Miller cycle engine

A Miller cycle and engine technology, applied in engine components, engine control, combustion engines, etc., can solve the problems of mechanical strength or thermal load, undisclosed Miller cycle engine thermal efficiency, and inability to obtain heat efficiency of pumping work, etc. , to achieve the effect of increasing the suction work and improving the thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

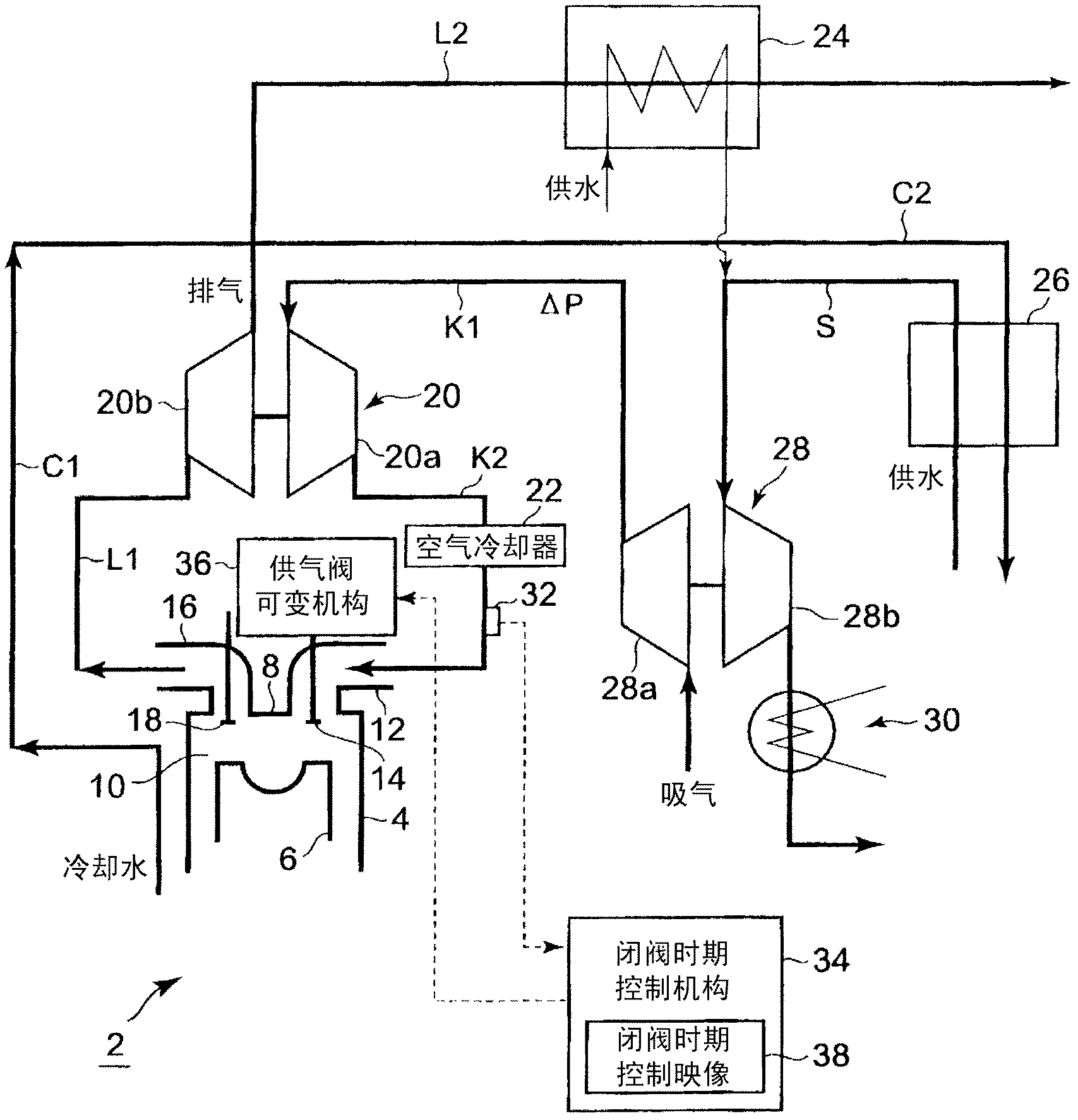

[0042] figure 1 It is an overall configuration diagram of a Miller cycle engine (hereinafter referred to as an engine) 2 according to the first embodiment of the present invention.

[0043] exist figure 1 Herein, the engine 2 is described as an example of a four-stroke gas engine, but it is not limited to the gas engine.

[0044] In the cylinder 4 of the engine main body, there are provided a piston 6 that is reciprocally slidably fitted, and a crankshaft that converts the reciprocating movement of the piston 6 into rotation via a connecting rod not shown, and is provided above the piston 6. A combustion chamber 10 formed between the surface and the inner surface of the cylinder head 8, an air supply port 12 connected to the combustion chamber 10, and an air supply valve 14 for opening and closing the air supply port 12 are also equipped with An exhaust port 16 connected to the chamber 10 and an exhaust valve 18 that opens and closes the exhaust port 16 .

[0045] In addi...

no. 2 approach

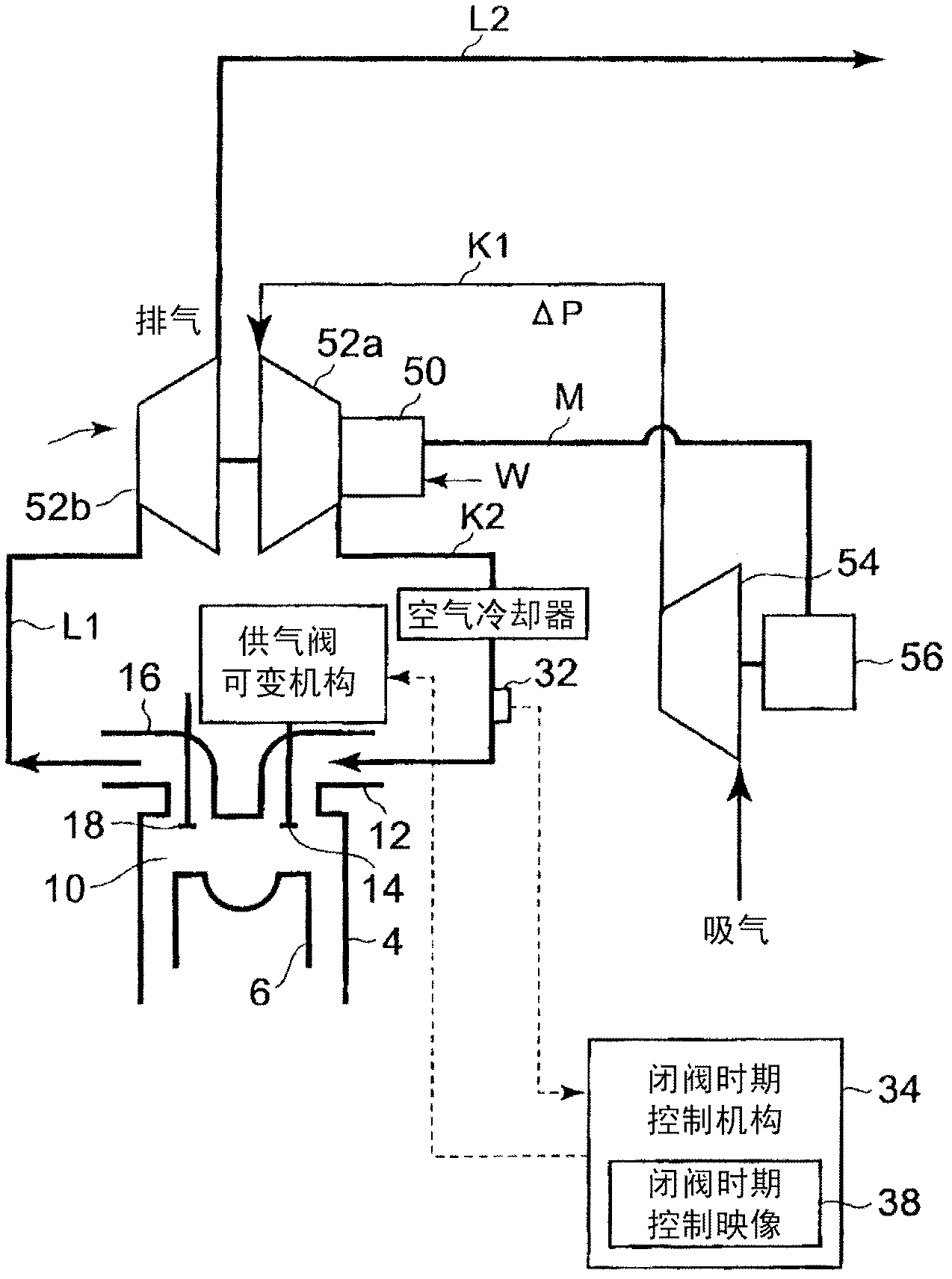

[0071] refer to figure 2 , to describe the second embodiment.

[0072] The second embodiment uses electric power generated by exhaust gas as regenerative energy of the engine.

[0073] Such as figure 2 As shown, the supercharger is composed of a hybrid supercharger 52 with a built-in generator motor 50 , and the air supply blower provided on the air supply passage K1 upstream of the hybrid supercharger 52 is driven by electric power generated by using exhaust gas. 54, thereby generating additional air supply pressure.

[0074]The hybrid supercharger 52 is composed of a compressor unit 52a and a turbine unit 52b, and the generator motor 50 is built in the compressor unit 52a. Power is generated by the rotation of the compressor unit 52a, and the generated power is supplied to the blower motor 56 that drives the air supply blower 54 through the power supply line M. The rotation speed of the blower motor 56 is controlled using an inverter or an increase / decrease gear (not s...

no. 3 approach

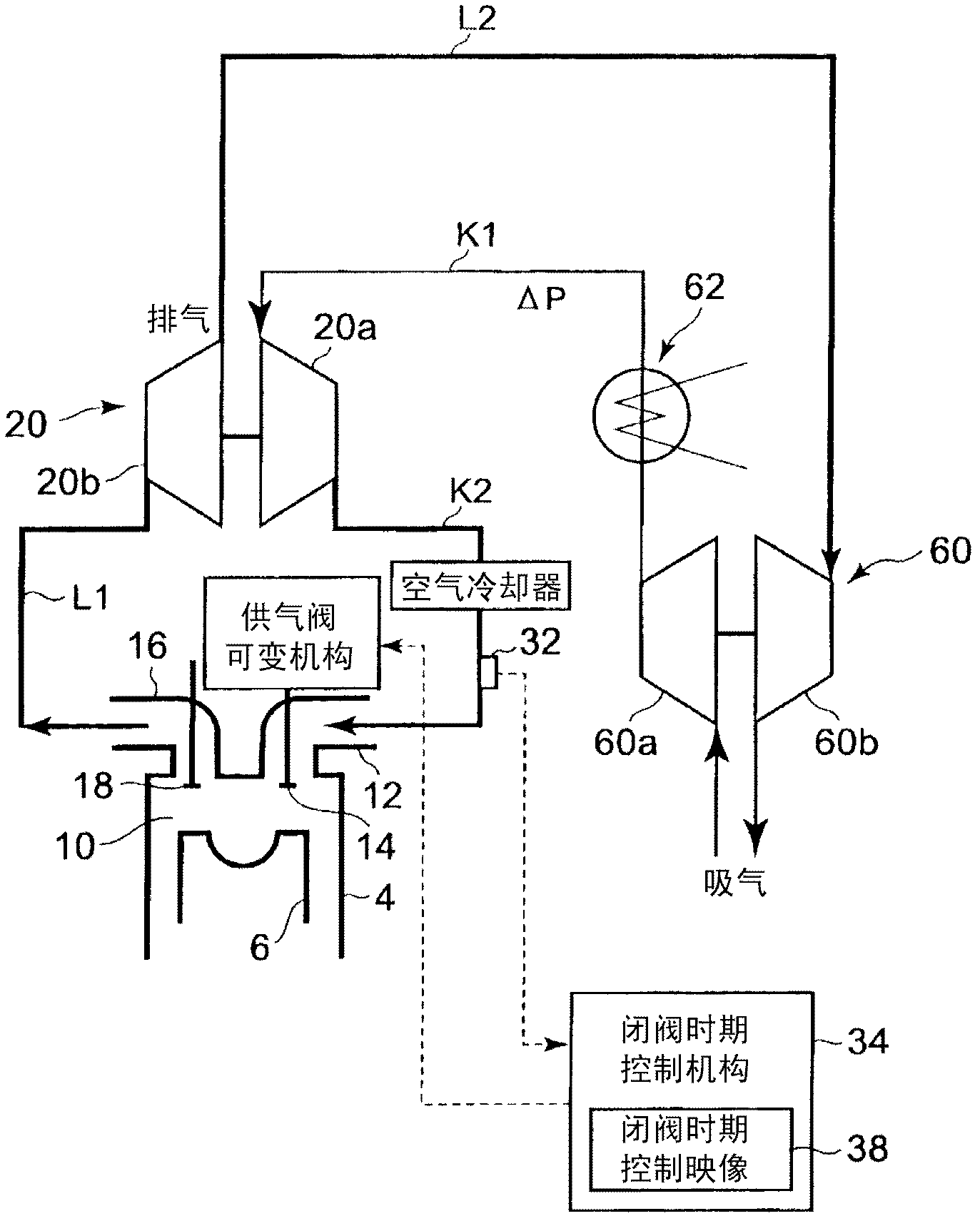

[0079] Next, refer to image 3 , to describe the third embodiment. This third embodiment drives the front-stage supercharger 60 using exhaust gas as regenerative energy of the engine. That is, a precharger 60 is provided instead of the steam turbine 28 described in the first embodiment.

[0080] Such as image 3 As shown, the exhaust gas having passed through the turbine portion 20b of the supercharger 20 flows into the turbine portion 60b of the pre-supercharger 60 to drive the compressor portion of the pre-supercharger 60 coaxially provided with the turbine portion 60b. 60a to pressurize the air supply. In order to supply the pressurized supply air to the compressor section 20a of the supercharger 20 and further pressurize it, the compressed air passes through both the compressor section 60a of the pre-stage supercharger 60 and the compressor section 20a of the supercharger 20. Stage supercharging composition.

[0081] In addition, an air cooler 62 is provided in the ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com