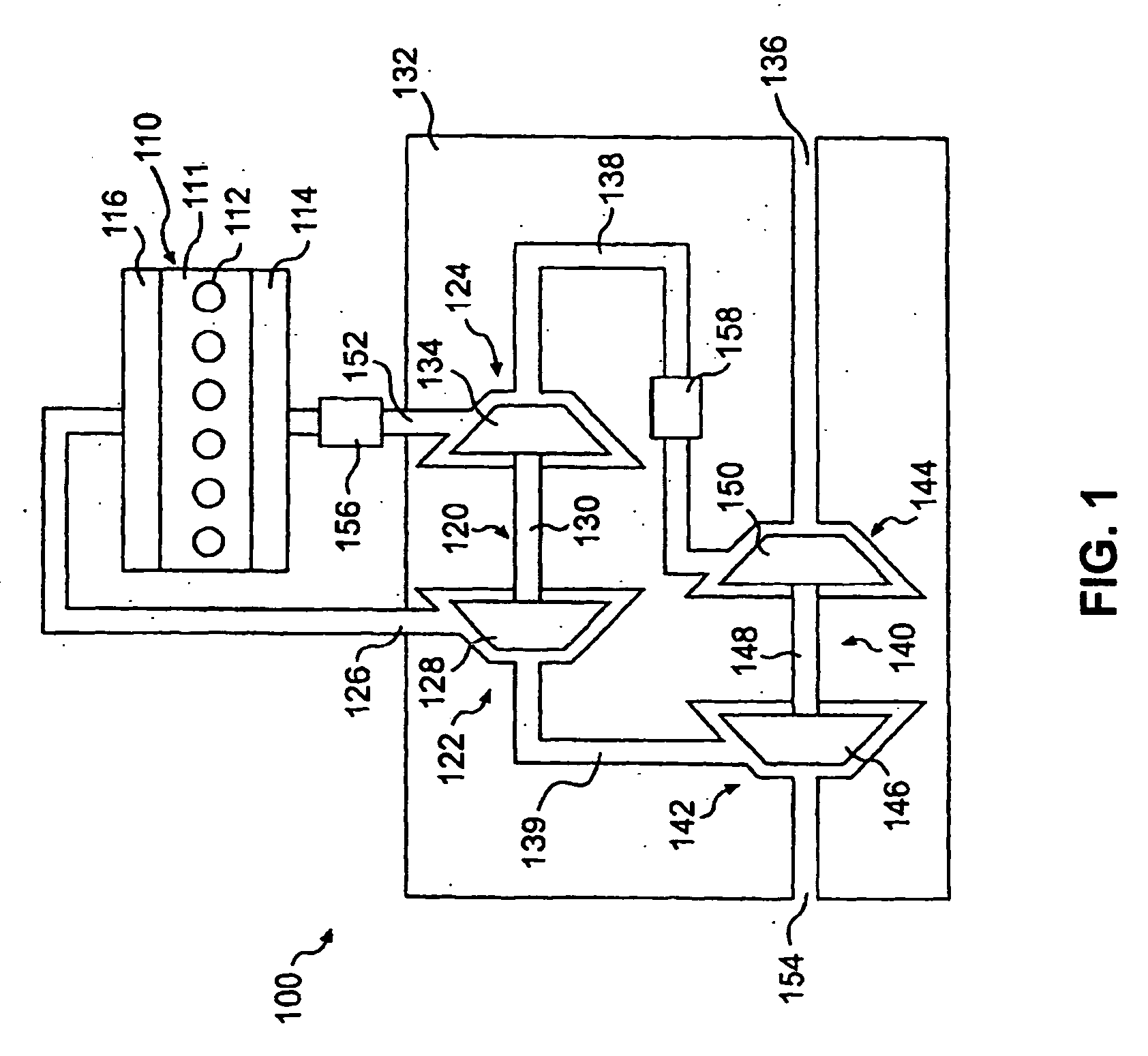

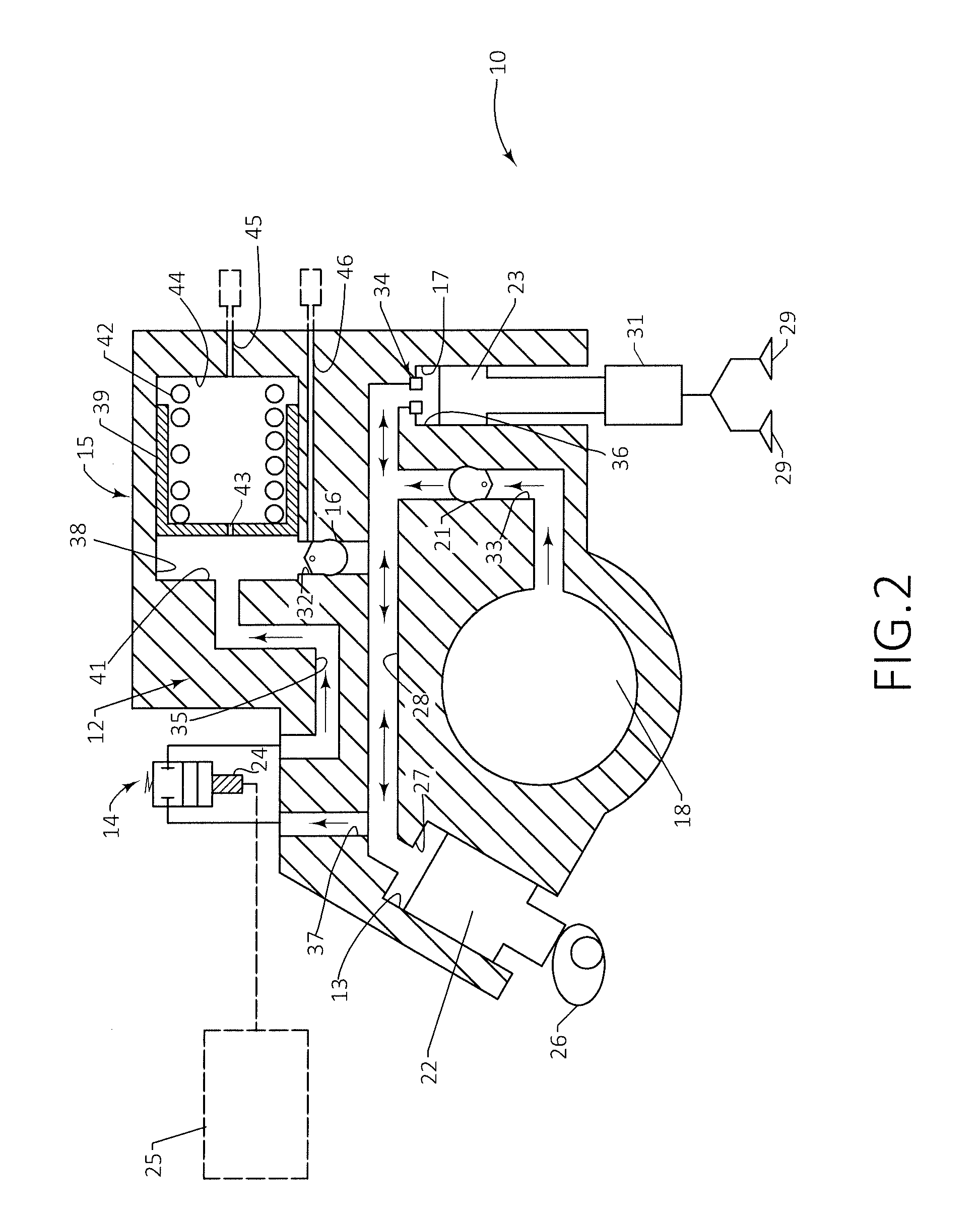

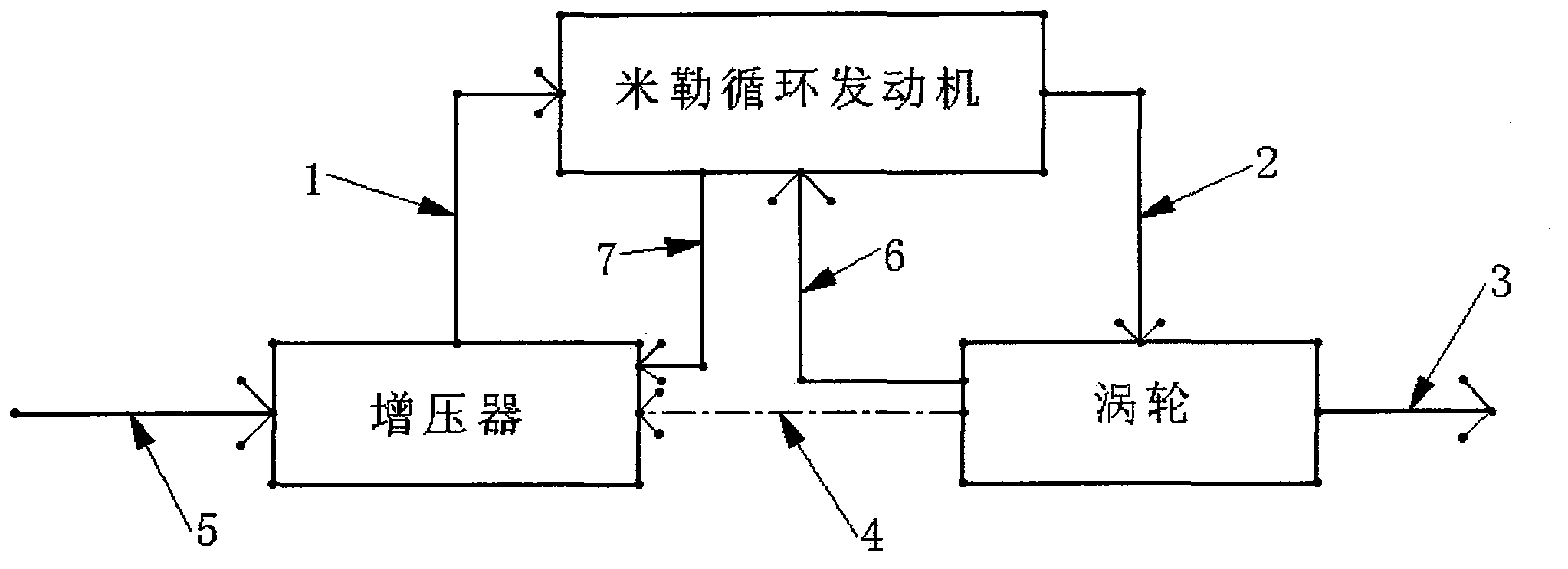

A compound cycle engine system has a rotary engine, which rotary engine generates exhaust gas. The system further has a compressor for increasing the pressure of inlet air to be supplied to the engine to a pressure in the range of from 3.0 to 5.0 atmospheres and an intercooler for providing the inlet air to the engine at a temperature in the range of from 150 to 250 degrees Fahrenheit. The system further has one or more turbines for extracting energy from the exhaust gas. The Miller Cycle is implemented in the rotary engine, enabling the compression ratio to be lower than the expansion ratio, allowing the overall cycle to be optimized for lowest weight and specific fuel consumption.

Owner:RTX CORP

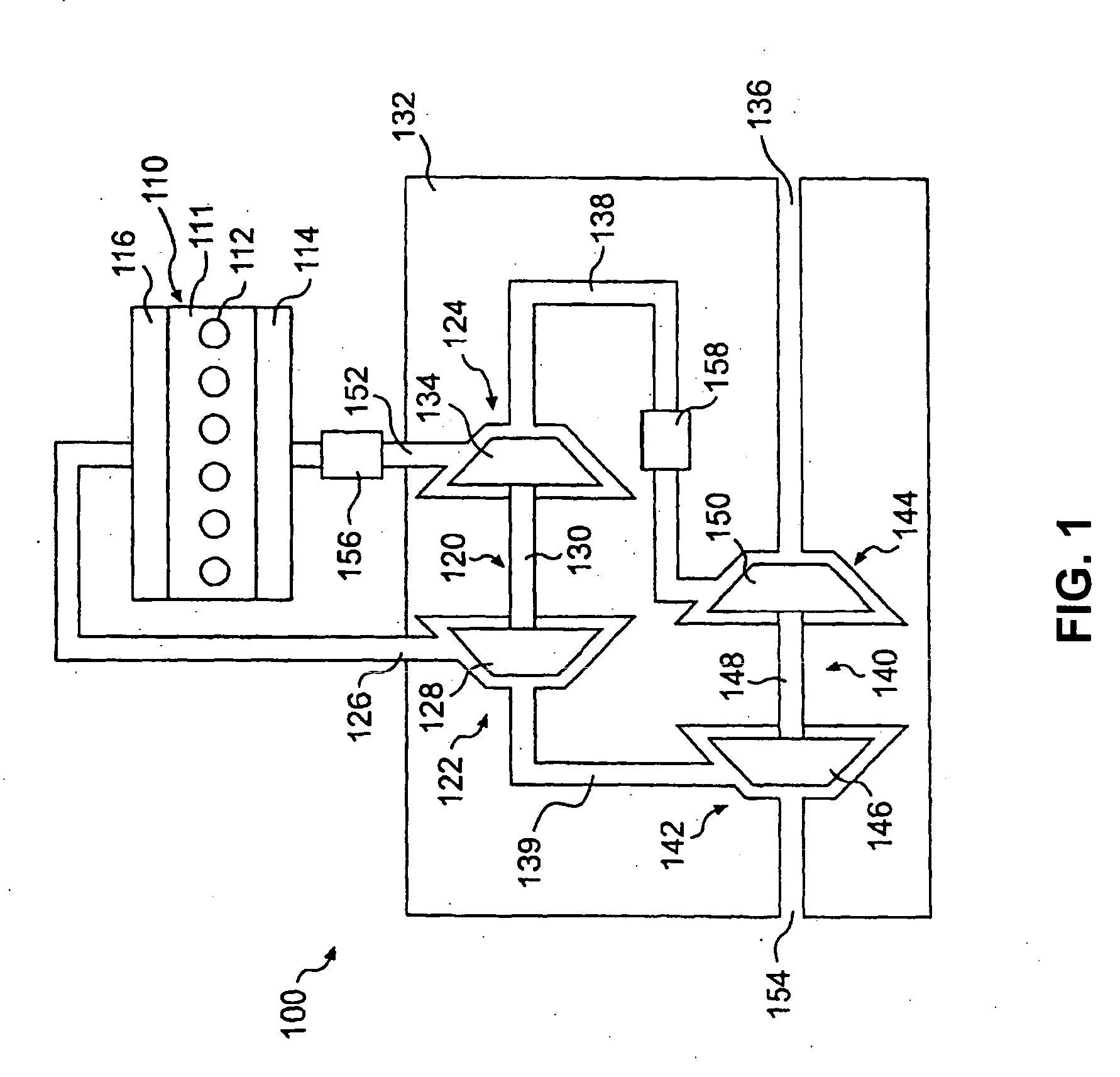

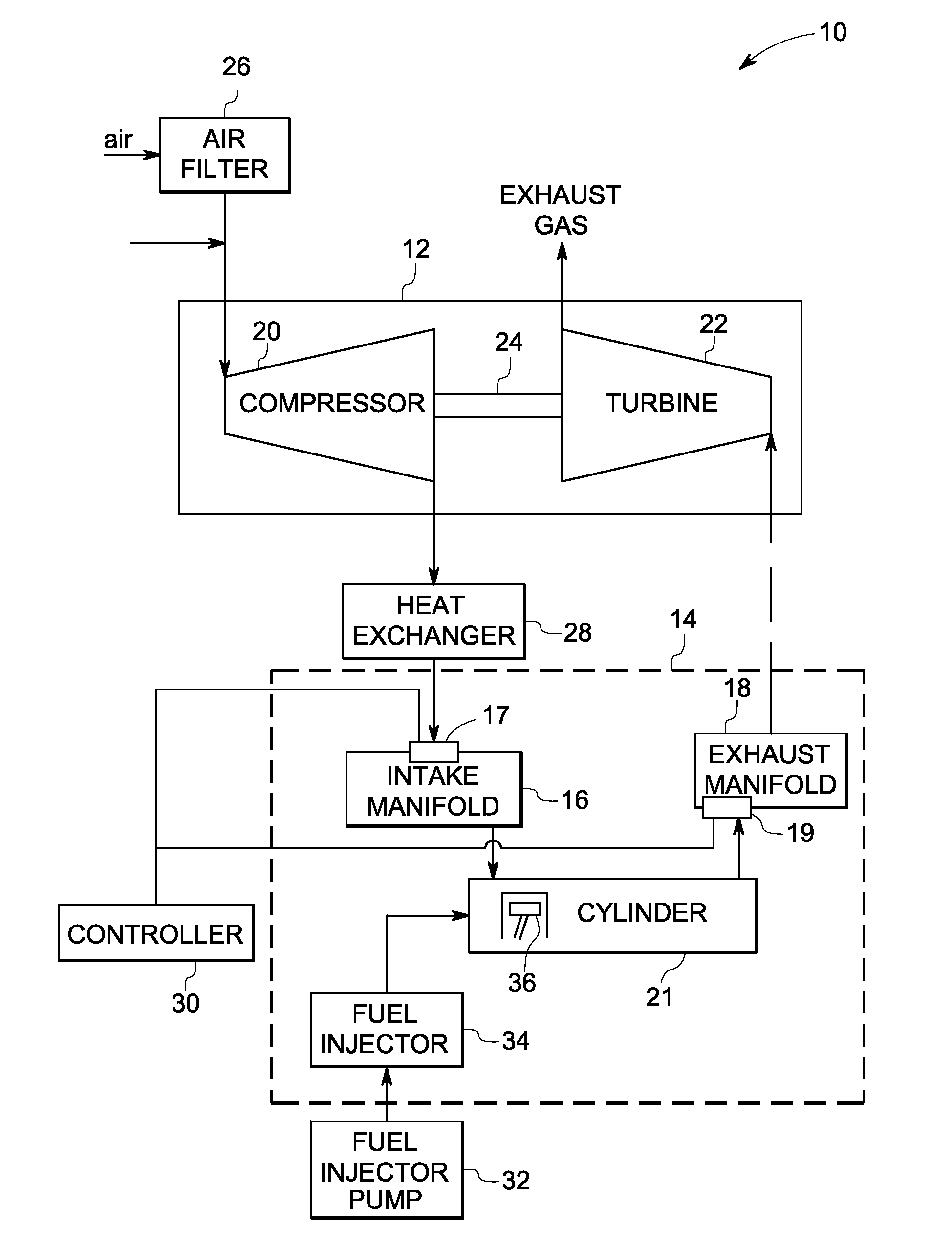

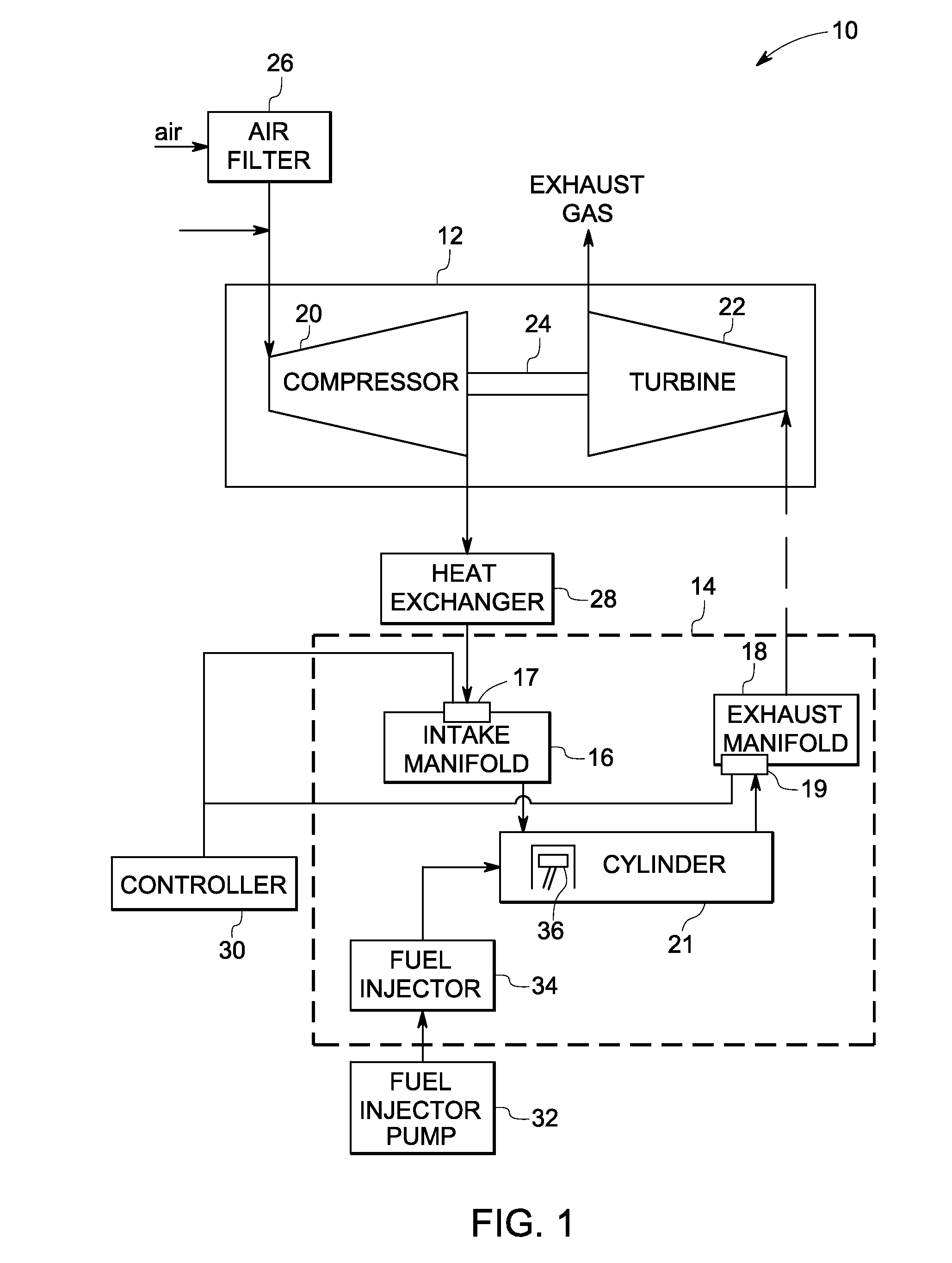

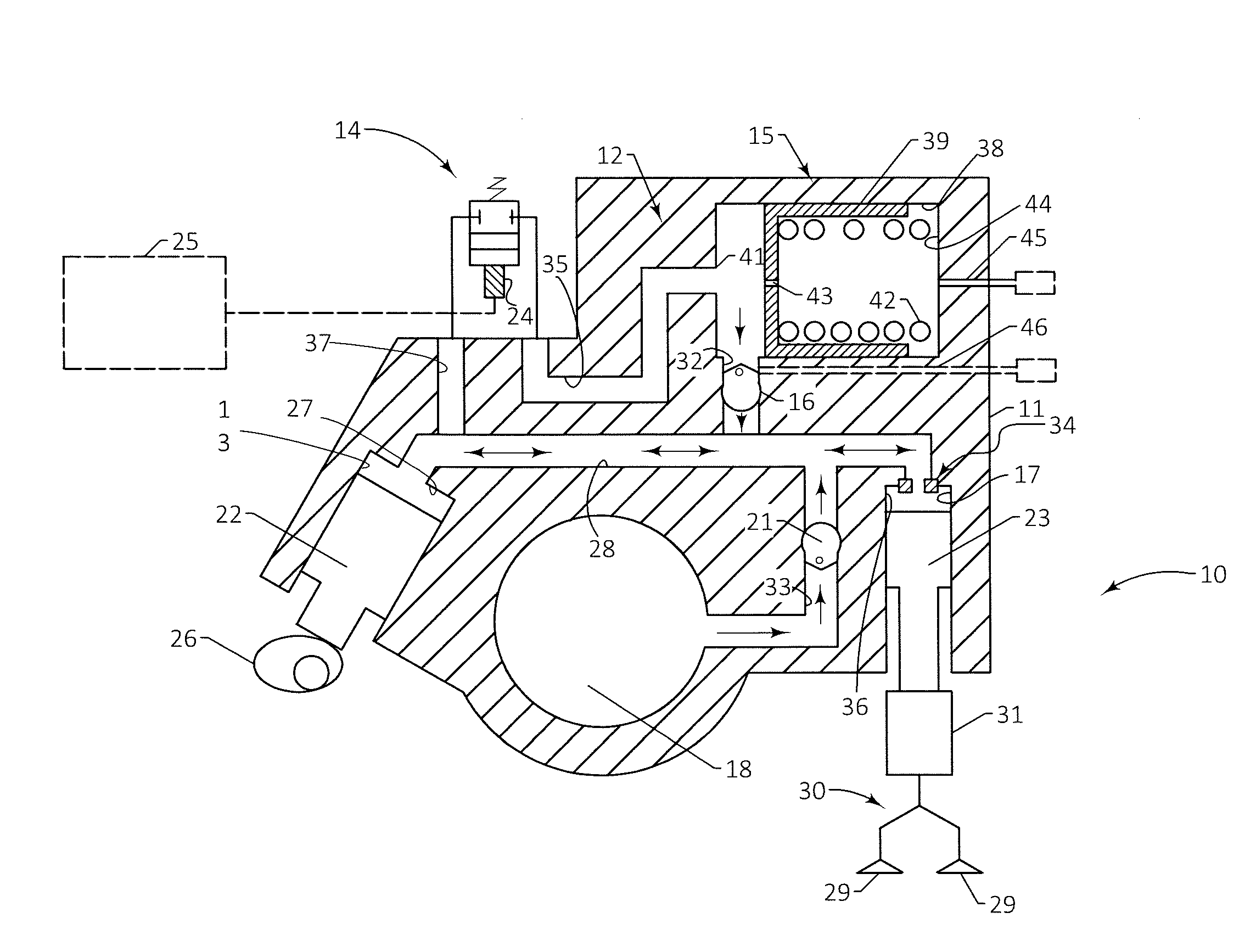

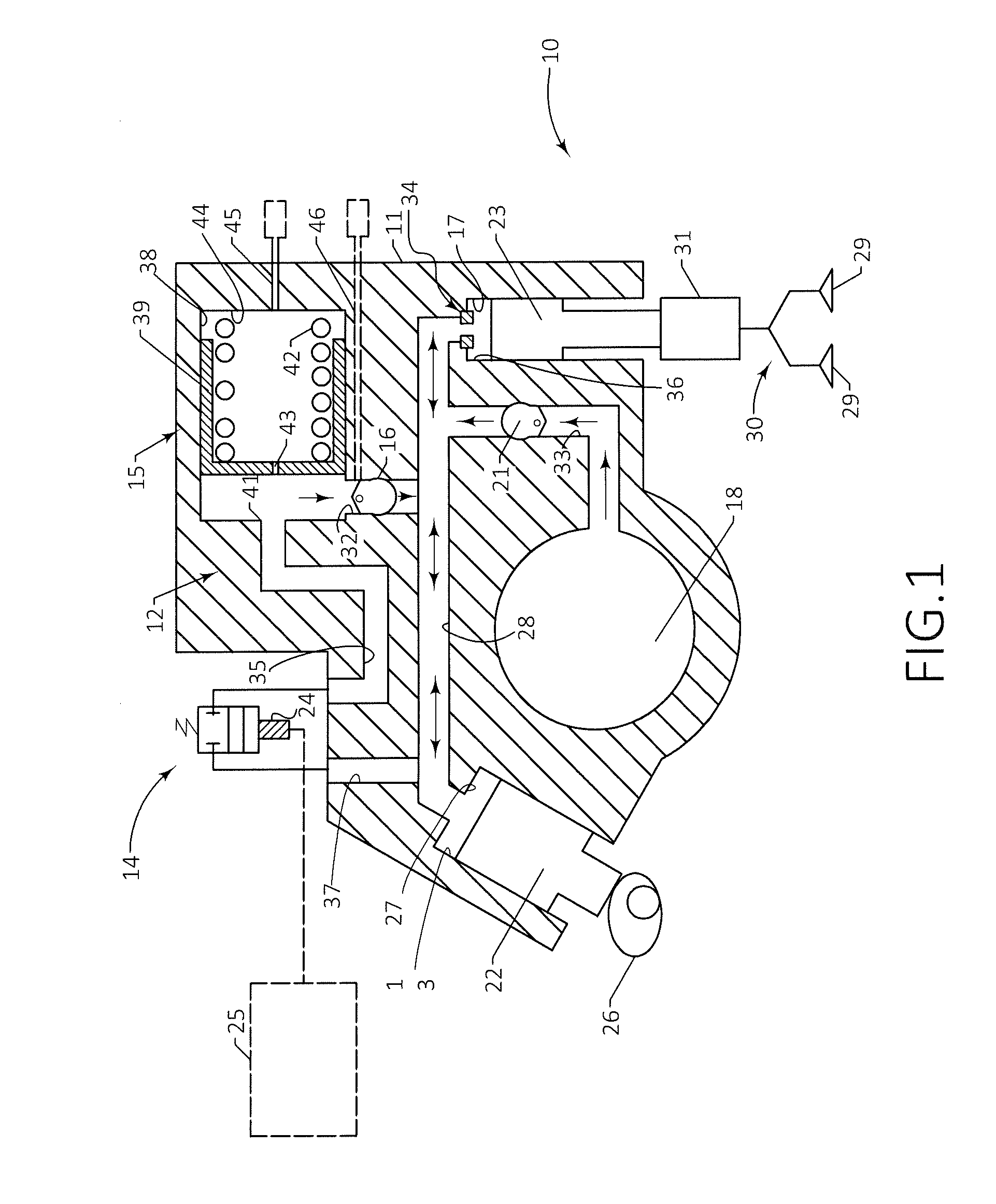

Charge air chiller

InactiveUS20090031999A1Maximum increase in energy efficiencyIncrease boost pressureInternal combustion piston enginesNon-fuel substance addition to fuelTurbochargerInlet valve

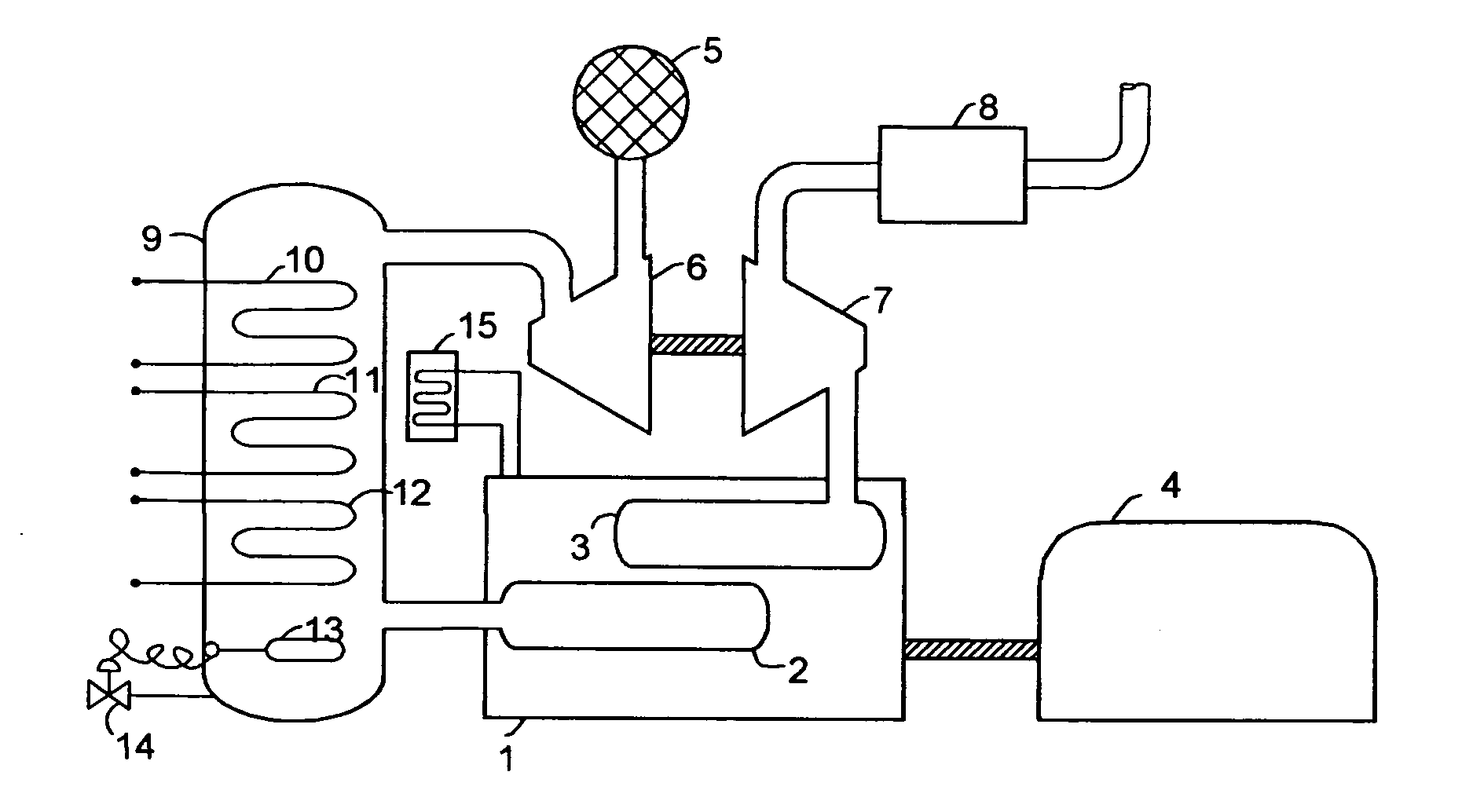

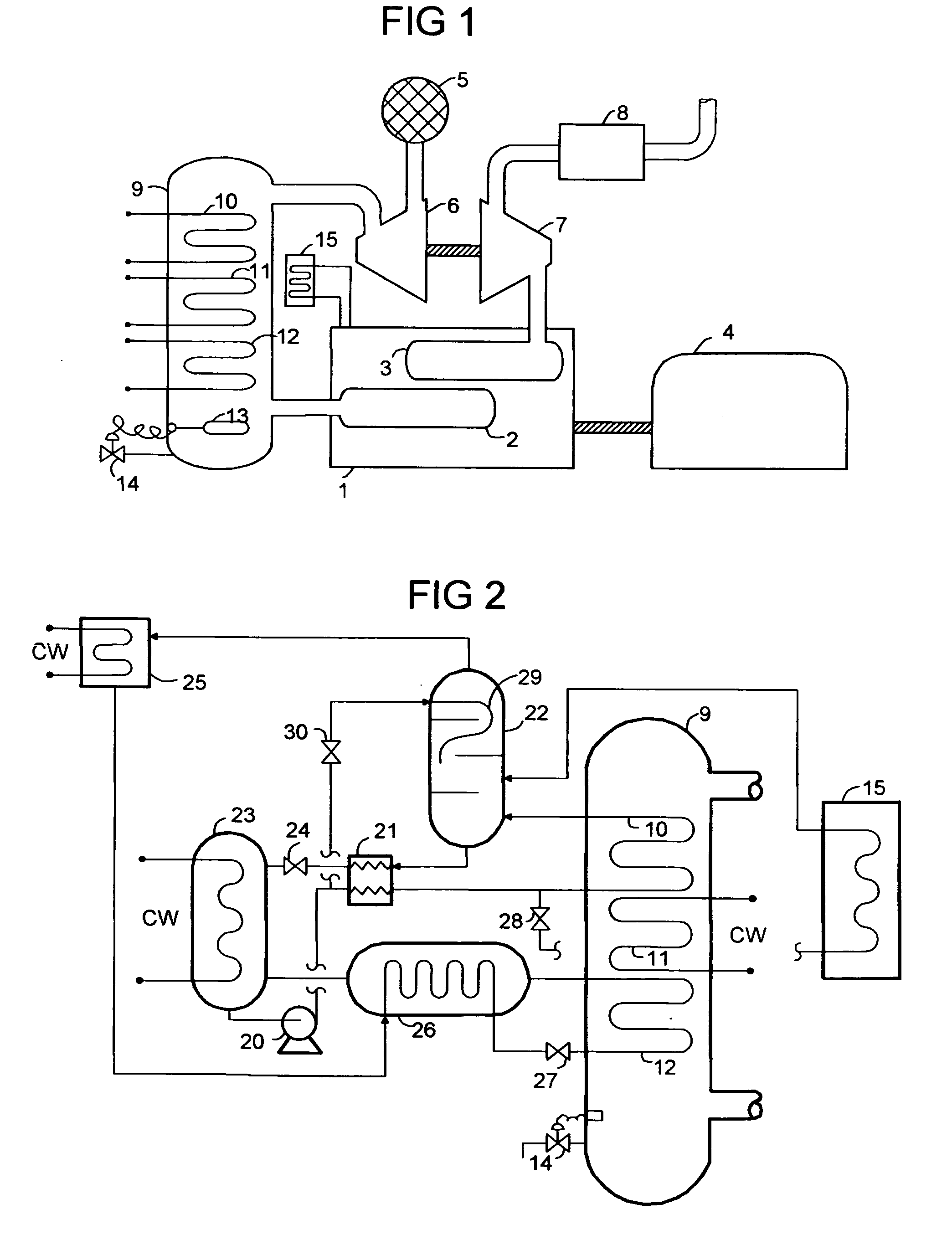

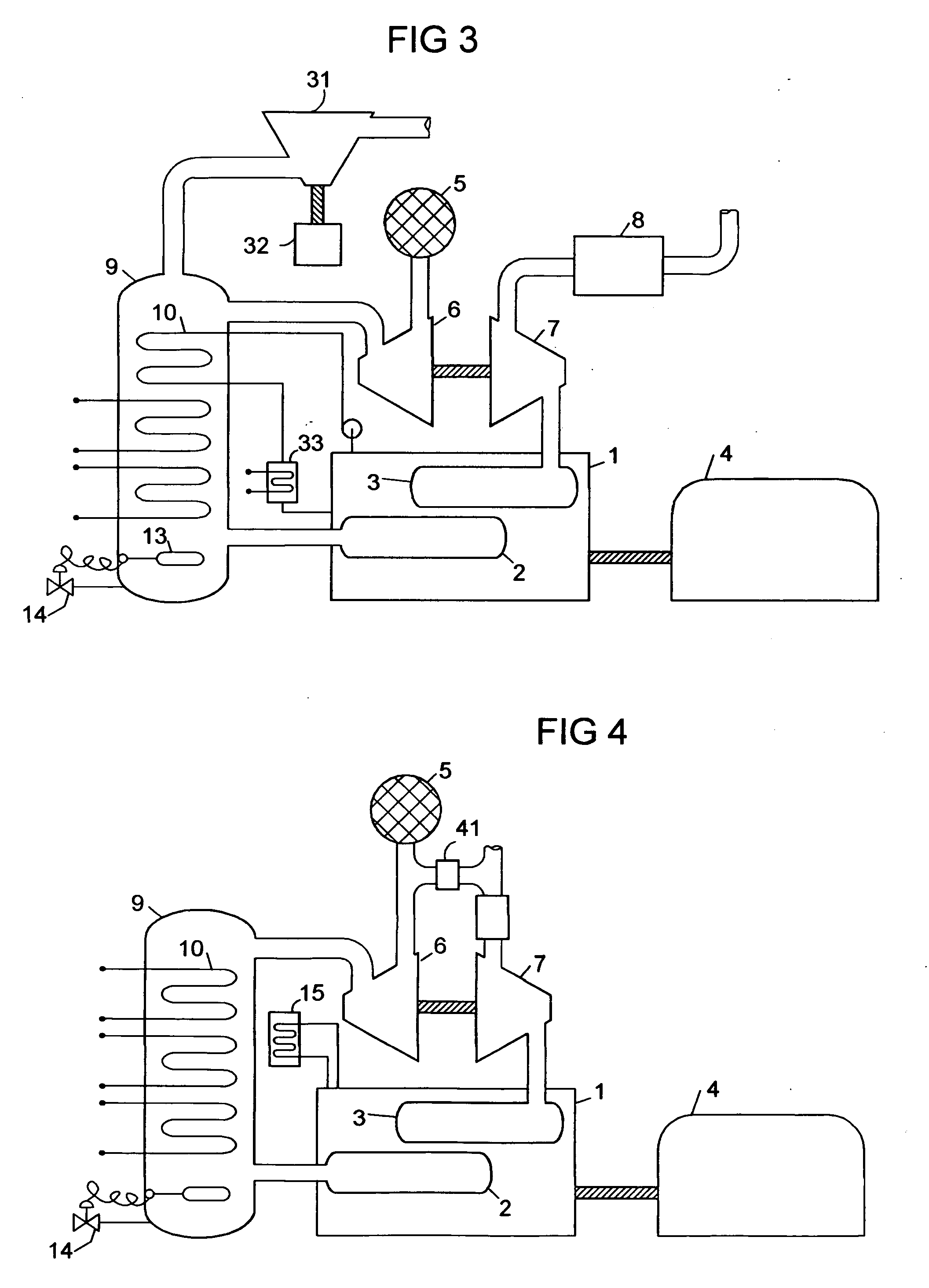

A system for chilling the pressurized charge air to a reciprocating engine is disclosed wherein the chilling is provided by a thermally activated refrigeration cycle powered by waste heat from the engine system. This reduces the required compression power, and also retards knock, making higher compression ratios possible. The chilling system is designed to minimize the amount of chilling required, and also to enable use of compression heat to power the chiller. The disclosed improvement also accommodates exhaust gas recirculation, plus providing activation heat from the exhaust gas, plus Miller cycle timing of the intake valves. Referring to FIG. 1, the charge air from turbocharger 5 is cooled in three stages: heat recovery stage 10; ambient-cooled stage 11; and chilling stage 12. Condensed moisture is removed from the charge air by valve 14 before the charge is supplied to inlet manifold 2.

Owner:ERICKSON DONALD CHARLES

Compound cycle rotary engine

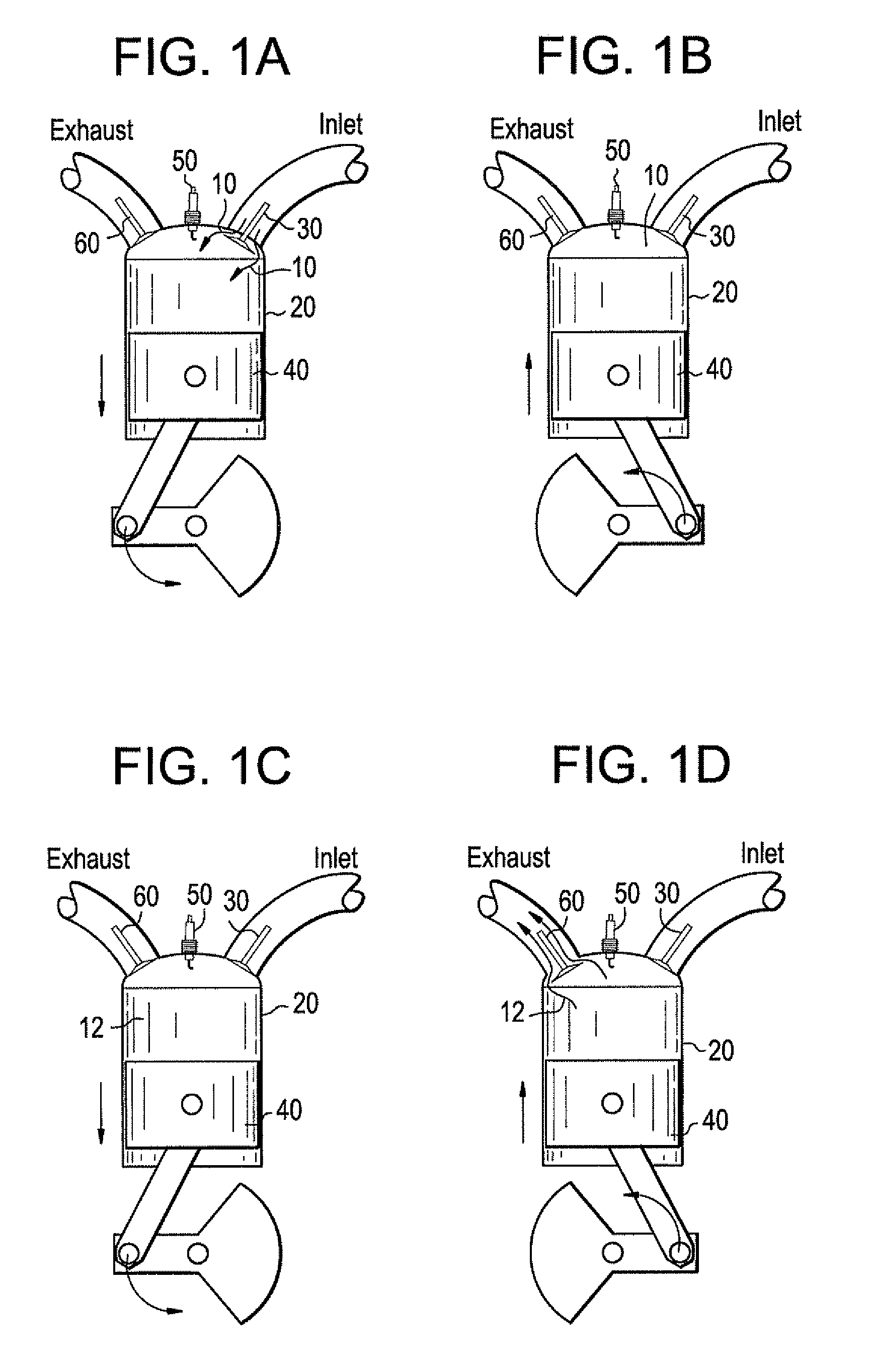

ActiveUS20090007882A1Reduce fuel consumptionHigh power to weightInternal combustion piston enginesCombination enginesRotary engineIntercooler

A compound cycle engine system has a rotary engine, which rotary engine generates exhaust gas. The system further has a compressor for increasing the pressure of inlet air to be supplied to the engine to a pressure in the range of from 3.0 to 5.0 atmospheres and an intercooler for providing the inlet air to the engine at a temperature in the range of from 150 to 250 degrees Fahrenheit. The system further has one or more turbines for extracting energy from the exhaust gas. The Miller Cycle is implemented in the rotary engine, enabling the compression ratio to be lower than the expansion ratio, allowing the overall cycle to be optimized for lowest weight and specific fuel consumption.

Owner:RTX CORP

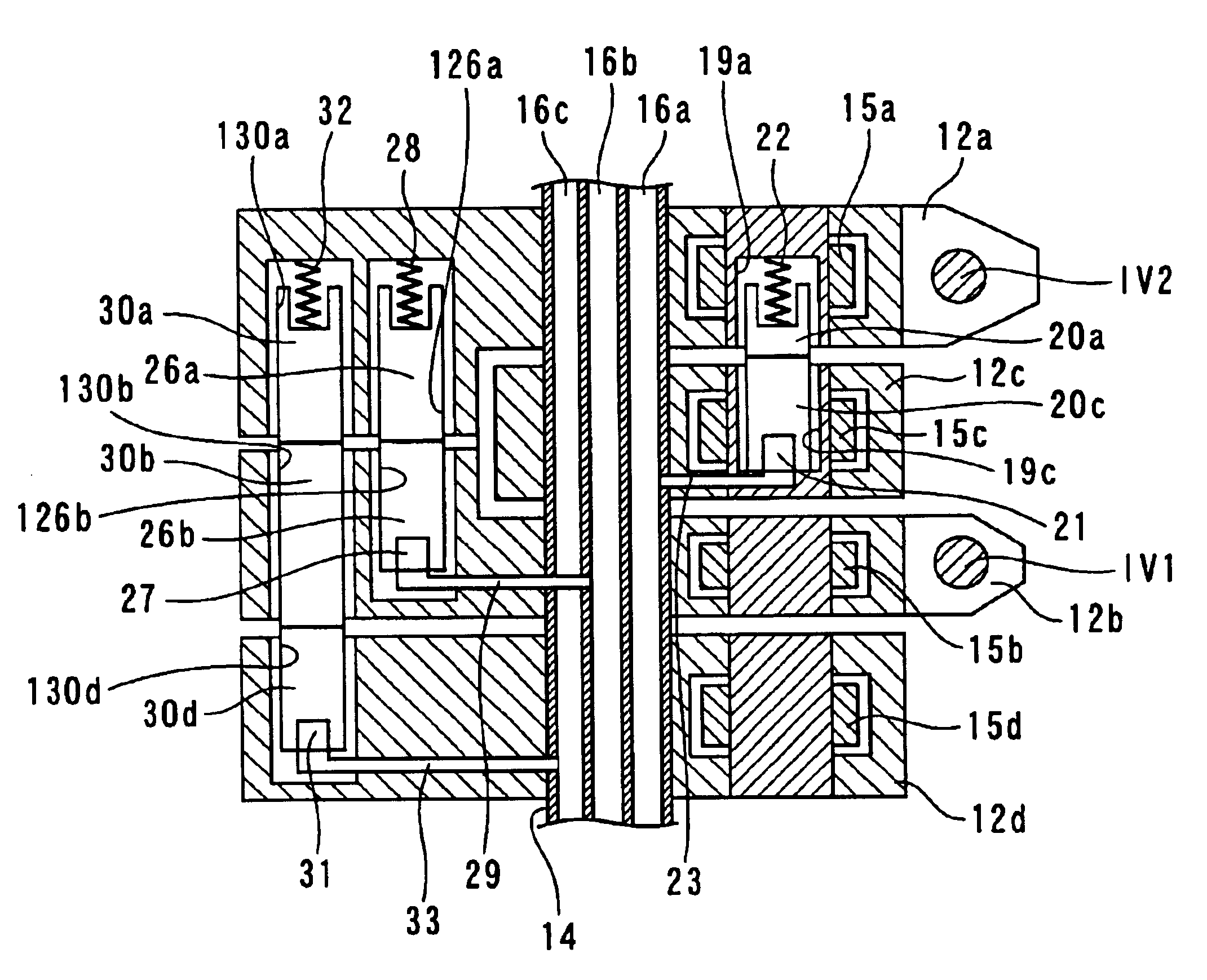

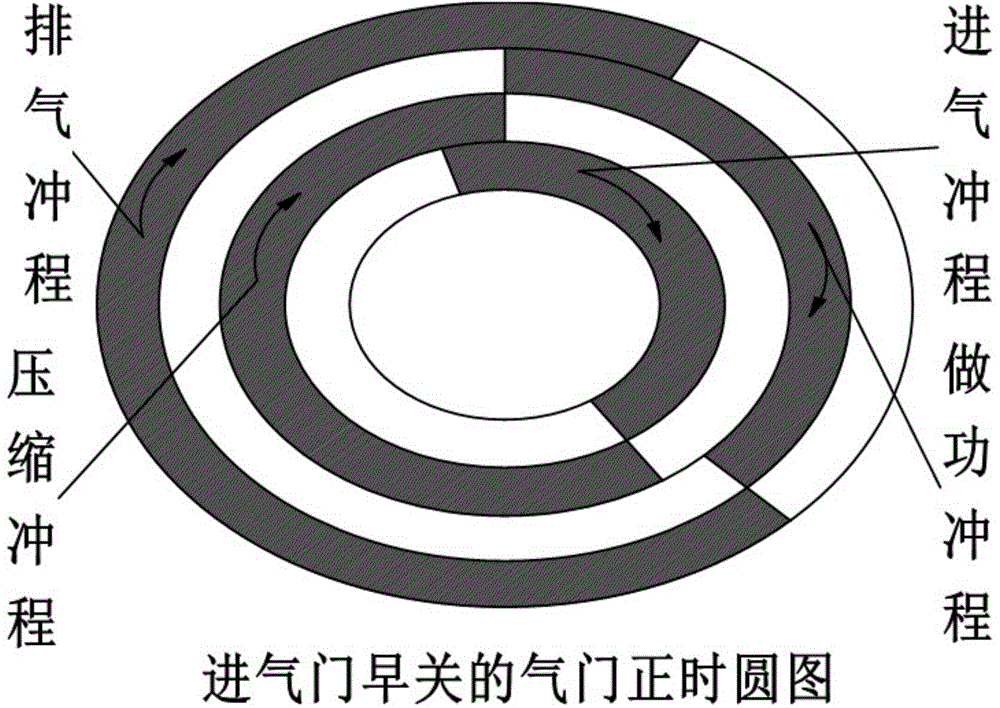

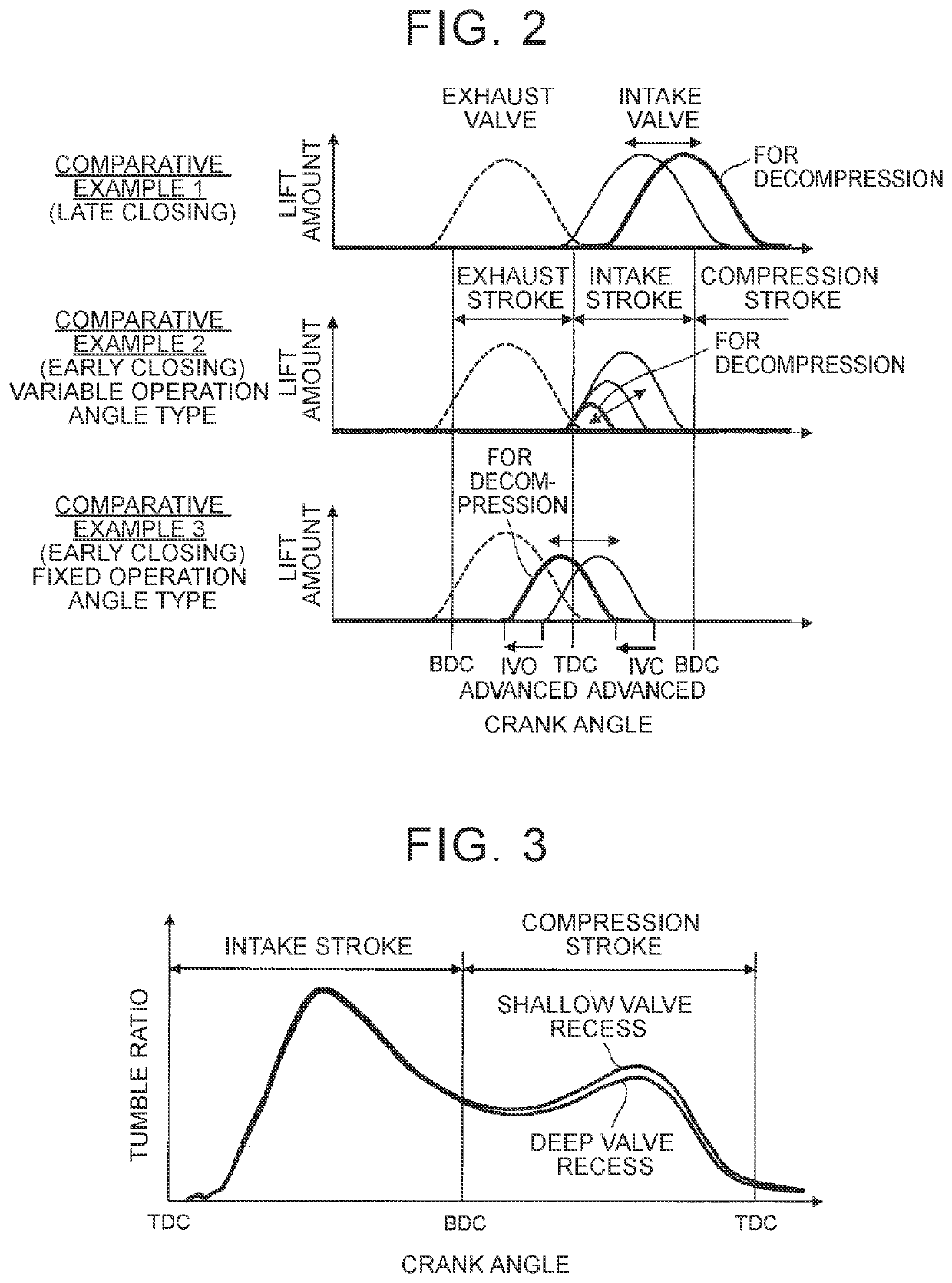

Early closing miller cycle internal combustion engine

InactiveUS20020026913A1Degrading durability of valveReduced flexibilityInternal combustion piston enginesOutput powerTop dead centerInlet valve

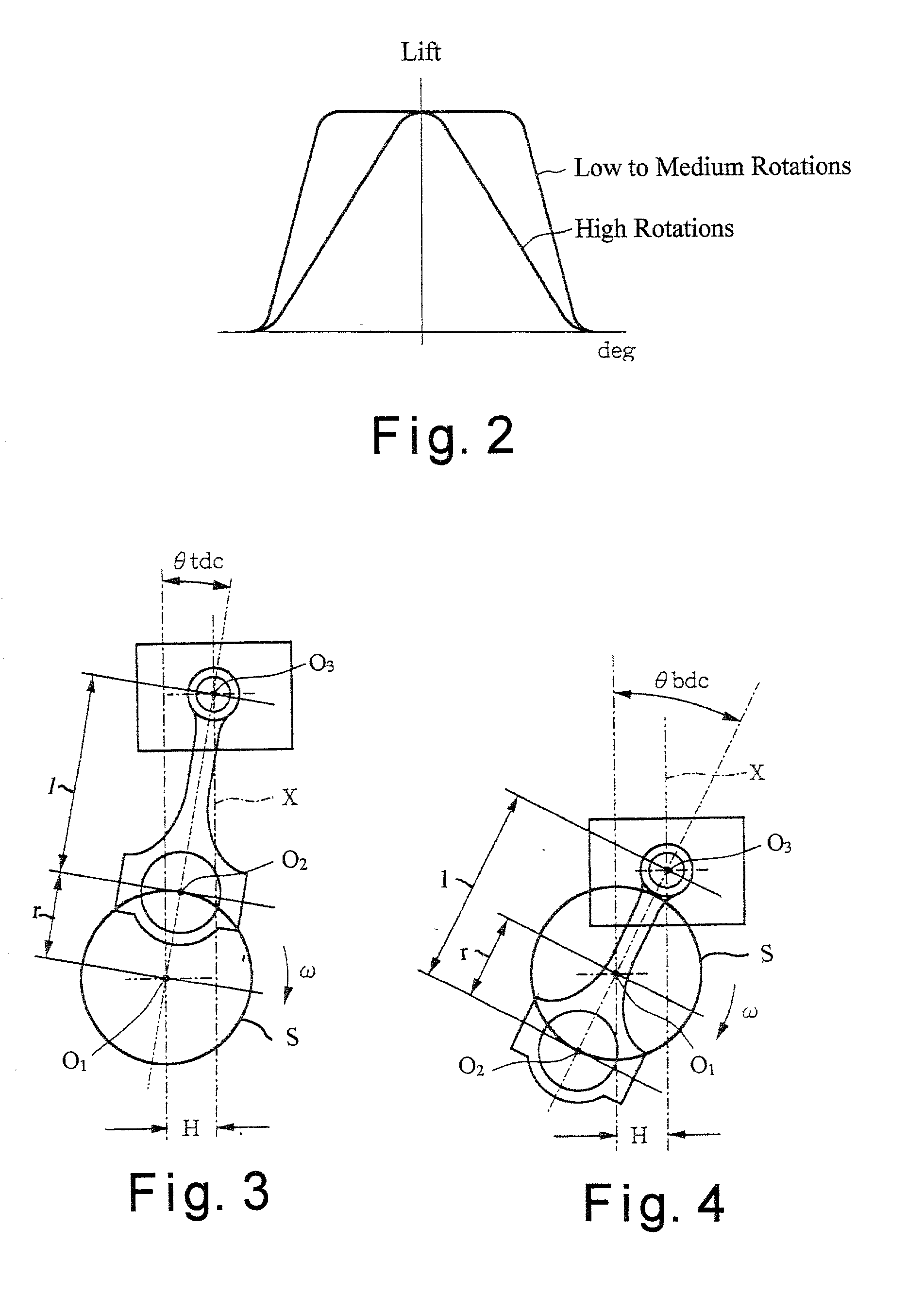

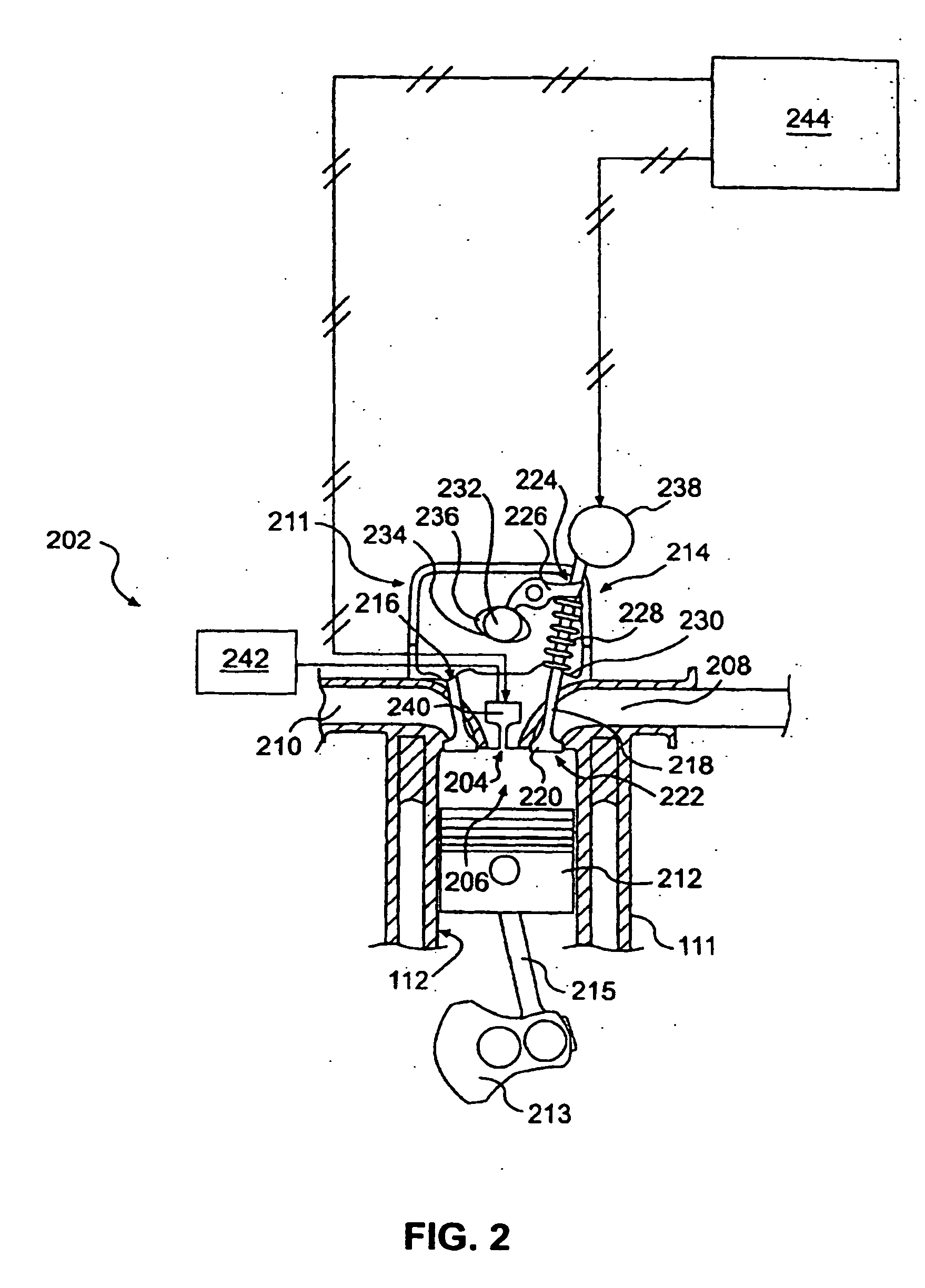

The present invention mitigates restriction due to the fact that the opening period (angular working range) of the intake valve becomes smaller in the early closing Miller cycle operation, in which the intake valve closing timing occurs before the bottom dead center. The crankshaft center O1 is offset on one side from the cylinder central axis X. The top dead center and the bottom dead center of the piston occur when the three points, namely the crankshaft center O1, the crankpin center O2, and the piston pin center O3 are aligned in one line. At this time, the connecting rod and the crank arm are inclined relative to the axis X. The inclination angle .theta..sub.bdc at the bottom dead center is greater than the inclination angle .theta..sub.tdc at the top dead center. Therefore, as the crankshaft rotates in the direction of arrow .omega., the intake process and the expansion process become greater than 180.degree. CA, while the compression process and the exhaust process become smaller than 180.degree. crank angle. Accordingly, the angular working range of the intake valve is enlarged. Therefore, the restriction to the valve lift curve is mitigated.

Owner:NISSAN MOTOR CO LTD

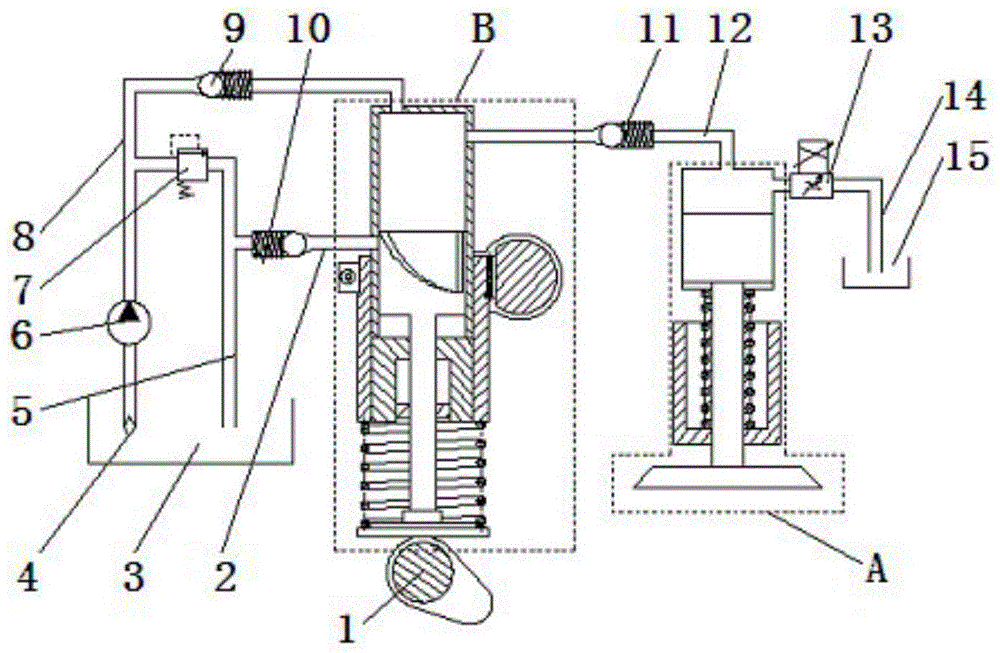

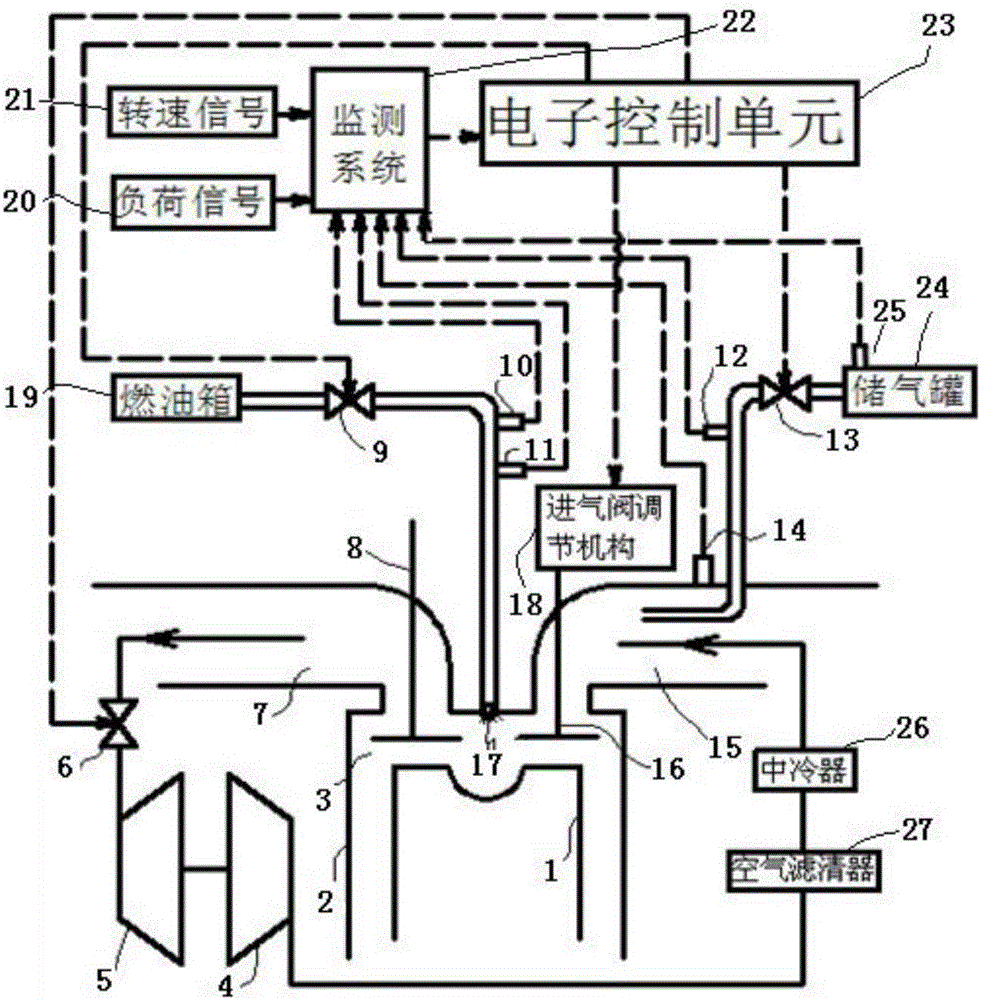

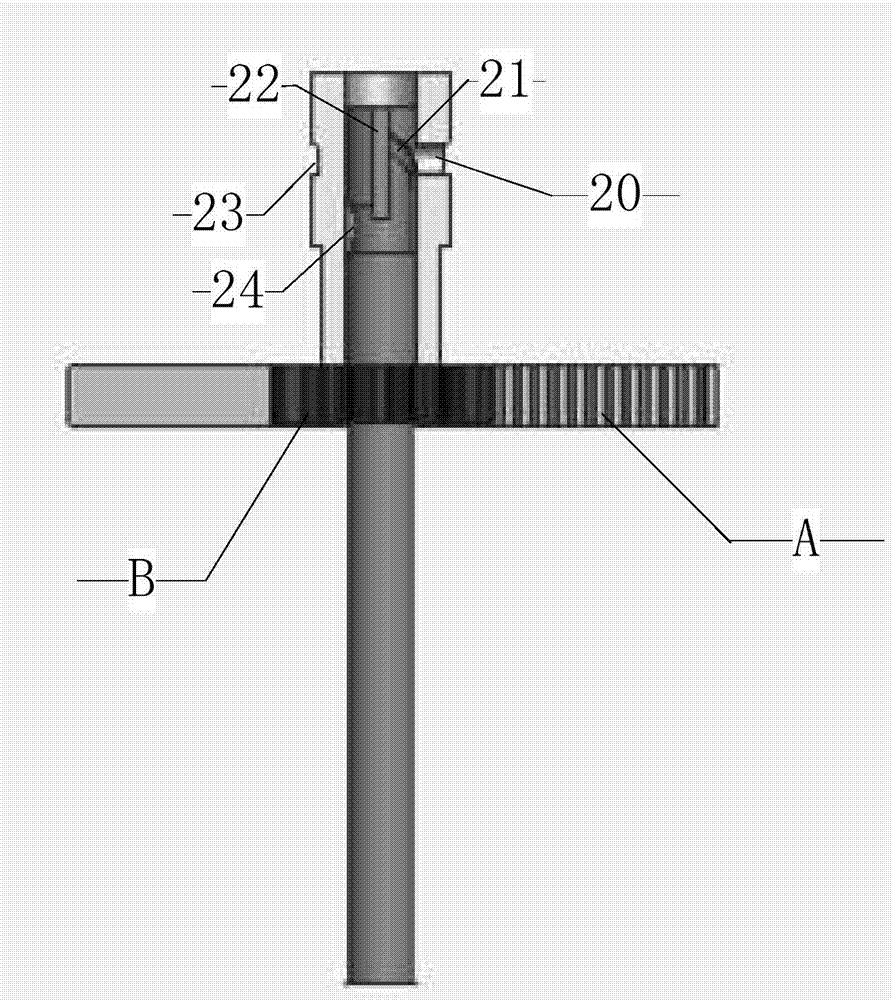

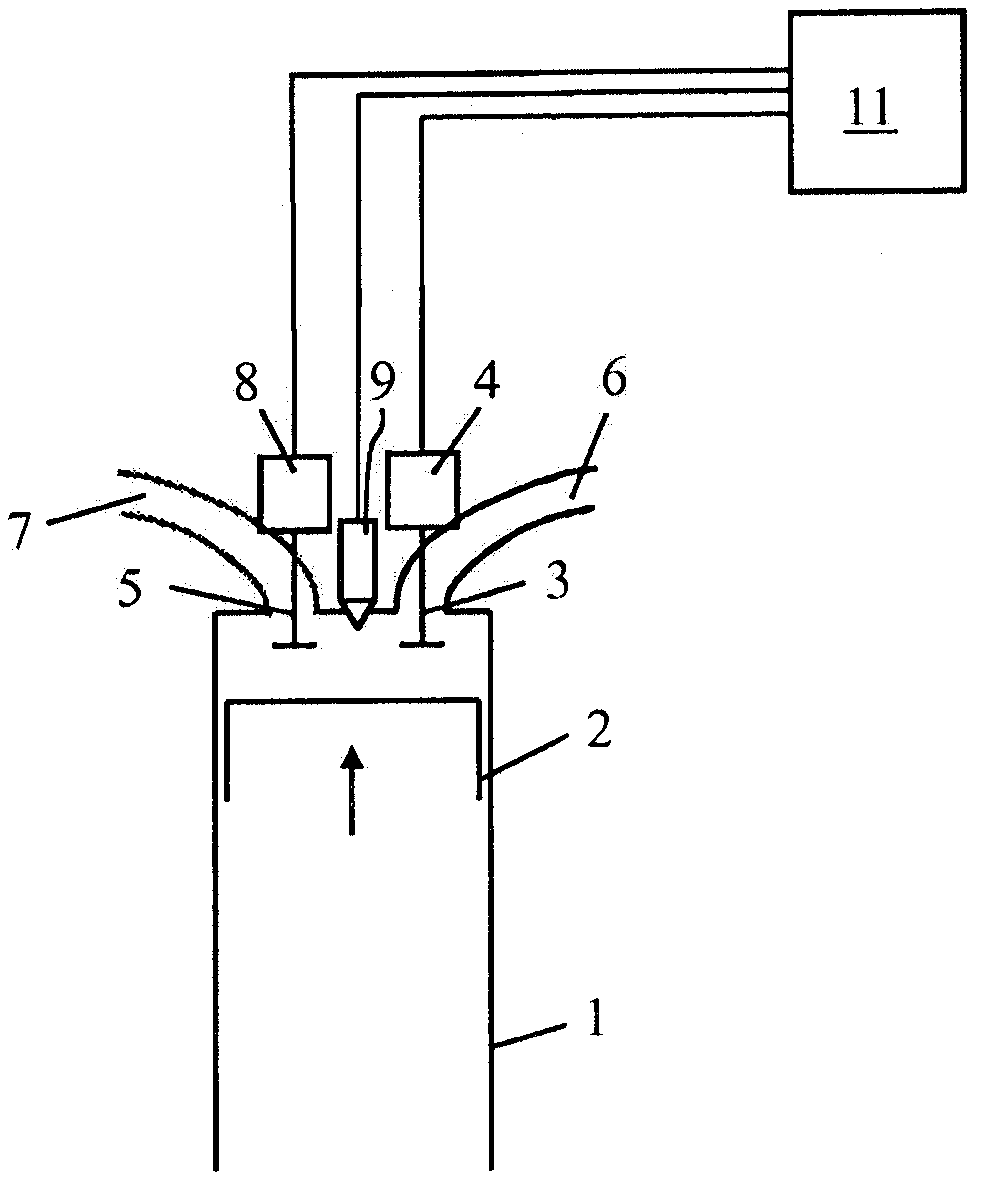

Cam-driven hydraulic fully variably valve mechanism of internal combustion engine

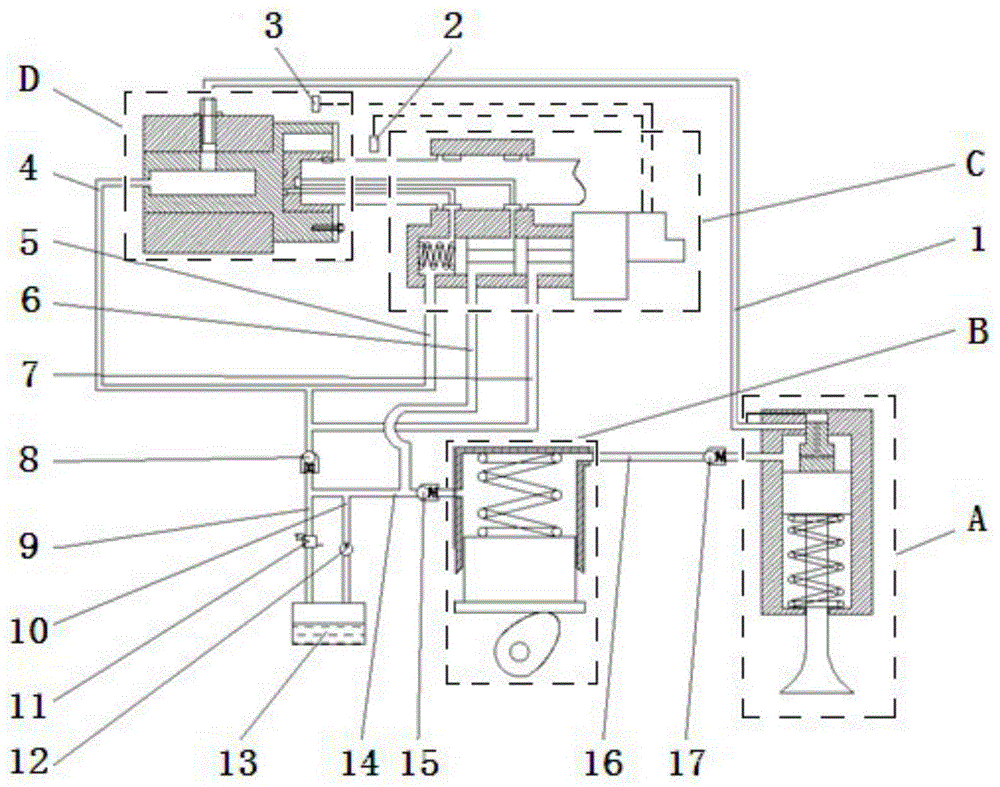

InactiveCN104564206AIncrease low speed torquePromotes air movementInternal combustion piston enginesValve drivesExternal combustion engineFuel tank

A cam-driven hydraulic fully variable valve mechanism of an internal combustion engine belongs to the technical field of engines. An inlet end of an oil tube III is arranged in an oil tank I, an outlet end of the oil tube is fixedly connected with an oil inlet hole I. The inlet end of the oil tube III is provided with a filter. An oil pump, an inlet end of an oil tube II and a check valve I are connected with the oil tube III in series. An overflow valve and an outlet end of an oil tube I are connected with the oil tube II in series. An outlet end of the oil tube II is arranged in the oil tank I. An inlet end of the oil tube I is fixedly connected with an oil drainage hole. The middle of the oil tube I is provided with a check valve II. The inlet end of an oil tube V is fixedly connected with an oil drainage hole II. The outlet end of the oil tube V is arranged in the oil tank II. An electro-hydraulic proportional valve is arranged adjacent to the inlet end of the oil tube V. The two ends of an oil tube IV are respectively communicated with a connecting hole and an oil inlet hole II of a tappet group. A check valve II is arranged in the middle of the oil tube IV. The cam-driven hydraulic fully variable valve mechanism of the internal combustion engine can realize continuous variable of valve lift and valve timing and throttle-free load control of a gasoline engine, reduce pumping loss, improve the volumetric efficiency, realize the Miller cycle, achieves the effect of energy saving and emission reduction, and is simple in structure and flexible in control.

Owner:JILIN UNIV

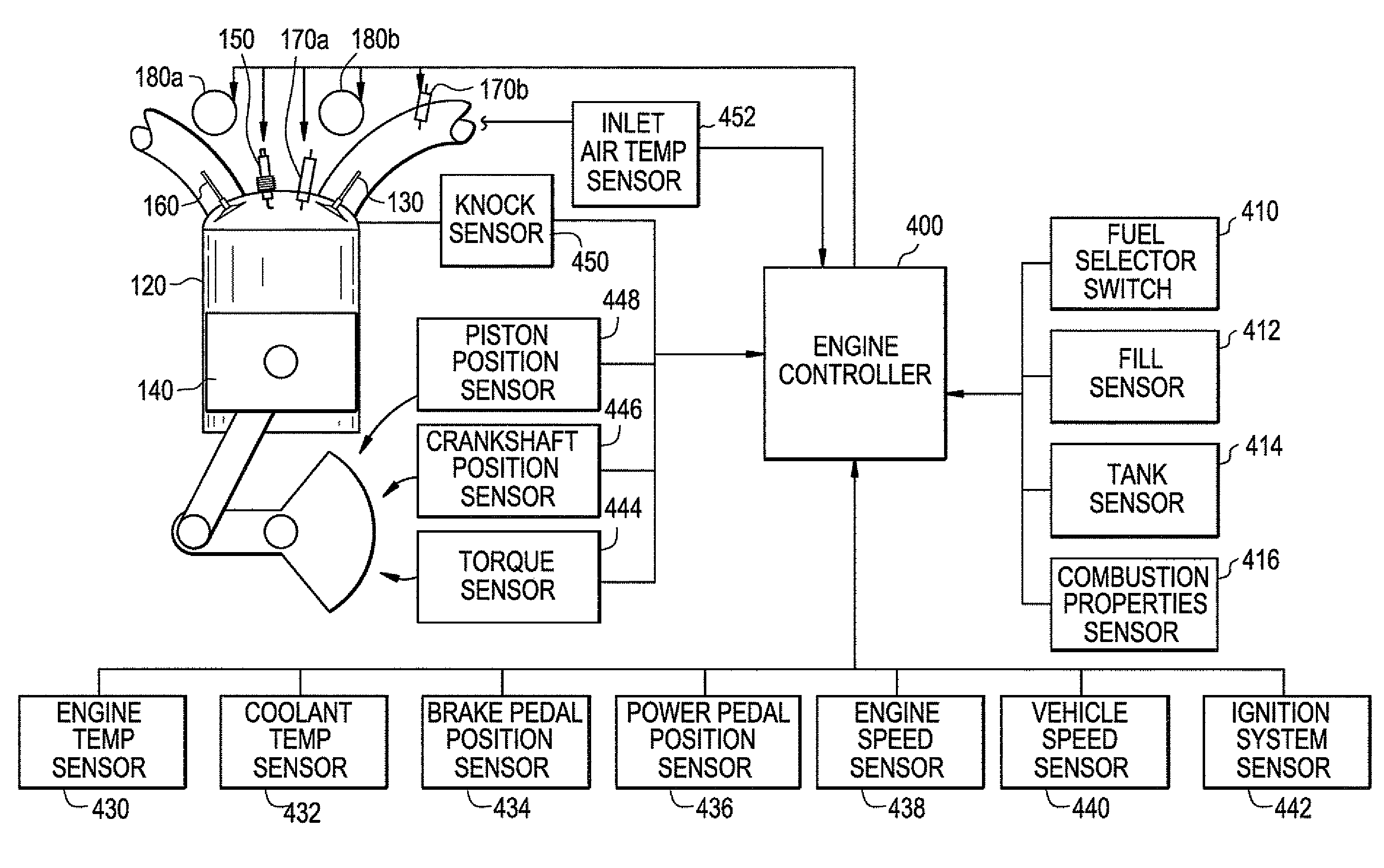

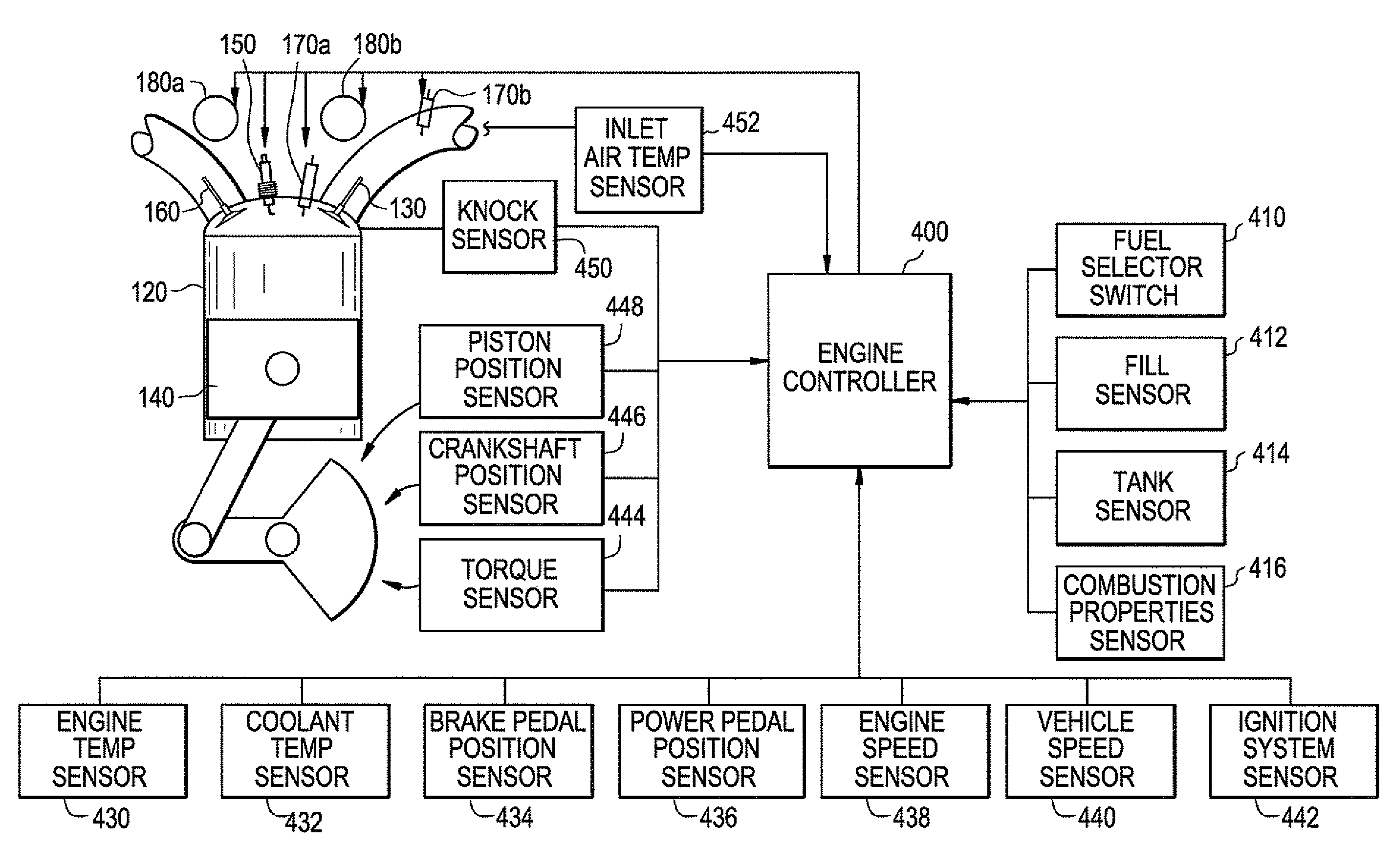

Adaptive miller cycle engine

A Miller cycle combustion engine capable of operating on multiple fuel types, and a method of operating the engine, is provided. The engine includes a fuel type determiner to determine the fuel type, and a compression adjustor to adjust the compression of a first cylinder of the engine to match the requirement of the determined fuel type. The compression adjustor is a variable valve timing system that provides a maximum compression when a fuel type requiring maximum compression is determined, and that advances or retards the opening of the intake valve to provide lower compression when a fuel type requiring lower compression is determined.

Owner:AI ALPINE US BIDCO INC

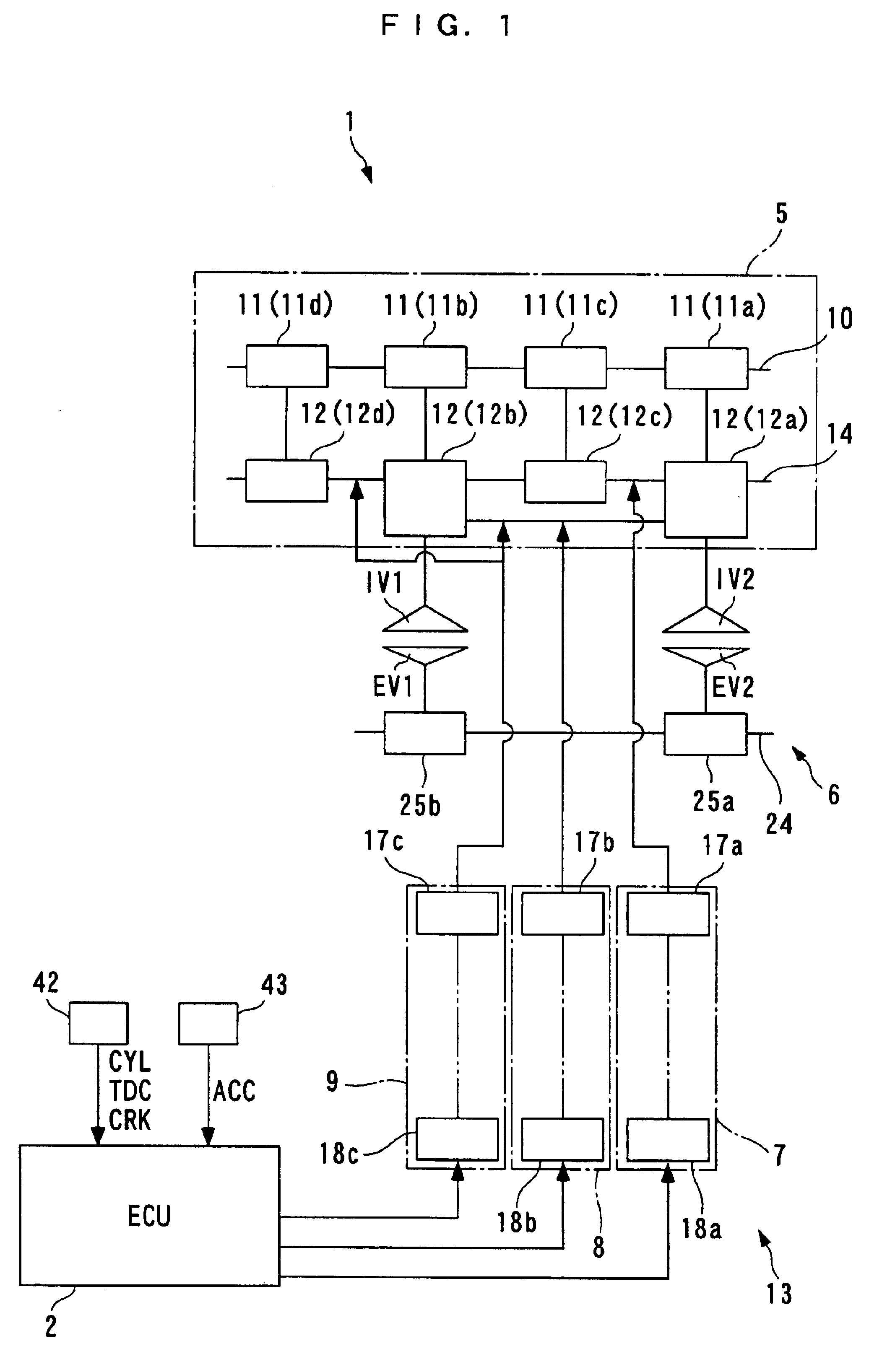

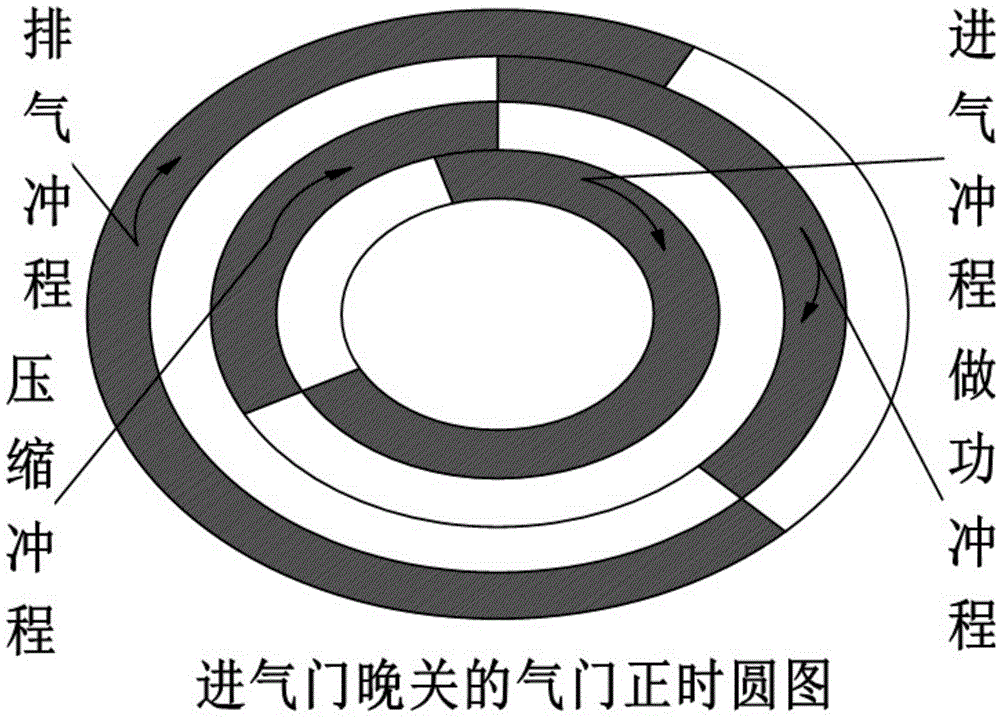

Valve actuating apparatus for internal combustion engine

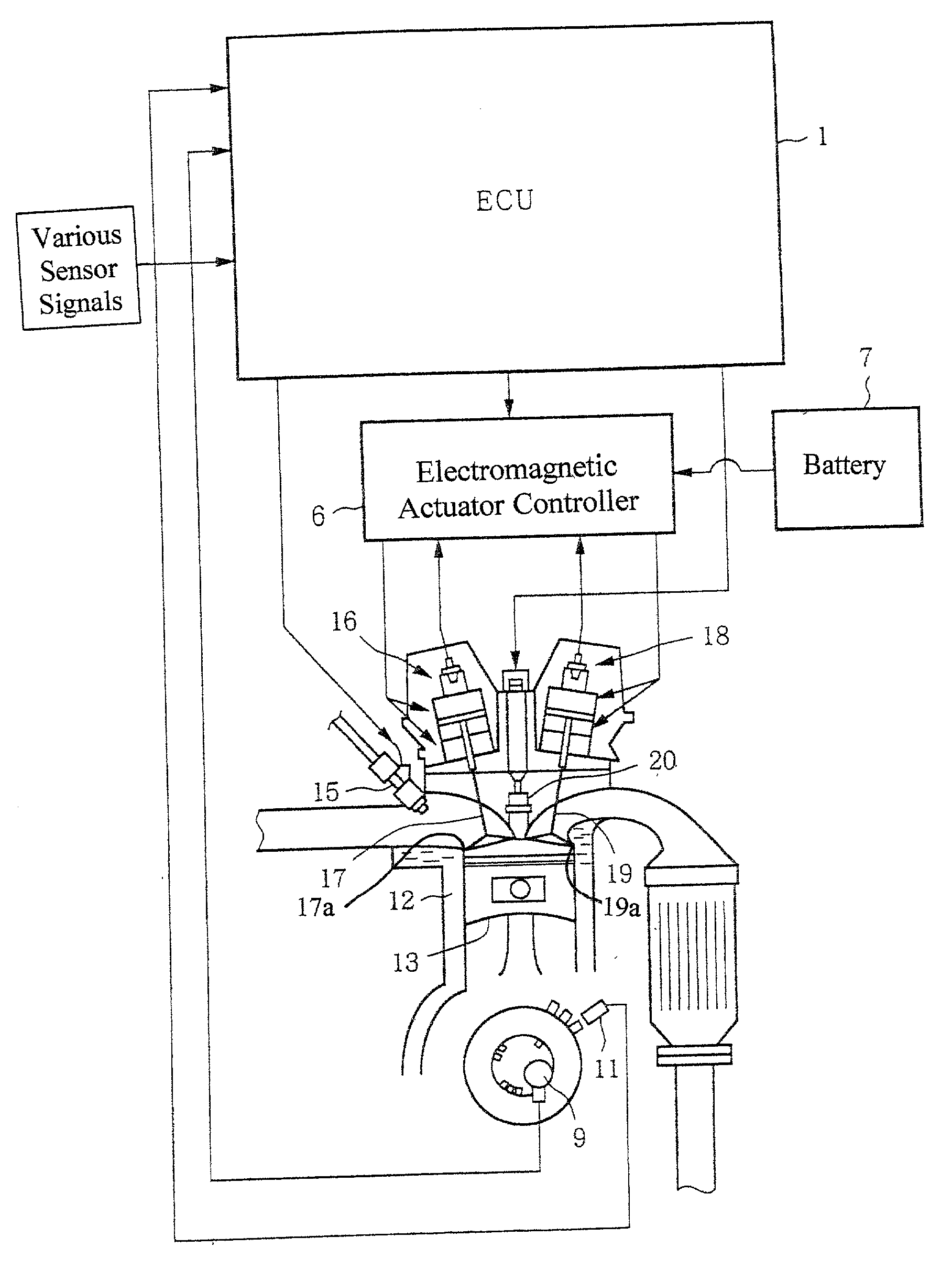

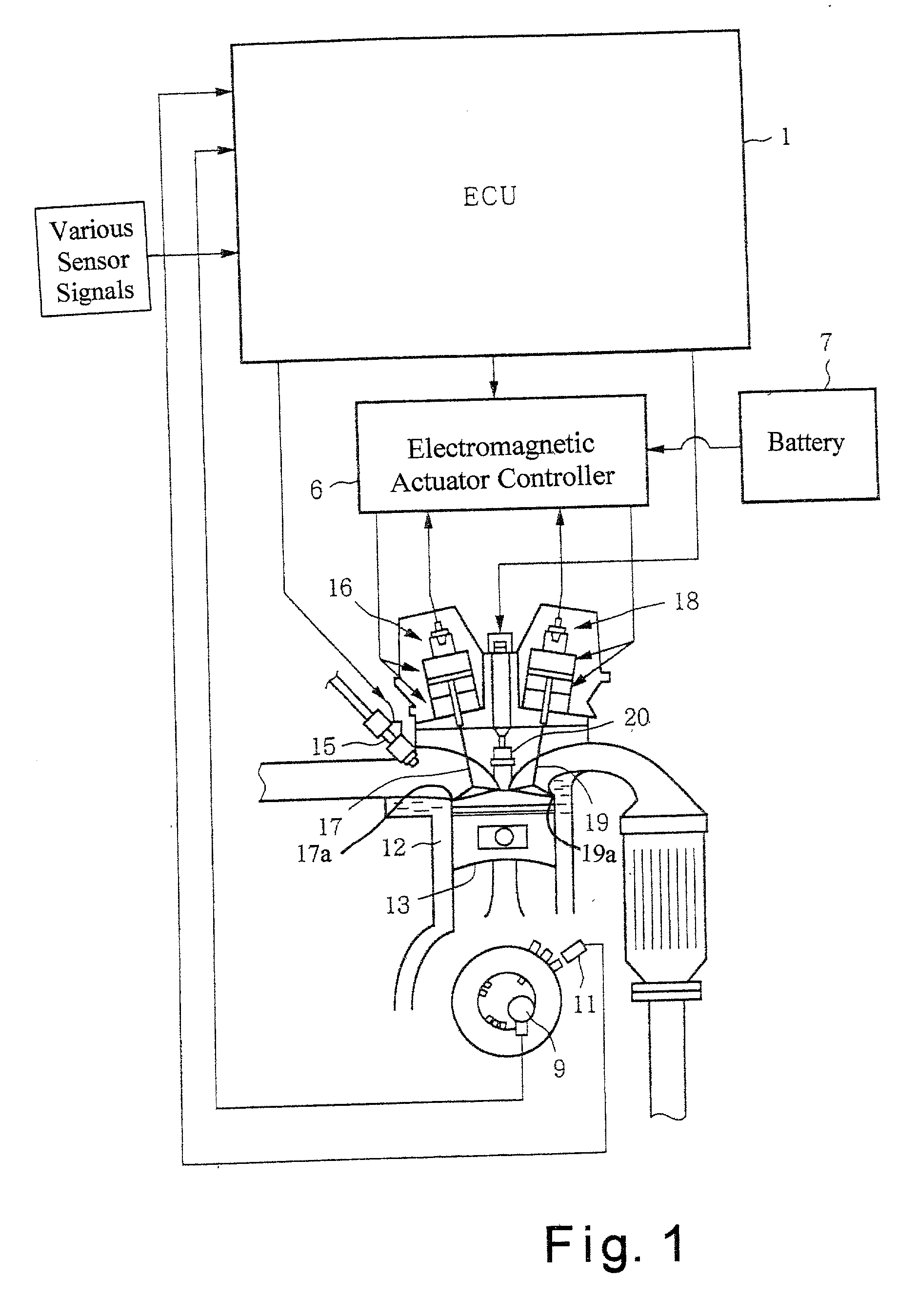

InactiveUS6837199B2Stable combustionImprove fuel economyValve arrangementsElectrical controlExternal combustion engineLow load

A valve actuating apparatus for an internal combustion engine selectively operating in the normal Otto cycle or the Miller cycle is provided which enables the engine to achieve stable combustion and improved fuel economy during cruising or in a low-load engine operating region. A delayed-closing cam for Miller cycle operation and a normal cam having a cam profile for earlier valve-closing timing of the intake valve than a cam profile of the delayed-closing cam are provided on a camshaft. A cam profile-switching mechanism switches between the delayed-closing cam and the normal cam, for opening and closing the intake valve. An ECU controls the switching mechanism such that when a detected operating condition of the engine indicates starting or idling, the intake valve is operated by the normal cam, and when the detected operating condition indicates cruising, the intake valve is operated by the delayed-closing cam.

Owner:HONDA MOTOR CO LTD

Adaptive miller cycle engine

Owner:AI ALPINE US BIDCO INC

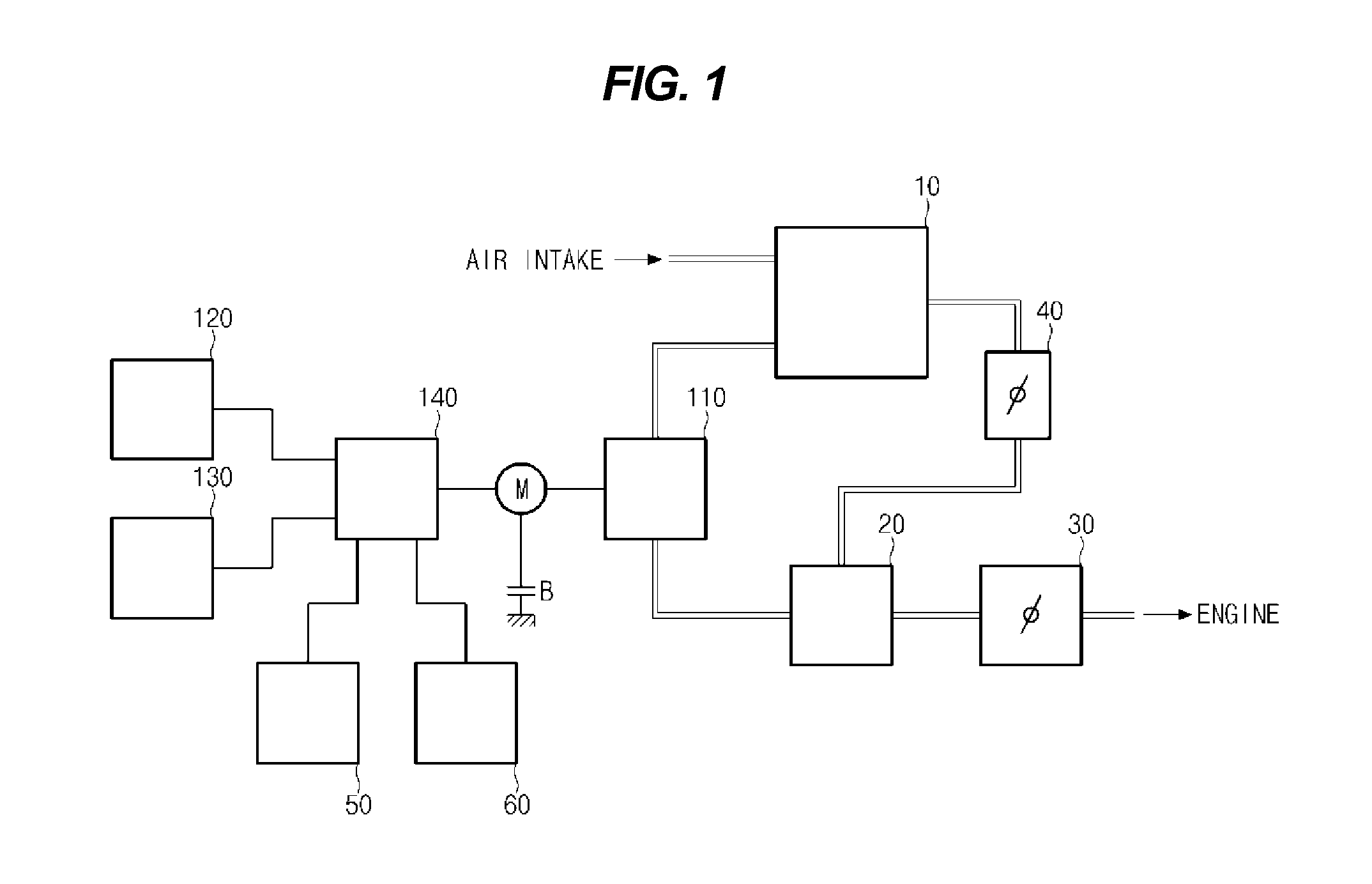

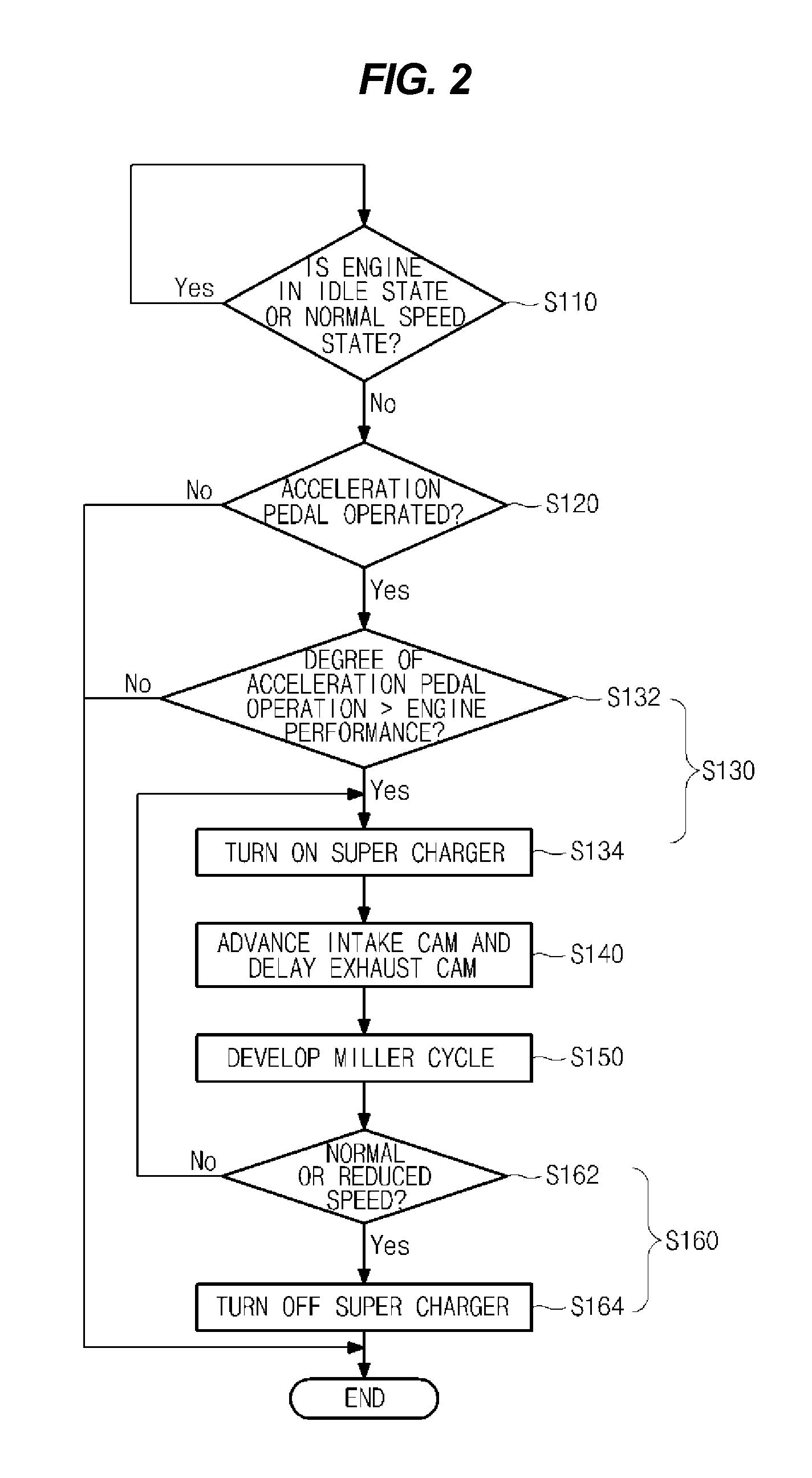

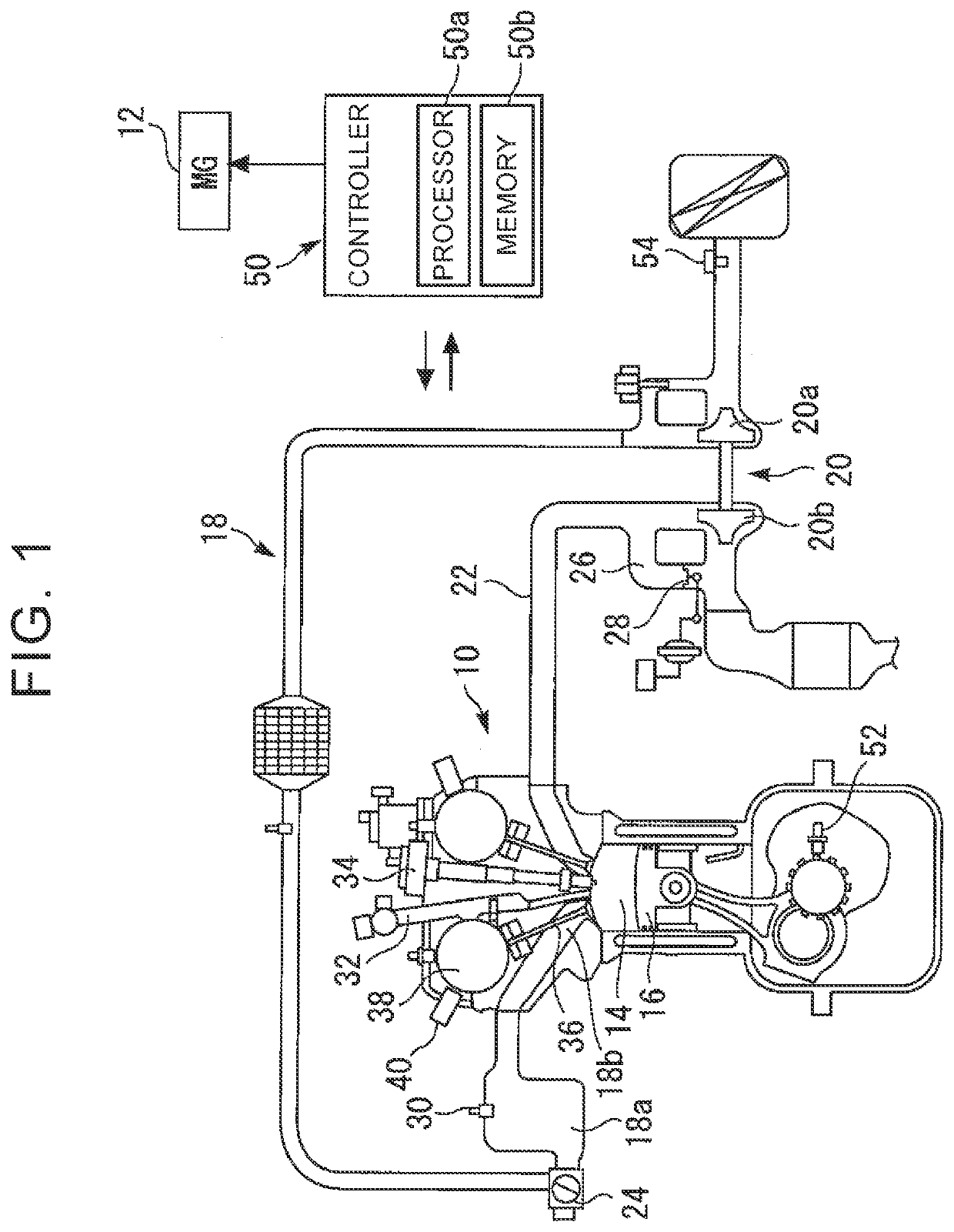

Miller cycle engine system and control method thereof

InactiveUS20130146037A1Easy to operateImprove efficiencyValve arrangementsElectrical controlVariable valve timingFuel efficiency

A miller cycle engine system is provided, which includes a motorized supercharger, and a miller cycle engine (having low compression and high explosion) having the motorized supercharger mounted thereon to improve a low-revolution performance of an engine using a scavenging phenomenon due to an operation of a variable valve device (variable valve timing, variable valve lift and variable valve duration) during an operation of the motorized supercharger and to improve a fuel efficiency through down-speeding of a gear ratio of a vehicle.

Owner:HYUNDAI MOTOR CO LTD

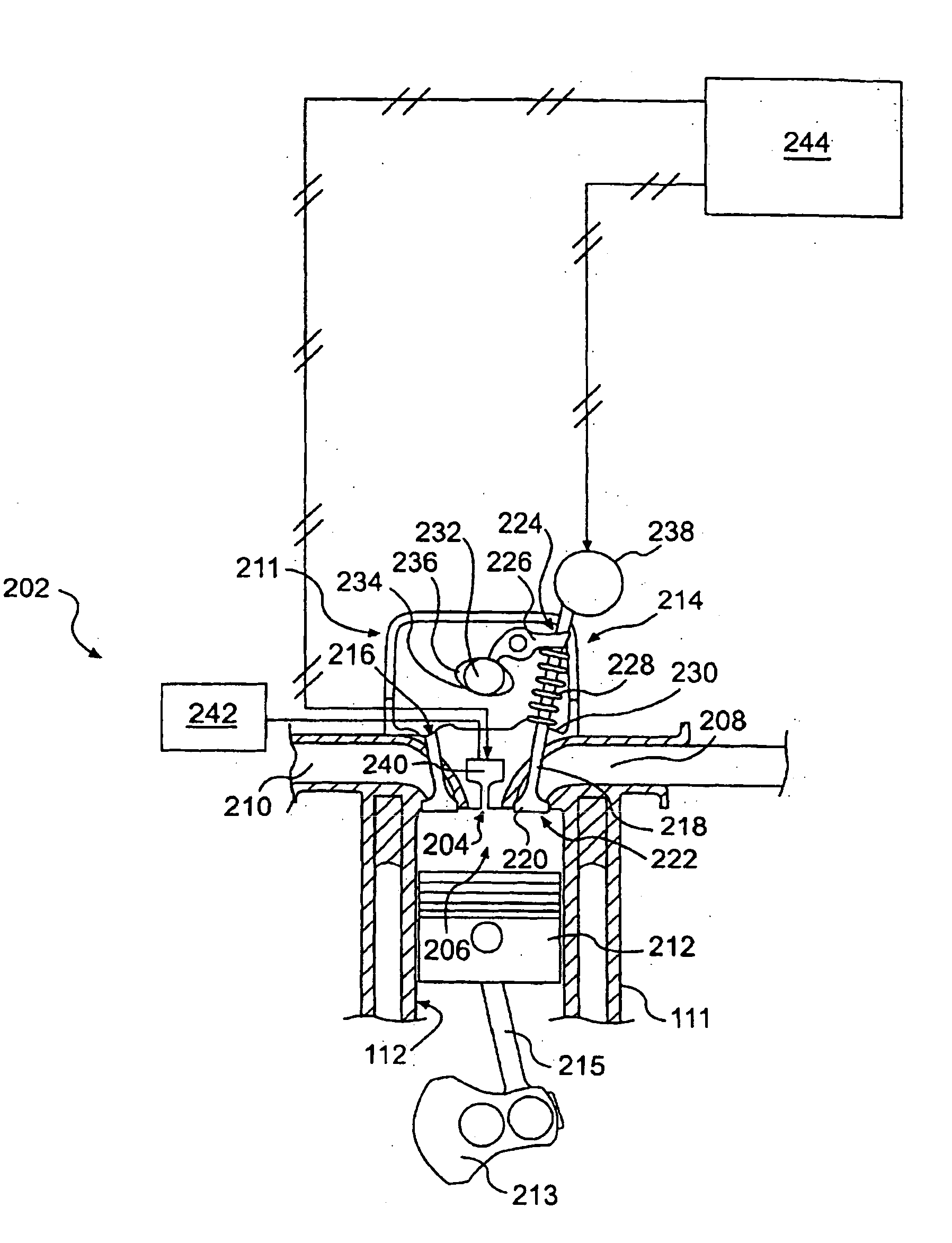

Combustion engine including engine valve actuation system

Engines and methods of controlling an engine may involve at least one fluid actuators associated with one or more engine intake and / or exhaust valves. Timing of valve closing / opening and use of an air supply system may enable engine operation according to a Miller cycle.

Owner:CATERPILLAR INC

Miller cycle diesel oil-natural gas dual fuel engine and control method thereof

ActiveCN105888832AReduce heat loadHigh thermal efficiencyElectrical controlInternal combustion piston enginesCombustionInlet valve

The invention discloses a Miller cycle diesel oil-natural gas dual fuel engine and a control method thereof, and relates to the technical field of engines. An early closing mode of an intake valve is realized through adjusting an intake valve adjusting mechanism; and a compression ratio is changed to separate from an expansion ratio, so that the cooling of mixed gas is facilitated, the thermal load of the engine is reduced, the positive suction power is generated in the expansion process to improve the thermal efficiency of the engine, and the fuel economy is preferably improved. The new control method is used for converting high / low compression ratio more flexibly, so that the diesel oil-natural gas dual fuel engine can achieve high-efficiency combustion operation in a full-load range.

Owner:JILIN UNIV

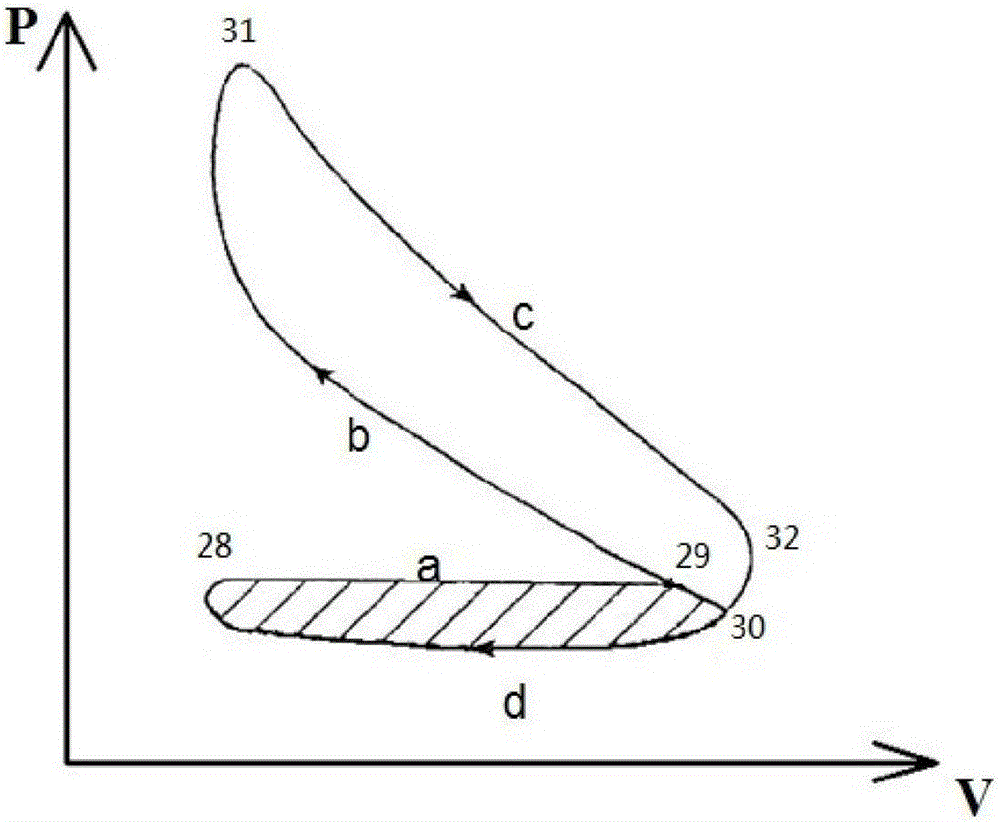

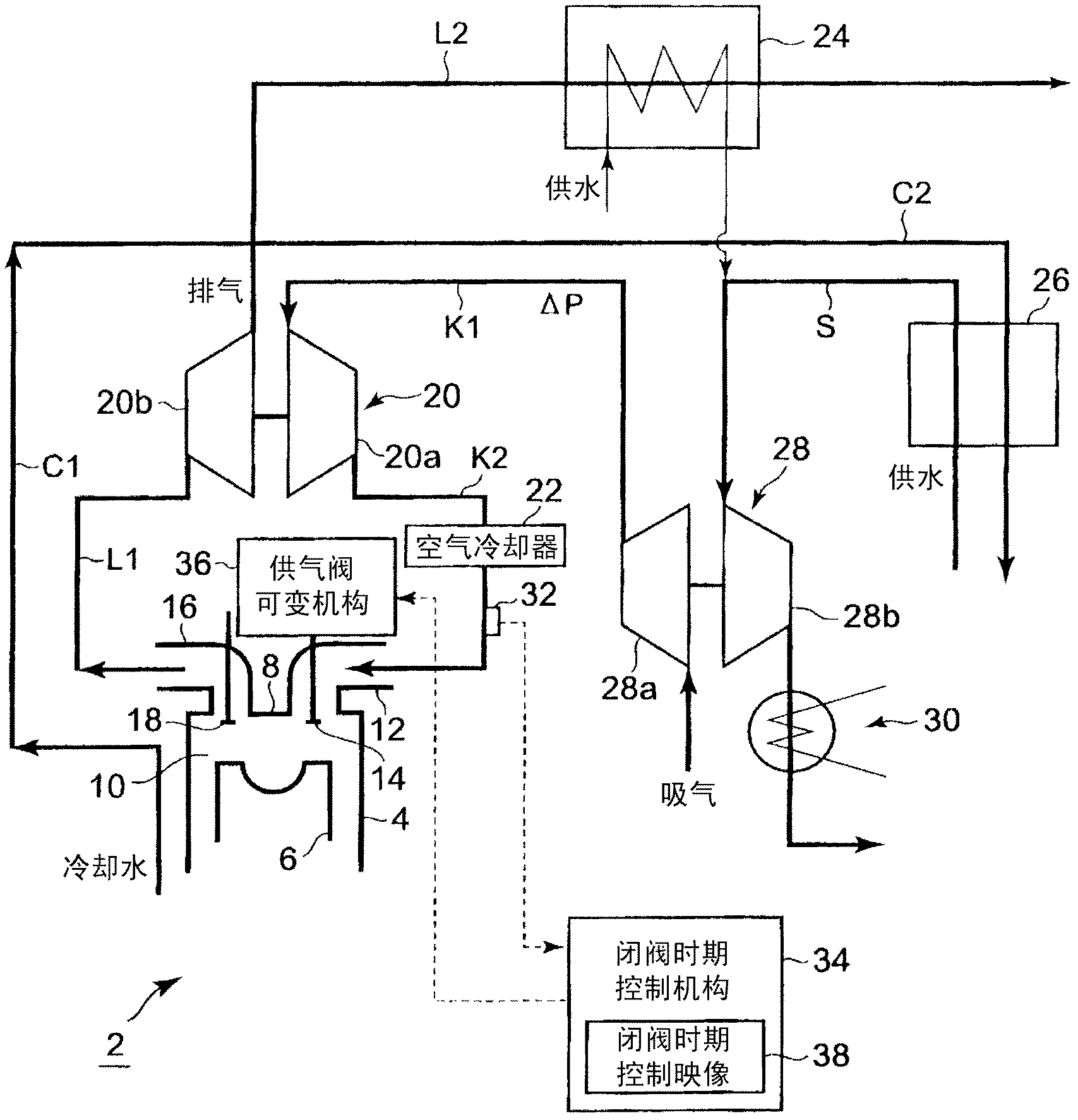

Miller cycle engine

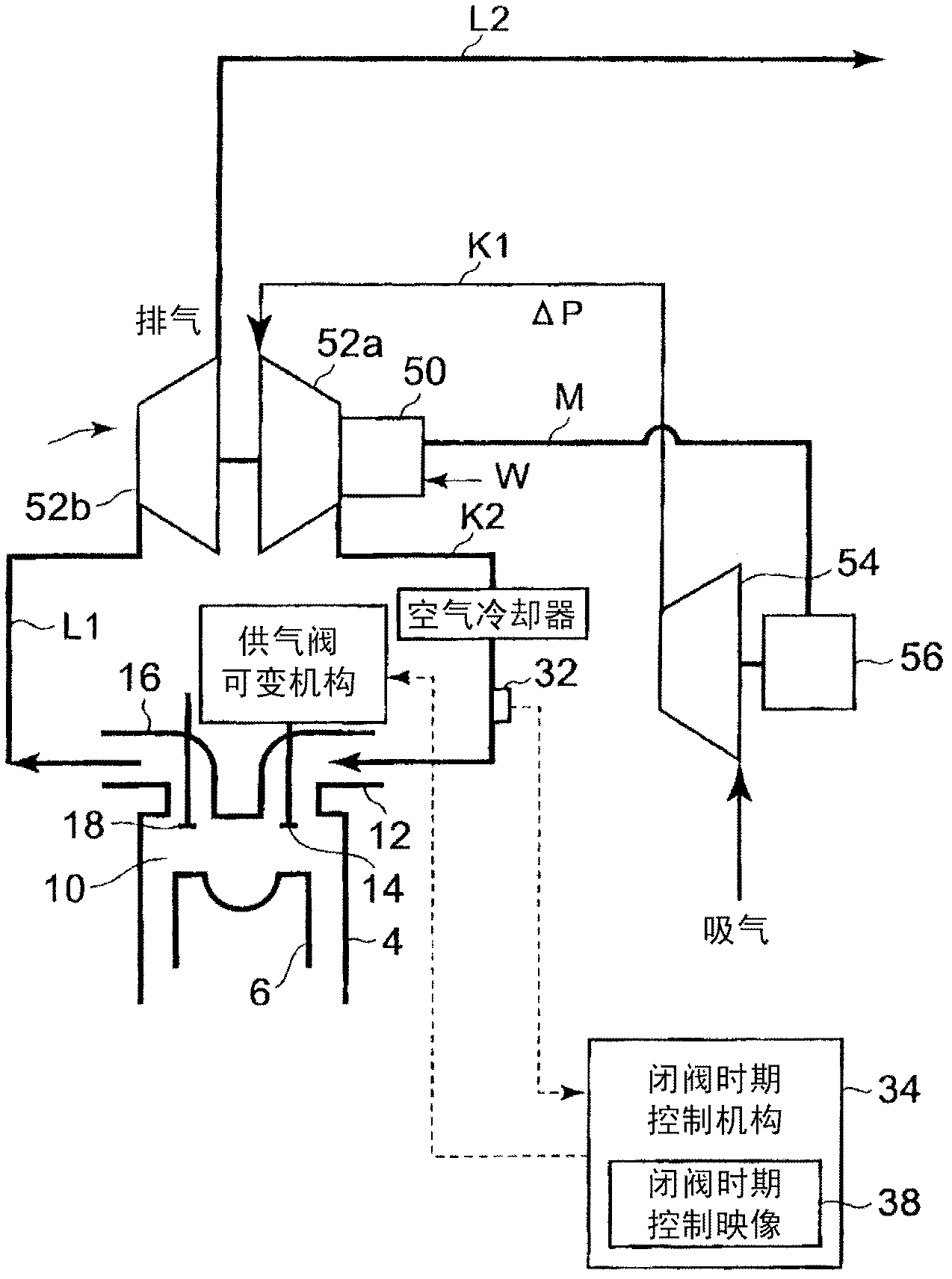

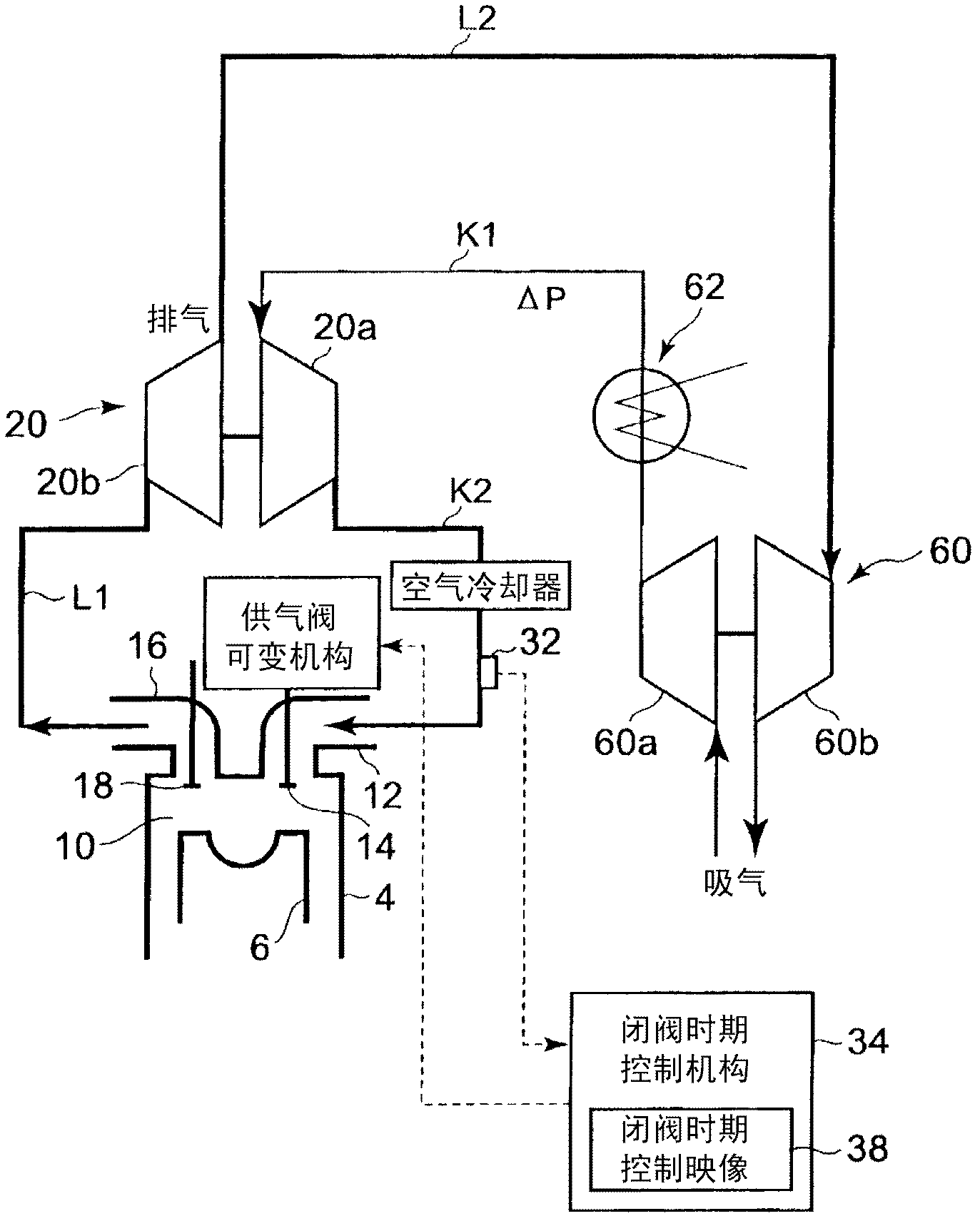

InactiveCN102575589AImprove suction workHigh thermal efficiencyInternal combustion piston enginesExhaust apparatusMiller cycleTime control

Disclosed is a Miller cycle engine wherein the heat efficiency is improved by increasing the supply air pressure and the reliability of the mechanical strength and thermal load of the engine body is maintained by maintaining the in-cylinder maximum pressure. Specifically disclosed is a Miller cycle engine characterized by being provided with a supply air valve varying means (36) which controls the valve opening / closing time of the supply air valve (14), a stream turbine (28) which serves as a supply air pressure adding device for additionally increasing only the supply air pressure with respect to supercharging by a supercharger (20) or increasing the supply air pressure more than the exhaust air pressure, and a valve closing time control means (34) which advances the valve closing time of the supply air valve (14) further as the supply air pressure added by the steam turbine (28); is higher to thereby maintain approximately the same in-cylinder maximum pressure as the in-cylinder maximum pressure before the addition.

Owner:MITSUBISHI HEAVY IND ENGINE & TURBOCHARGER LTD

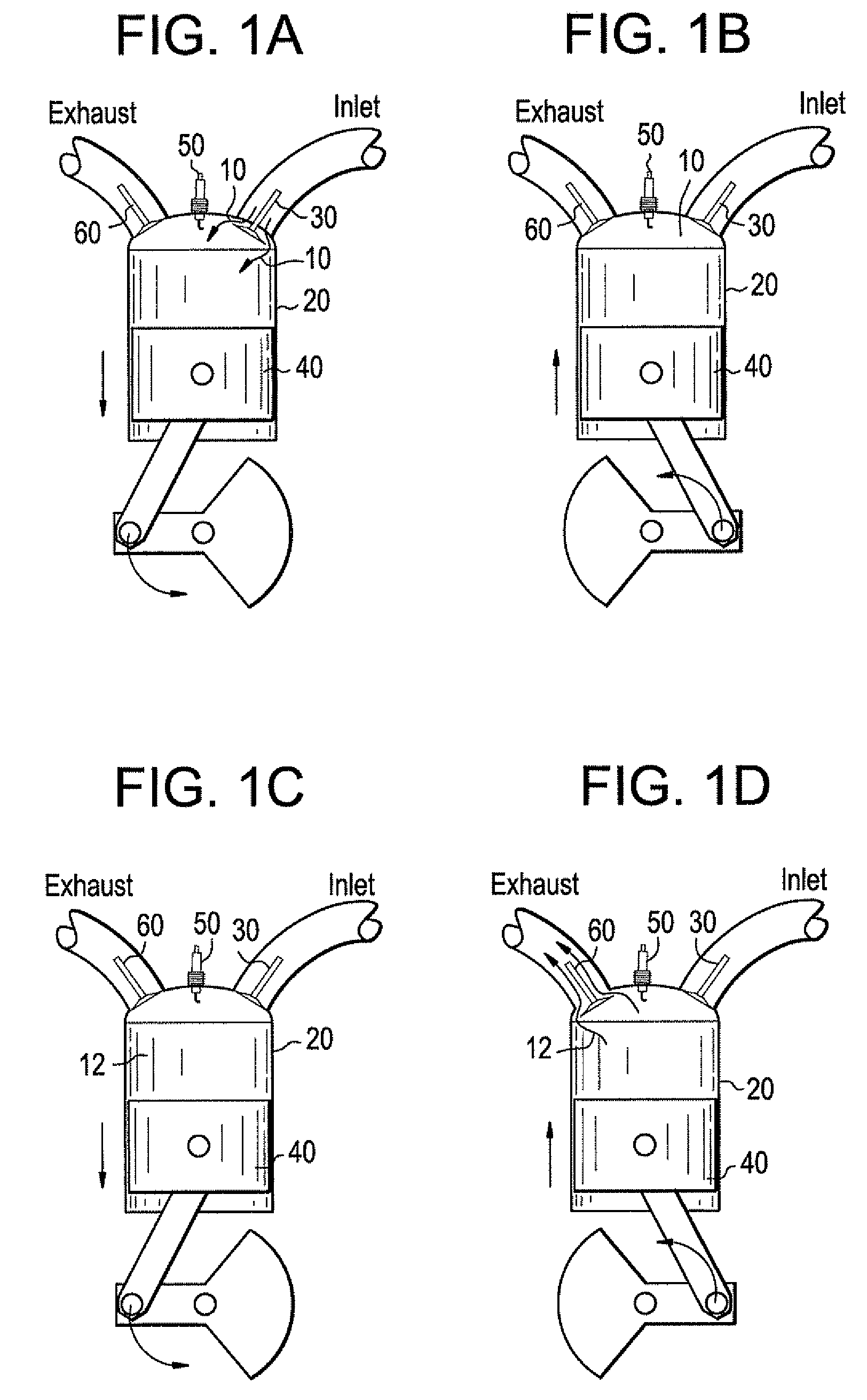

System and method for operating an internal combustion engine

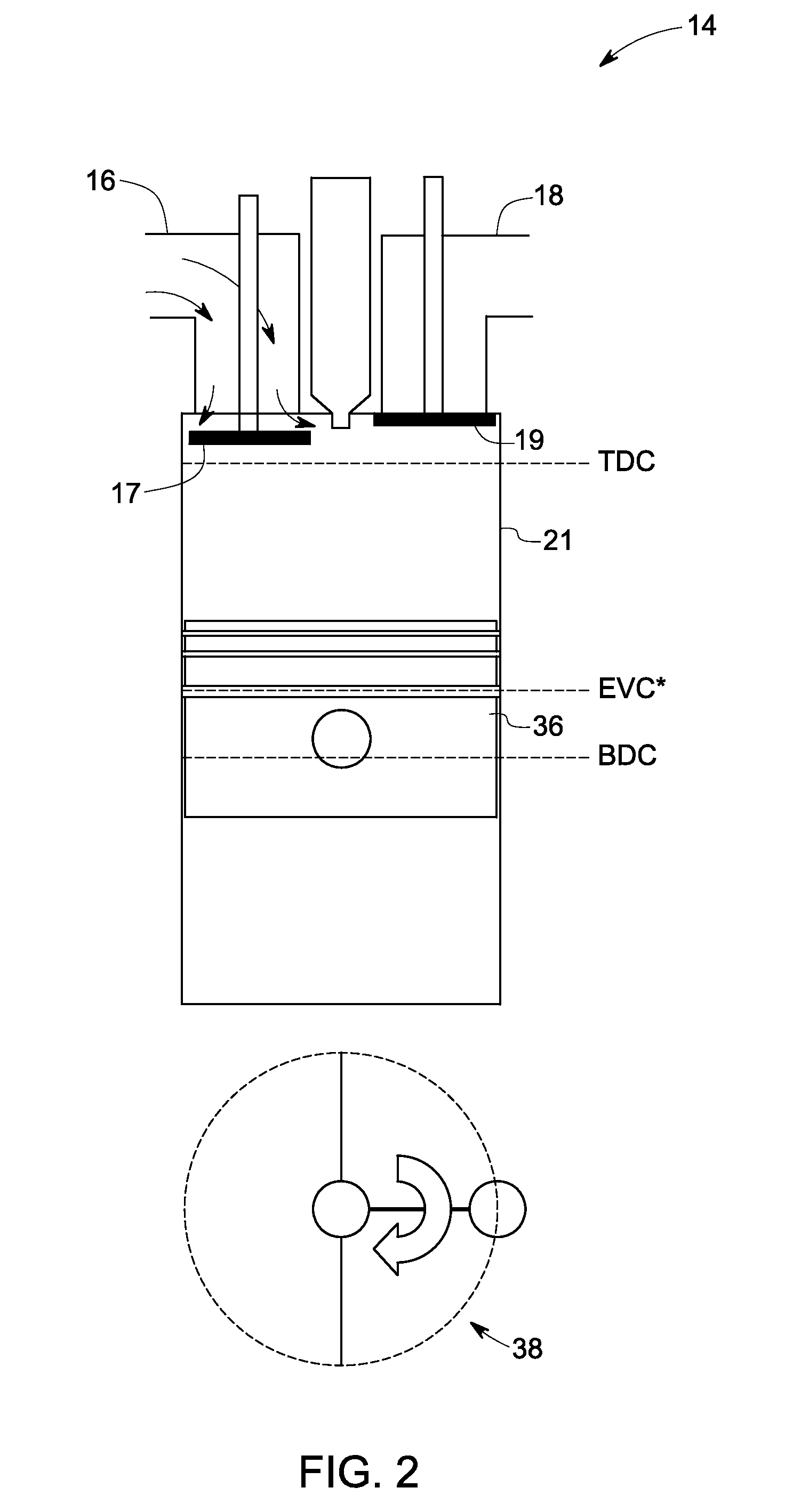

InactiveUS20120048218A1Valve arrangementsInternal combustion piston enginesExhaust valveTop dead center

An internal combustion engine is operated in accordance with a Miller cycle. The engine includes a piston disposed in the engine cylinder and configured to reciprocate between a top dead center position and a bottom dead center position of the engine cylinder. An air intake valve is coupled to the cylinder. The air intake valve is closed when the piston is about the bottom dead center position in the engine cylinder. An exhaust valve is coupled to the engine cylinder. The exhaust valve is opened for a predetermined time period when the piston is about the bottom dead center position of the engine cylinder after closing the intake valve so as to exhaust a predetermined quantity of fresh charge from the engine cylinder via the exhaust valve.

Owner:GENERAL ELECTRIC CO

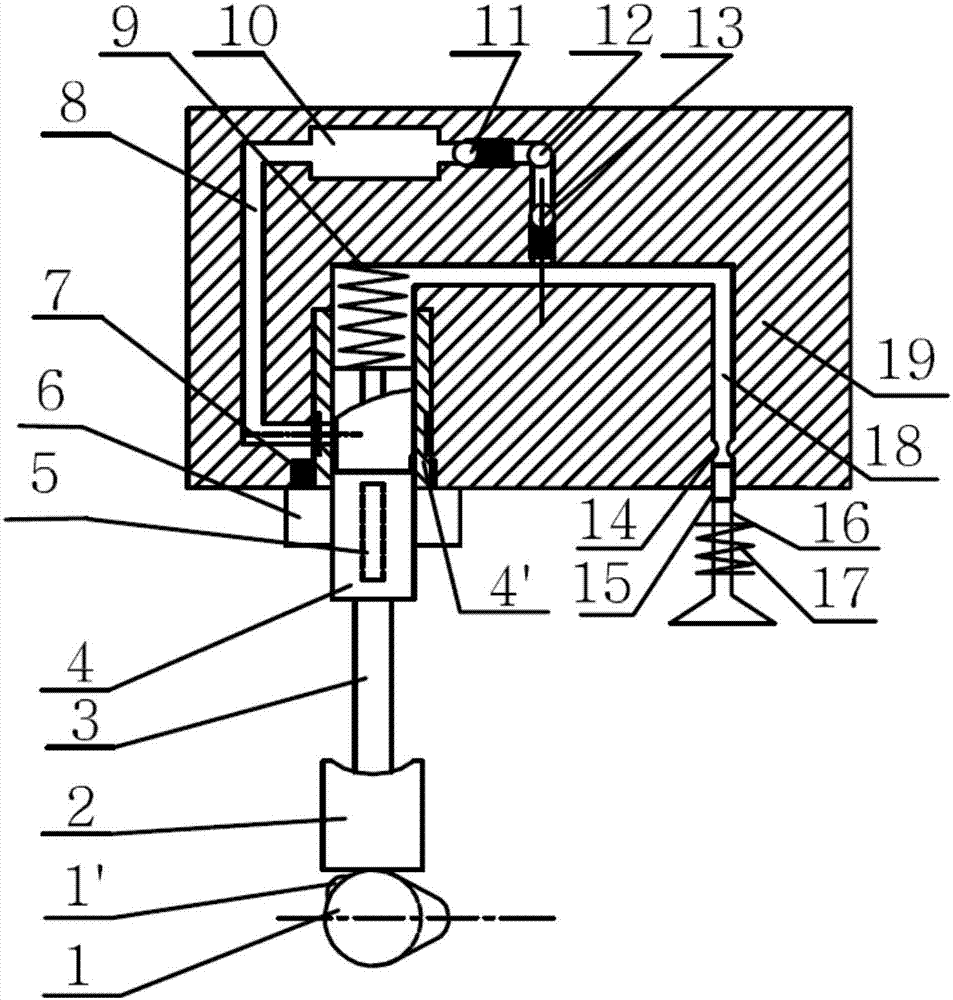

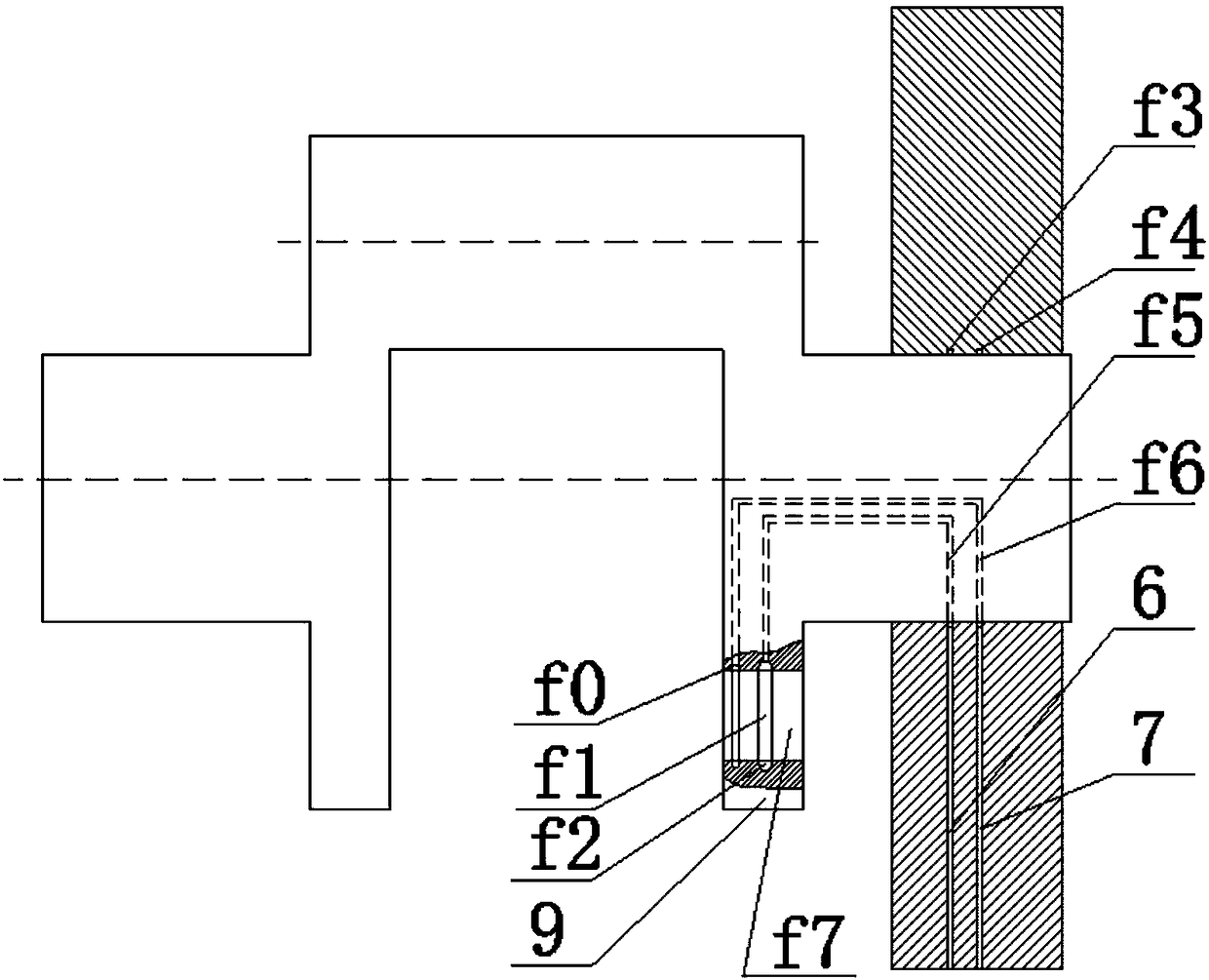

Gas intake and distribution system based on electric hydraulic control mode

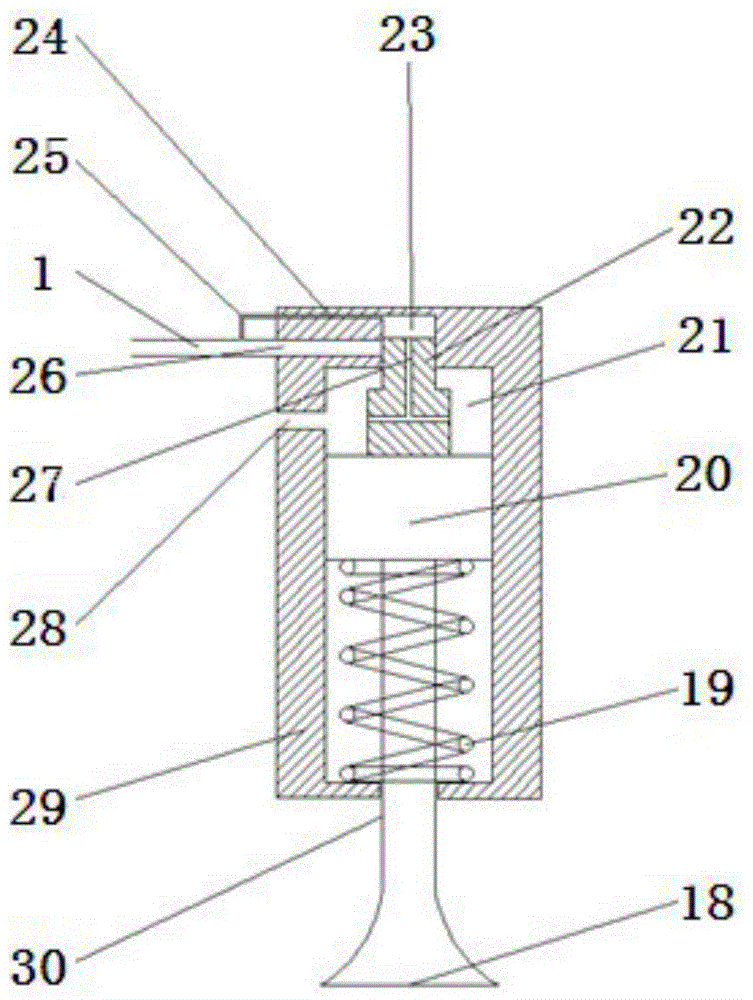

InactiveCN104612773ASmall impact when seatedAvoid insufficient responsivenessInternal combustion piston enginesValve drivesCombustionFuel tank

The invention provides a gas intake and distribution system based on an electric hydraulic control mode and belongs to the technical field of internal combustion engines. An outlet and an inlet of a high pressure oil pipe are communicated with an oil inlet I and a high pressure oil outlet respectively, an outlet and an inlet of an oil return pipe I are communicated with a valve casing hole and an oil return hole I respectively, an outlet and an inlet of an oil return pipe II are communicated with an inlet of an oil return pipe III and an oil drain duct respectively, an inlet of an engine oil valve oil return pipe II is communicated with an engine oil valve oil return hole II, an inlet of an engine oil valve oil return pipe I is communicated with an engine oil valve oil return hole I, an outlet and an inlet of a low pressure oil pipe are communicated with a low pressure oil inlet and a low pressure oil pipe I respectively, and an inlet of the low pressure oil pipe I and an outlet of the oil return pipe III are arranged in an oil tank; a low pressure oil pipe II is connected with an inlet of an engine oil valve oil intake pipe and a one-way valve II in series, an outlet of the engine oil valve oil intake pipe is communicated with an engine oil valve oil inlet, and a stepping motor, a rotation outer valve cylinder position sensor and a camshaft position sensor are controlled by an electronic control unit. Valve seating impact is small, valve closing moment and lift control is flexible, throttle-valve-free control and a miller cycle can be achieved, reliability is high and manufacturing cost is low.

Owner:JILIN UNIV

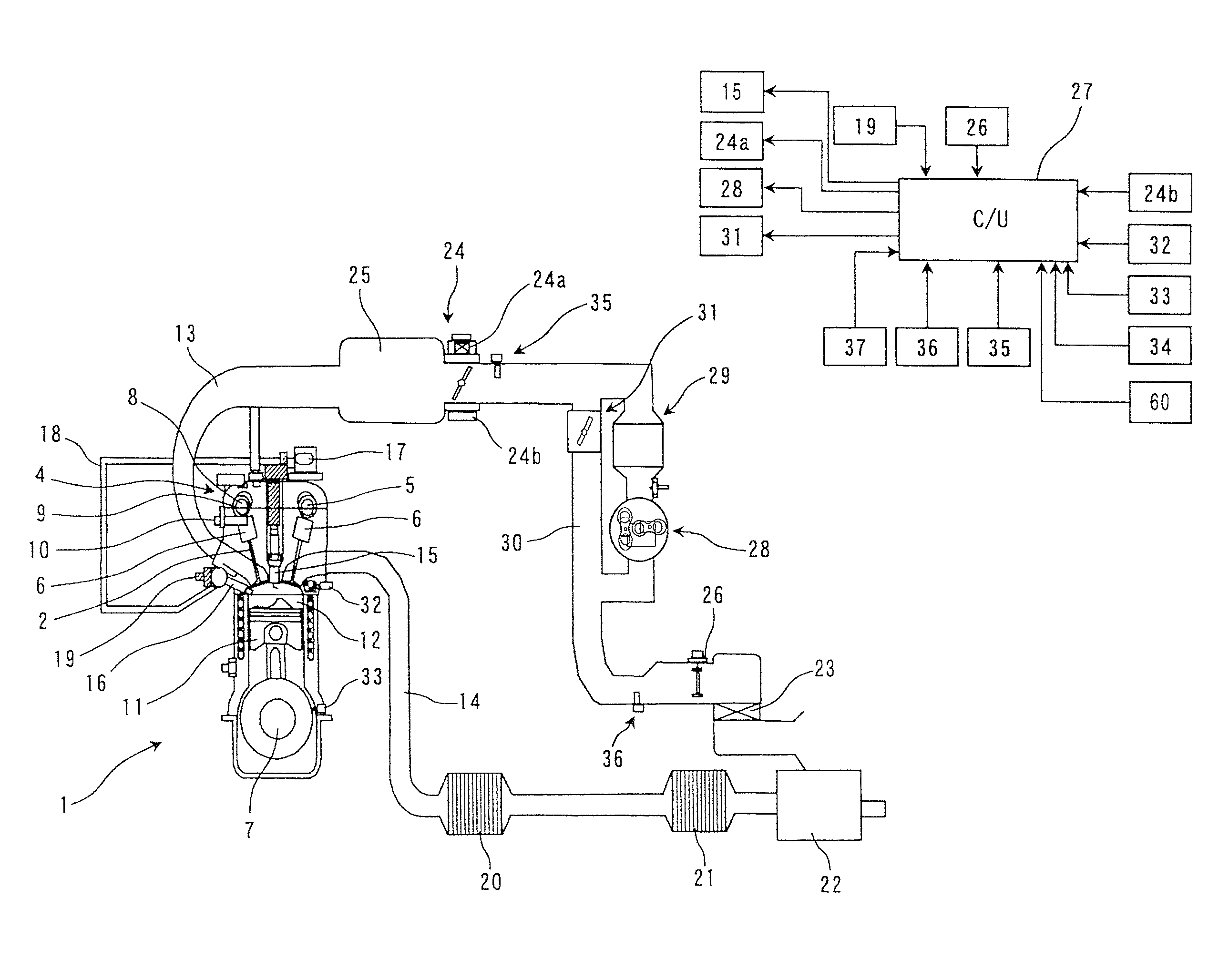

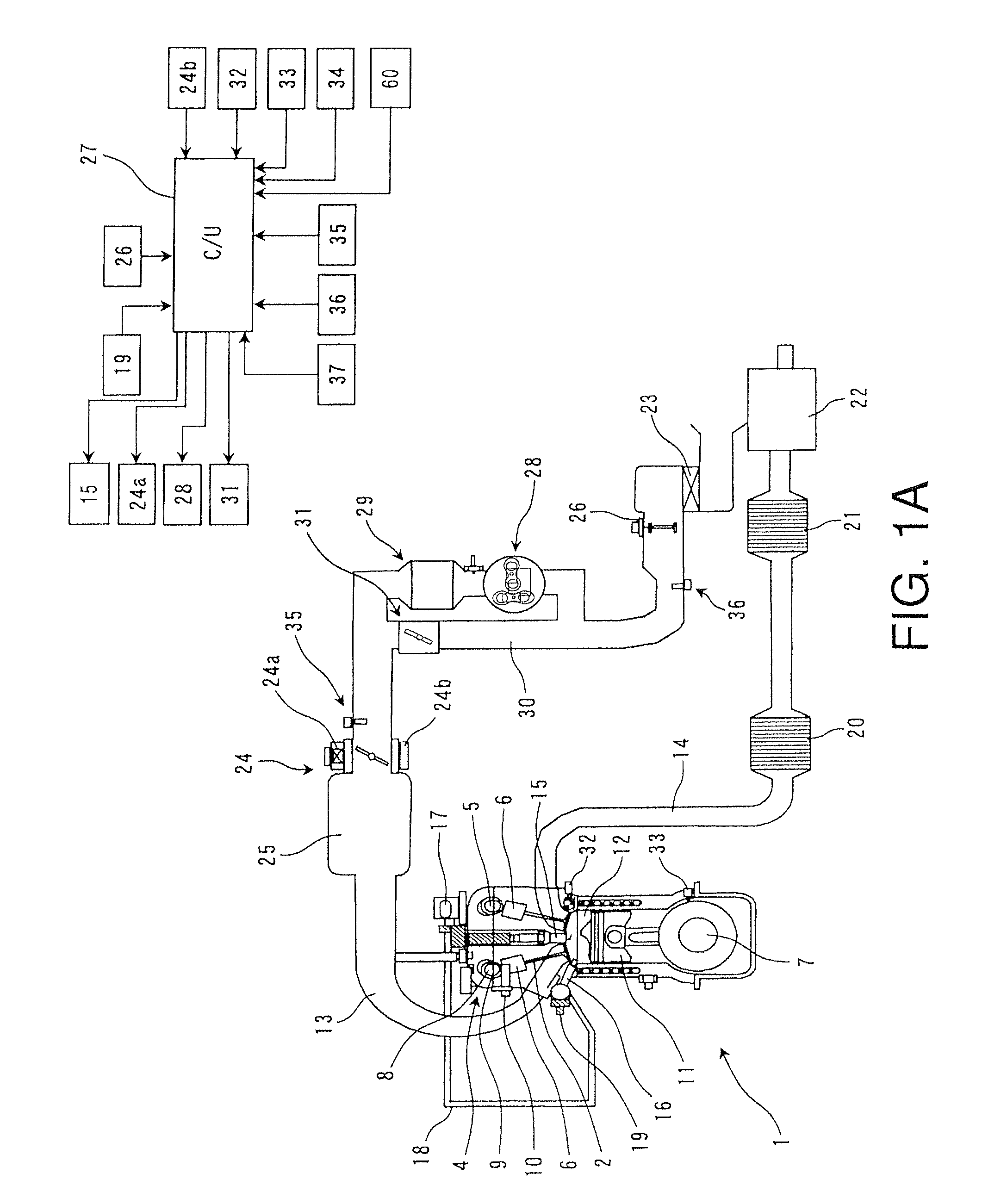

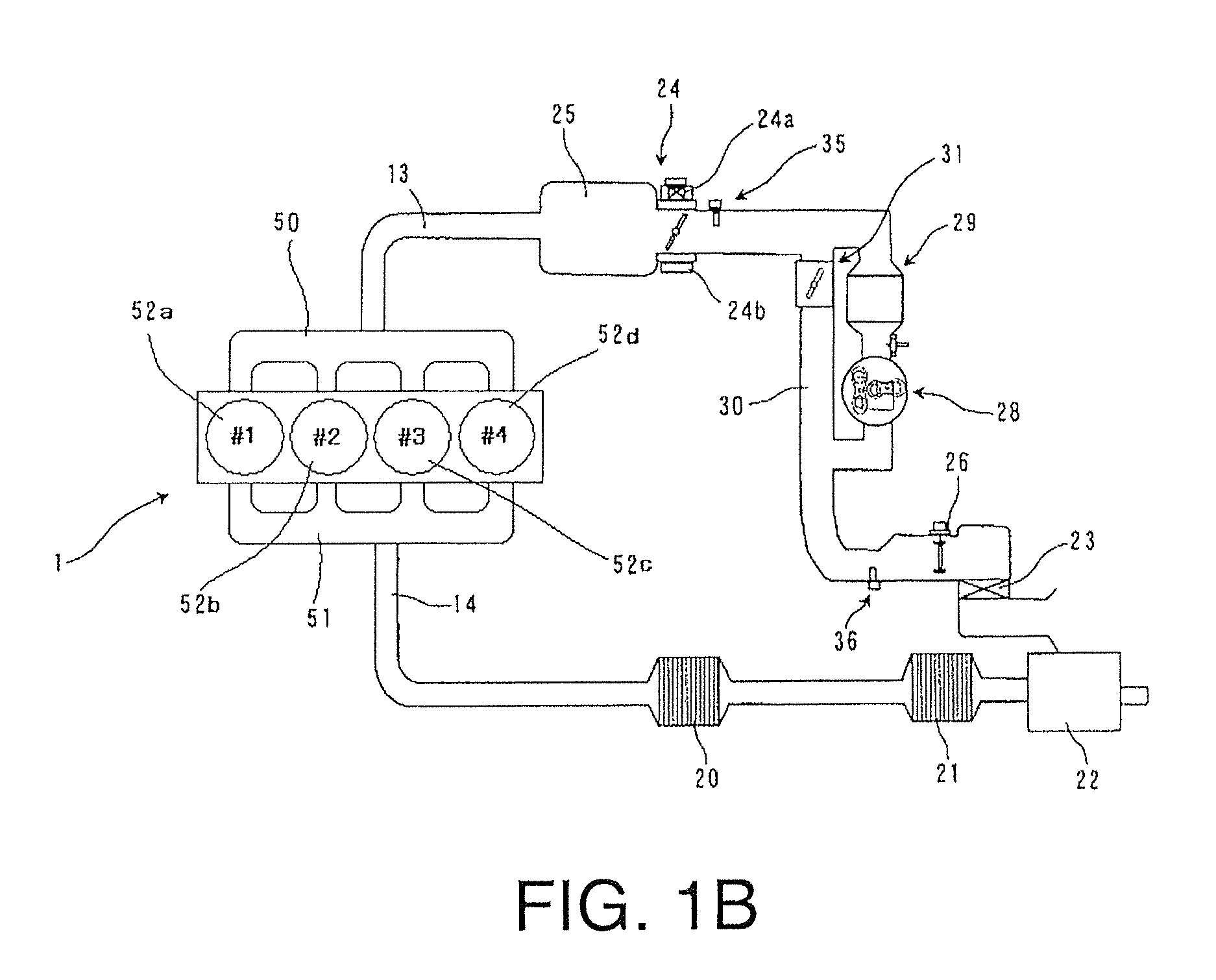

Apparatus for engine control

InactiveUS8186330B2Effective compression ratioValve arrangementsElectrical controlInlet valveEngineering

An engine control apparatus is provided with an engine, an ignition device, a valve timing changing mechanism, an intake valve close timing detecting device, a supercharger and a controller. The engine achieves a Miller cycle by the valve timing changing mechanism setting an intake valve close timing to occur after a bottom dead center timing. The controller controls an ignition timing of the ignition device, the open timing of the intake valve and the close timing of the intake valve. The controller retards the ignition timing during supercharging and when a detected value of the intake valve close timing is earlier than a target value of the intake valve close timing by at least a prescribed value in comparison with a situation in which the detected value matches the target value of the intake valve close timing.

Owner:NISSAN MOTOR CO LTD

Combustion engine including engine valve actuation system

Engines and methods of controlling an engine may involve at least one fluid actuators associated with one or more engine intake and / or exhaust valves. Timing of valve closing / opening and use of an air supply system may enable engine operation according to a Miller cycle.

Owner:CATERPILLAR INC

Variable valve control device and method and engine comprising variable valve control device

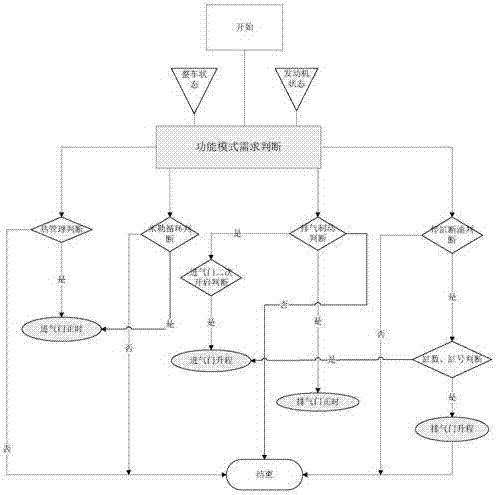

ActiveCN106870055AAchieve thermal managementImplementing the Miller cycleInternal combustion piston enginesNon-mechanical valveHeat managementElectro hydraulic

The invention provides a variable valve control device. In a traditional electro-hydraulic variable valve mechanism, a plunger type oil leakage control mechanism is arranged between a valve train cam and a hydraulic cavity, oil leakage time is controlled by adjusting the relative position between a spiral groove and an oil leakage hole in the plunger type oil leakage control mechanism, and the valve stroke and timing variability are achieved. The invention further provides a variable valve control method. The method can judge function requirements according to whole vehicle and engine operation states and comprises the steps of heat management, miller cycle, exhaust braking and cylinder deactivation and oil cut, and the function requirements are met according to the variable valve control device. The device and the method can be applied to a side-arranged cam shaft engine, and the structure is simple.

Owner:WEICHAI POWER CO LTD

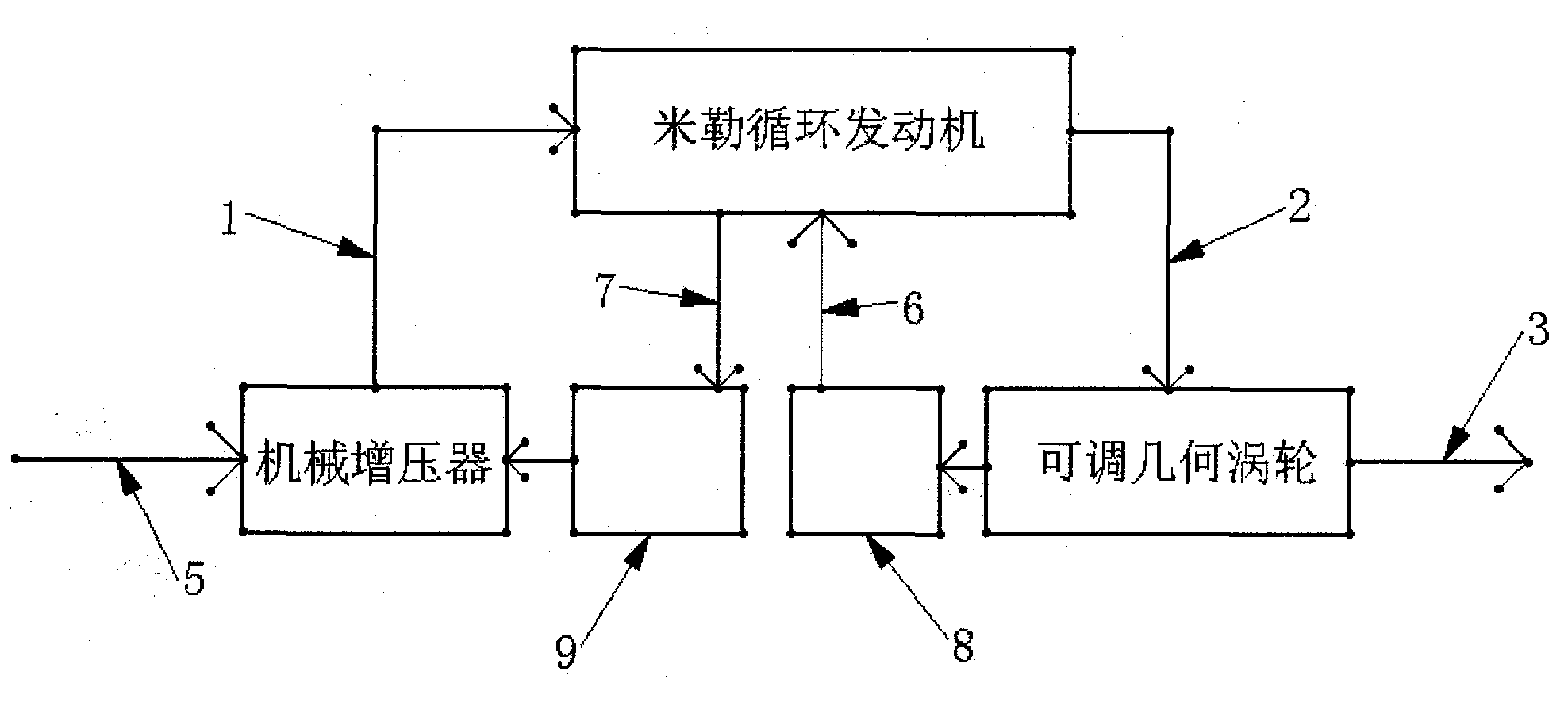

Method for realizing accurate equipower torque characteristics

InactiveCN102011646AIncrease speedImprove adaptabilityInternal combustion piston enginesEngine componentsAir managementMiller cycle

The invention discloses a method for realizing accurate equipower torque characteristics. On the premise of ensuring that the maximum explosion pressure and the thermal load of a diesel engine are in an allowed range, the accurate equipower torque characteristic with the torque adaptive coefficient and the rotating speed adaptive coefficient of larger than 2.5 of the diesel engine is realized by adopting technical approaches of a Hyperbrid boosting system, various cycle modes of Miller cycle / symmetrical cycle, 2 / 4 stroke cycle and other cycle modes, a pressure and flow stepless adjustable air management system, and the like. The technical scheme of the invention can expand the rotating speed and torque adaptive coefficient of the diesel engine, especially rotating speed adaptive coefficient, ensure that the rotating speed adaptive coefficient is easier to meet the requirement of a vehicle, simplify a drive device, improve the compactness of the whole power drive device of the vehicle, reduce the gear shifting operation of the vehicle and improve the efficiency of the whole system.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

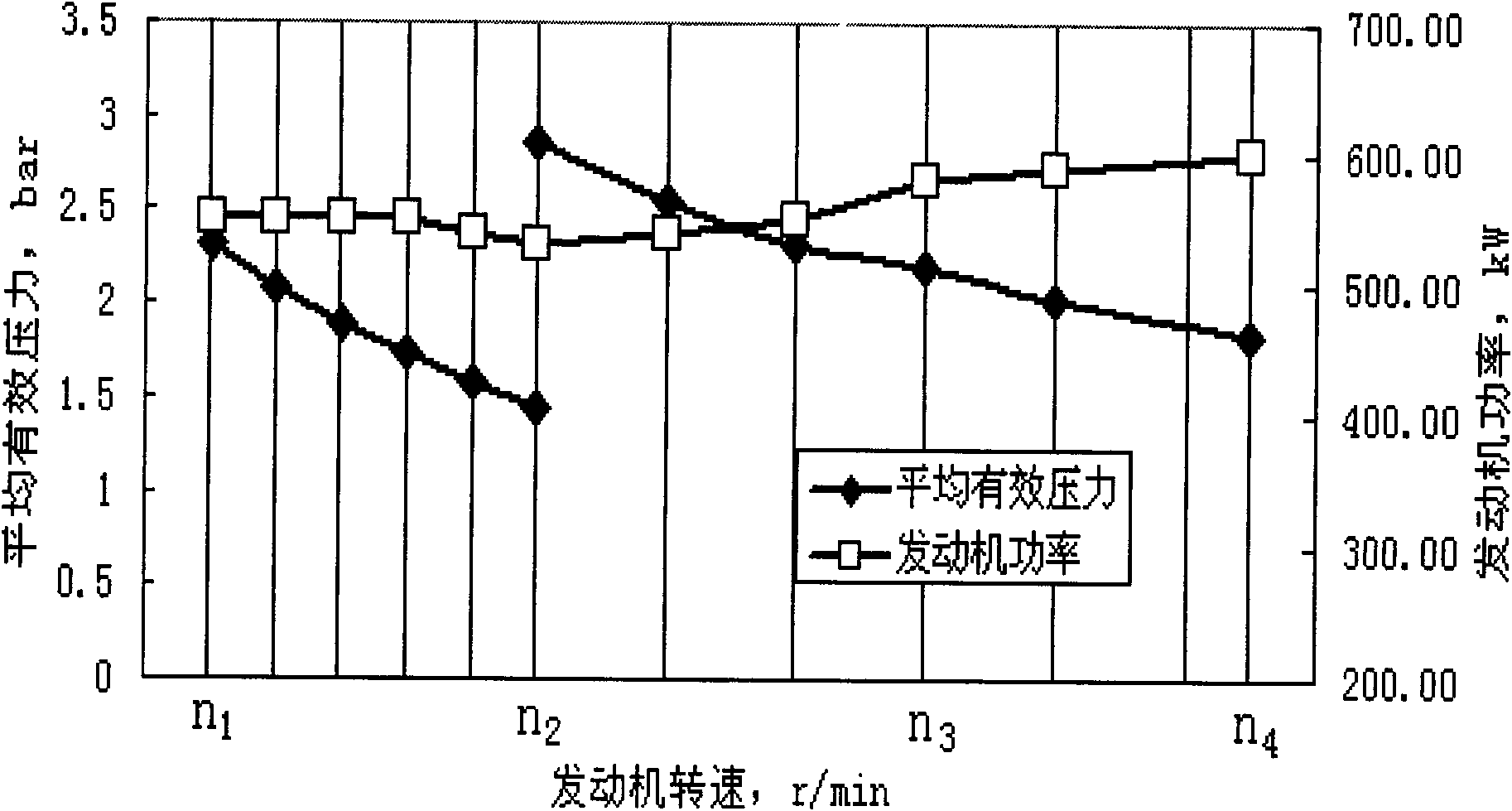

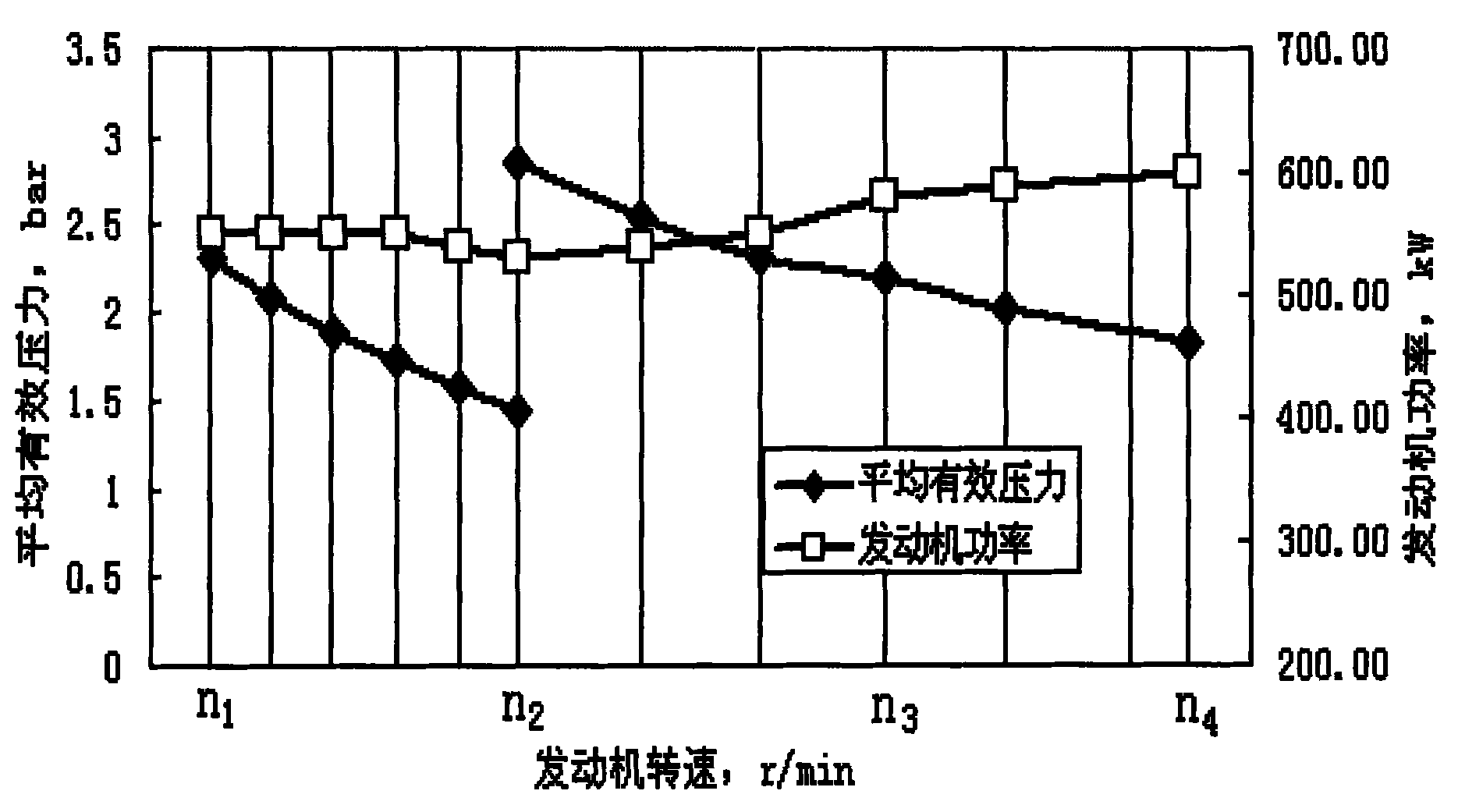

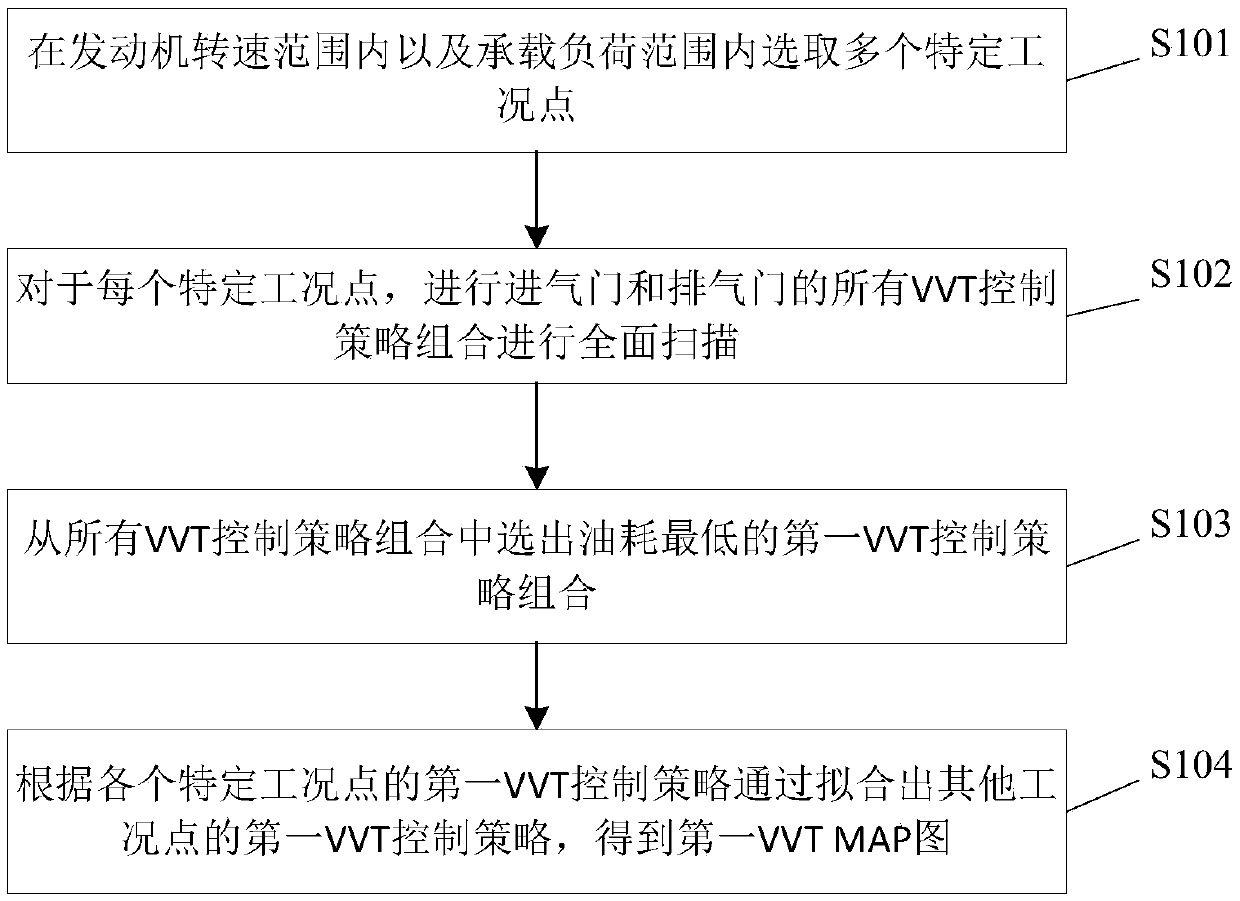

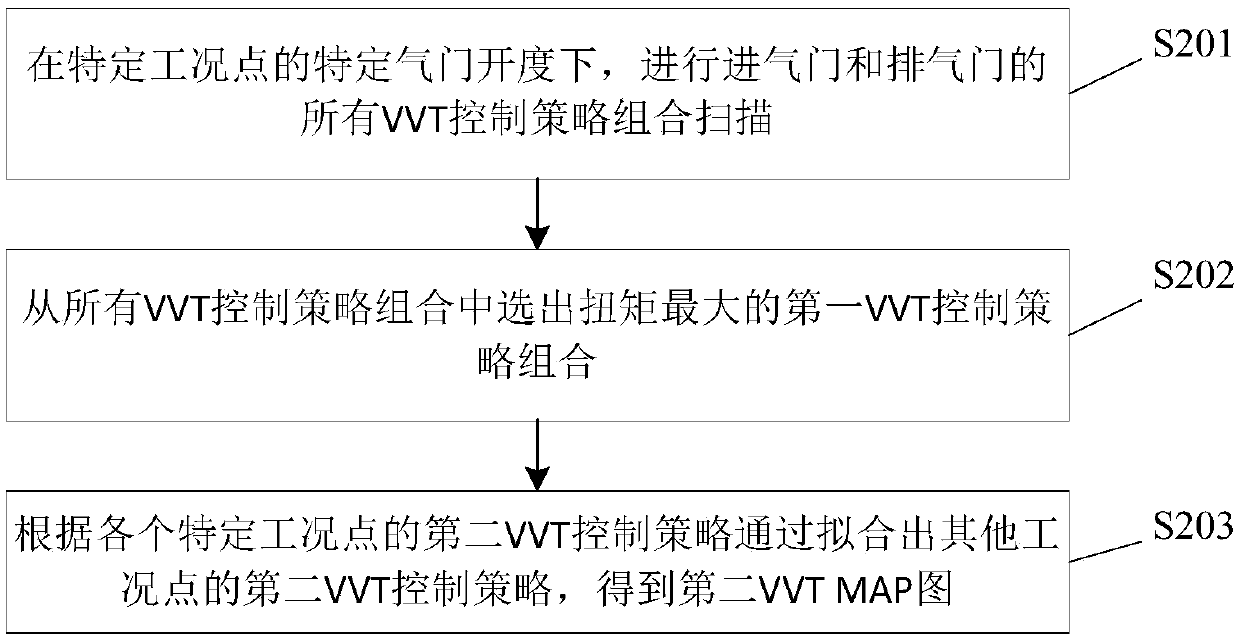

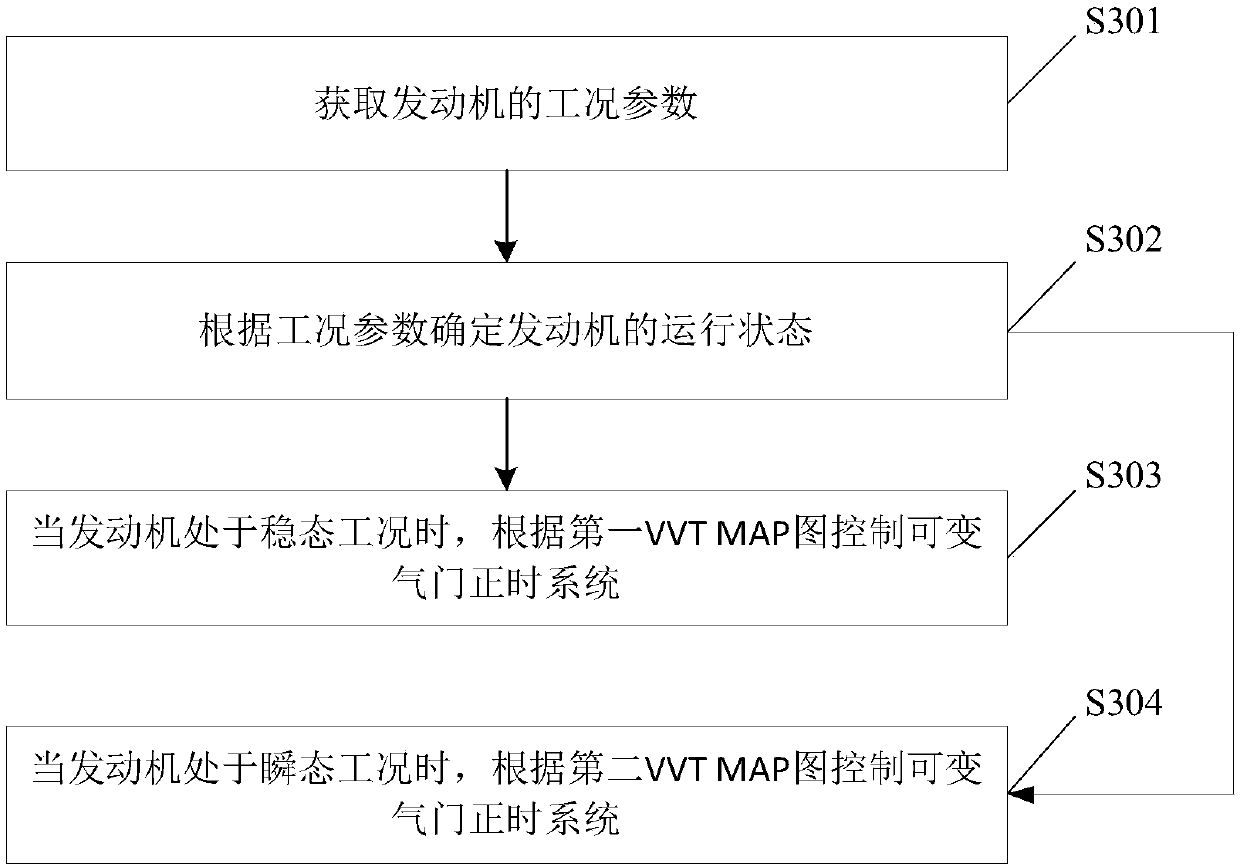

Control method and device for variable valve timing system of Miller cycle engine

ActiveCN110966063AAchieve economyAchieve dynamicsValve arrangementsInternal combustion piston enginesVariable valve timingControl engineering

The invention provides a control method and device for a variable valve timing system of a Miller cycle engine. In the control method, a first VVT MAP taking economical efficiency as a target and a second VVT MAP taking dynamic property as a target are previously demarcated, and when the engine is in a running state under a steady-state working condition, the variable valve timing system is controlled by virtue of the first VVT MAP, and the economical efficiency of the engine is realized; and when the engine is in a running state under a transient accelerated loading working condition, the variable valve timing system is controlled by virtue of the second VVT MAP, and the dynamic property of the engine is realized, and in this way, when the working conditions of the engine are different, the different VVT MAPs are chosen to control the variable valve timing system. Compared with the purpose of realizing the economical efficiency of the engine in the prior art, the control method and device for the variable valve timing system of the Miller cycle engine give consideration to the economical efficiency and the dynamic property of the engine simultaneously, and improves the acceleratedloading capacity under the transient working condition of the engine.

Owner:SAIC MOTOR

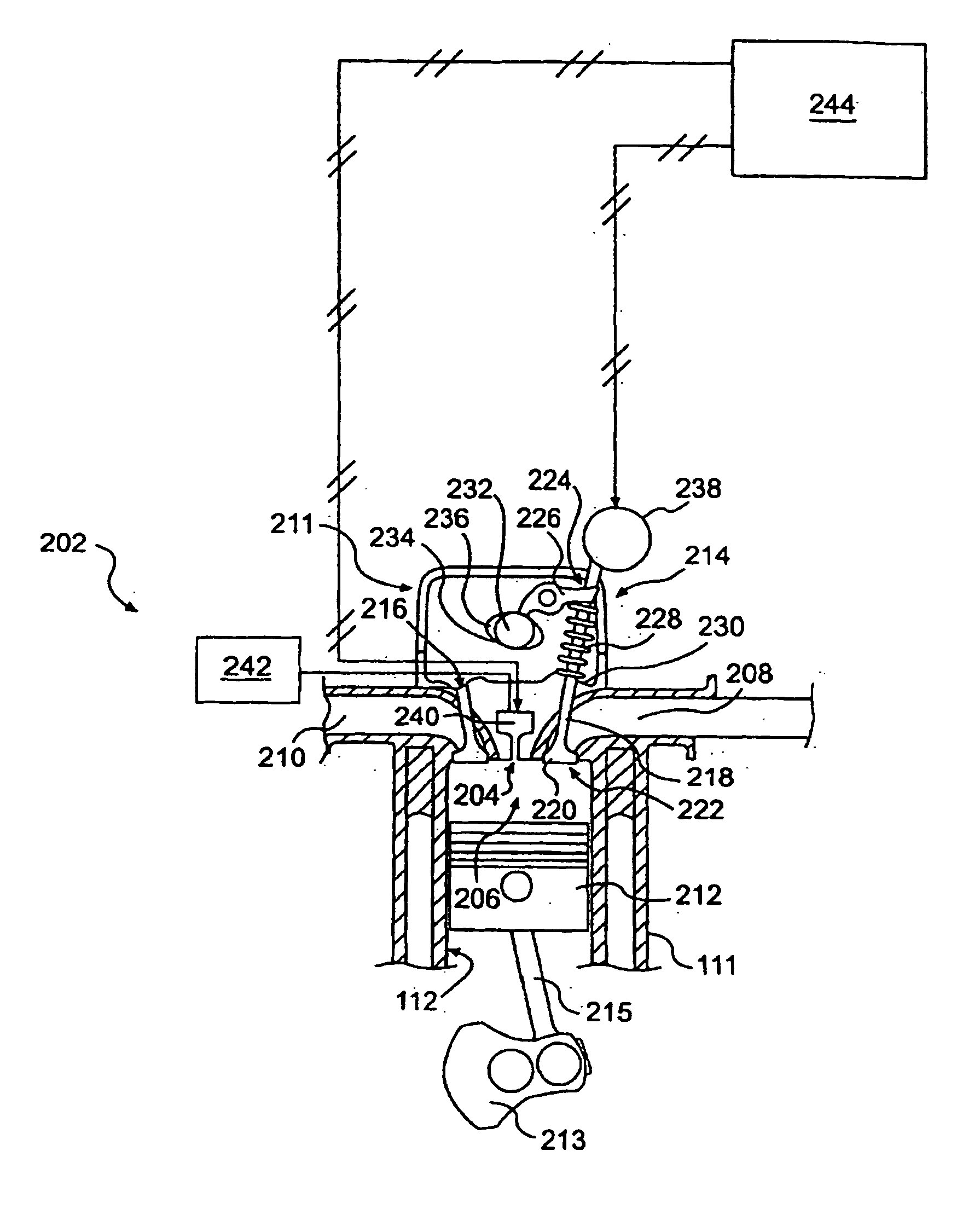

Intake Valve Closure Control for Dual-Fuel Engines

ActiveUS20150345347A1Avoid flowAvoid communicationInternal combustion piston enginesNon-mechanical valveControl flowOtto cycle

A system and a method for actuating intake valves of an internal combustion engine. The system includes a hydraulic circuit including a master cylinder, a control valve, an accumulator, a first one-way valve and a slave cylinder. The slave cylinder accommodates a slave piston, which is coupled to the intake valves. The control valve is disposed upstream of the accumulator for controlling flow from the hydraulic circuit to the accumulator. The first one-way valve is disposed downstream of the accumulator for permitting flow from the accumulator to the hydraulic circuit and for preventing flow from the hydraulic circuit to the accumulator without first passing through the control valve. The control valve has an open position that provides communication between the hydraulic circuit and the accumulator for a Miller cycle or Miller-like cycle operation. The control valve also has a closed position that prevents communication between the hydraulic circuit and the accumulator during Otto cycle operation.

Owner:CATERPILLAR INC

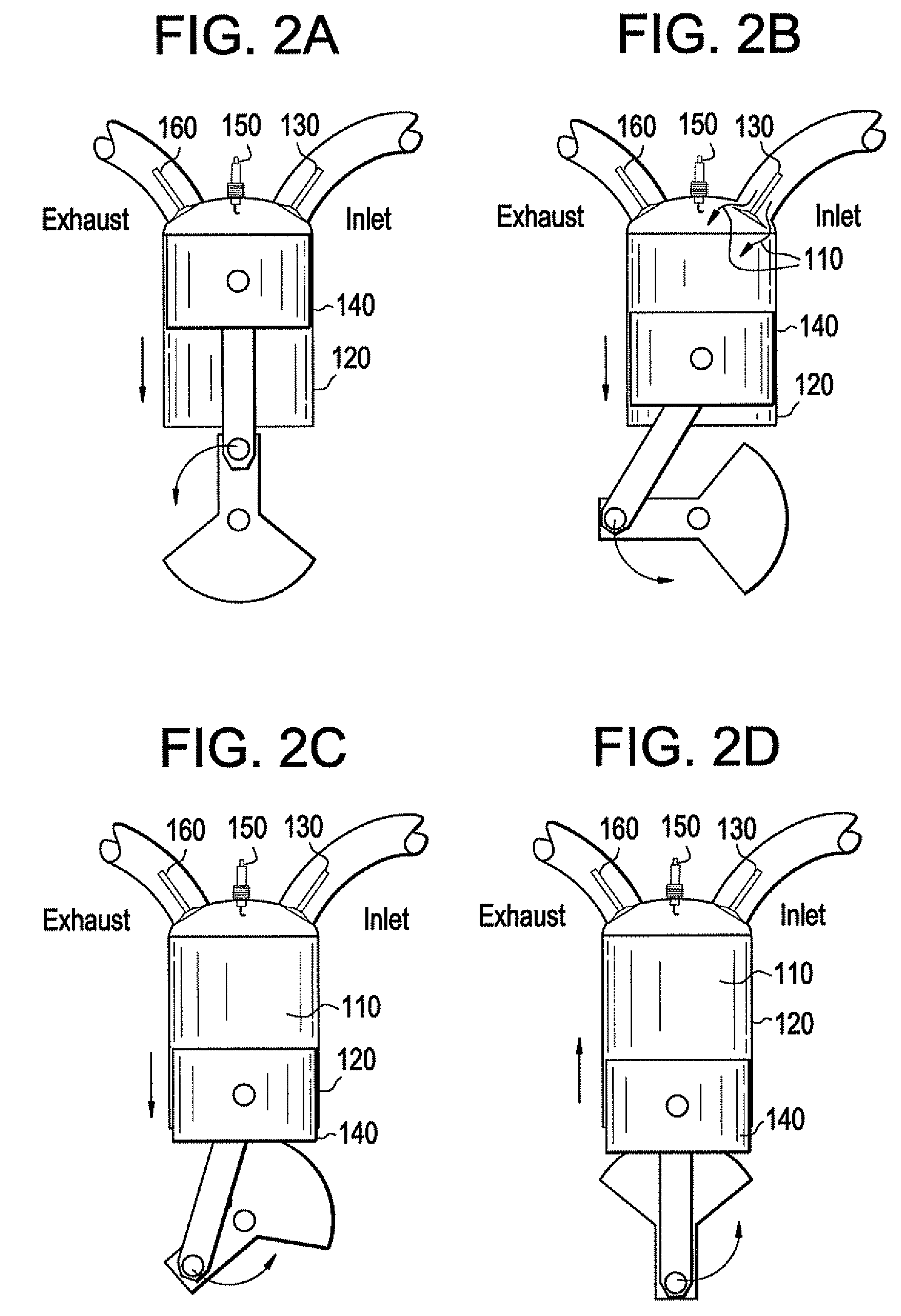

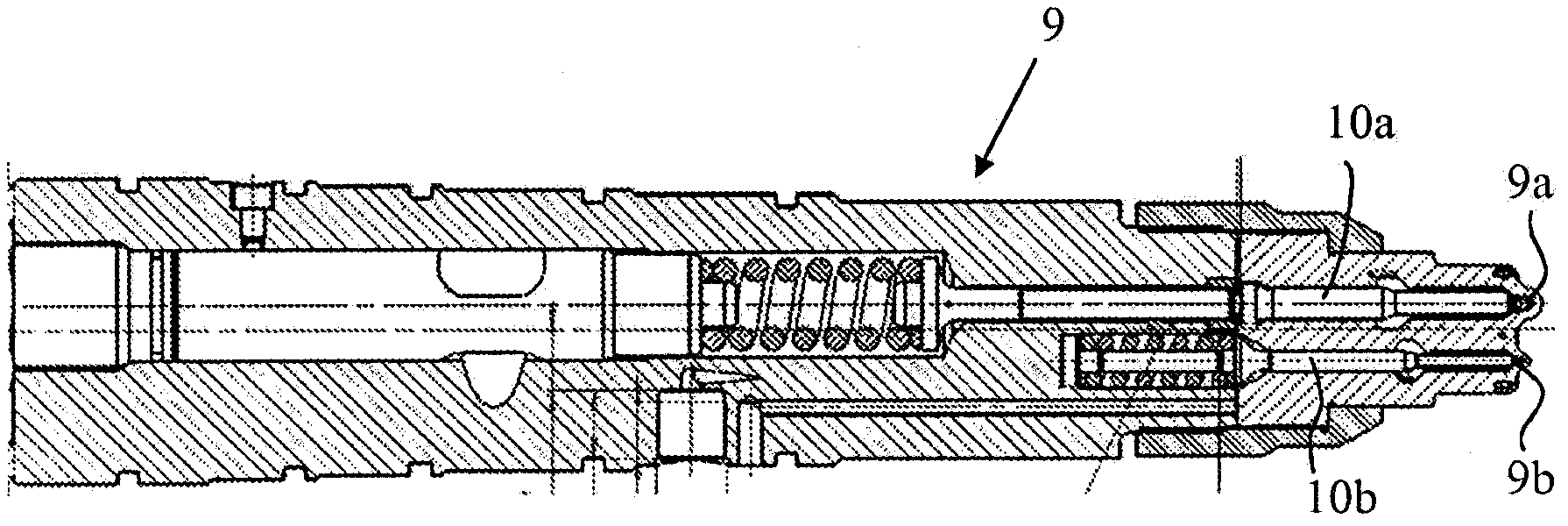

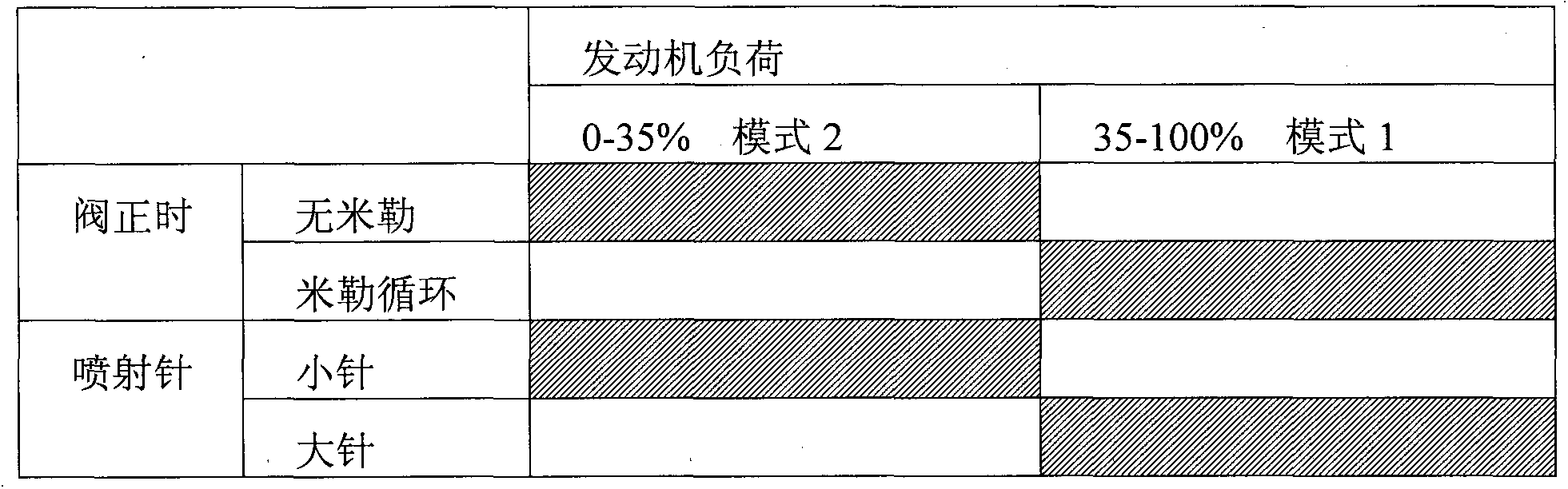

Control method for an internal combustion engine and internal combustion engine

ActiveUS20140041637A1Reduce nitrogen oxide emissionsHigh smoke emissionElectrical controlInternal combustion piston enginesExternal combustion engineInlet valve

The method for controlling the operation of an internal combustion engine comprises at least two operating modes. In a first operating mode, the intake valve is closed at a first predetermined crank angle, in accordance with the Miller cycle, before the piston reaches bottom dead center during the intake stroke for reducing pressure in the cylinder, and fuel is injected using first fuel injection means optimized for large amounts of fuel. In a second operating mode the intake valve is closed at a second predetermined crank angle, in accordance with conventional intake valve closing timing, after or slightly before the piston has passed bottom dead center, and fuel is injected using second fuel injection means optimized for small amounts of fuel. The invention also concerns an internal combustion engine.

Owner:WARTSILA FINLAND OY

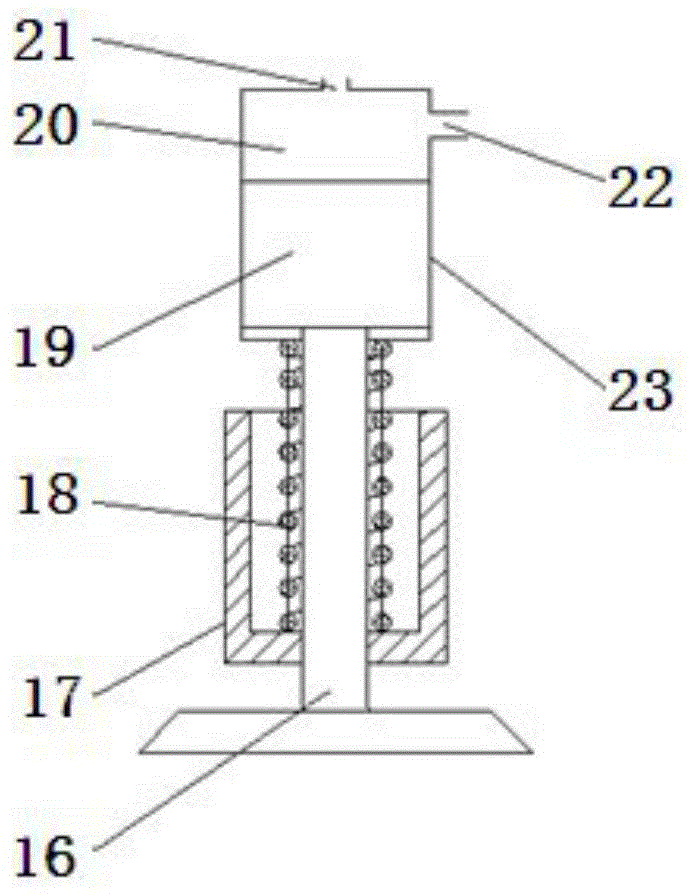

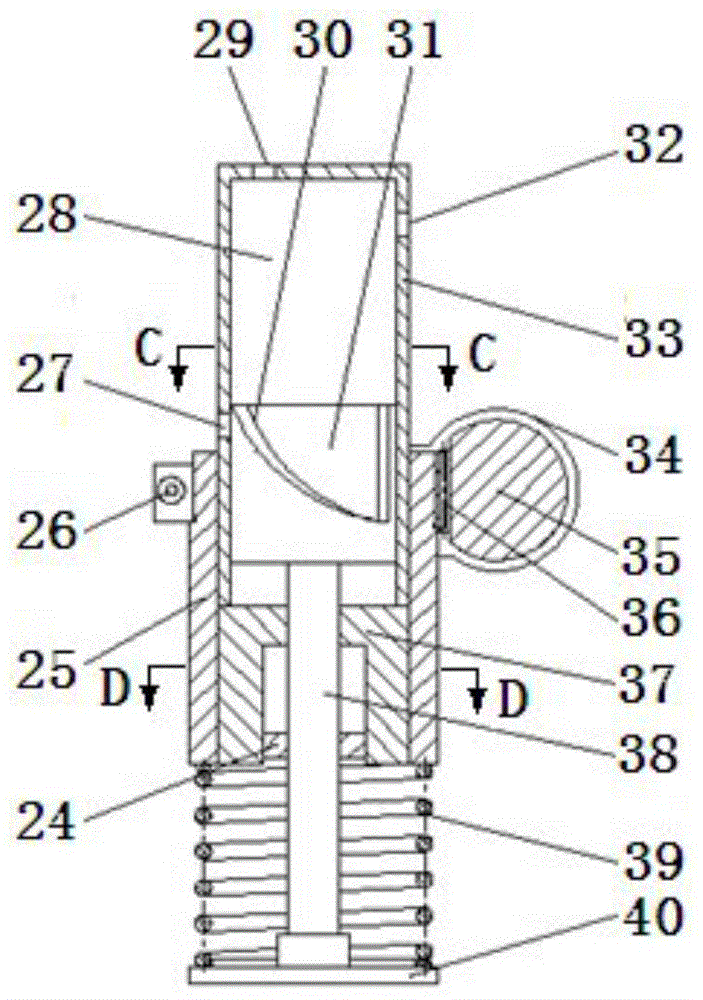

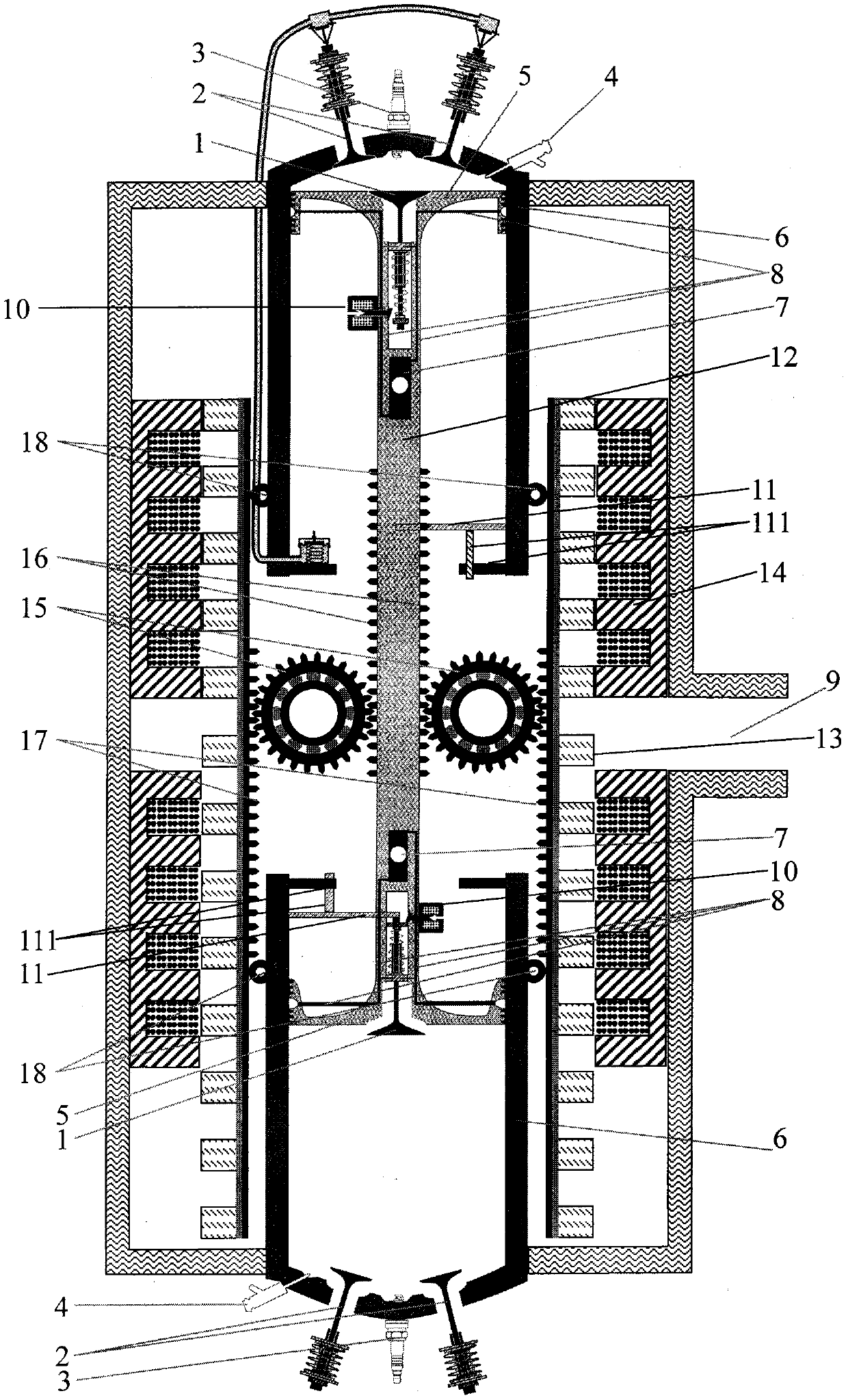

Valve electro-hydraulic driving system and method for achieving Miller cycle of engine

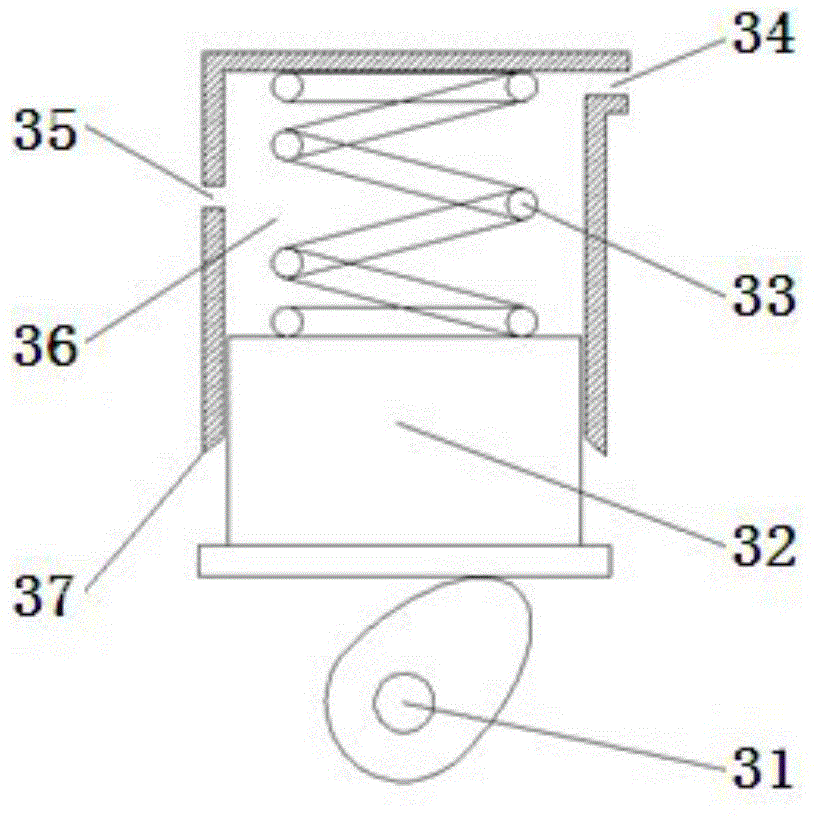

InactiveCN104791043AMeet gas distribution needsFlexible Timing AdjustmentInternal combustion piston enginesNon-mechanical valveSpool valveSolenoid valve

The invention provides a valve electro-hydraulic driving system and method for achieving Miller cycle of an engine. A crankshaft position sensor is connected with an ECU, the ECU is connected with a two-position three-way electromagnetic valve and a normally-open electromagnetic valve, the two-position three-way electromagnetic valve is connected with a high-pressure oil tank, a low-pressure oil tank and a conical slide valve, a feedback piston cylinder is fixed to a main piston cylinder, a feedback piston and a main piston are fixedly connected through a piston rod, the main piston is connected with an inlet valve, a spring is installed between the main piston and the main piston cylinder below the main piston, the conical slide valve is connected with an upper feedback cavity, a main upper cavity and a main lower cavity, a limiting hole is formed in the main lower cavity, the normally-open electromagnetic valve is connected with the upper feedback cavity, and the limiting hole and the normally-open electromagnetic valve are connected with the low-pressure oil tank through the same pipeline. The system and method are used for achieving Miller cycle of the engine, and technology universality and transferability are high.

Owner:HARBIN ENG UNIV

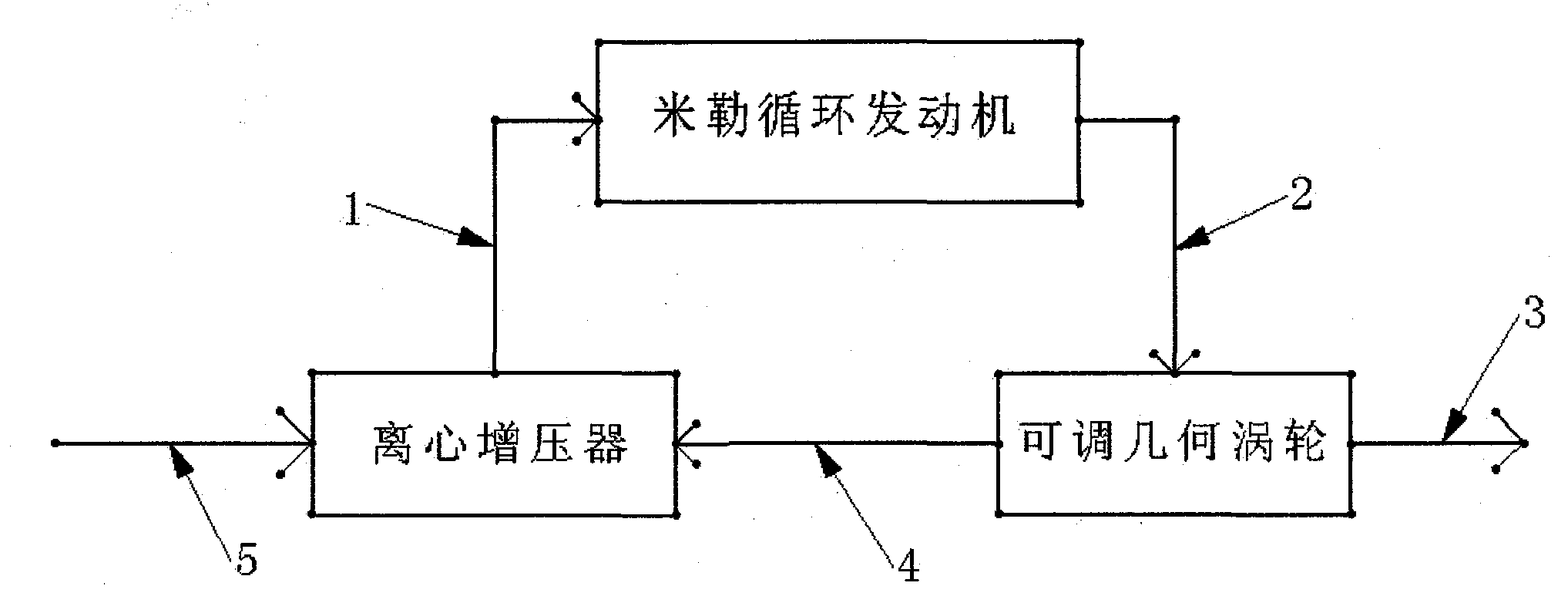

Ultrahigh-supercharging turbo-charging Miller cycle engine

InactiveCN103557068AReduce the compression ratioMulti powerInternal combustion piston enginesEngine componentsTurbochargerMiller cycle

The invention discloses an ultrahigh-supercharging turbo-charging Miller cycle engine which comprises a turbocharger and a Miller cycle engine body. The supercharge ratio of the turbocharger can exceed 2.5, but the compression ratio of the Miller cycle engine body is as low as 4. A turbine in the turbocharger can absorb much power and is a variable turbine geometry (VTG) turbine. The turbocharger can be a centrifugal supercharger, or a roots pump supercharger or a rotor pump and provides the condition that heat work absorbed by the turbine is very close to releasable heat work contained in exhaust gas. The compression ratio of the Miller cycle engine body can be fixed or adjustable. When the Miller cycle engine with fixed compression ratio is adopted, the supercharger is a supercharger with fixed flow, such as a roots pump or a rotor pump. When the supercharger with the fixed flow is adopted, the VTG turbine is connected with a crankshaft of the Miller cycle engine through a transmission. The efficiency of an internal combustion engine is remarkably improved.

Owner:朱譞晟

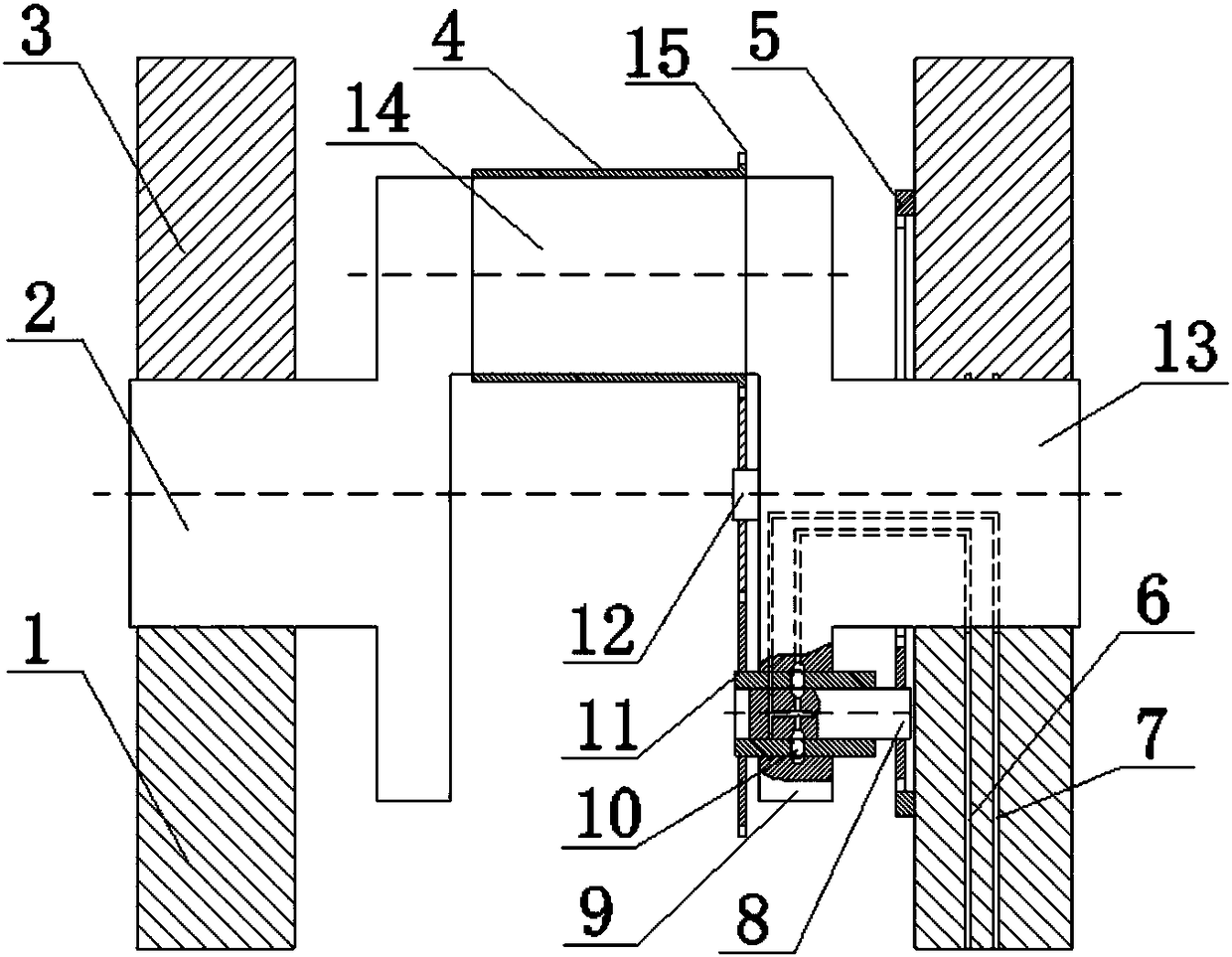

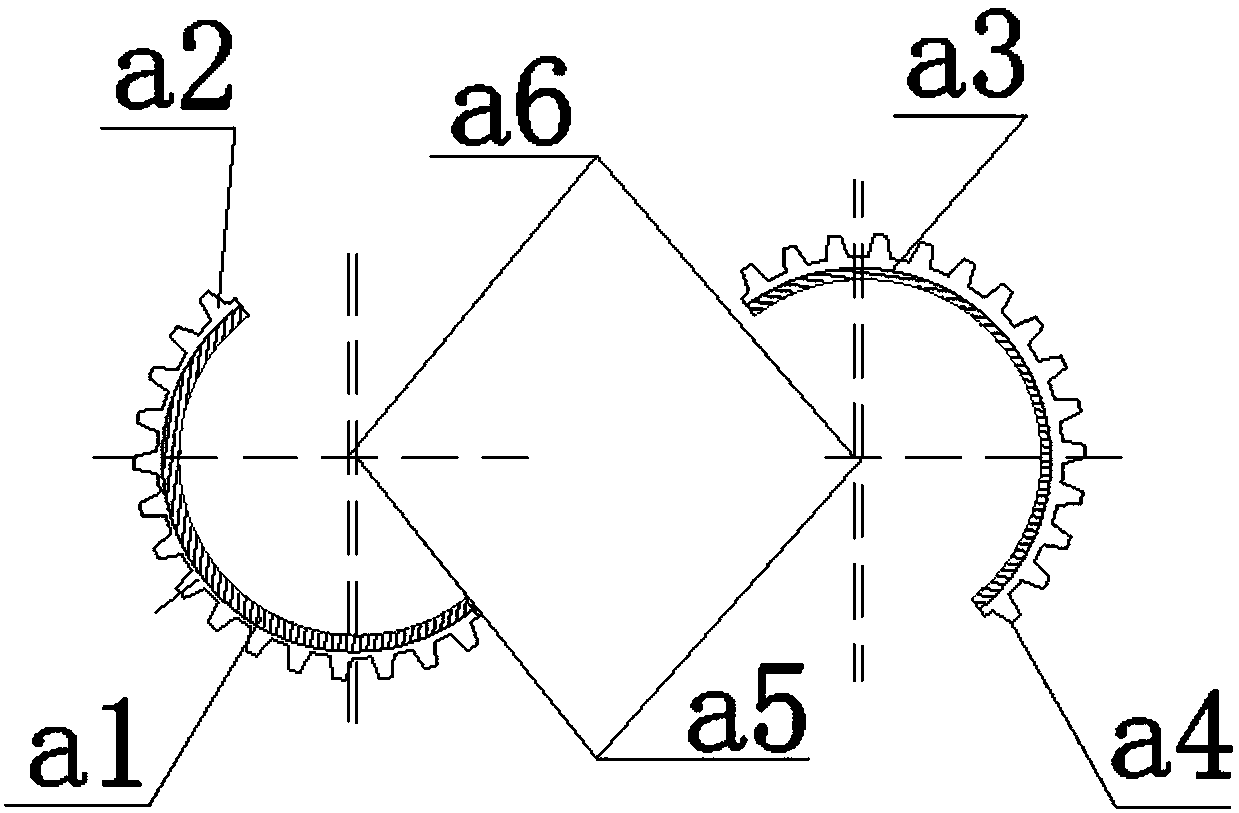

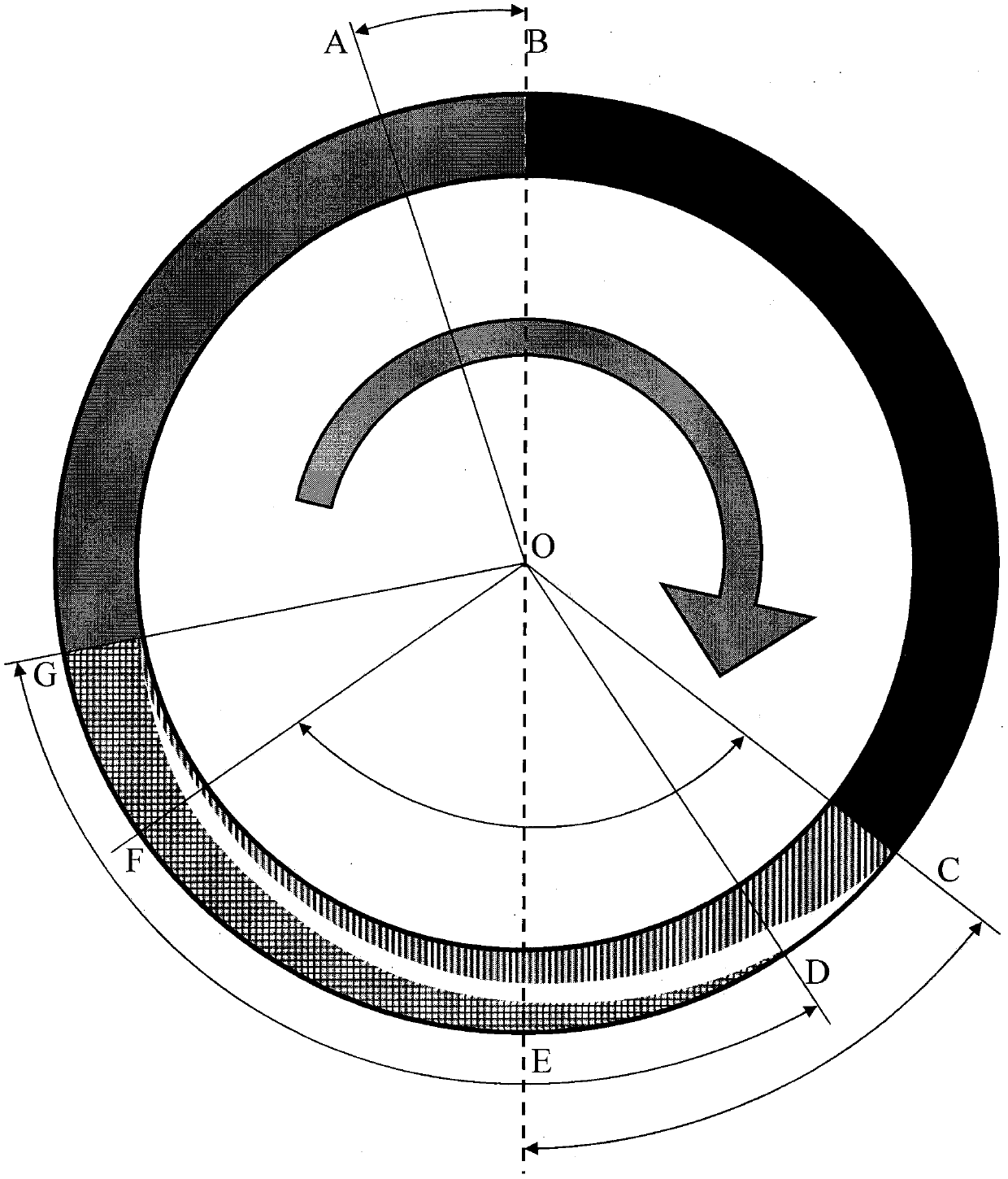

Crank-connecting rod mechanism capable of achieving Miller cycle and control method

ActiveCN108590849ASmall drive torqueSimplify the drive systemCrankshaftsConnecting rod bearingsMiller cycleMechanical engineering

The invention discloses a crank-connecting rod mechanism capable of achieving the Miller cycle and a control method. A driving oil channel and a locking oil channel are arranged in a crankshaft, an eccentric connecting rod bearing is arranged on a connecting rod neck of the crankshaft, a driving gear which meshes with an outer meshing gear ring of the eccentric connecting rod bearing through an idle gear is installed in a crankshaft balancing block, a planetary gear is installed in a driving gear hollow shaft, and the driving gear hollow shaft is provided with locking pins capable of locking the hollow shaft and the crankshaft balancing block or locking the hollow shaft and a planetary gear shaft; and the driving gear hollow shaft and the planetary gear shaft are locked by applying hydraulic oil to the driving oil channel to enable the planetary gear shaft to transmit movement to the driving gear and then transmit movement to the outer meshing gear ring of the eccentric connecting rodbearing through the idle gear, the eccentric connecting rod bearing rotates around the connecting rod neck of the crankshaft, and then the compression ratio of an engine is changed. According to the crank-connecting rod mechanism capable of achieving the Miller cycle and the control method, the crank-connecting rod mechanism can achieve synchronous movement with rotation of the engine, compressionratio adjustment of the engine in one working stroke can be achieved, then the Miller cycle is achieved, the control flexibility is high, and control is flexible.

Owner:XIHUA UNIV

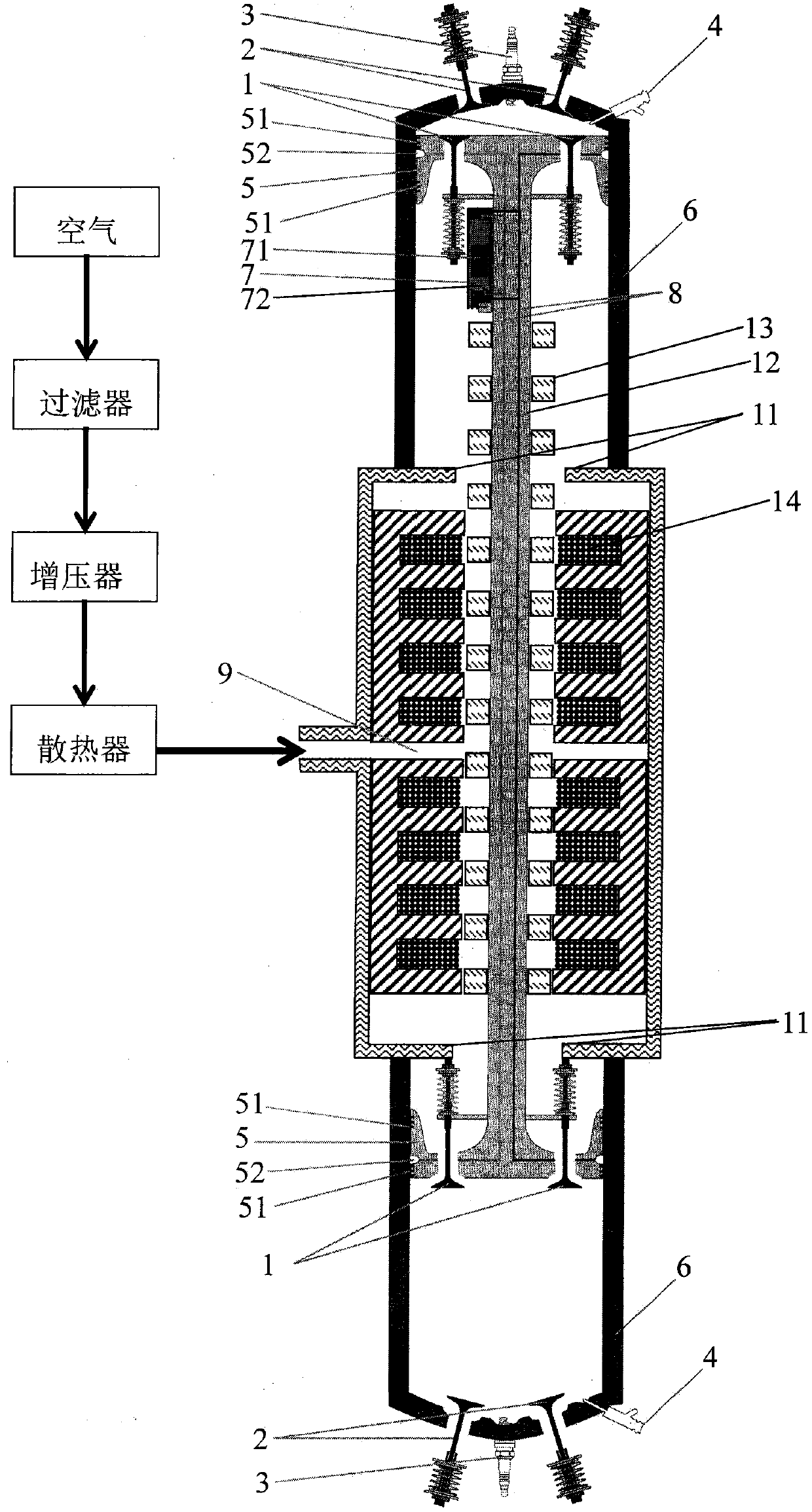

Linear range-extending generator driven by pre-boost gas ventilation and exhaust free piston engine

ActiveCN111365121AReduce consumptionImprove efficiencyElectrical controlInternal combustion piston enginesFree-piston engineExhaust valve

The invention provides a linear range-extending generator driven by a pre-boost gas ventilation and exhaust free piston engine, and relates to engines and generators. Two sets of cylinder bodies are connected to a generator body, and in-cylinder pistons form a group of free pistons through connecting rods; through a full-stroke boosting system, when the pistons reciprocate once, an exhaust valve and an intake valve of each cylinder are opened and closed once, and exhaust gas is flushed and exhausted by using fresh air and air intake is completed; then compression and acting are completed oncewhich mean in-cylinder exhaust gas recirculation is combined with the similar Miller cycle; and by means of a piezoelectric knock sensor and a controller, the highest compression ratio which is reached when the engine is suitable for the current condition is automatically selected, the piston part lubrication is the inner circulation lubrication taking an inertia density difference-driven self-circulating pump as the core, the generator is a cylindrical rare earth permanent magnet reciprocating linear generator comprising two tooth groove-shaped cylinder stators with stator coil windings and aphase difference of 90 degrees, the electric energy output of the generator is realized by a power controlled regulation output circuit, and the generator also serves as a starting motor.

Owner:钱裕智

Control method for an internal combustion engine and internal combustion engine

ActiveCN103237972ARelieve pressureEmission reductionElectrical controlInternal combustion piston enginesExternal combustion engineInlet valve

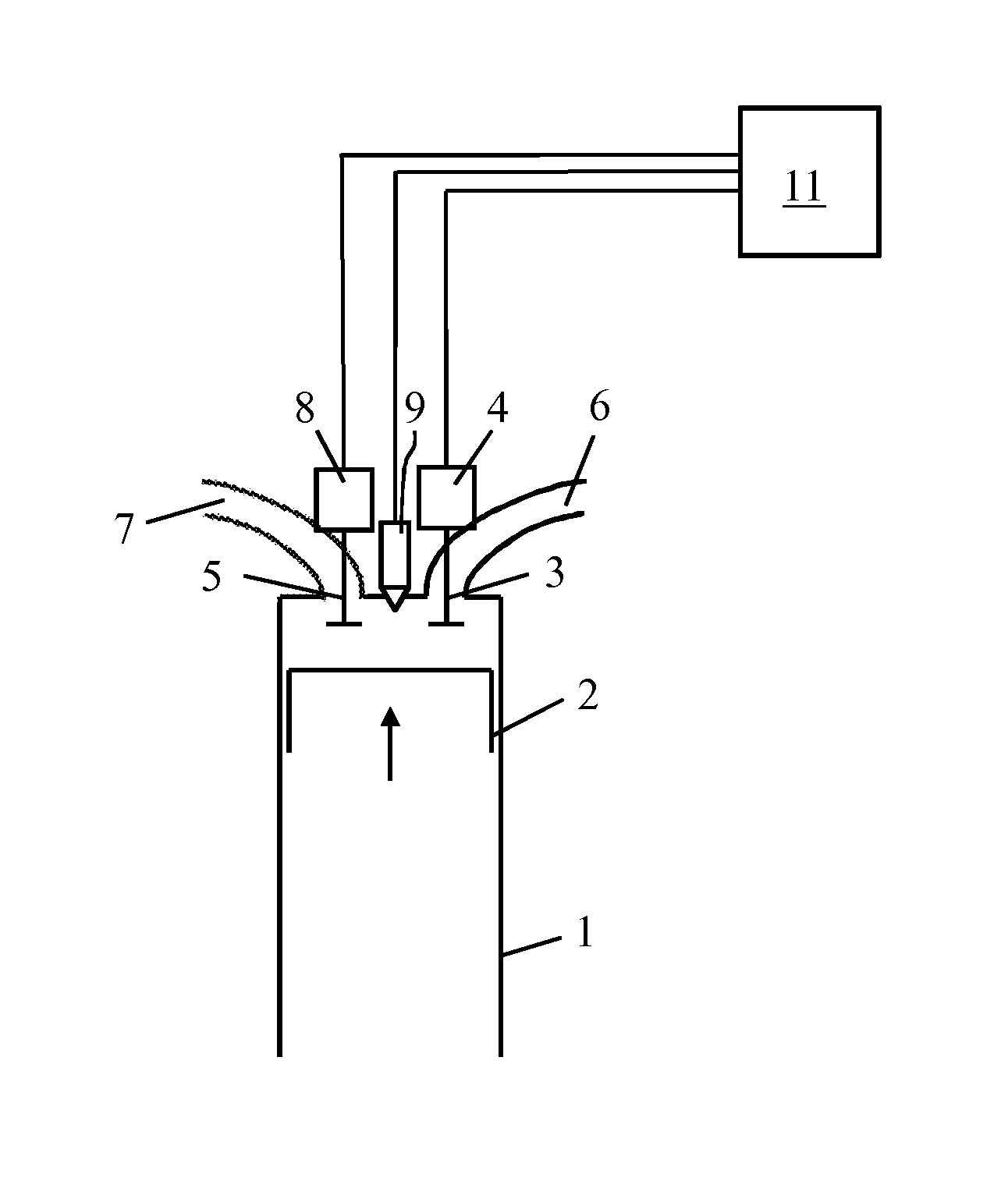

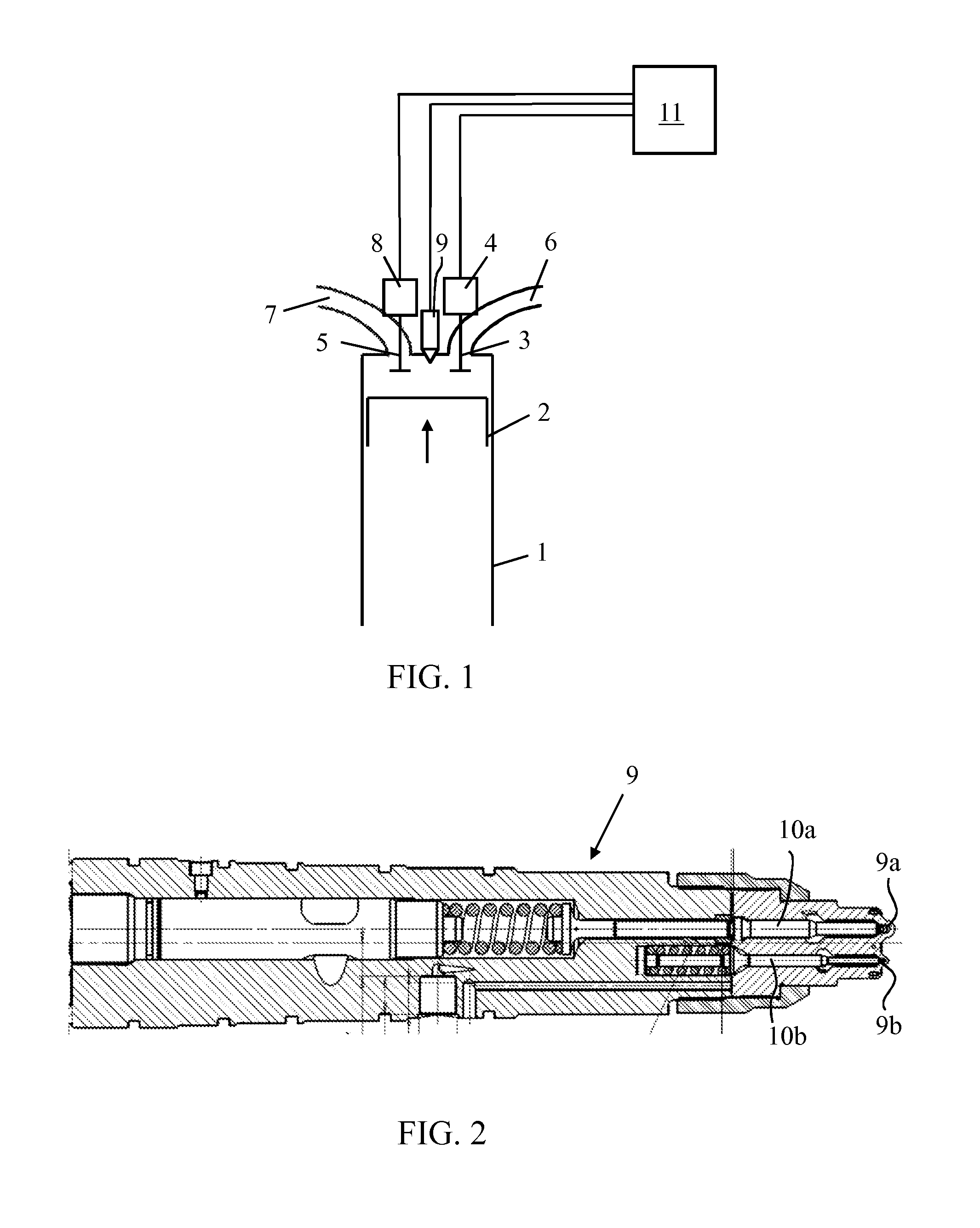

The method for controlling the operation of an internal combustion engine comprises at least two operating modes. In a first operating mode, the intake valve (3) is closed at a first predetermined crank angle, in accordance with the Miller cycle, before the piston (2) reaches bottom dead center during the intake stroke for reducing pressure in the cylinder (1), and fuel is injected using first fuel injection means (9a) optimized for large amounts of fuel. In a second operating mode the intake valve (3) is closed at a second predetermined crank angle, in accordance with conventional intake valve closing timing, after or slightly before the piston (2) has passed bottom dead center, and fuel is injected using second fuel injection means (9b) optimized for small amounts of fuel. The invention also concerns an internal combustion engine.

Owner:WARTSILA FINLAND OY

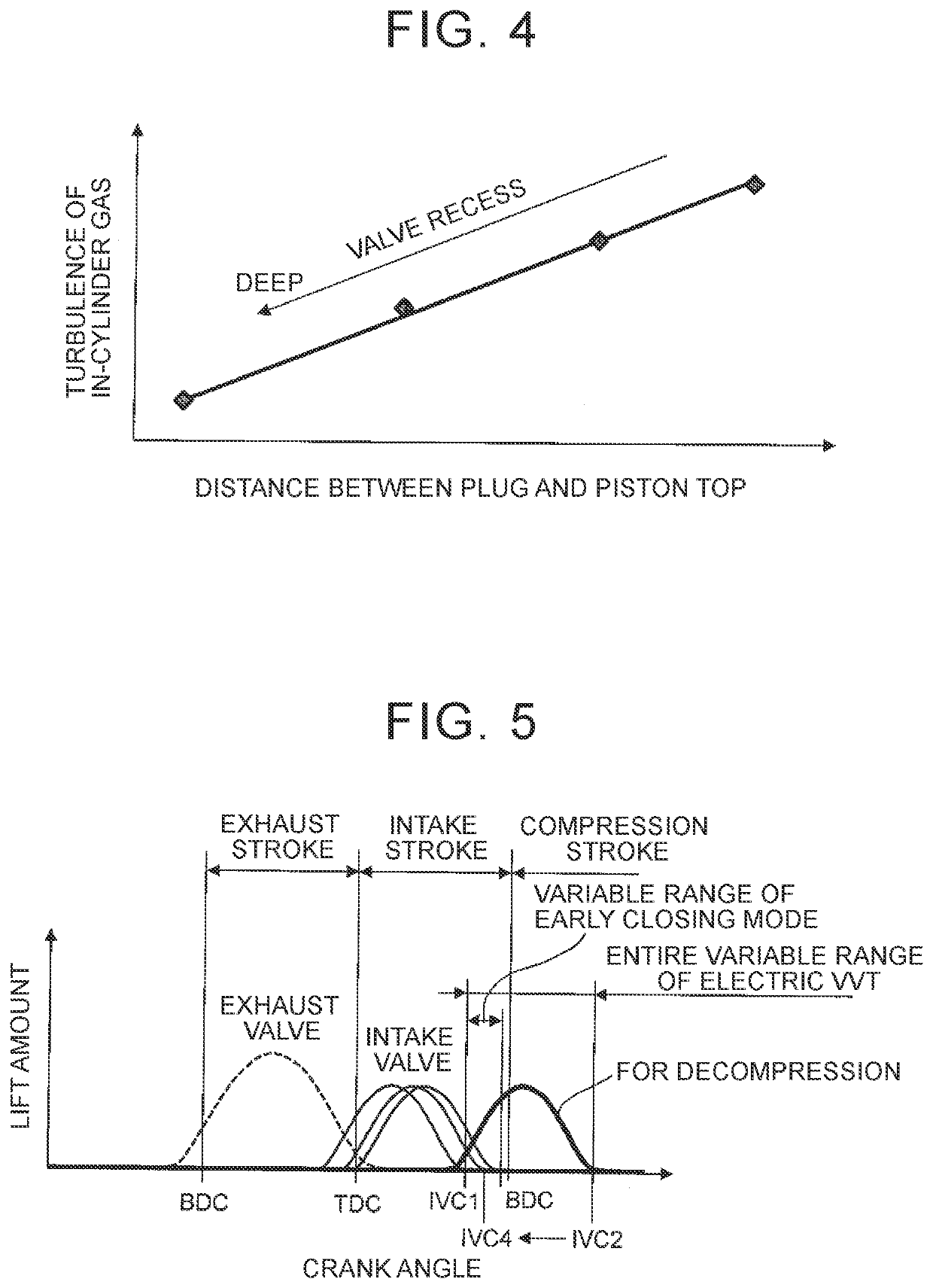

Control system of miller cycle engine and method of controlling miller cycle engine

ActiveUS20200072135A1Improve reducibilityElectrical controlInternal combustion piston enginesControl systemControl engineering

A control system of a Miller cycle engine includes an ECU. The ECU executes an early closing Miller cycle operating mode in which a variable valve mechanism is controlled to close an intake valve before an intake bottom dead center. The ECU executes a decompression mode in which the variable valve mechanism is controlled to close the intake valve at a point later than the intake BDC, when the engine is started. The electronic control unit executes the early closing Miller cycle operating mode after completion of the decompression mode. A later closing amount of the intake valve relative to the intake BDC, for use in the decompression mode, is larger than an early closing amount of the intake valve relative to the intake BDC when the closing timing of the intake valve is most advanced.

Owner:TOYOTA JIDOSHA KK

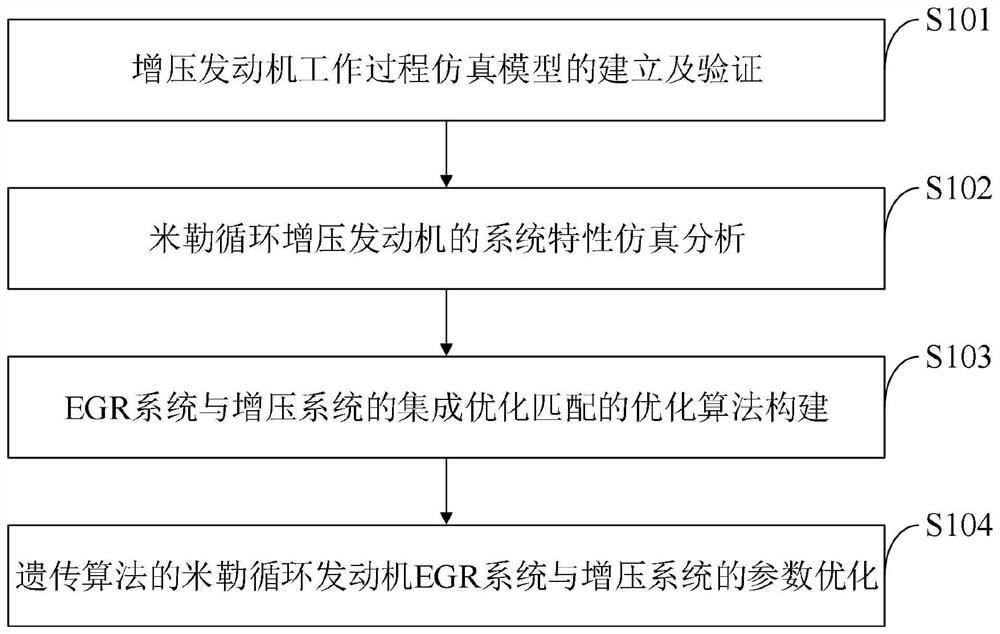

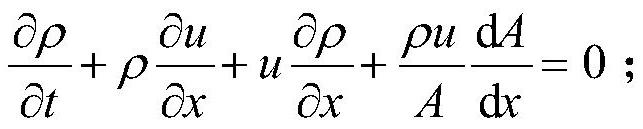

Optimization method for integrated optimization matching of EGR system and pressurization system

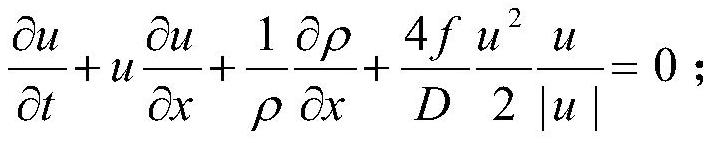

PendingCN113741211AImprove machine performanceSimulator controlMathematical modelControl engineering

The invention belongs to the technical field of engines, and discloses an optimization method for integrated optimization matching of an EGR system and a pressurization system, and the optimization method for the integrated optimization matching of the EGR system and the pressurization system comprises the steps: building and verifying a simulation model of the working process of a supercharged engine; performing system characteristic simulation analysis on the Miller cycle supercharged engine; constructing an optimization algorithm for integrated optimization matching of the EGR system and the pressurization system; and optimizing the parameters of the EGR system and the supercharging system of the Miller cycle engine based on the genetic algorithm. According to the method, a certain domestic engine is used as a prototype engine for paper research, a mathematical model of the working process of each subsystem of the turbocharged gasoline engine is established, and the gasoline engine simulation calculation model established based on GT-POWER is compared with test data to verify the accuracy of the model; and the design of a high-efficiency domestic hybrid gasoline engine is promoted, the overall performance of the engine is improved, and important academic value significance and engineering application value are achieved.

Owner:BEIJING JIAOTONG UNIV

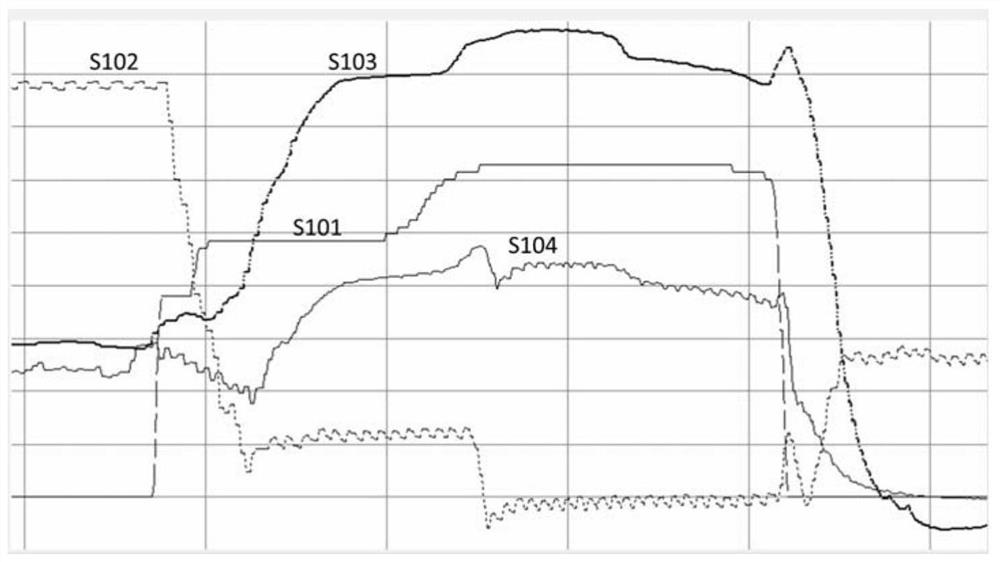

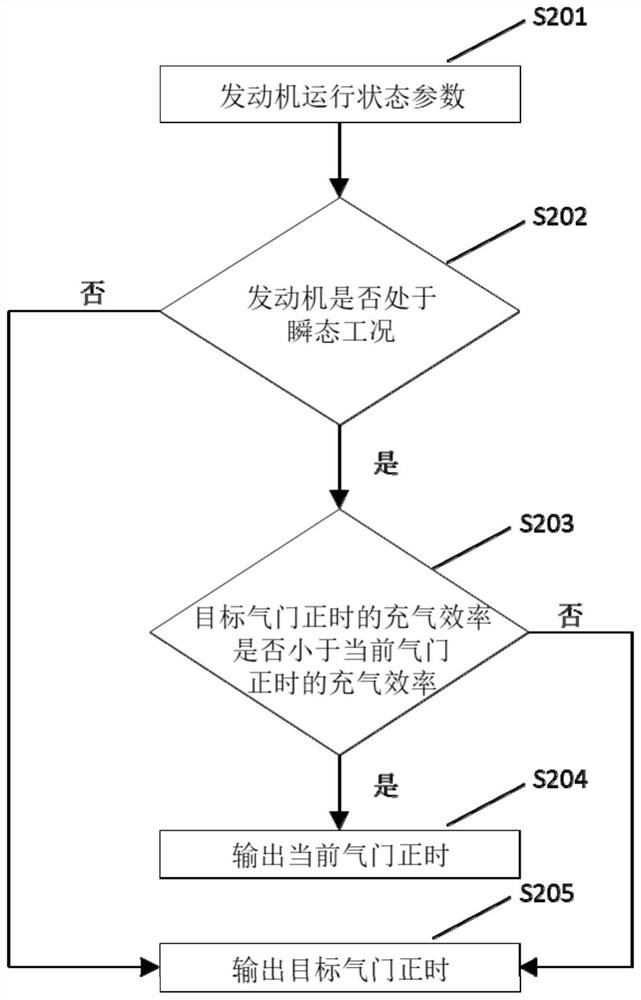

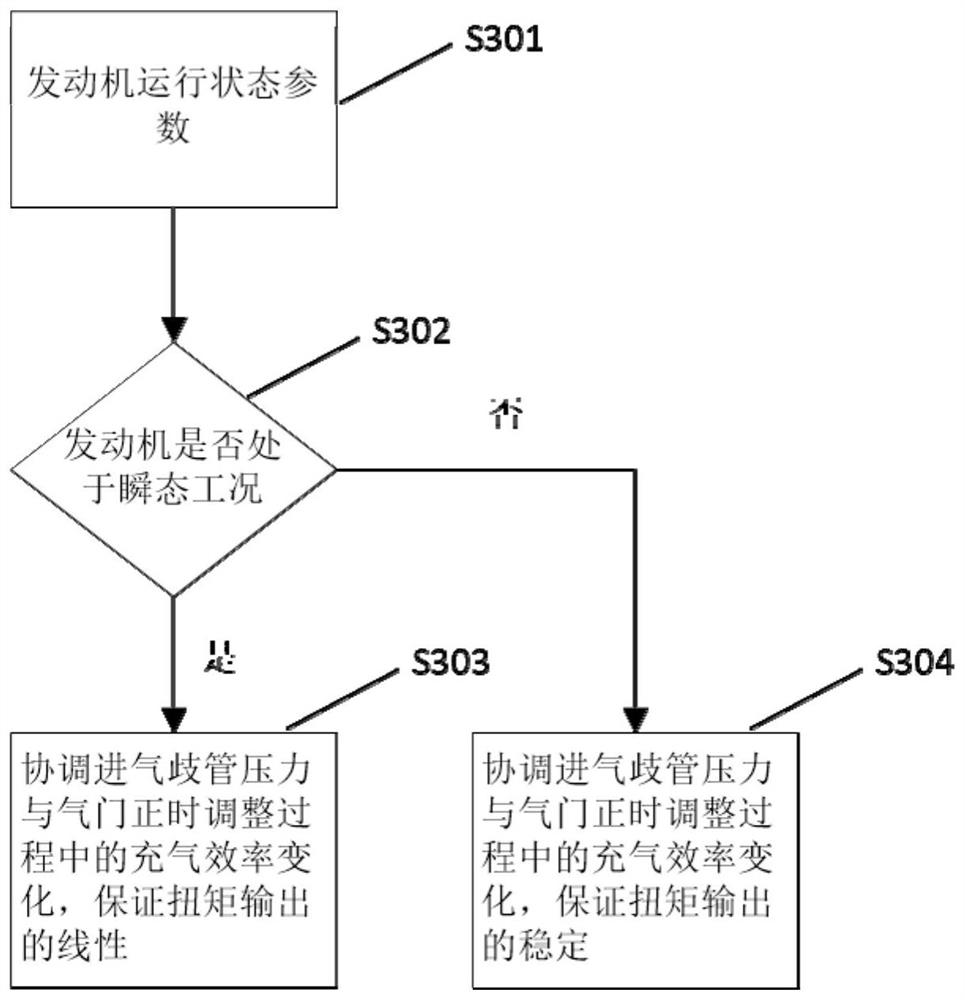

Transient control method and device for Variable valve timing system and Miller cycle engine

ActiveCN113357023AImprove driving experienceInternal combustion piston enginesOutput powerVariable valve timingMiller cycle

The invention provides a transient control method and device for a variable valve timing system and a Miller cycle engine, and the method comprises the following steps: 1, judging whether an engine enters a transient working condition or not according to obtained engine operation state parameters; 2, determining target valve timing according to the rotating speed and the target load, and judging whether the inflation efficiency of the target valve timing is smaller than the inflation efficiency of the current valve timing or not; 3, keeping the current valve timing unchanged; and 4, adjusting valve timing to the target position, in the valve timing adjusting process, according to different operation states of the engine, coordinating the inflation efficiency change caused by the pressure of the intake manifold and the valve timing change, and achieving different torque output characteristics. The invention aims to at least solve the drivability problems of slow torque transient response and torque pit falling mentioned in the background technology.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

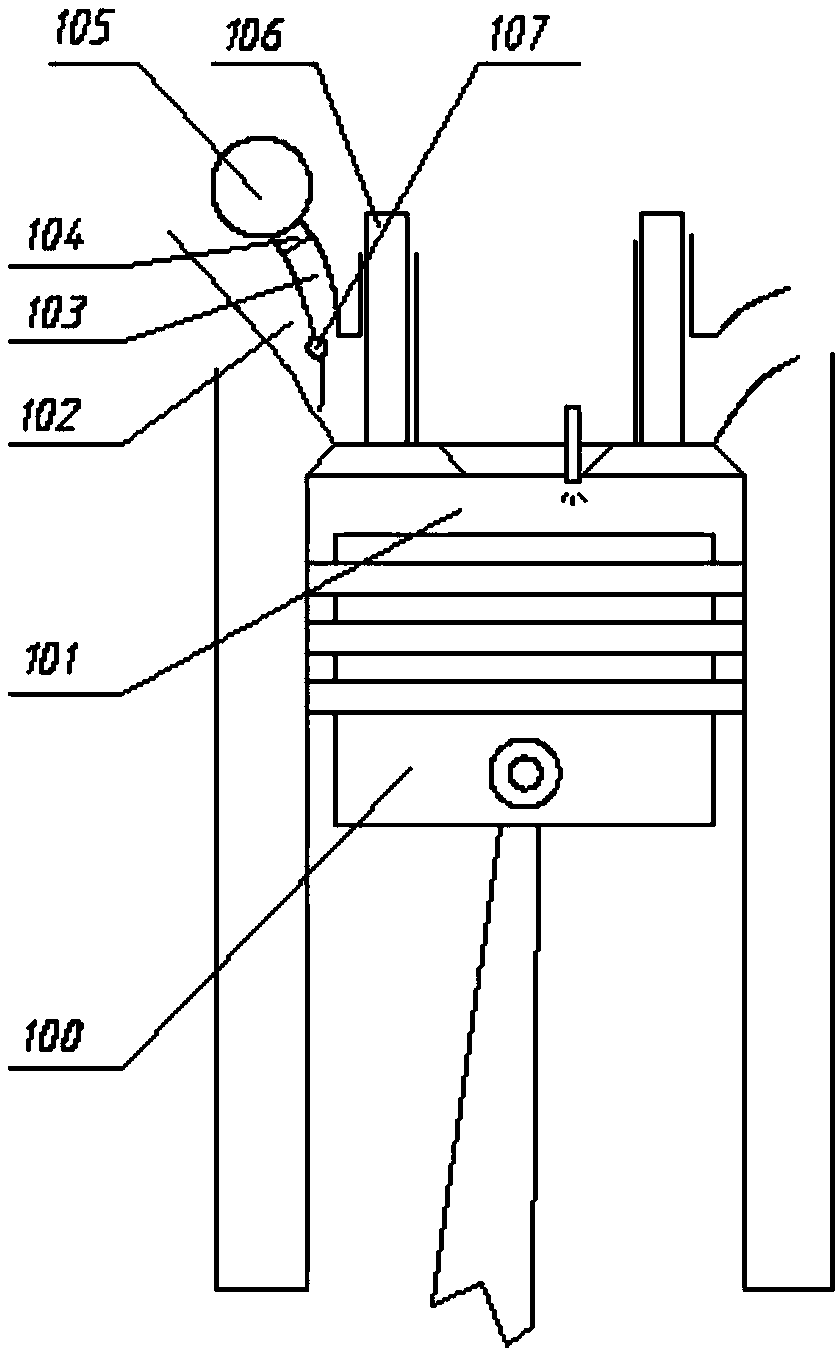

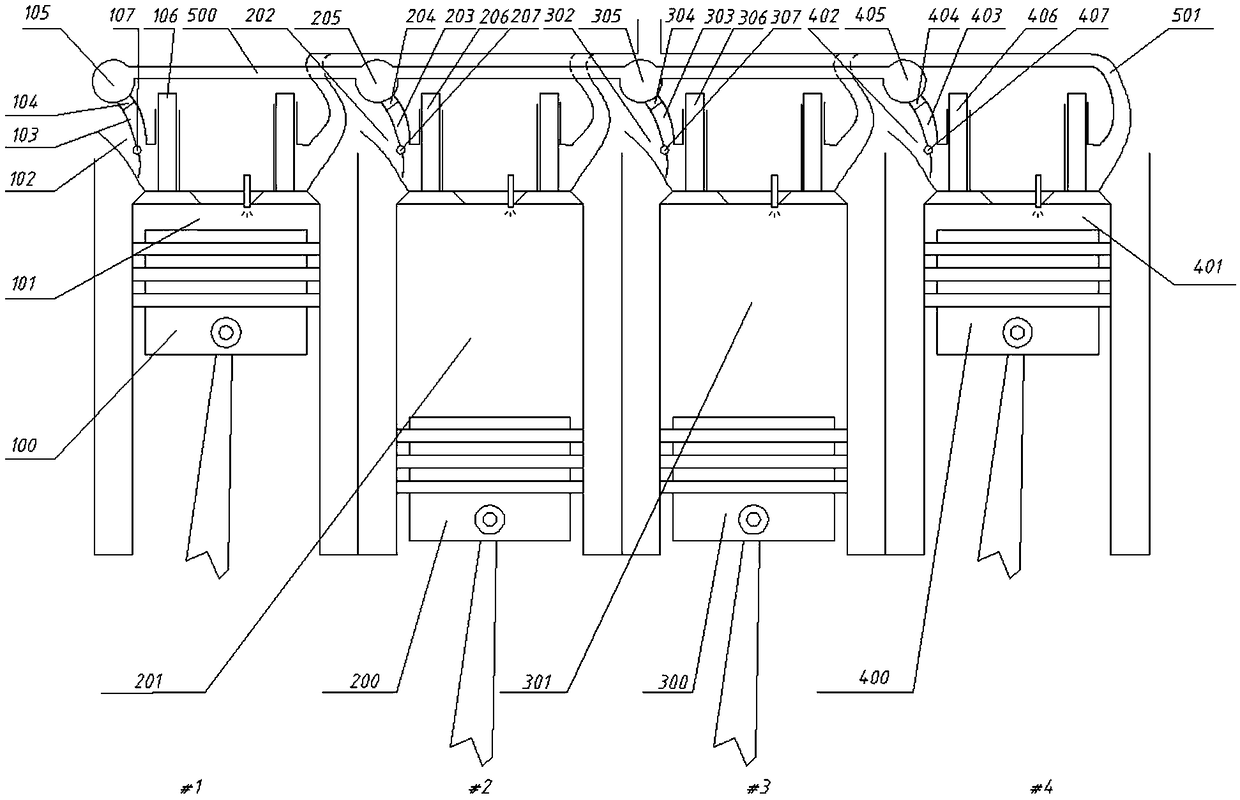

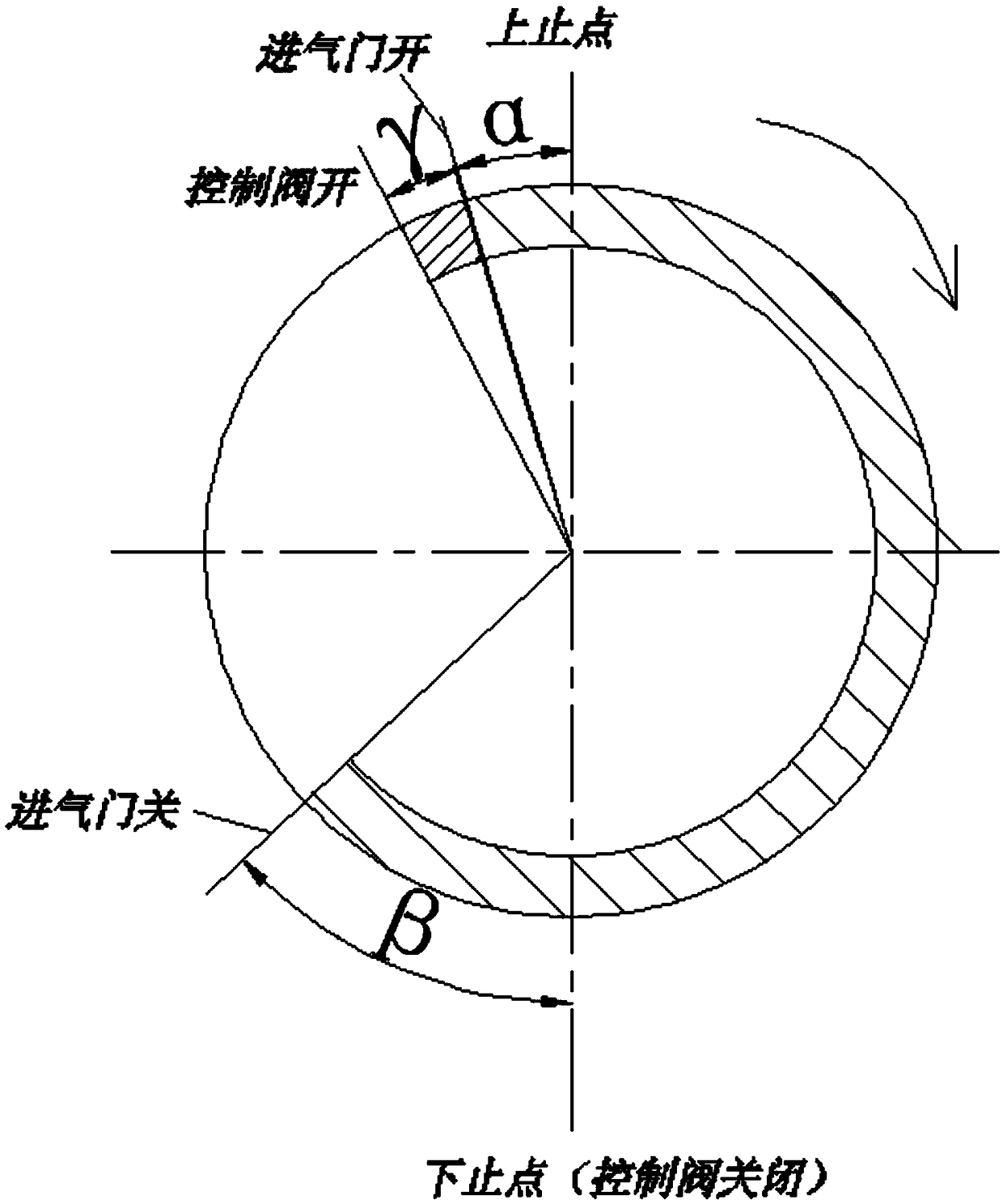

Multi-cylinder Miller cycle engine synergetic gas intake energy-saving device and control method thereof

PendingCN108798874AReduce refluxAchieve recyclingInternal combustion piston enginesEngine controllersCombustion chamberInlet valve

The invention discloses a multi-cylinder Miller cycle engine synergetic gas intake energy-saving device and a control method thereof. The device comprises a gas storage chamber, a control valve and amechanical movable valve, wherein the gas storage chamber communicates with an inlet valve through a gas inlet branch pipe and is used for storing high-pressure low-temperature combustible mixed gas of a combustion chamber; the control valve is arranged in the gas inlet branch pipe and used for controlling opening and closing of a channel; the mechanical movable valve has the one-way communicatingfunction; gas can get into the combustion chamber from a main gas inlet pipeline, and gas in the combustion chamber cannot return. When the control valve is turned on, the high-pressure low-temperature combustible mixed gas gets into the combustion chamber and is combusted with intake gas of a gas inlet main pipe to do work. The engine synergetic gas intake device provided by the invention can temporarily store the high-pressure low-temperature combustible mixed gas discharged from a Miller engine during compression travel and supplies gas together with the inlet valve when a next cylinder takes in the gas. Meanwhile, according to the turn-on time of the control valve, the whole engine is equivalent to a variable compression ratio engine, and the comprehensive performance of the engine isimproved.

Owner:JILIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com