Valve electro-hydraulic driving system and method for achieving Miller cycle of engine

A Miller cycle and engine technology, applied in engine components, combustion engines, machines/engines, etc., can solve problems such as not meeting the optimal performance of the engine and unsuitable for the application of Miller cycle, and achieve the maximum lift controllable, maximum Stable lift opening and less impact on seating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

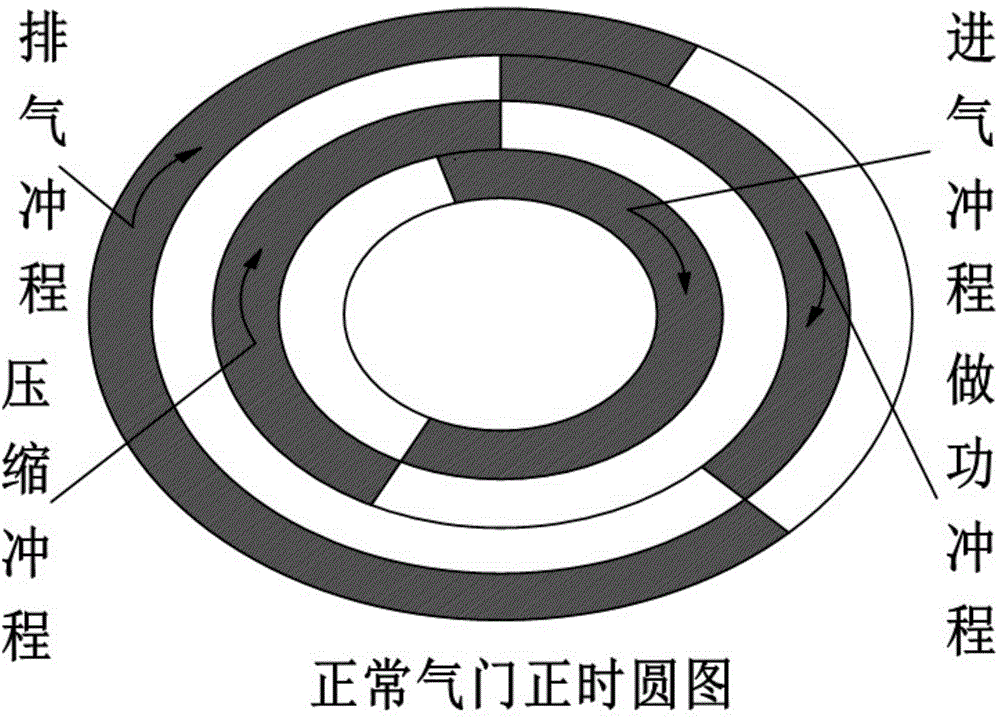

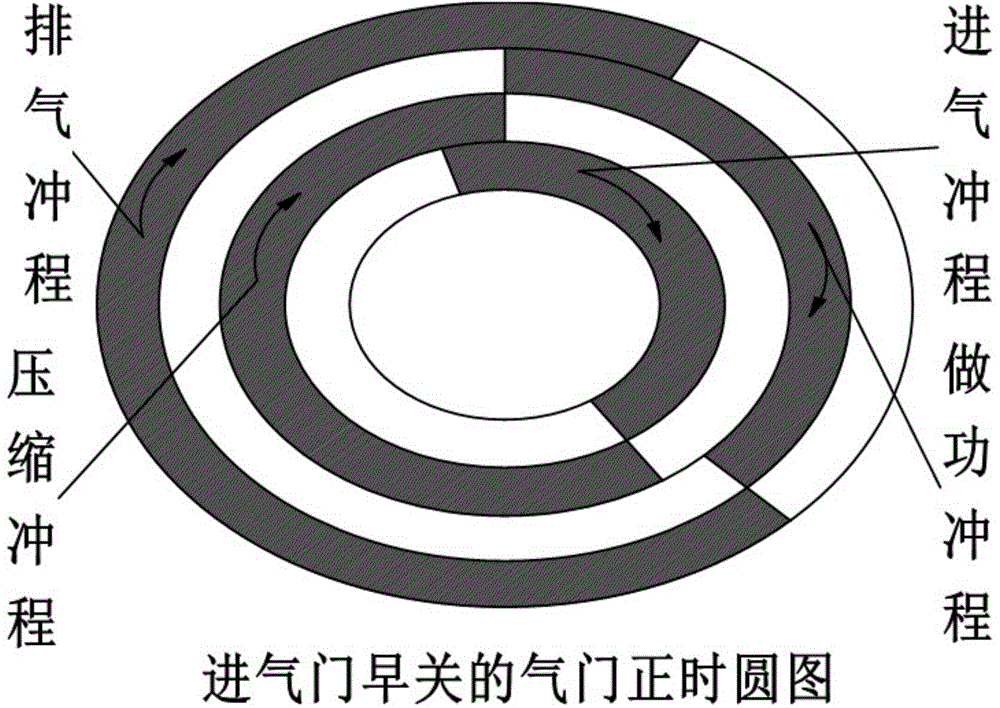

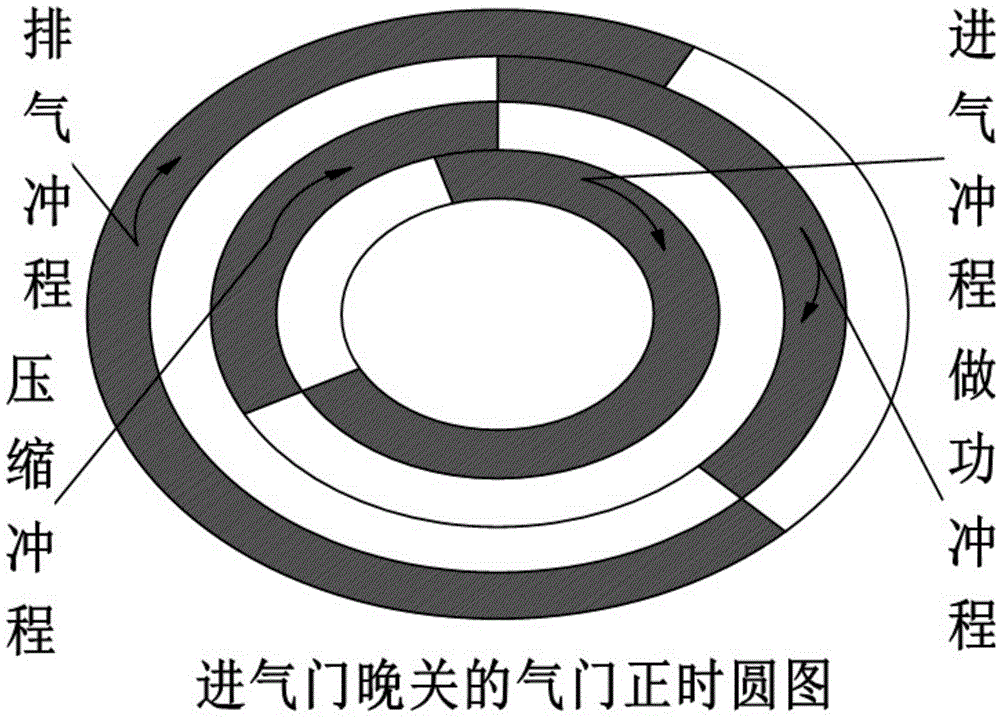

[0020] The present invention is described in more detail below in conjunction with accompanying drawing example:

[0021] Combined with Figures 1 to 4, the system consists of the following four main parts, crankshaft position sensor, electronic control unit (ECU), electro-hydraulic fully variable valve drive mechanism, and valve displacement sensor. Among them, the crankshaft position sensor is a commercially available Hall effect sensor, which is used to measure the position of the bottom dead center (BDC) of the crankshaft; the core component of the electronic control unit is a single-chip microcomputer using Freescale 9S12 series; the fully variable electro-hydraulic drive mechanism mainly includes Feedback chamber composed of high-pressure fuel tank, low-pressure fuel tank, two-position three-way solenoid valve V1, normally open solenoid valve V2, conical slide valve Vc, and a propulsion chamber composed of main piston P1 and feedback piston P2 (P1P2 rigidly connected); Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com