Method for realizing accurate equipower torque characteristics

A torque characteristic and equal power technology, applied in the field of turbocharged diesel engines, can solve the problems of reducing diesel engine efficiency, reducing exhaust energy recovery, complex structure, etc., to expand the speed adaptability coefficient and expand torque adaptability coefficient, reducing the effect of shifting operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

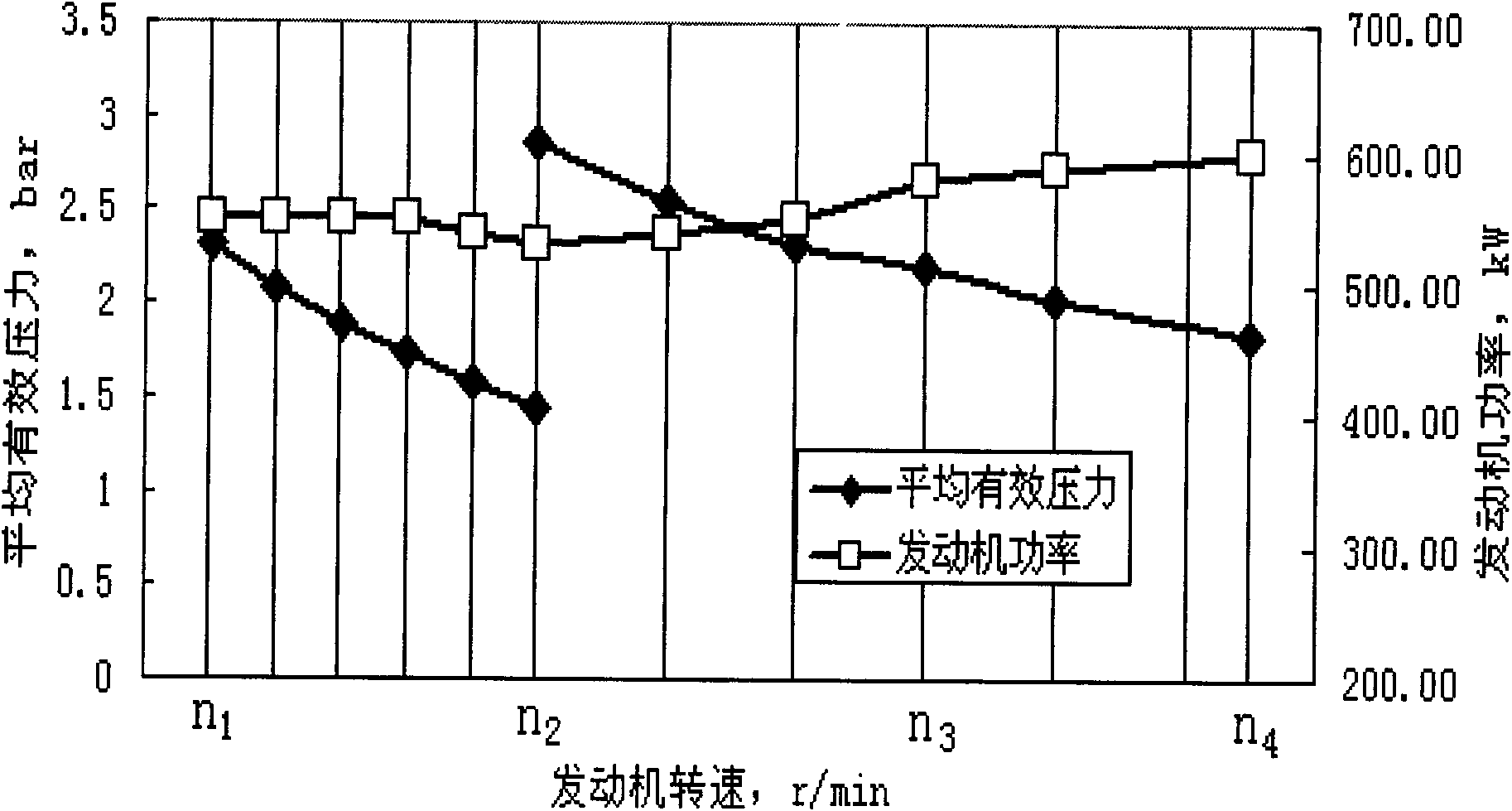

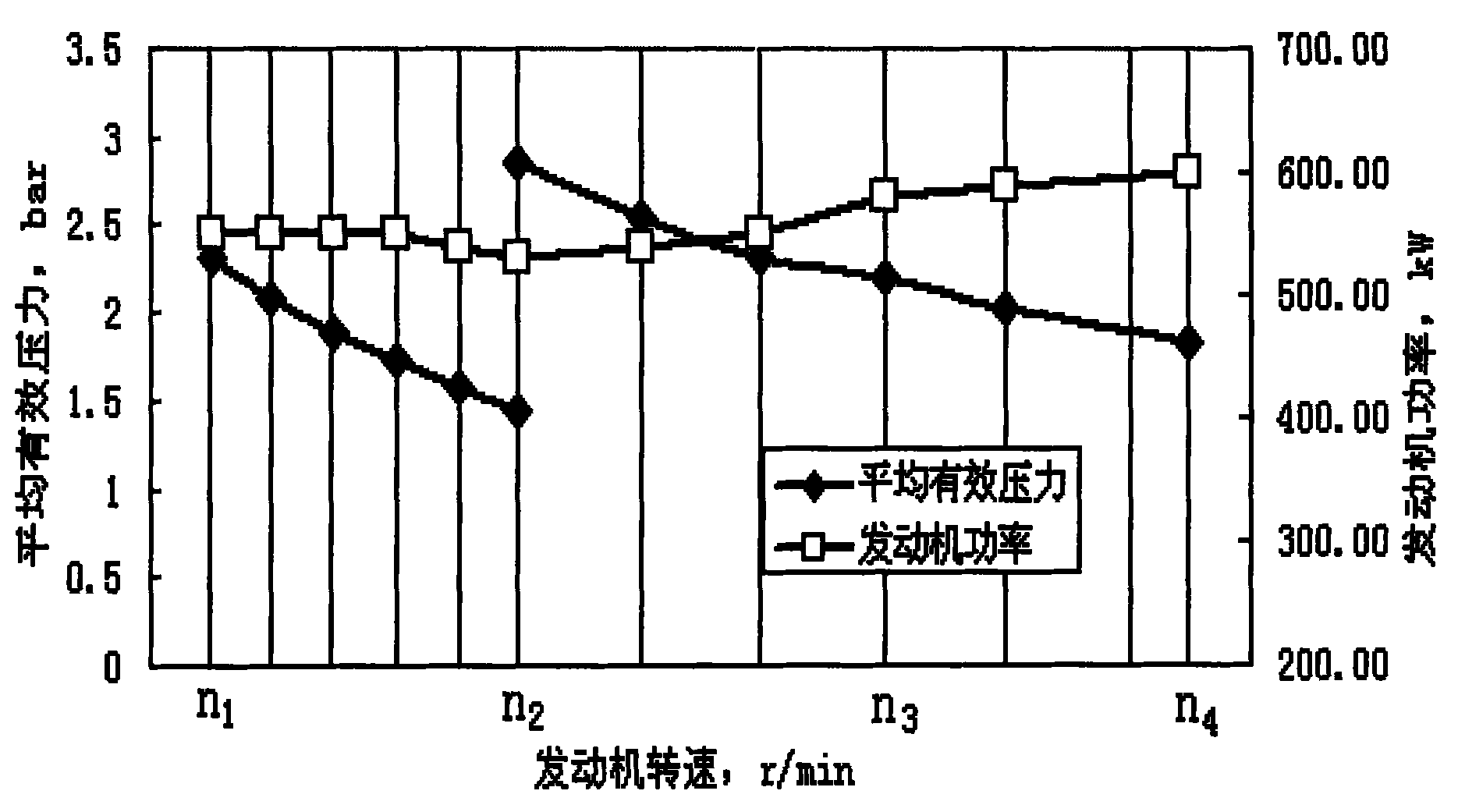

[0037] The main idea of the technical solution of the present invention is under the premise that the maximum explosion pressure and heat load of the diesel engine are within the allowable range, multiple circulation modes such as Hyperbrid supercharging system, Miller cycle / symmetrical cycle and 2 / 4 stroke cycle are adopted, The pressure and flow stepless adjustable air management system and other technical means realize the quasi-equal power torque characteristic of the diesel engine whose torque adaptability coefficient and speed adaptability coefficient are both greater than 2.5.

[0038] The invention adopts the camless variable valve phase technology to realize the process control of Miller cycle / symmetrical cycle and the switching of 2 / 4 stroke cycle. The valve mechanism is directly driven ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com