Patents

Literature

32results about How to "Strong technical versatility" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

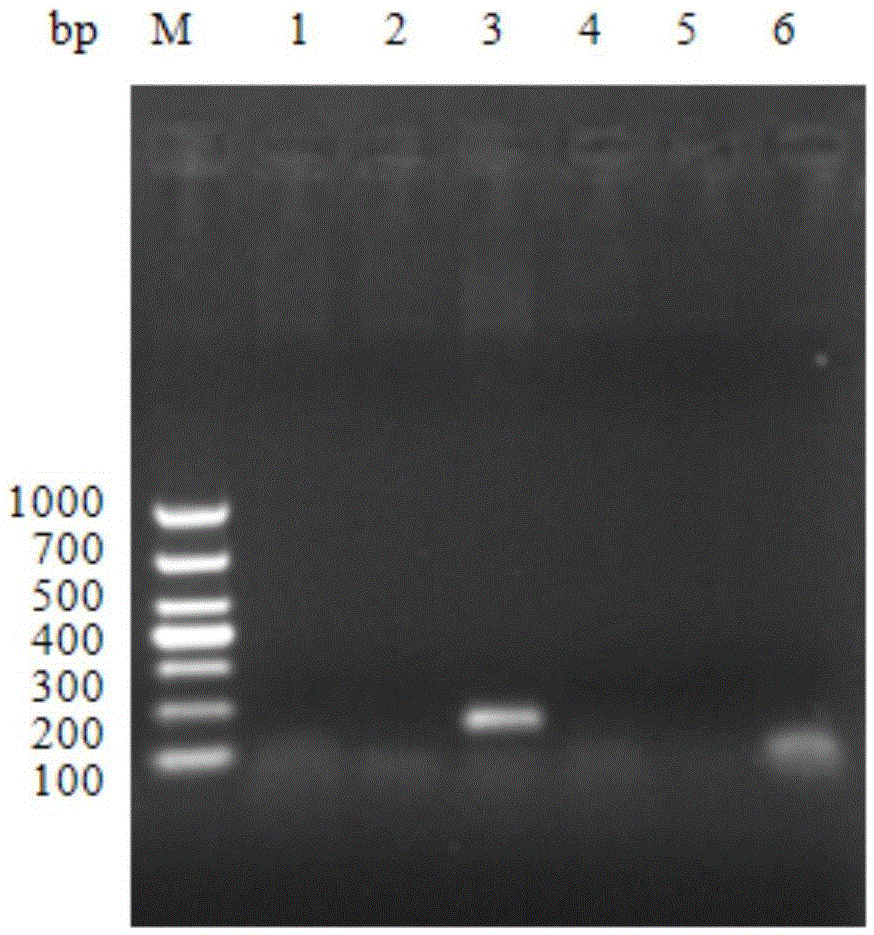

Kit for identifying fruit flies and special primers therefor

InactiveCN102517388AStrong representativeGuaranteed accuracyMicrobiological testing/measurementDNA/RNA fragmentationEcology

Owner:CHINA AGRI UNIV +1

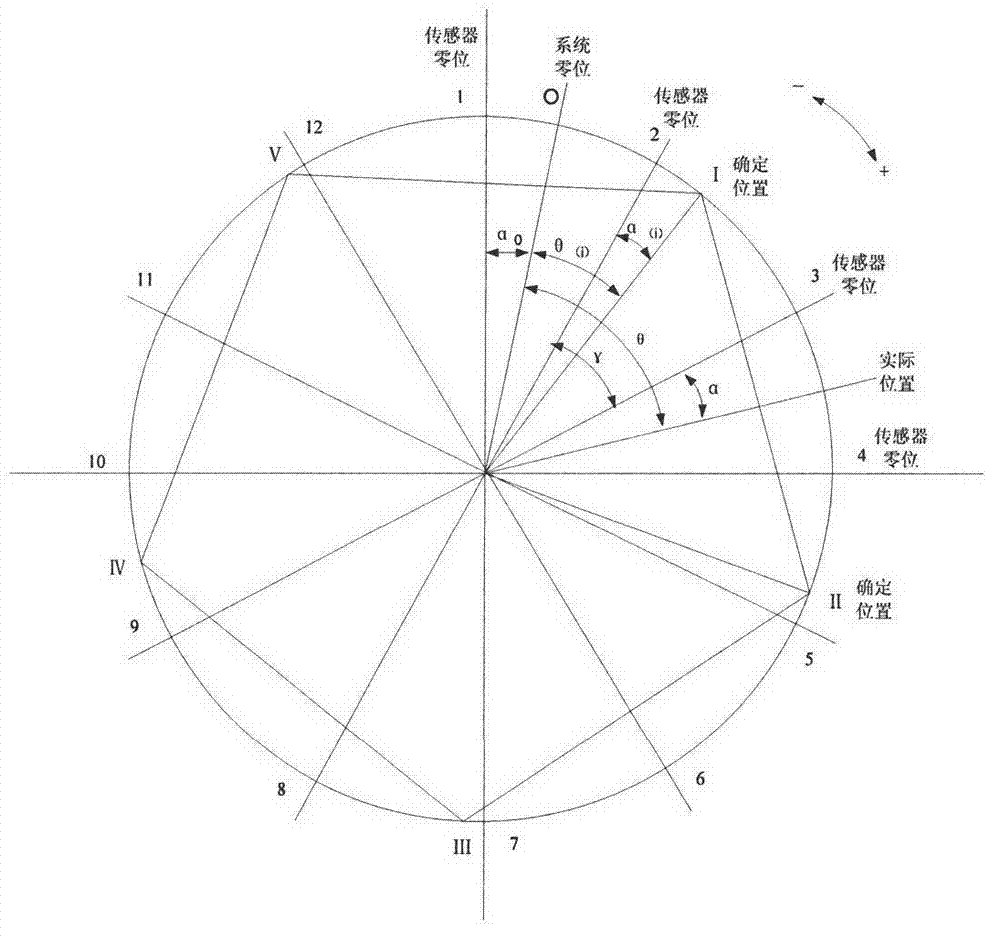

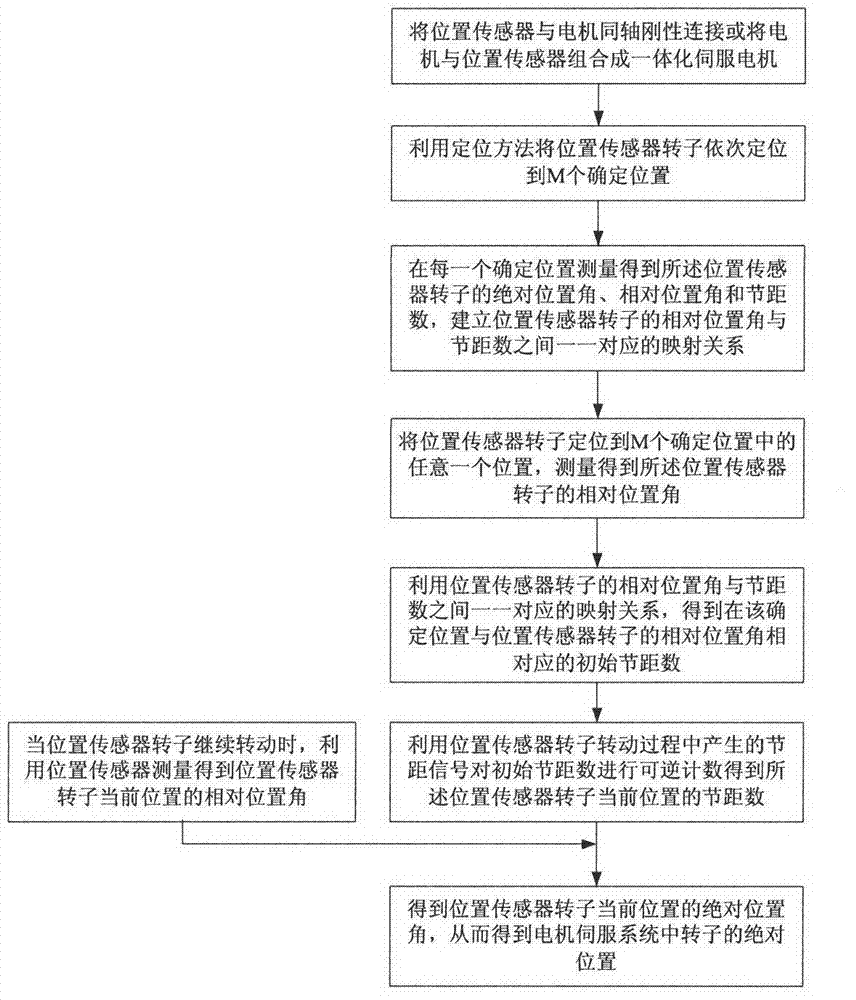

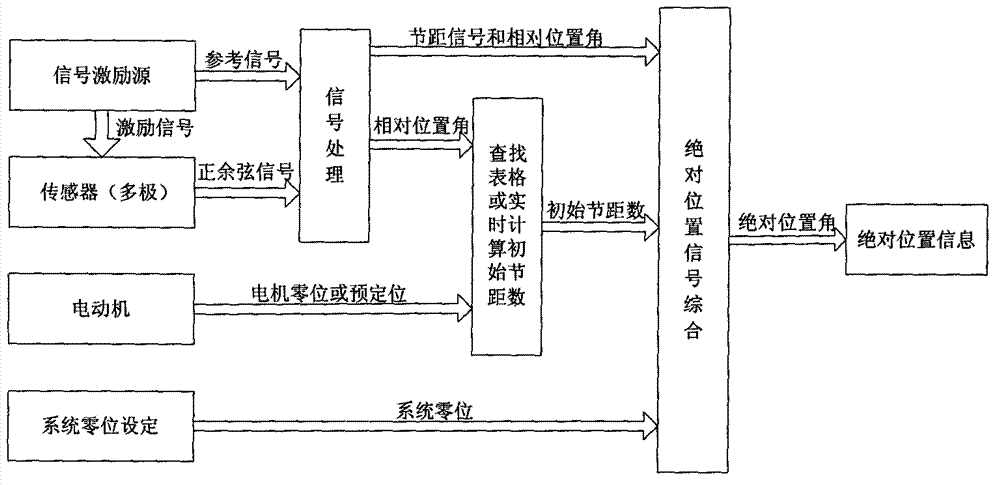

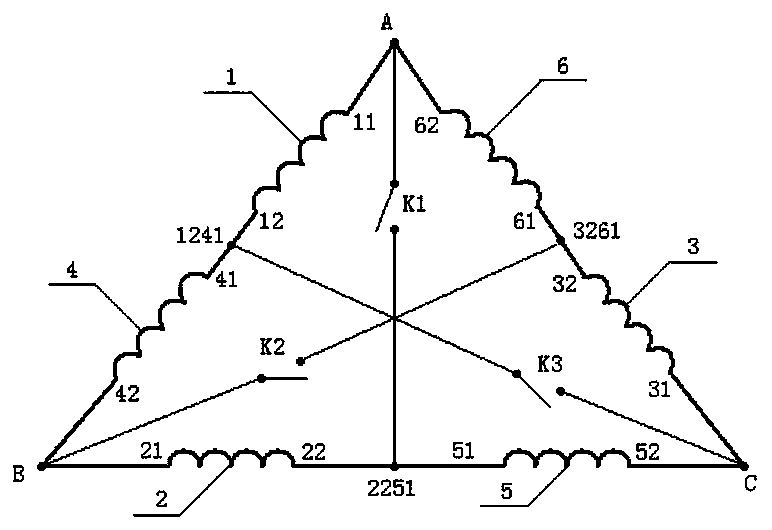

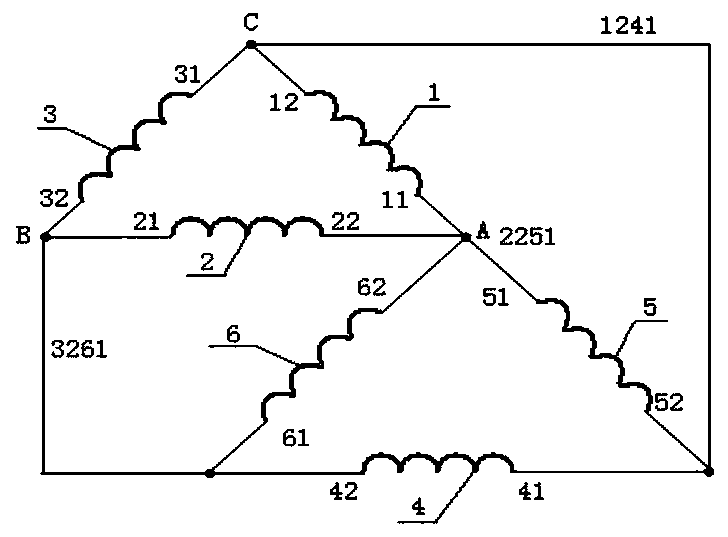

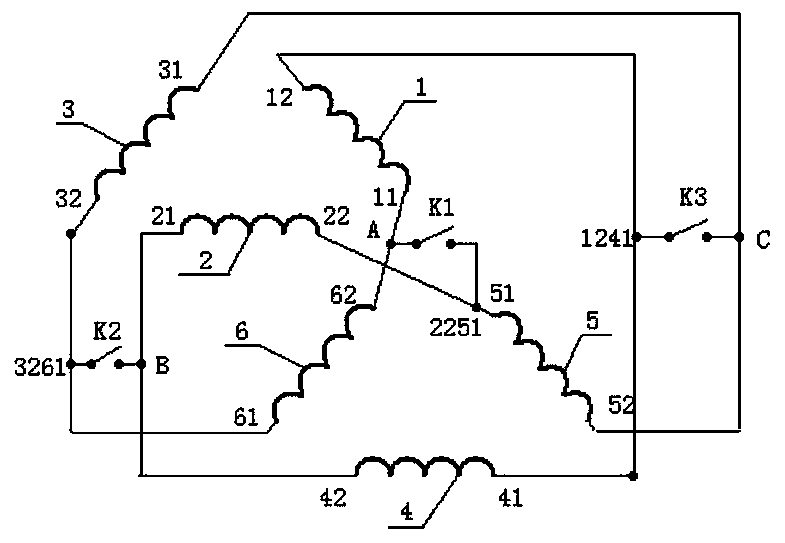

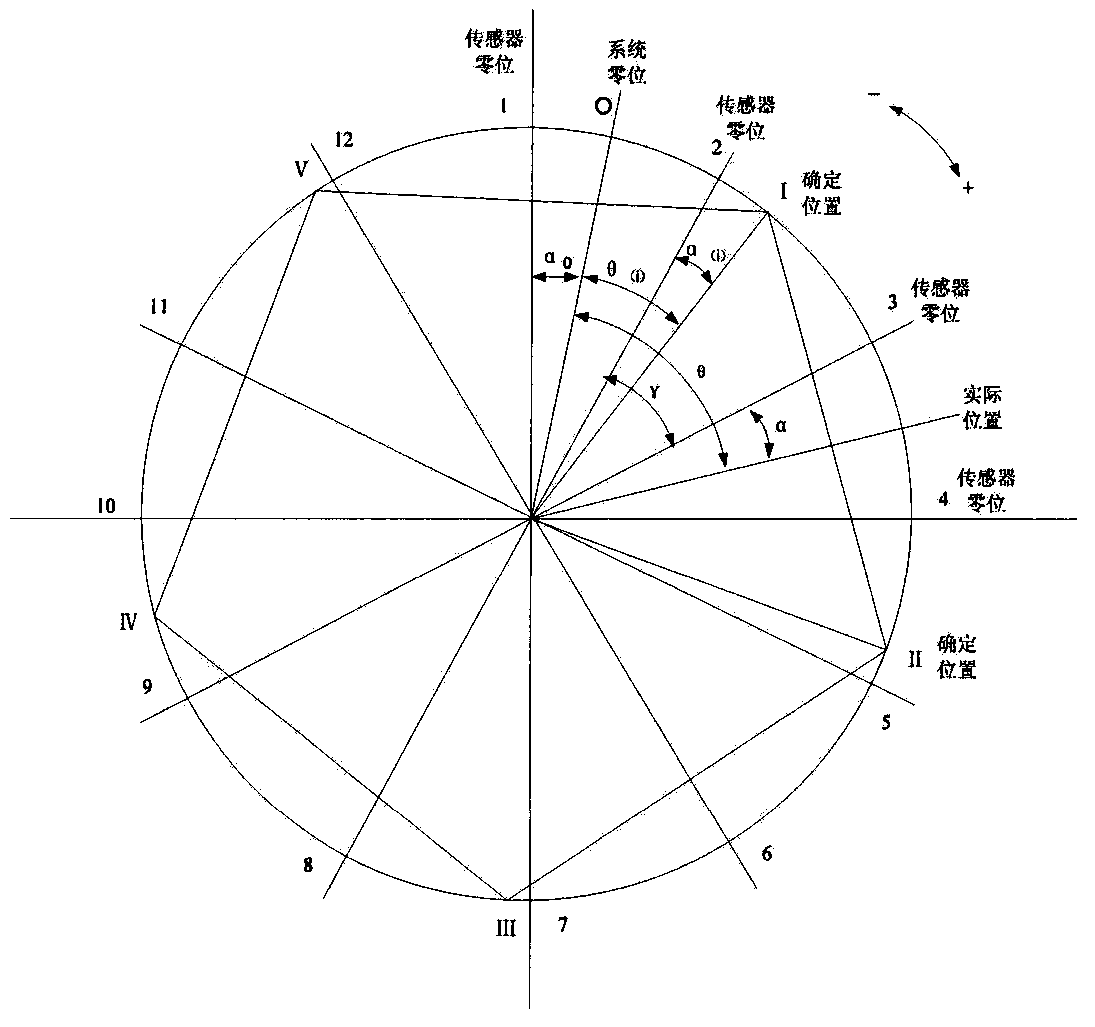

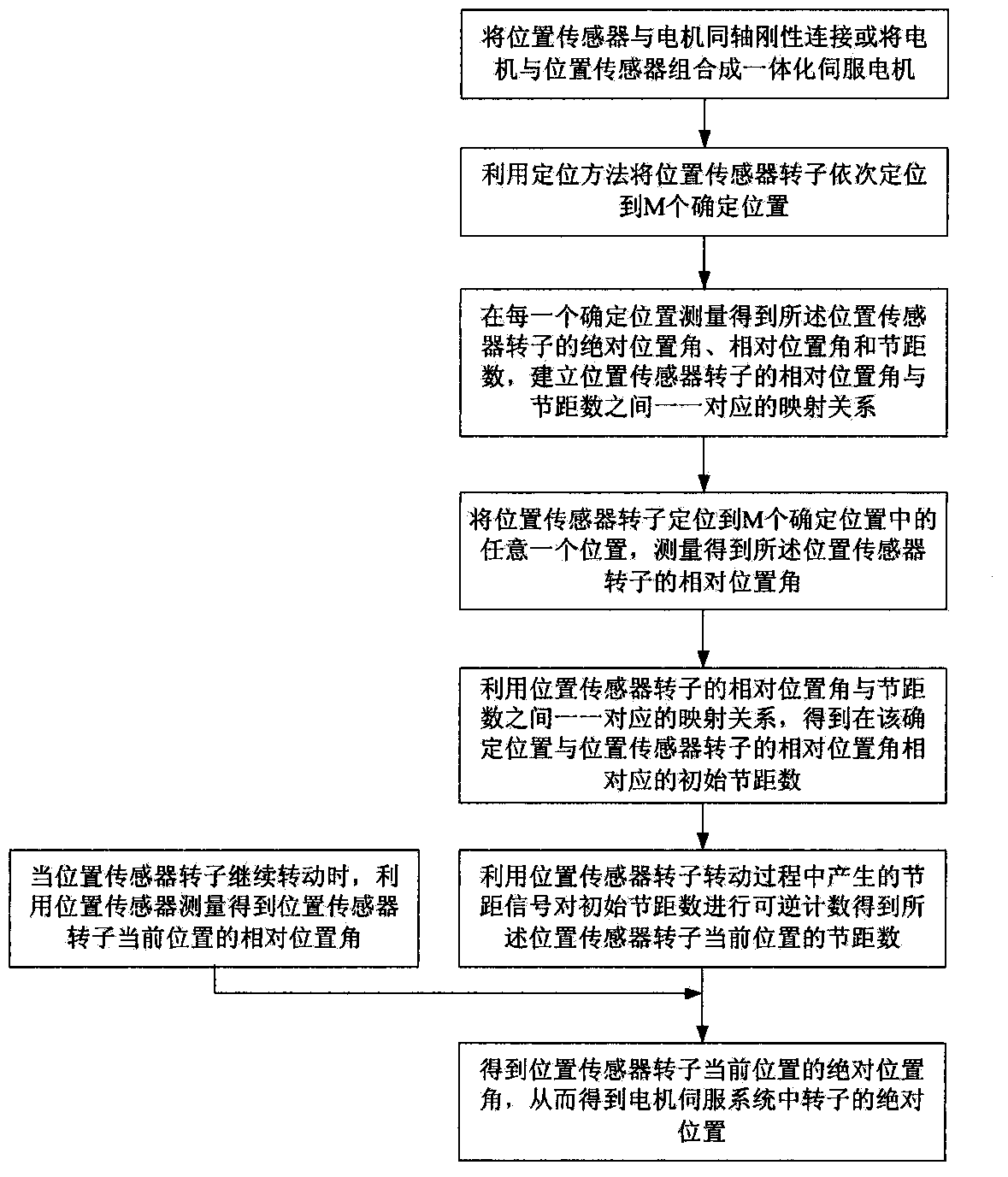

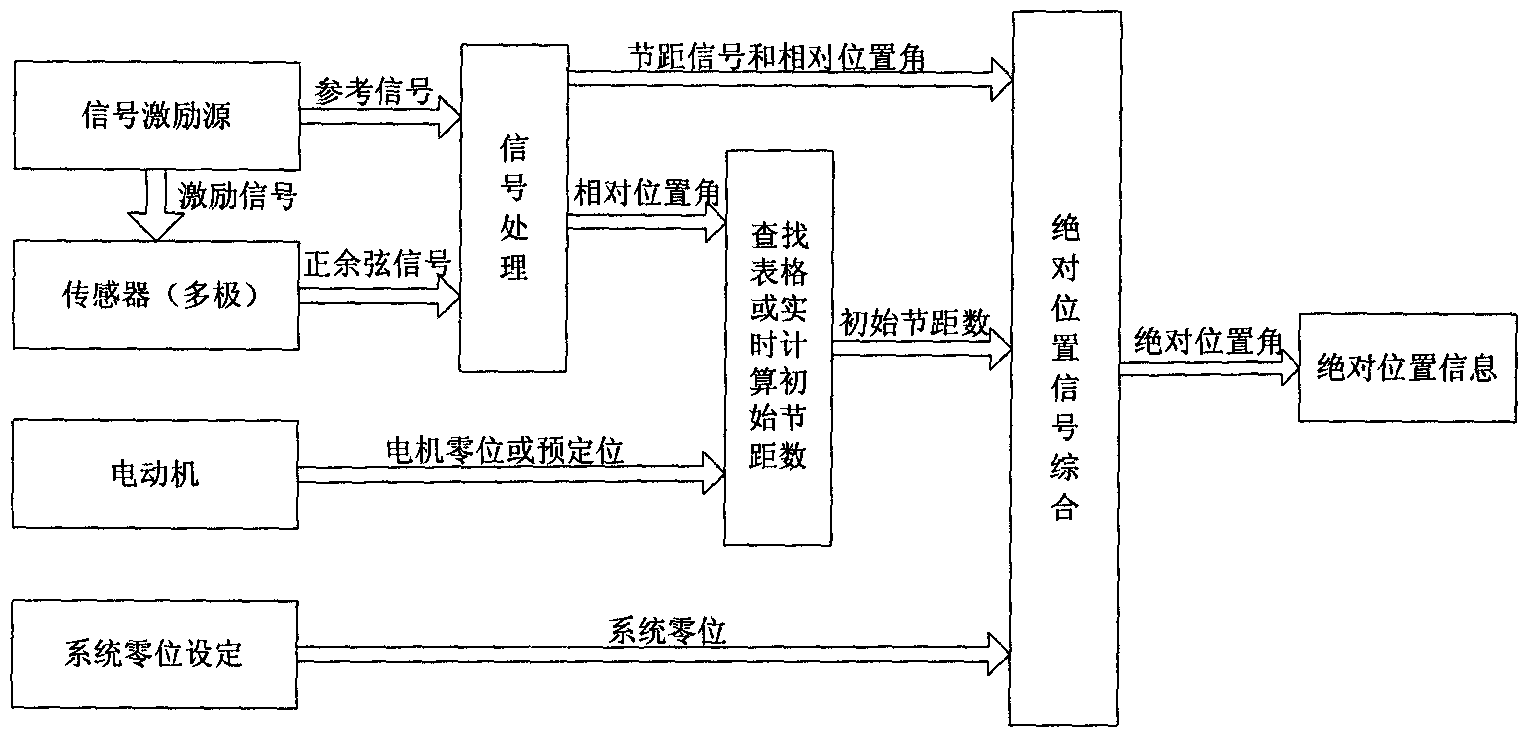

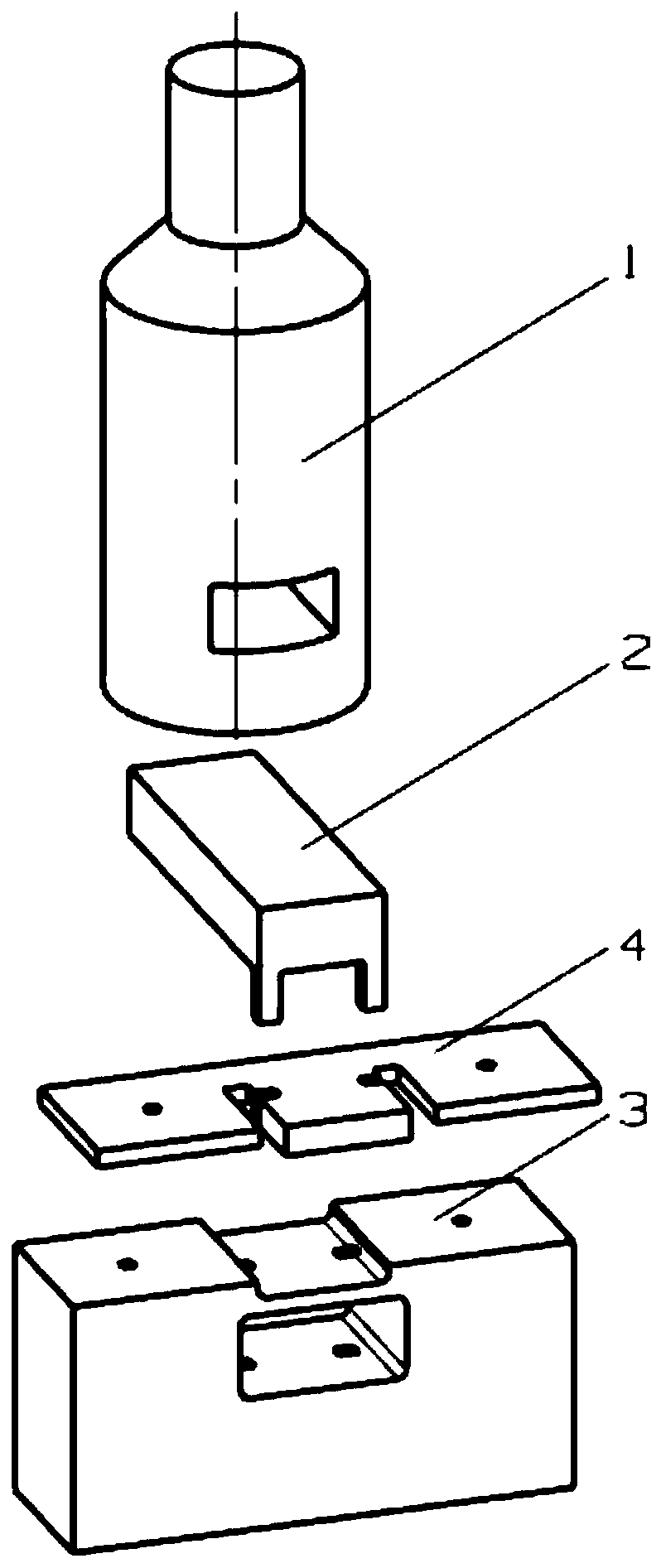

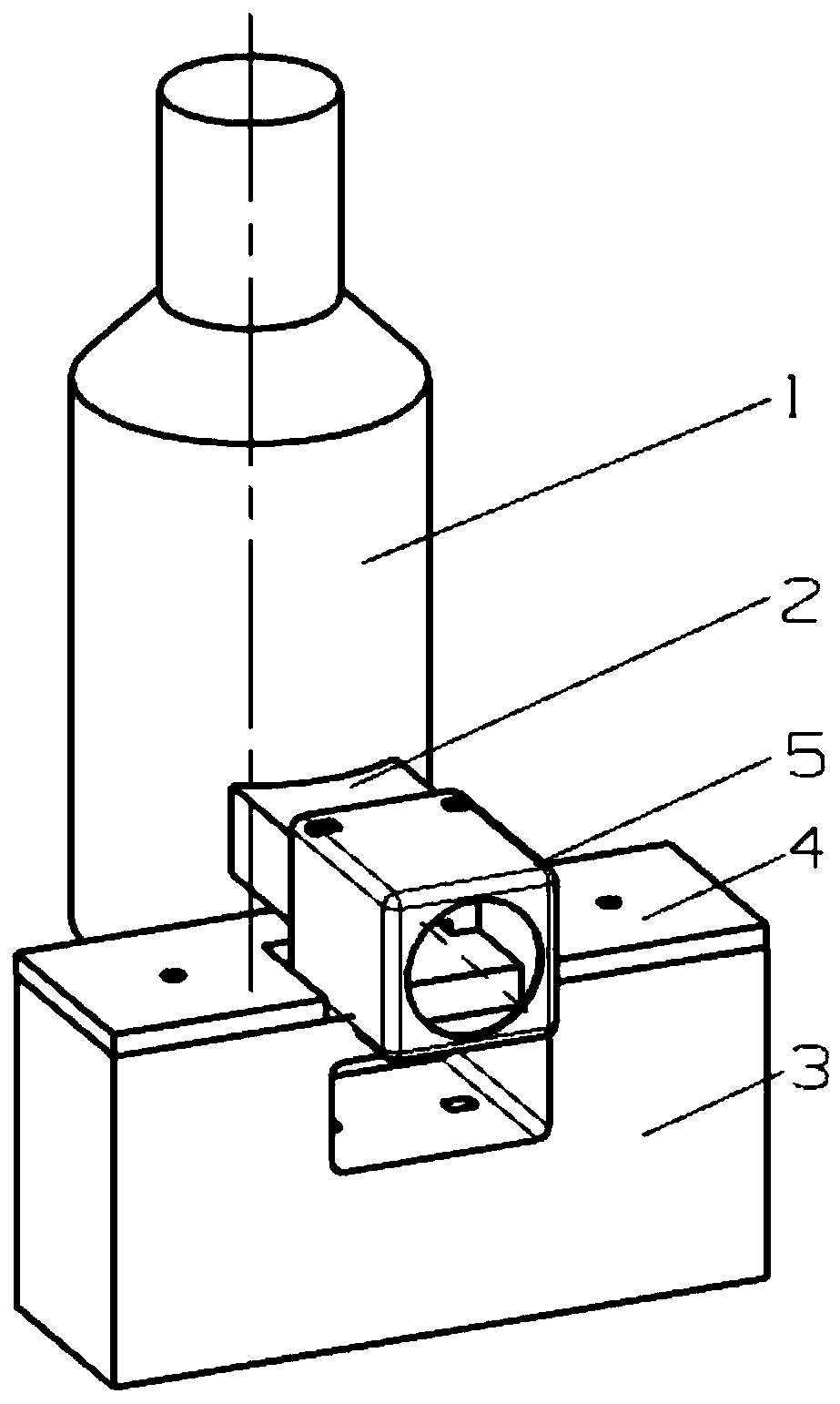

Method for measuring absolute position of rotor in motor servo system

ActiveCN102829742ASimple mechanical structureReduce volumeMeasurement devicesSignal processing circuitsCoupling

The invention discloses a method for measuring the absolute position of a rotor in a motor servo system, comprising the steps of: integrally combining the motor and a position sensor; and by utilizing position information provided by a predetermined position as well as relative position information and pitch information provided by the sensor, and recombining the position information through using a proper method so as to obtain absolute position information of the motor rotor. According to the method, a zero position indicator is not required; after outage, the absolute position of a zero position of a relative system of the motor rotor can be obtained through the predetermined position of the motor rotor; compared with a coarse / fine coupling double-speed rotary transformer system, the high-precision absolute position information is obtained by using the simple and reliable sensor, so that the structure of the integrated high-performance servo motor is simplified and decreased, then the structure is more compact and the volume is decreased; and at the same time, a signal processing circuit and coarse / fine coupling operation are decreased, so that compared with the coarse / fine coupling double-speed rotary transformer system, the performance-price ratio is improved and the complexity level is reduced.

Owner:BEIJING PULIMEN ELECTRO MECHANICAL HIGH TECHN CO

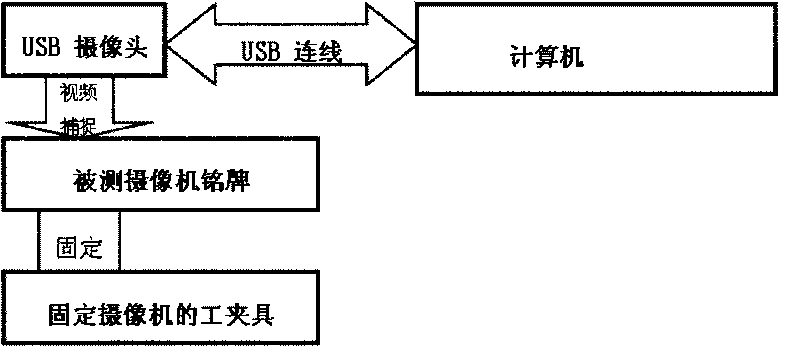

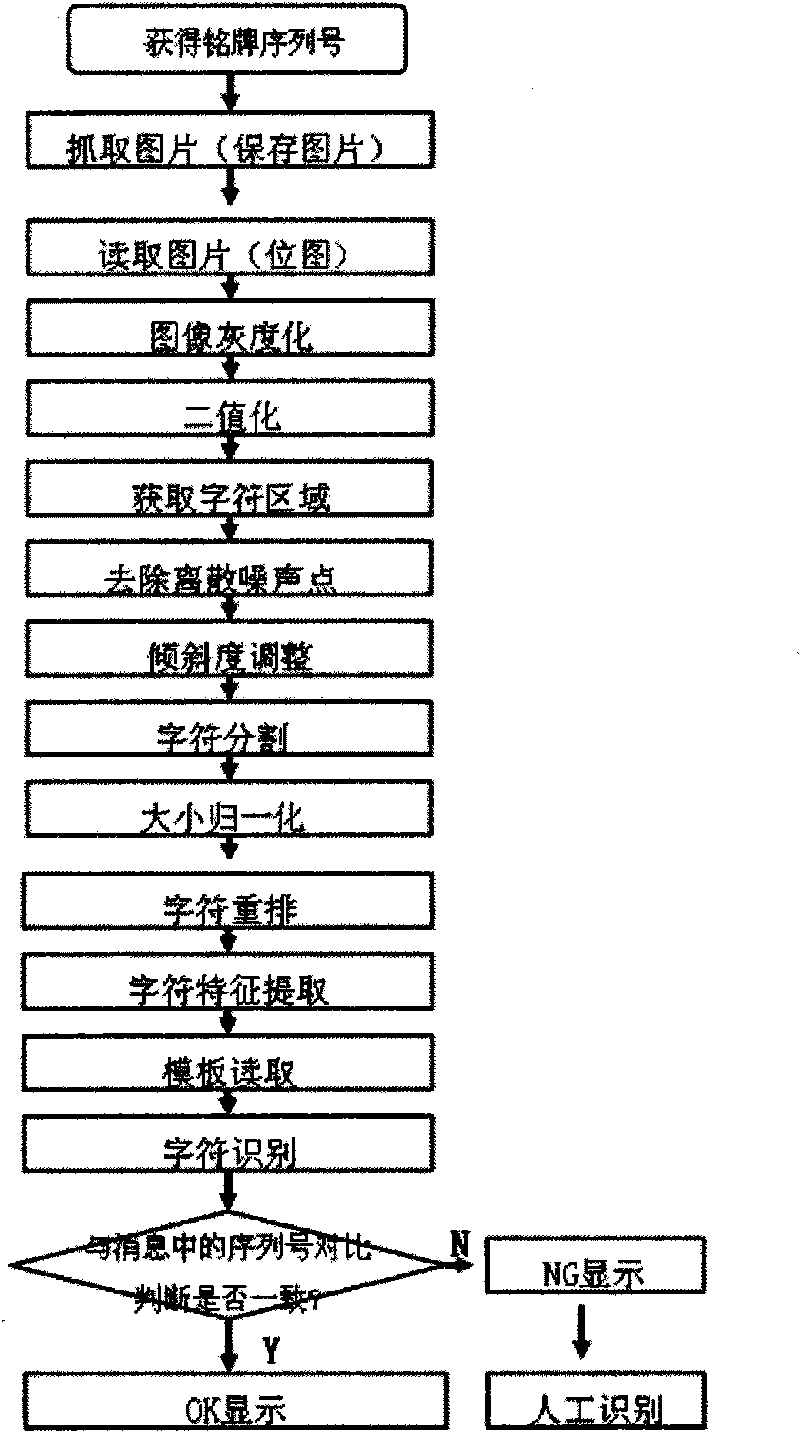

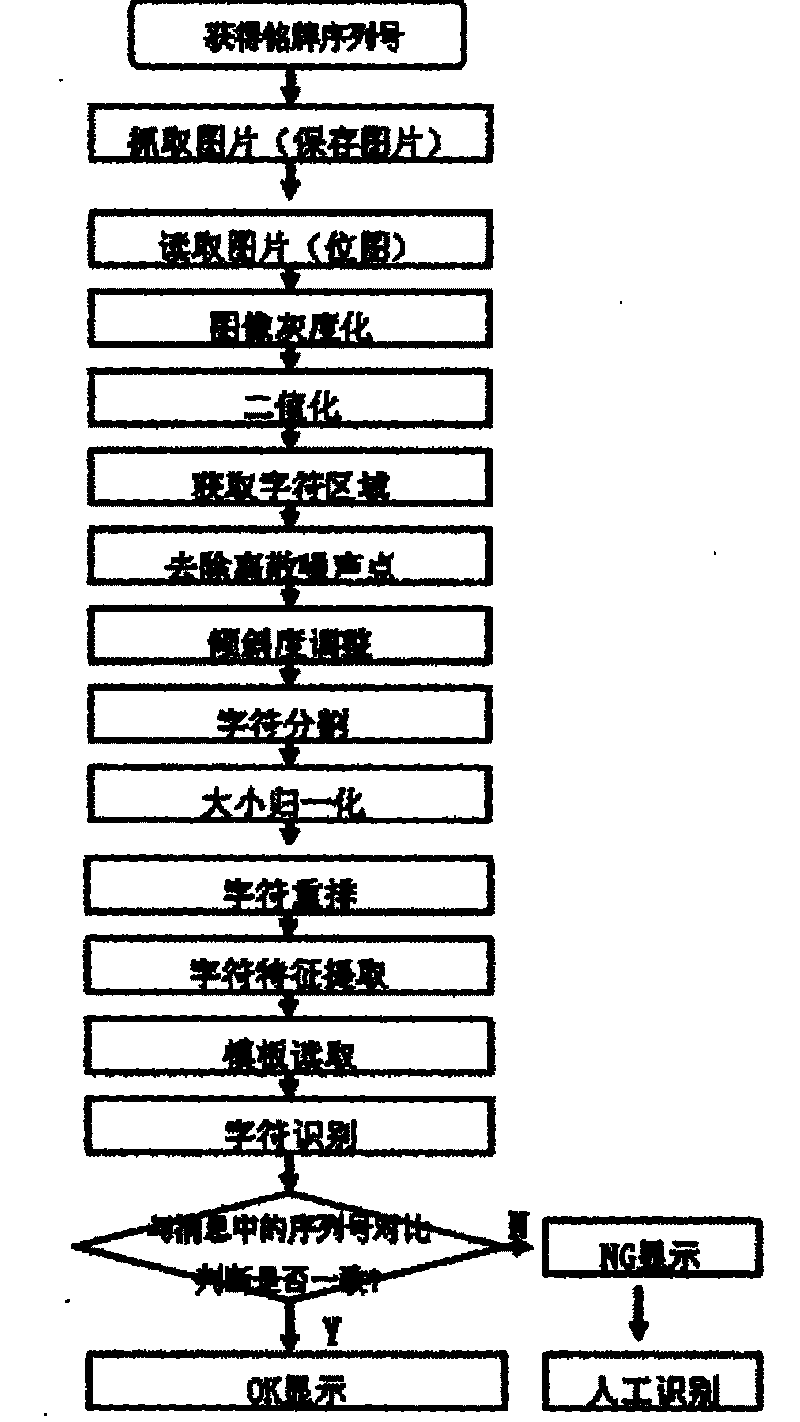

Digital identification system and method for serial numbers of name plate of camera

InactiveCN101697196AAccurate thresholdAdaptableCharacter and pattern recognitionImaging processingDigital image

The invention provides a digital identification system and a method for serial numbers of a name plate of a camera, belonging to the technical field of digital identification. The digital identification system for serial numbers of the name plate of the camera is characterized by comprising a USB camera arranged above the name plate of the camera to be identified, and the USB camera is connected with a computer by a USB connection wire, wherein the computer is provided with an evaluation program communication module, a video capture and image capture module as well as an image processing and digital identification module which are sequentially connected. The invention adopts digital image identification technology to identify the serial numbers on the name plate, then the serial numbers are compared with the numbers read out from a memory by the testing program, and judgment is made so that the reliability of the operation is improved.

Owner:SHANGHAI SUOGUANG ELECTRONICS

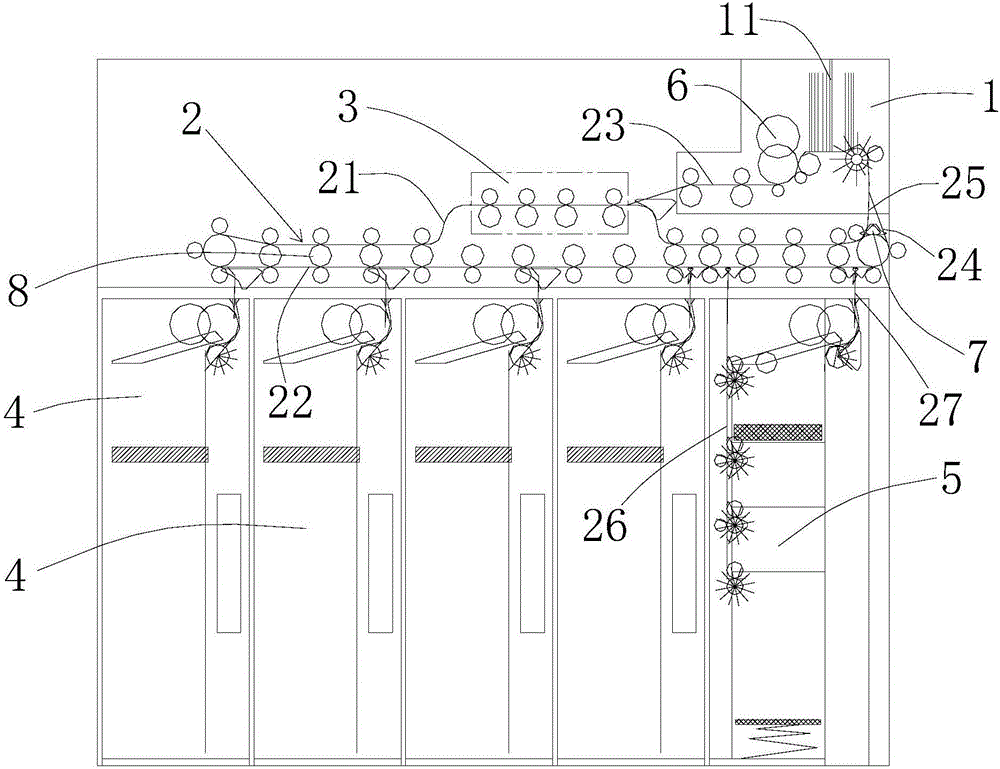

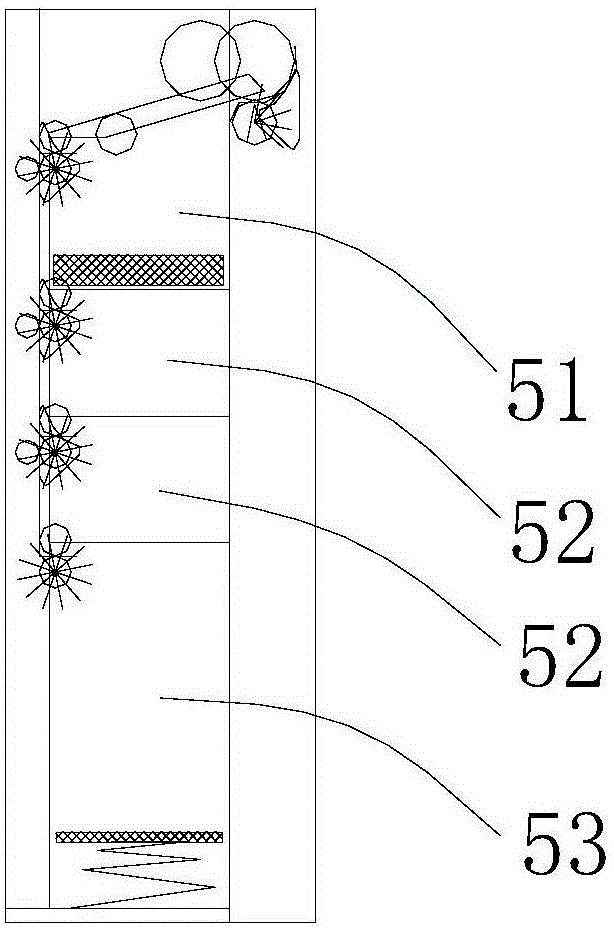

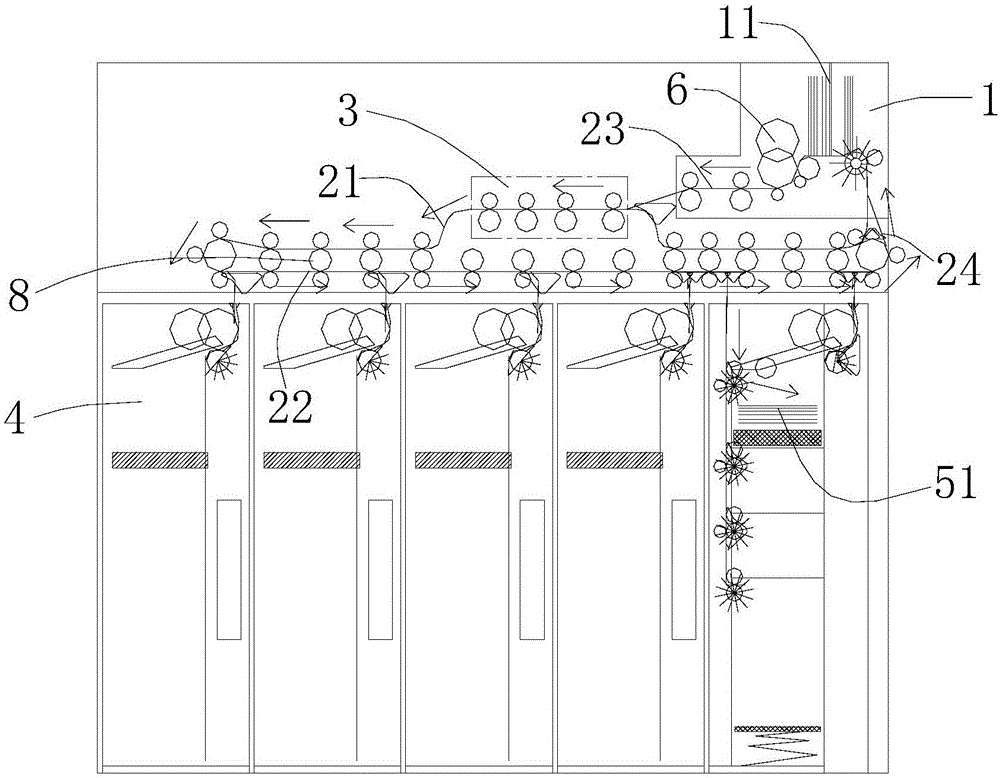

Automatic teller machine deposit/withdrawal device

InactiveCN106097568AReduce jammingOptimize layoutCoin/currency accepting devicesEngineeringBank note

The invention discloses an automatic teller machine deposit / withdrawal device. The device comprises a bank note identification part, at least one bank note storage box, a recycling box for placing bank notes, a bank note separator, a deposit / withdrawal port, and a circulating conveying channel for conveying bank notes. The bank note identification part is installed on the circulating conveying channel. The bank note separator is installed on a bank note inlet end of the deposit / withdrawal port. The bank note inlet end of the deposit / withdrawal port is connected with a bank note inlet end of the bank note identification part through a bank note sending channel, and a bank note outlet end of the deposit / withdrawal port is connected with the circulating conveying channel through a bank note outputting channel. The bank note storage box and the recycling box are arranged under the circulating conveying channel and are connected with the circulating conveying channel separately through connecting channels. The device is simple in structure, convenient for maintenance, low in cost, suitable for promotion and application, and small in vertical size. The bank note deposit / withdrawal port is low and facilitates operation by a customer. The device is high in technical versatility.

Owner:广州智清电子科技有限公司

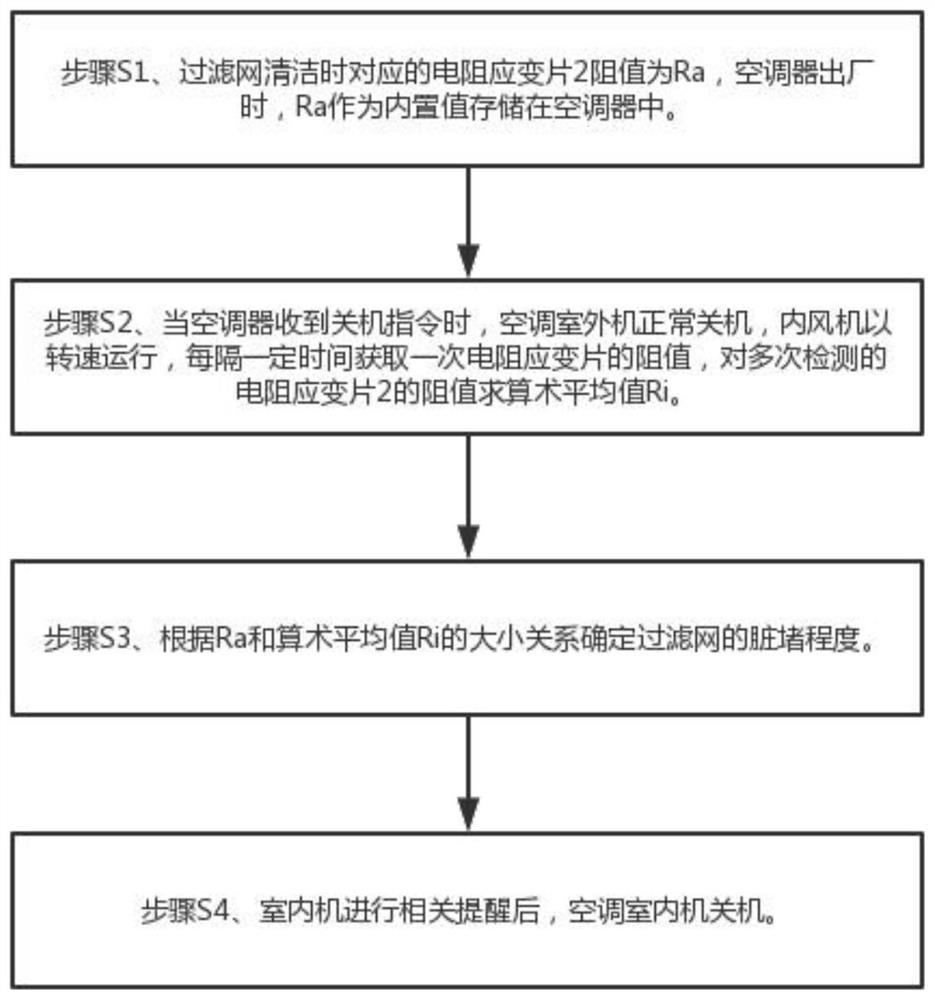

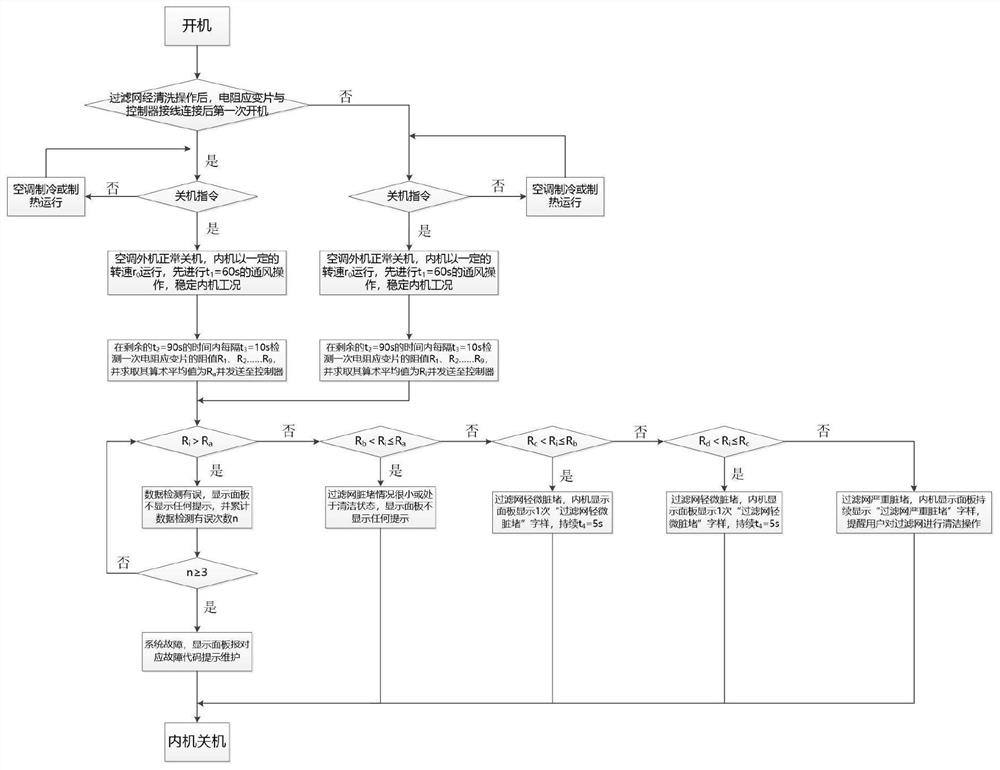

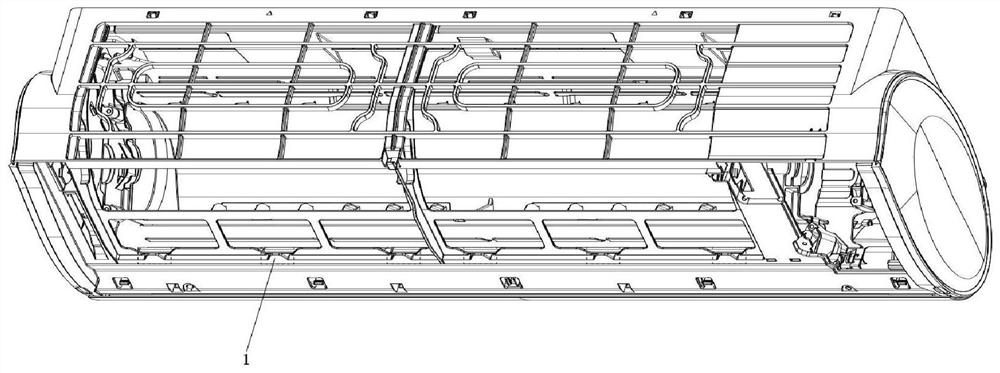

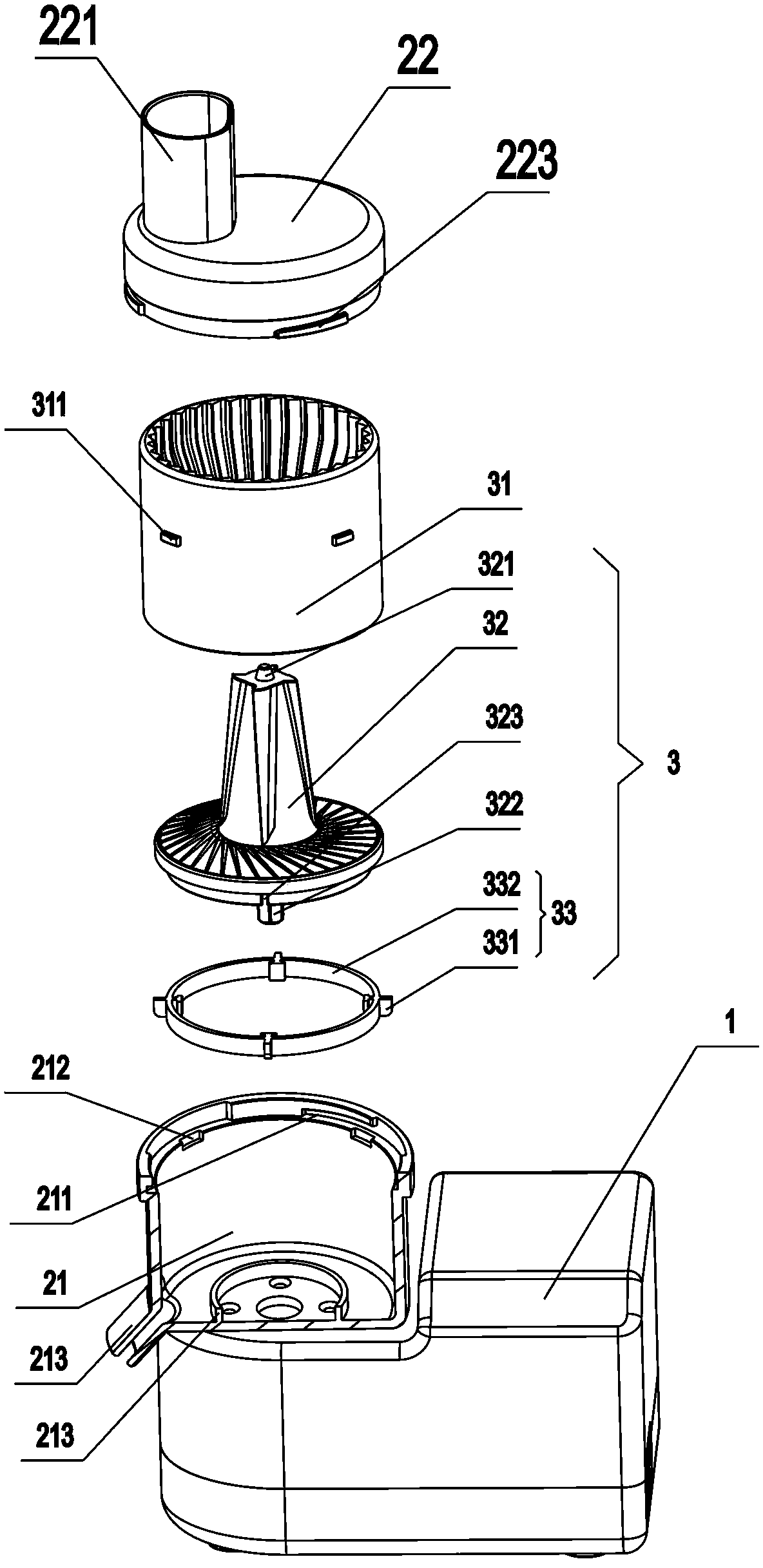

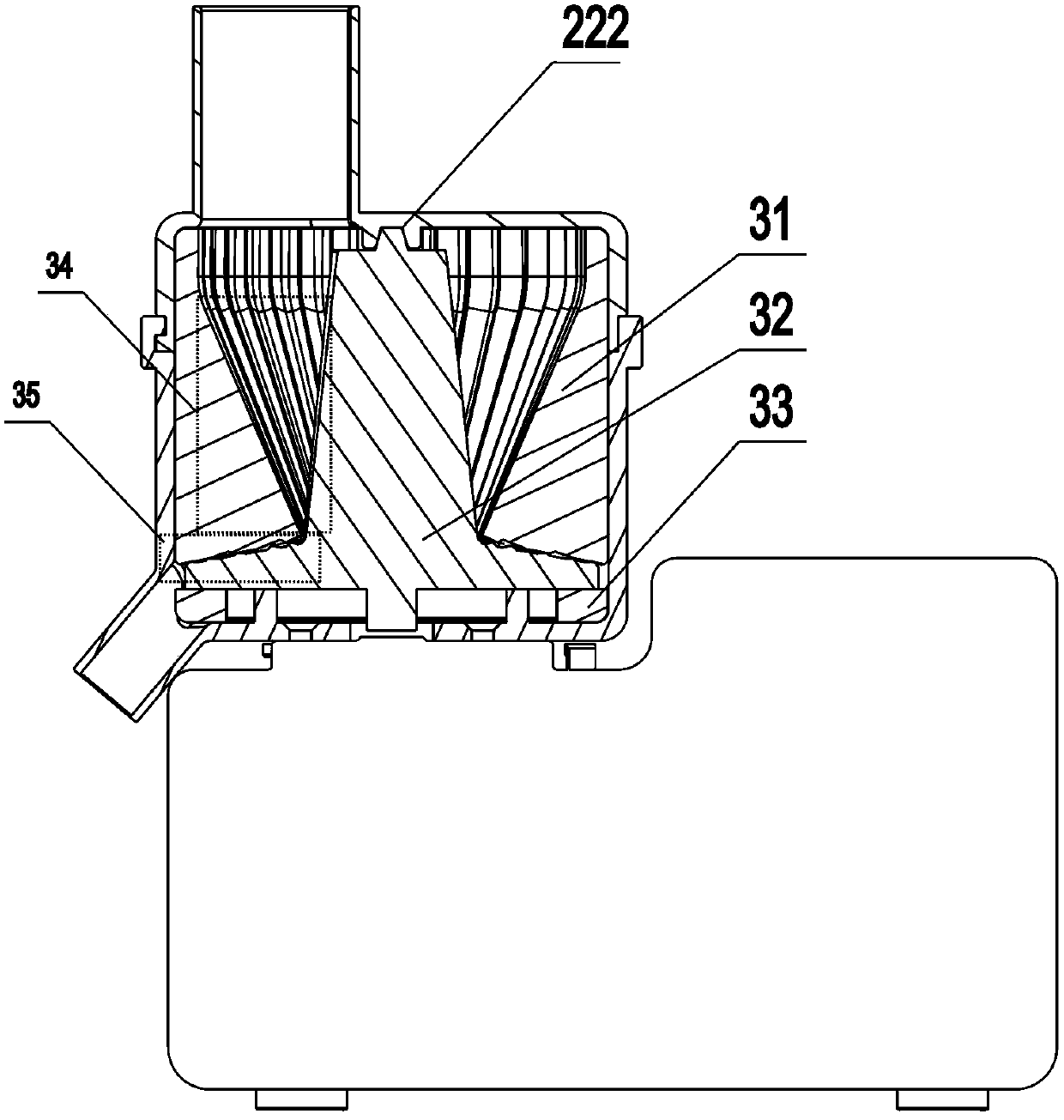

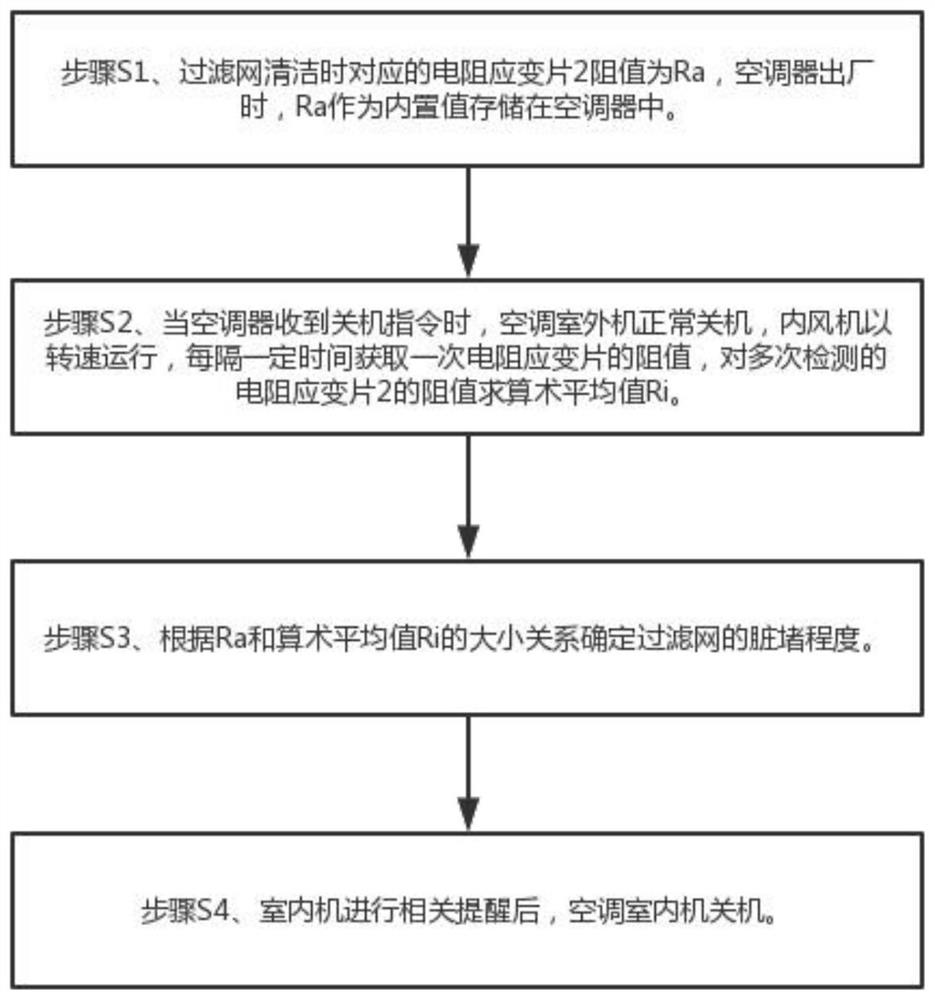

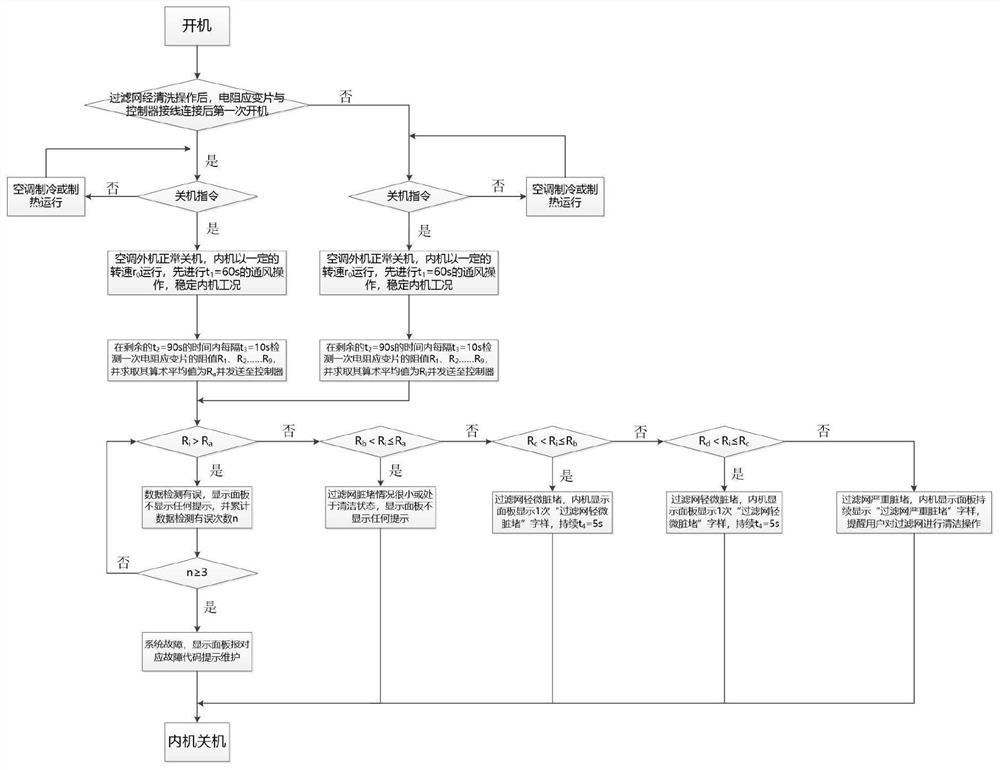

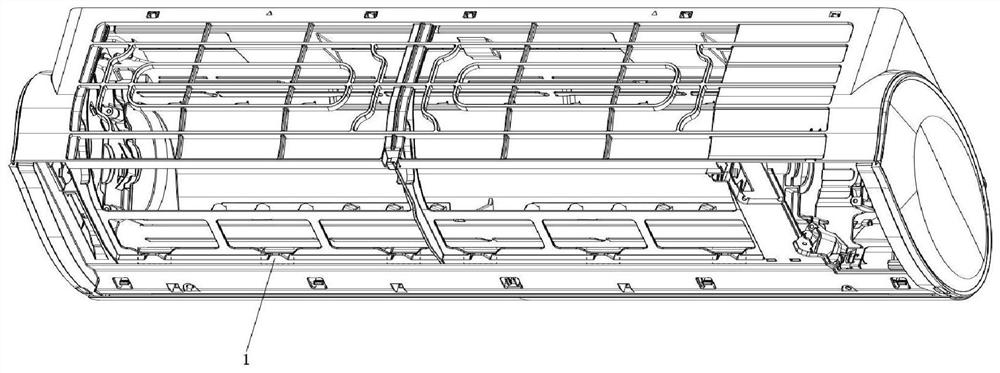

Filter screen dust removal reminding method and device and air conditioner

ActiveCN111649450AJudging the degree of dirtinessStrong technical versatilityMechanical apparatusSpace heating and ventilation safety systemsDust controlStrain gauge

The invention relates to a filter screen dust removal reminding method and device and an air conditioner. The filth blockage state of a filter screen is reflected by monitoring the resistance value change of a resistance strain gauge. When filth blockage of the filter screen reaches a certain degree, dust removal reminding is conducted. By comparing the resistance value Ri of the resistance straingauge in the normal work state with the resistance value Ra of the resistance strain gauge obtained after the filter screen is cleaned, whether the resistance strain gauge is in the normal work stateor not is identified, so that the filth blockage state of the filter screen can be reflected. The reflection and reminding effects are good. According to the scheme, the structure of an existing airconditioner is not changed, only the resistance strain gauge needs to be arranged on the filter screen and a filter screen limiting buckle of a middle frame, and the technical effects that the technical universality is high and later overhauling and maintaining are simple are achieved.

Owner:NINGBO AUX ELECTRIC +1

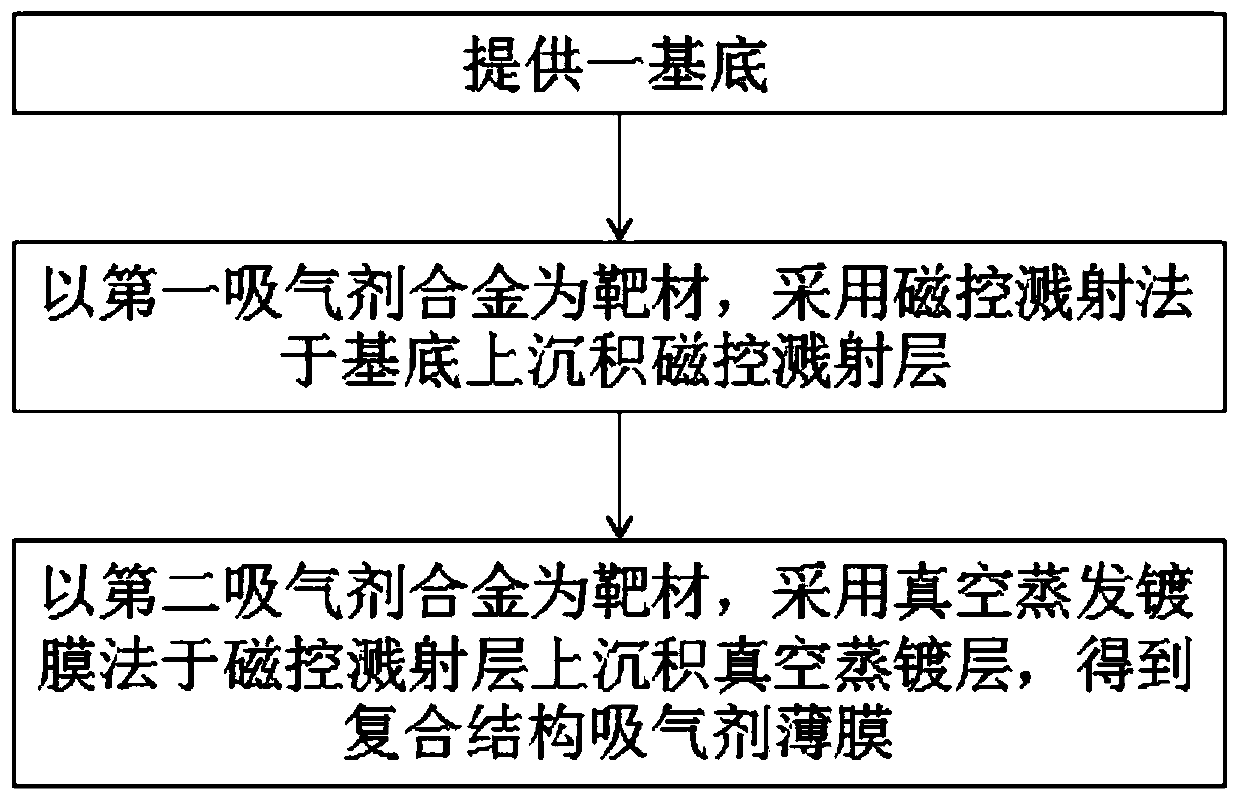

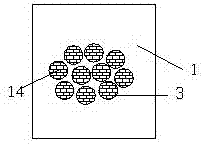

Complex structure getter film and preparation method thereof

ActiveCN110863183AGood mechanical propertiesHigh porosityVacuum evaporation coatingSputtering coatingCompound structureThin membrane

The invention provides a complex structure getter film and a preparation method thereof. The method comprises the steps that a substrate is provided; a first getter alloy is adopted as a target, and amagnetron sputtering layer is deposited on the substrate through a magnetron sputtering method; and a second getter alloy is adopted as a target, a vacuum evaporation layer is deposited on the magnetron sputtering layer through a vacuum evaporation coating method, and the complex structure getter film is obtained. According to the complex structure getter film and the preparation method thereof,the complex structure getter film with microcosmic gradient morphology design is constructed, so that the complex structure getter film meets the characteristics of good film layer mechanical property, high porosity, high air suction capacity, high air suction rate, low-temperature activation and the like, and god industrial application prospects are achieved.

Owner:ZHONGSHAN KAIXUAN VACUUM SCI & TECH CO LTD

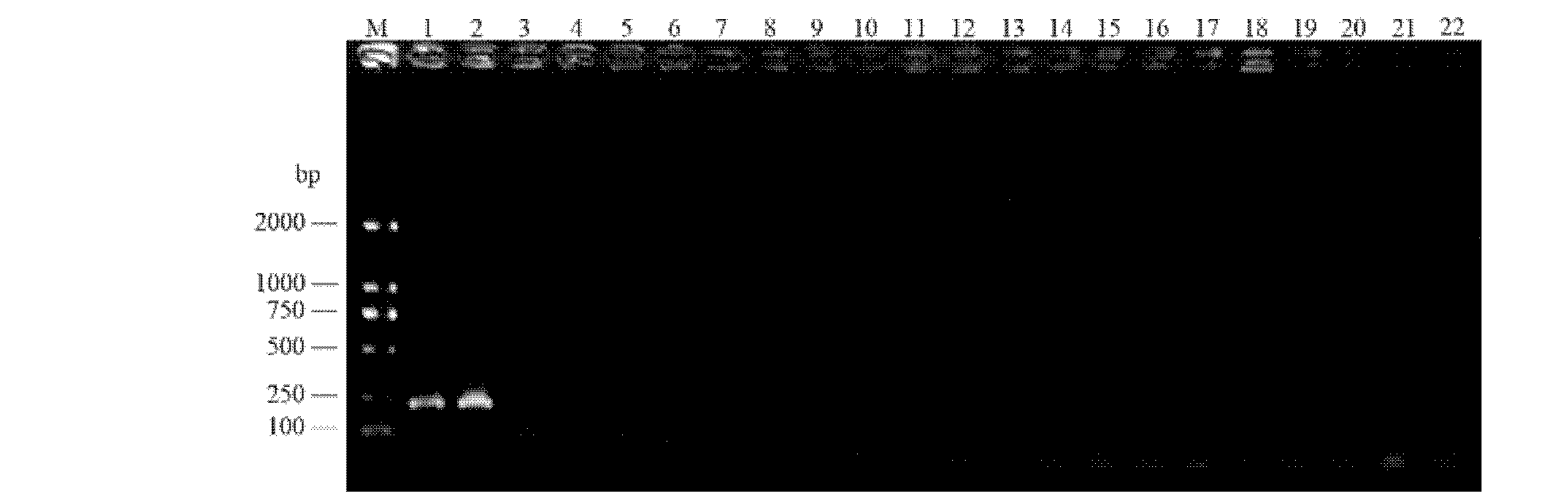

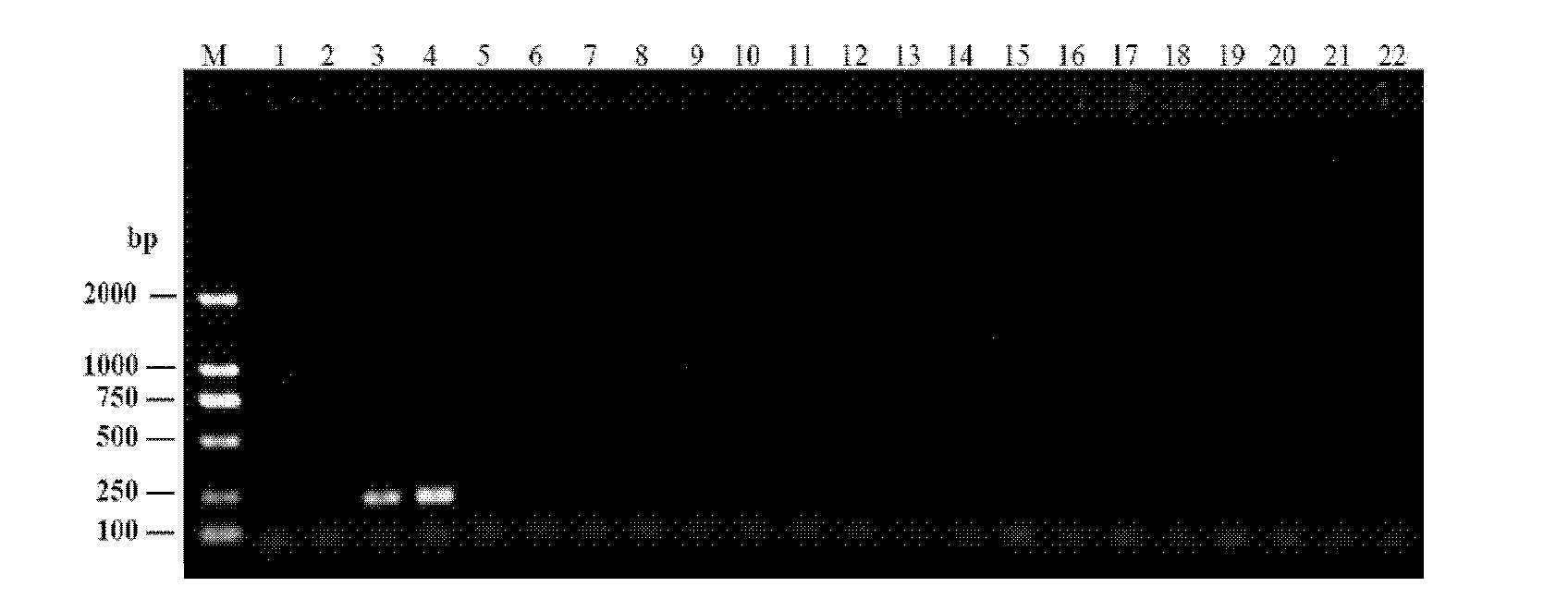

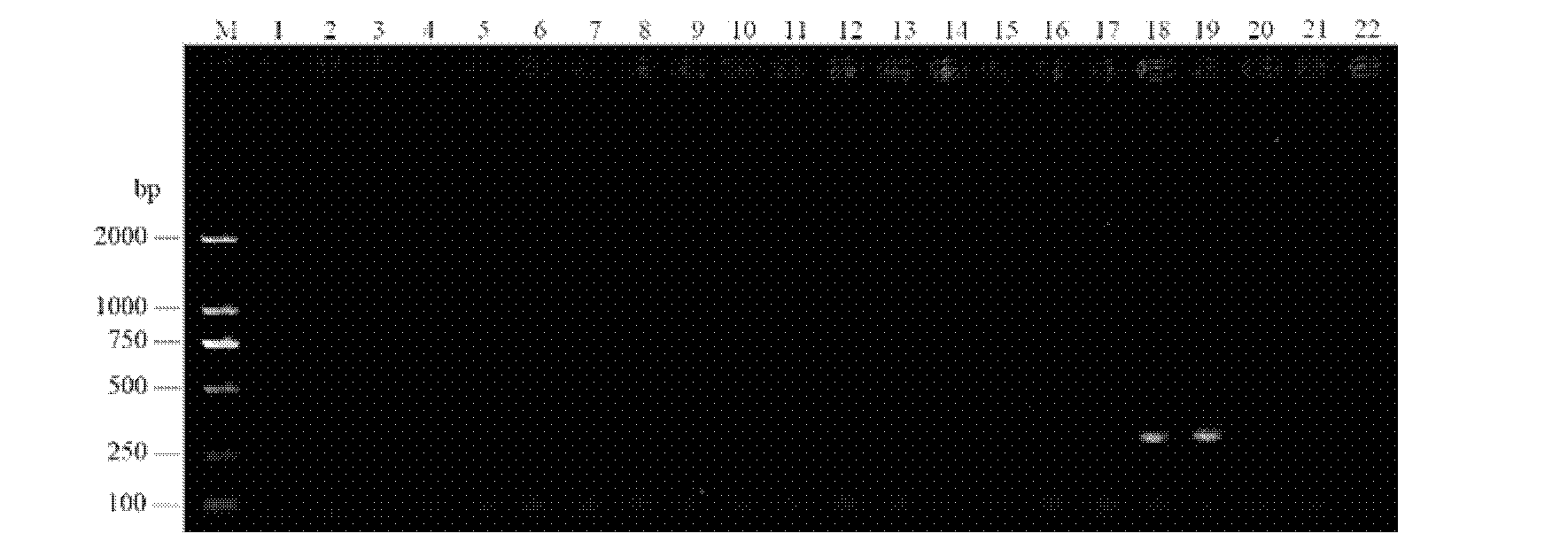

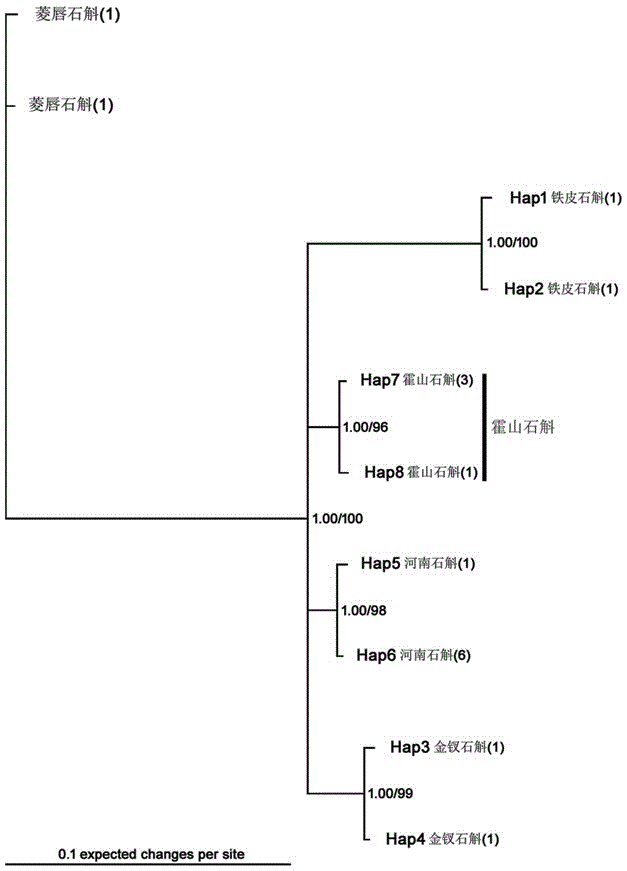

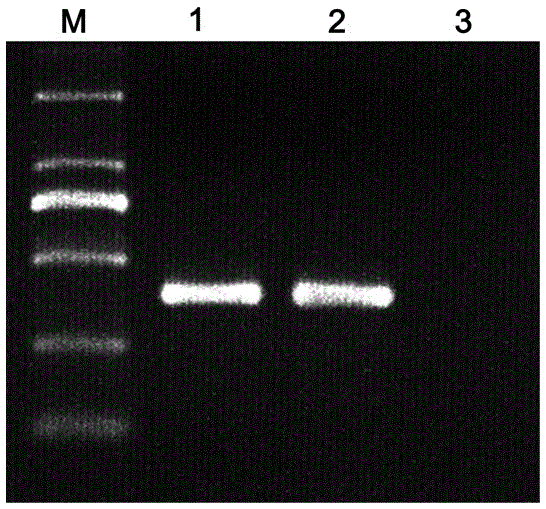

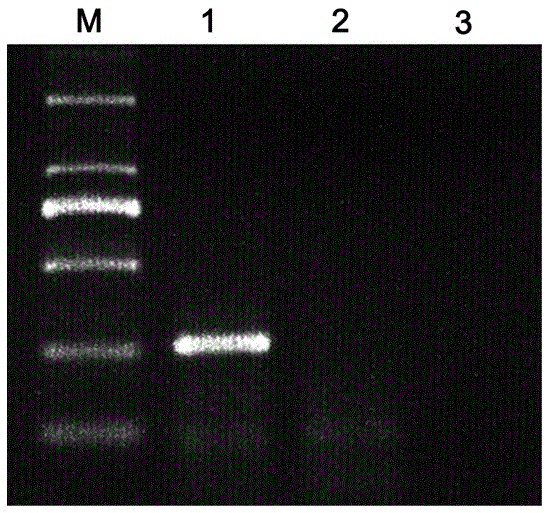

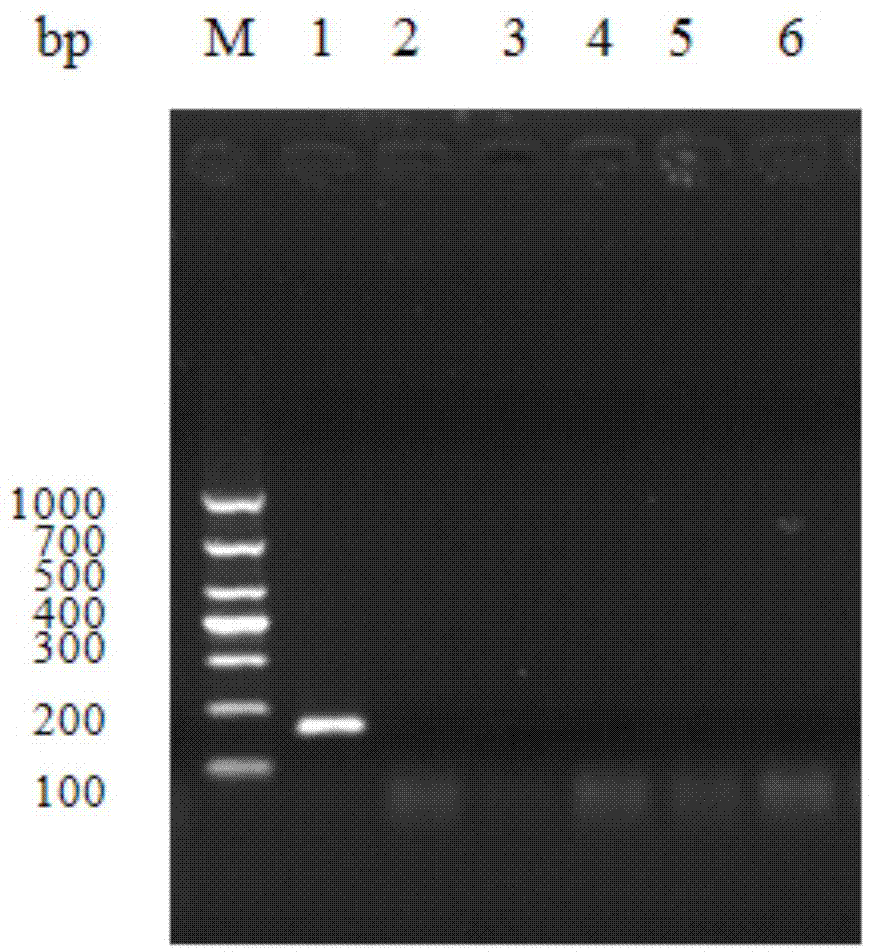

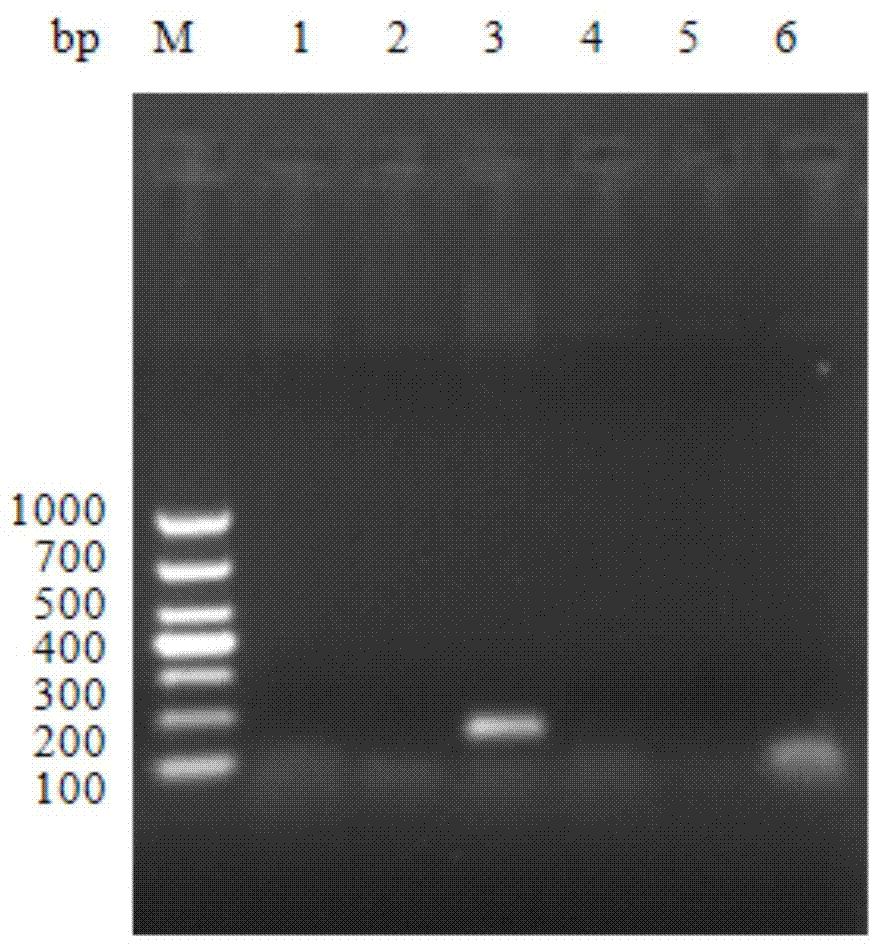

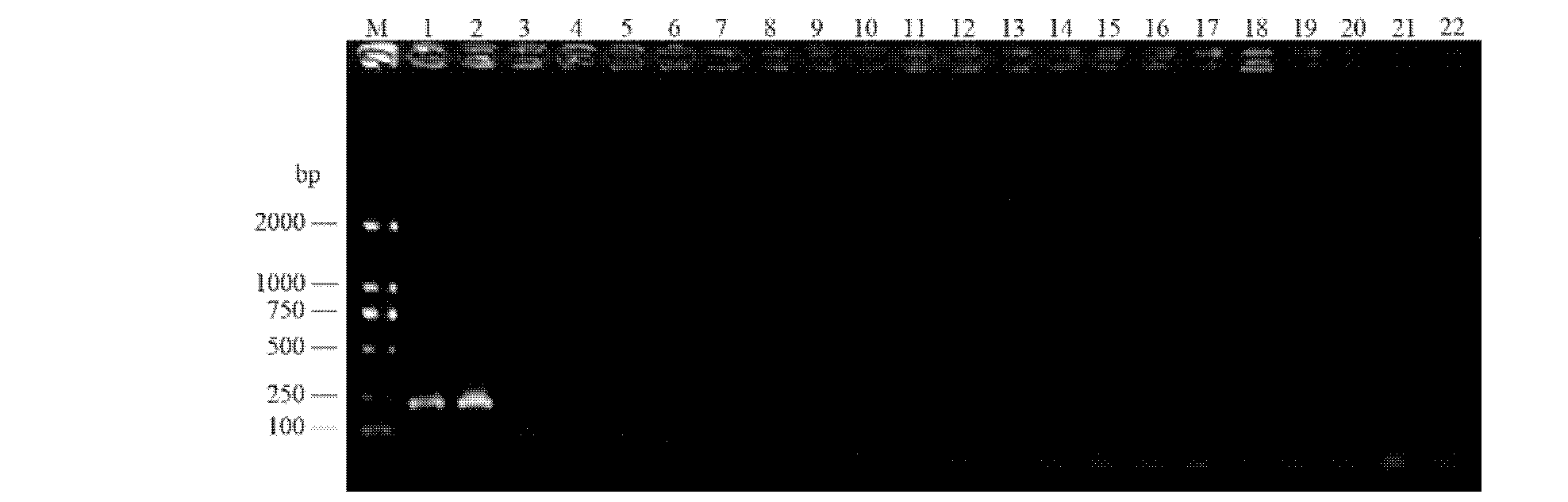

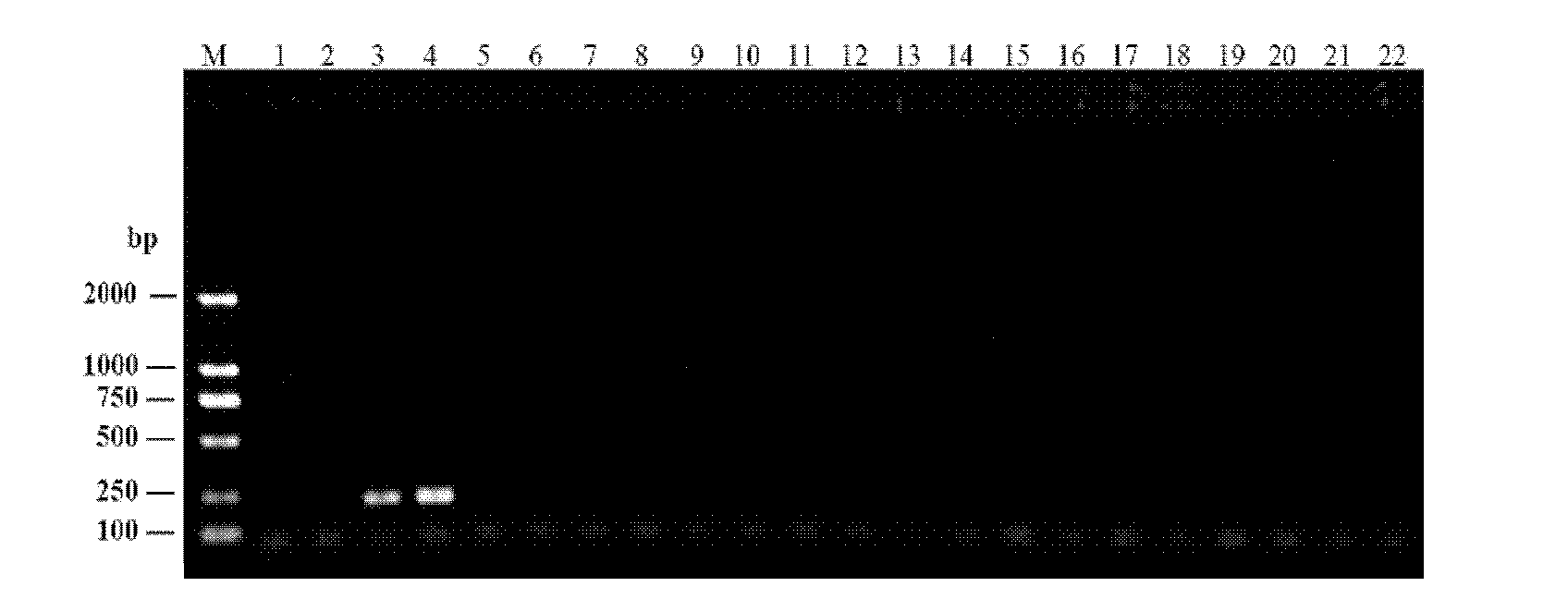

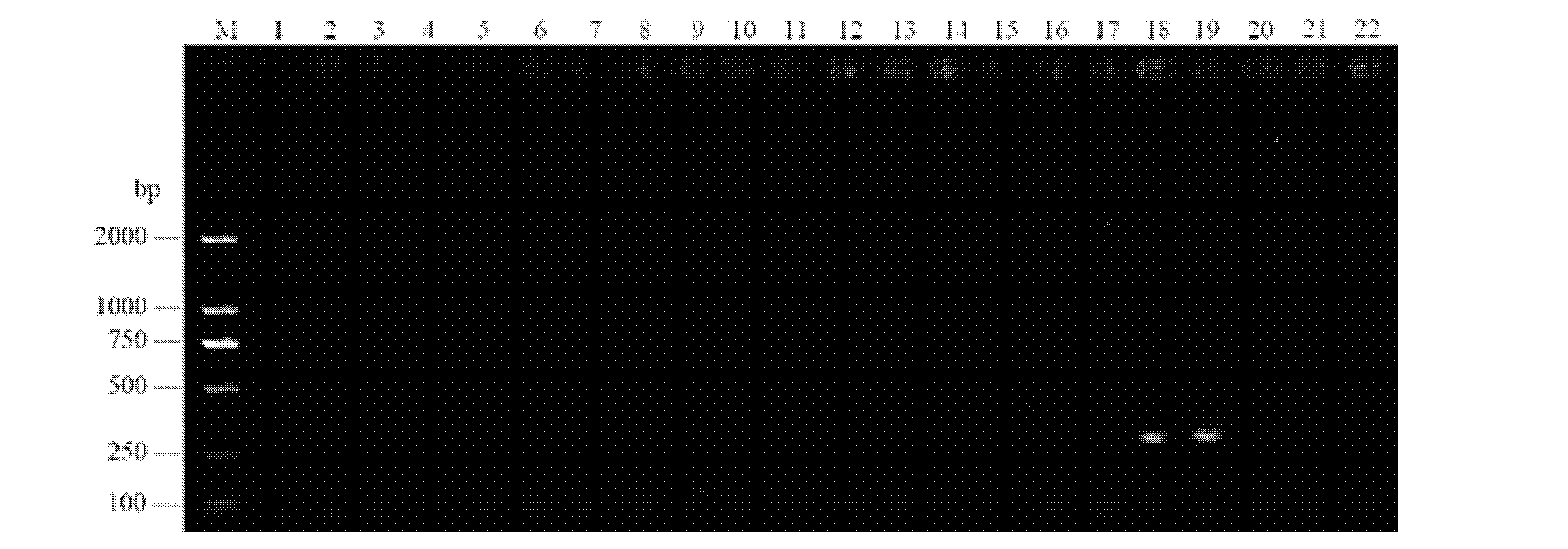

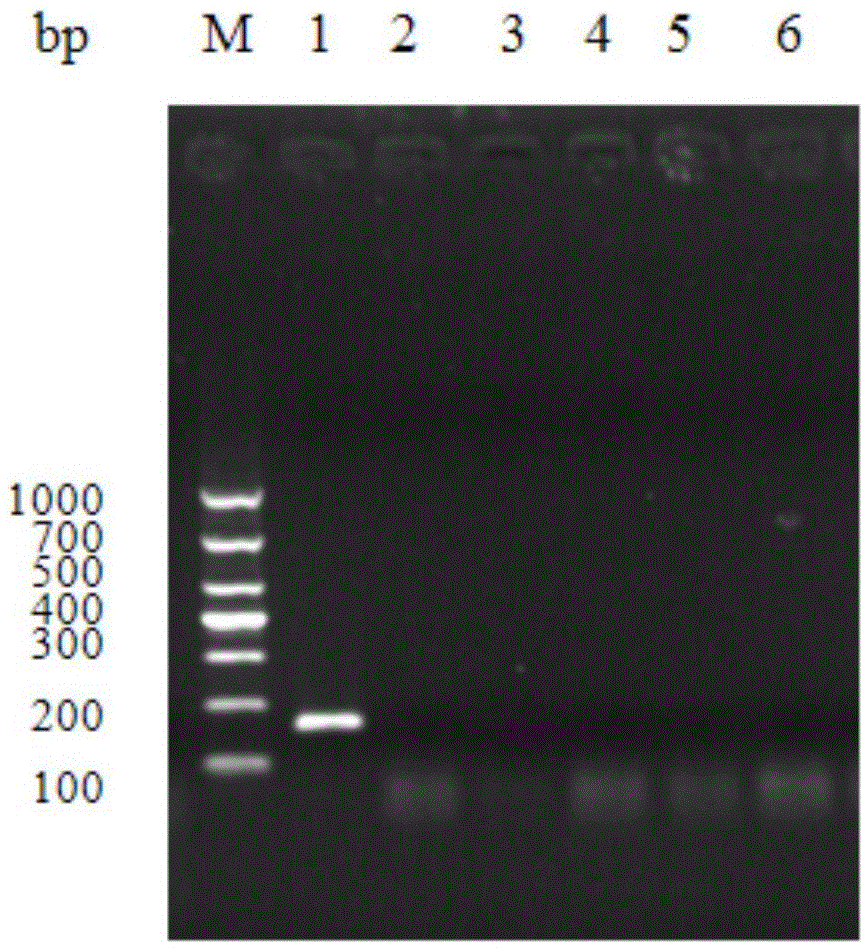

Method for identifying dendrobium huoshanense and dendrobium henanense through comparison

InactiveCN106282373ARapid identificationSolve problemsMicrobiological testing/measurementGenomic DNADNA fragmentation

The invention relates to a method for identifying dendrobium huoshanense and dendrobium henanense through comparison. The method comprises comparison identification operation steps as follows: (1) genomic DNA is extracted from two to-be-detected samples and taken as a template, primers are adopted to perform a PCR (polymerase chain reaction) amplification reaction respectively, and two PCR amplified products are obtained; (2) the two PCR amplified products are detected with an agarose gel electrophoresis method, and if one of the PCR amplified products contains DNA fragments of 262bp, one of the to-be-detected samples contains the dendrobium huoshanense or a candidate contains the dendrobium huoshanense; if the PCR products don't contain the DNA fragments of 262bp, one of the to-be-detected samples doesn't contain the dendrobium huoshanense or a candidate doesn't contain the dendrobium huoshanense. By means of the method, the dendrobium huoshanense and the dendrobium henanense are rapidly and accurately identified.

Owner:WEST ANHUI UNIV

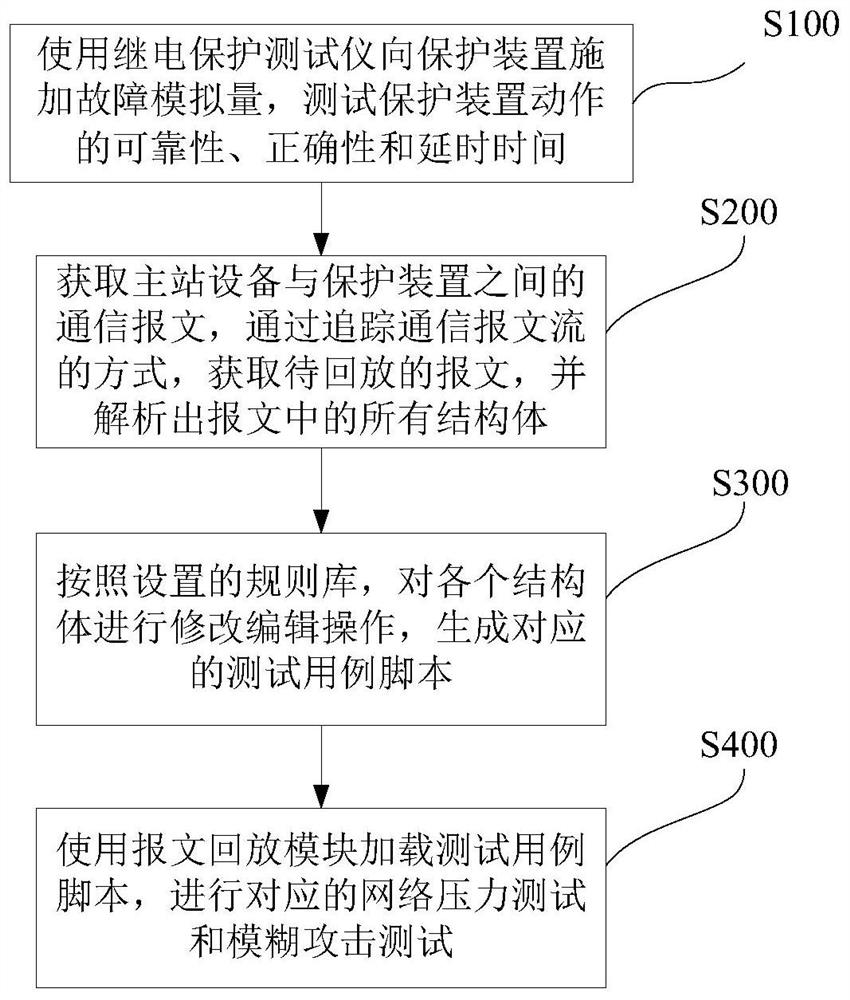

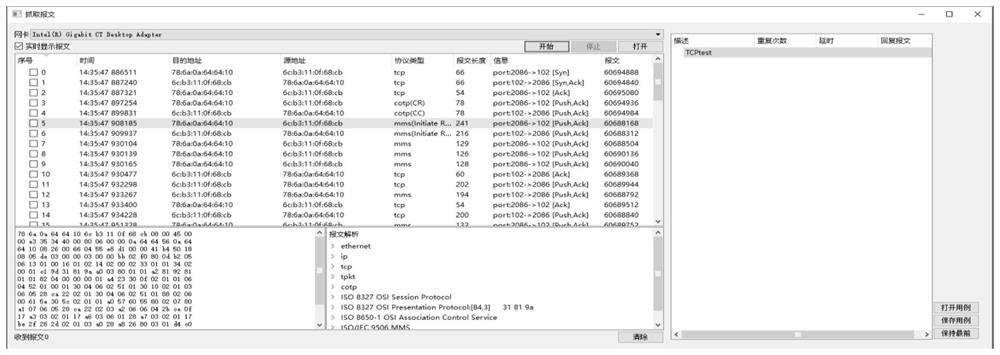

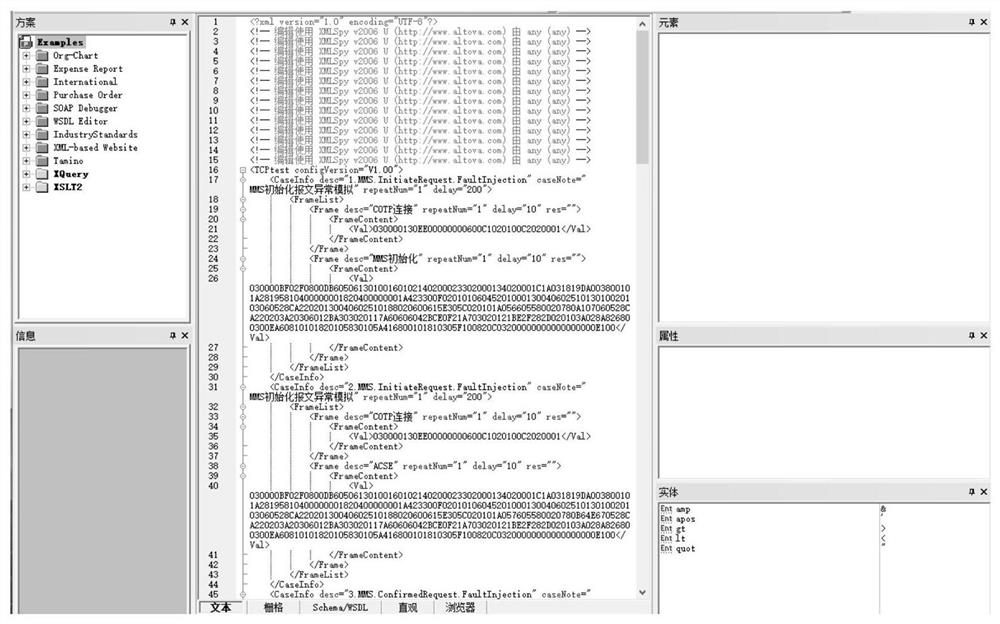

Power control protection industrial control protocol security test method and system

ActiveCN111901200AStrong technical versatilityEasy to operateData switching networksPower controlReal-time computing

The invention discloses a power control protection industrial control protocol security test method and system. The method comprises the steps of: simulating a typical fault of a power system, and testing the correctness of a protection operation, the operation delay and the correctness of an information uploading monitoring system; using a message generation and playback technology in the environment to simulate and generate multiple clients and multiple servers to realize communication node pressure testing; generating various random fields and message playback strategies according to a setrule base, simulating fuzzy attacks of the protocol, and testing the security of the industrial control protocol; judging the communication state and the logic correctness of an application layer by analyzing structural bodies of a reply message of the device, and testing the robustness of a power control protection industrial control protocol; under the working conditions of network pressure andfuzzy attack, comprehensively assessing the correctness of a device protection function, the stability of performance and the reliability of communication. According to the method and the system, a message playback technology is irrelevant to specific protocol implementation, and the technical universality is high.

Owner:XUJI GRP +1

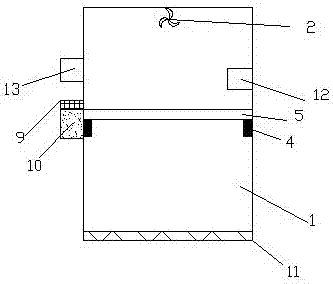

Heat-dissipation switch cabinet

InactiveCN107017560AEnsure safetyImprove insulation performanceSubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsLiquid circulationComputer engineering

The invention discloses a heat dissipation switch cabinet, which relates to the technical field of switch cabinets, comprising a cabinet body, a cooling fan is arranged on the top of the inner wall of the cabinet, a plurality of air holes are correspondingly provided on the upper bottom surface of the cabinet body and the cooling fan, and the middle part of the side of the inner wall of the cabinet is symmetrical There are horizontal slide rails, and baffles are arranged on the horizontal slide rails. There are multiple strip-shaped cavities inside the baffles and are connected to each other. There are a number of heat dissipation holes on the upper and lower bottom surfaces of the cavities. The pipes are connected to each other. The outer wall of the cabinet is provided with a water pump and a liquid storage bin. The water pump, the liquid storage bin and the pipe are connected in pairs to form a liquid circulation cooling system. The bottom of the cabinet is connected with a cooling plate. The temperature sensor is provided with a controller on the outer wall of the cabinet, and the temperature sensor, the water pump and the cooling fan are respectively connected with the controller. The invention adopts the heat dissipation mode combining liquid circulation cooling and heat dissipation with a heat dissipation fan, and has the characteristics of high heat dissipation efficiency, long service life, simple structure and strong technical versatility.

Owner:合肥易美特建材有限公司

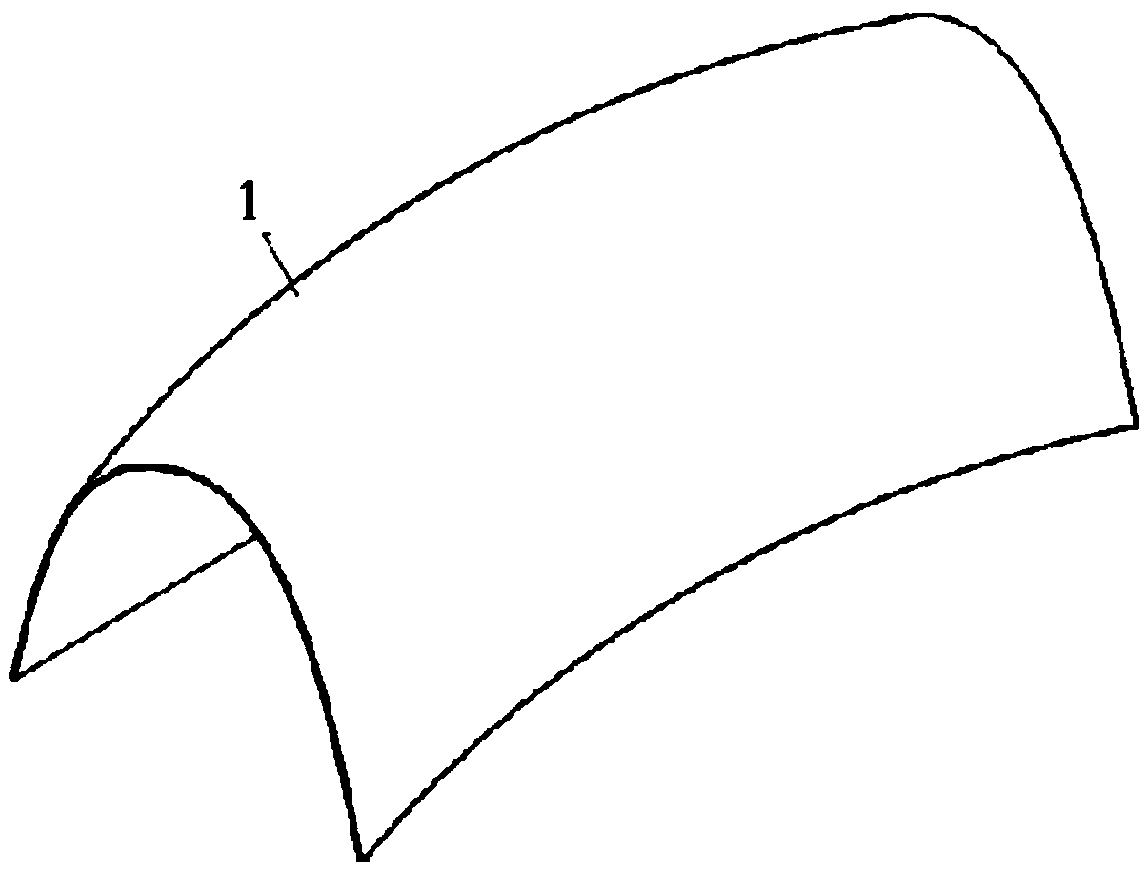

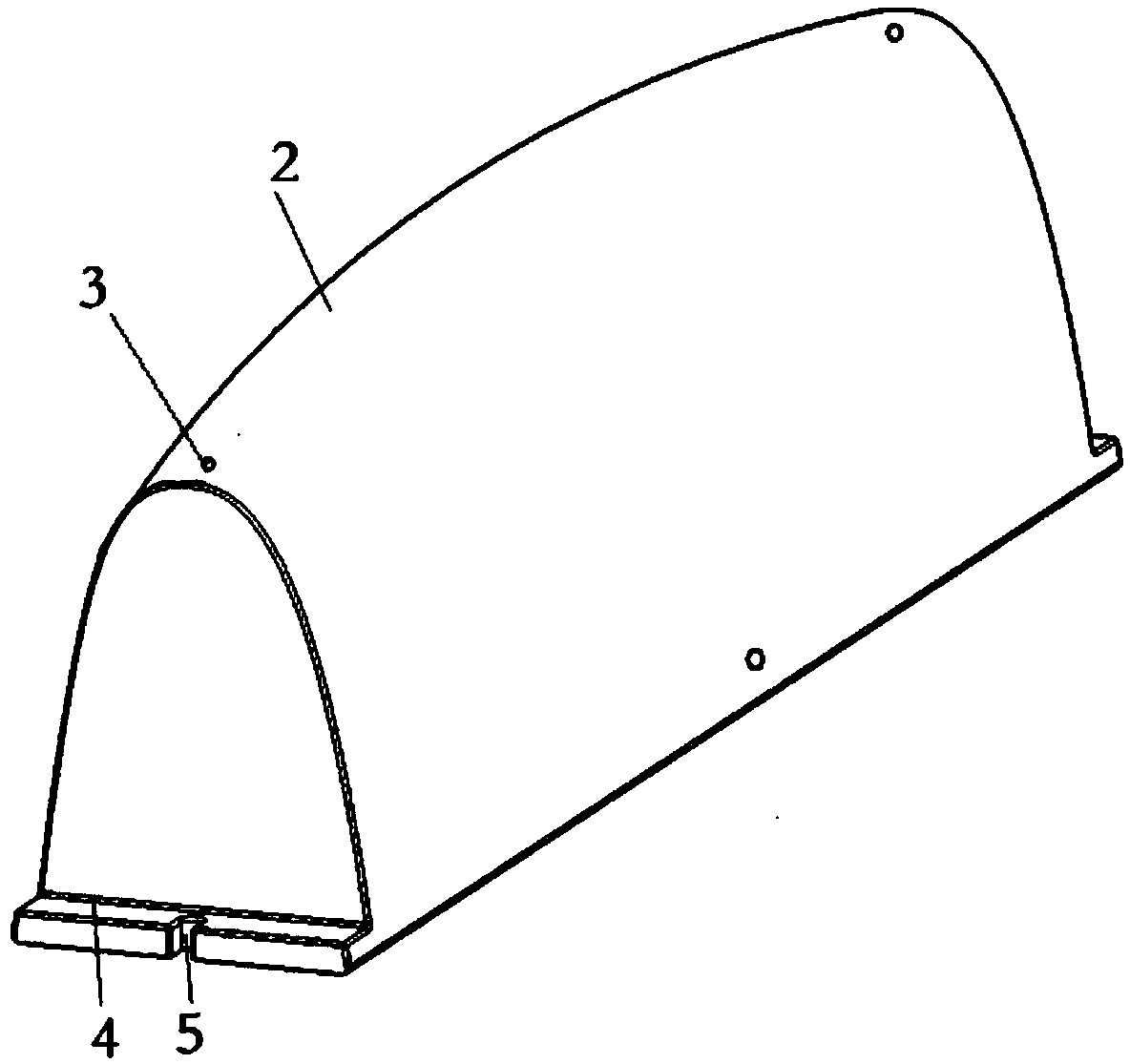

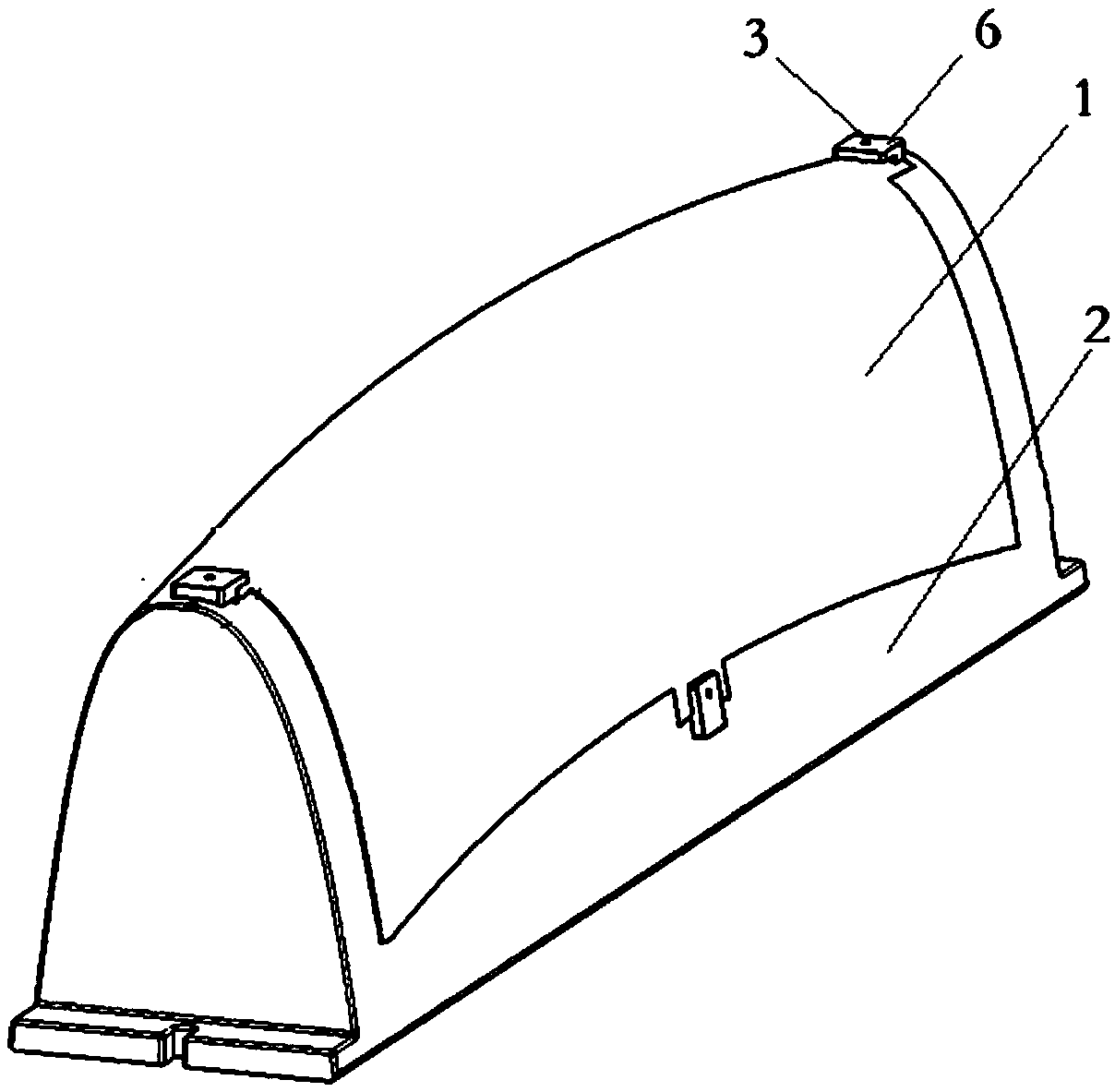

Detecting method for double-curvature skin part of airplane

InactiveCN108917685ARealize the detection of the degree of pastingThere is no problem of easy detection blind spotsMeasurement devicesJet aeroplaneMeasuring instrument

A detecting method for a double-curvature skin part of an airplane comprises the steps that a detecting mould is arranged, a convex profile matched with a skin theoretical model is arranged on the detecting mould, the convex profile is a detecting datum face, datum holes are formed in the convex profile and correspond to positioning holes in the double-curvature skin part, and the machined double-curvature skin part is placed on the detecting mould to be positioned and fixed; space coordinate values of a plurality of detecting points are measured on the surface of the skin part through a measuring instrument, and a computer of the measuring instrument automatically forms a virtual model of the double-curvature skin part in a fitting mode according to the space coordinate values of all thedetecting points; and the skin theoretical model and the virtual model are positioned on the computer through the datum holes and the datum face, thus stacked assembling is completed, the normal distance from any to-be-detected point on the virtual model to the theoretical model is measured, and the normal distances between all the detected points and the theoretical model are compared, so that the attaching degree of any space point on a double-curvature skin can be detected precisely.

Owner:XIAN AIRCRAFT IND GROUP

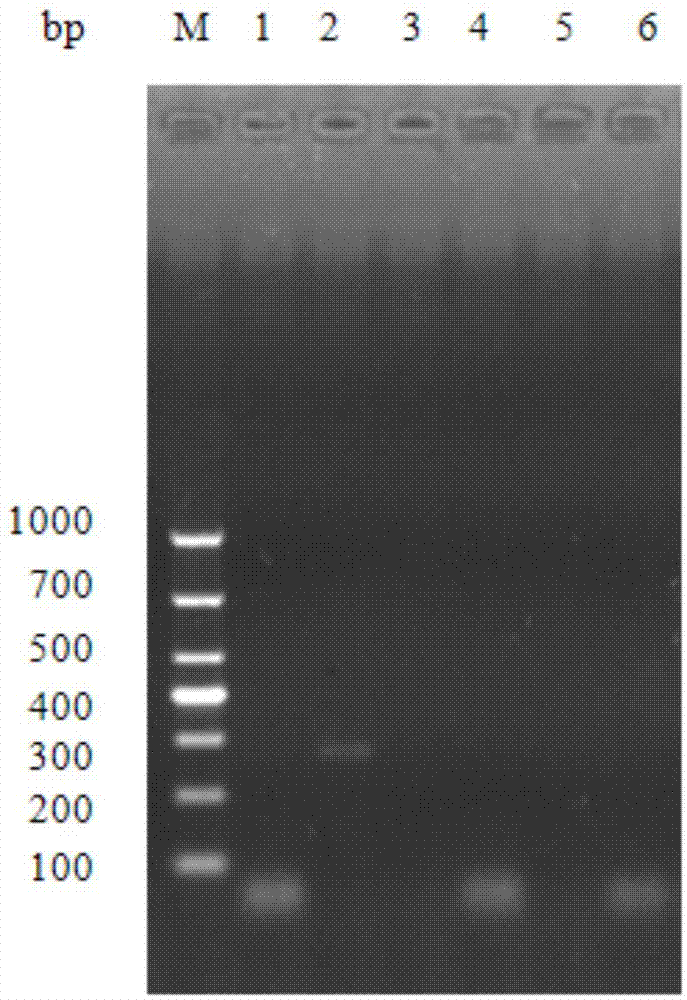

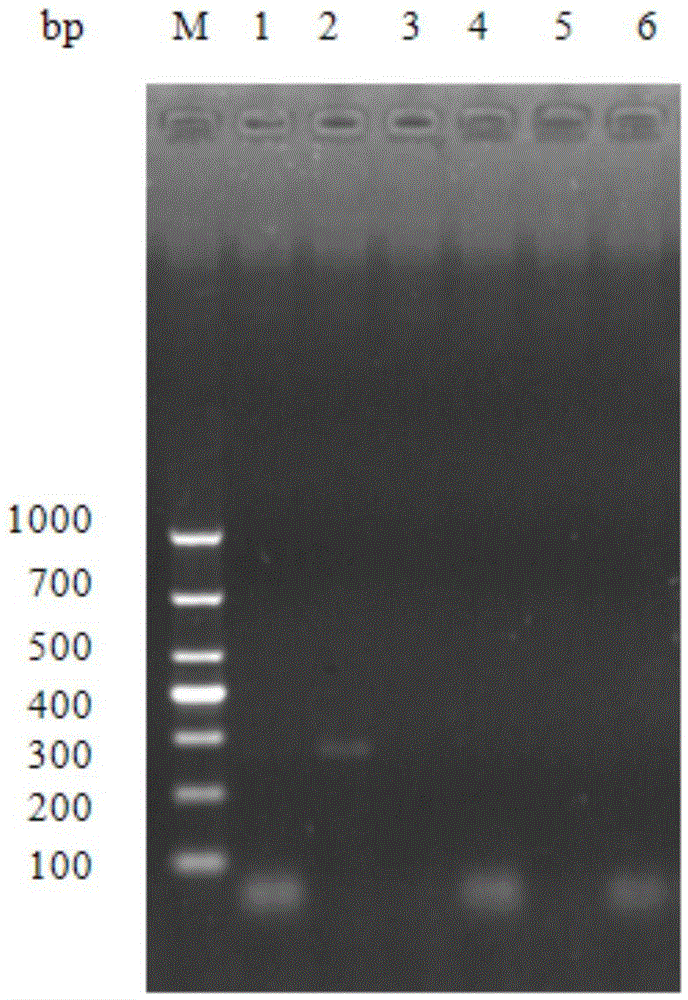

Primer pair and kit for identification or assisted identification of stored bean weevils

ActiveCN104498593AIdentification achievedLower requirementMicrobiological testing/measurementDNA/RNA fragmentationSample integrityBean weevil

The invention discloses a primer pair and a kit for identification or assisted identification of stored bean weevils. The primer pair disclosed by the invention is composed of the following five primer pairs: a primer pair 1 (a sequence 1 and a sequence 2), a primer pair 2 (a sequence 3 and a sequence 4), a primer pair 3 (a sequence 5 and a sequence 6), a primer pair 4 (a sequence 7 and a sequence 8) and a primer pair 5 (a sequence 9 and a sequence 10). Used for identification of species of the stored bean, the kit is not affected by the individual development status of a sample and the integrity of the sample, and has the advantages of being time-saving, high-efficient and accurate; and the primer pair and the kit can be widely applied to the food storage departments and quarantine departments.

Owner:INST OF FOOD CROPS HUBEI ACAD OF AGRI SCI

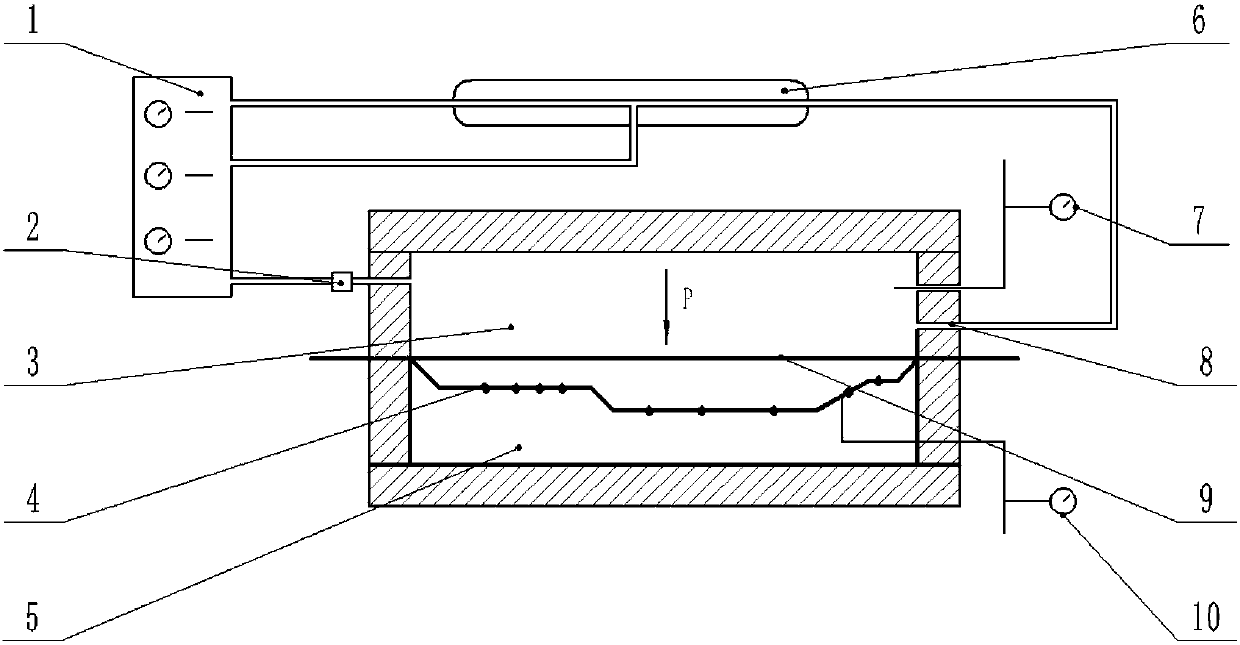

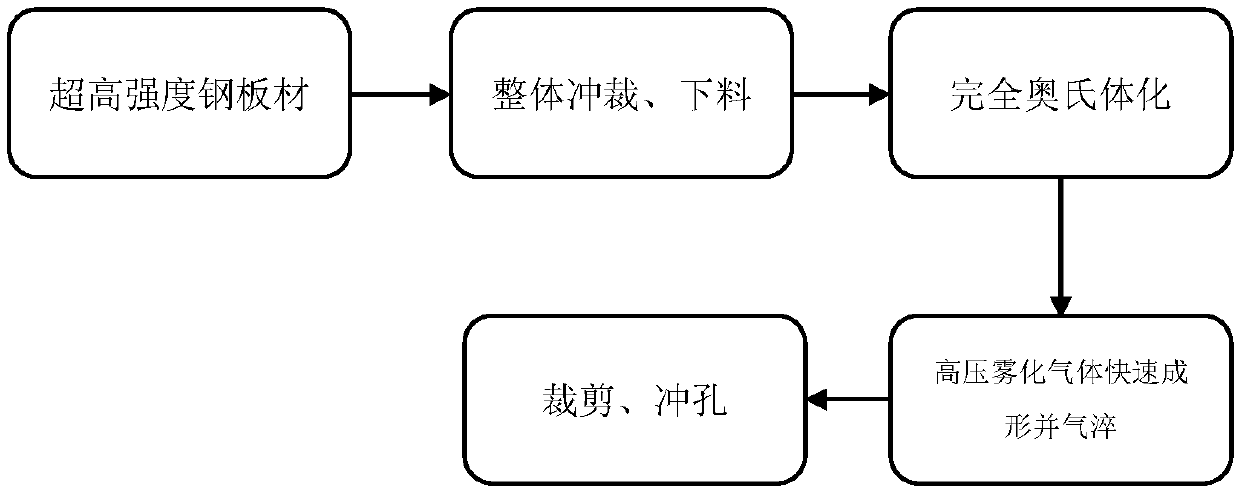

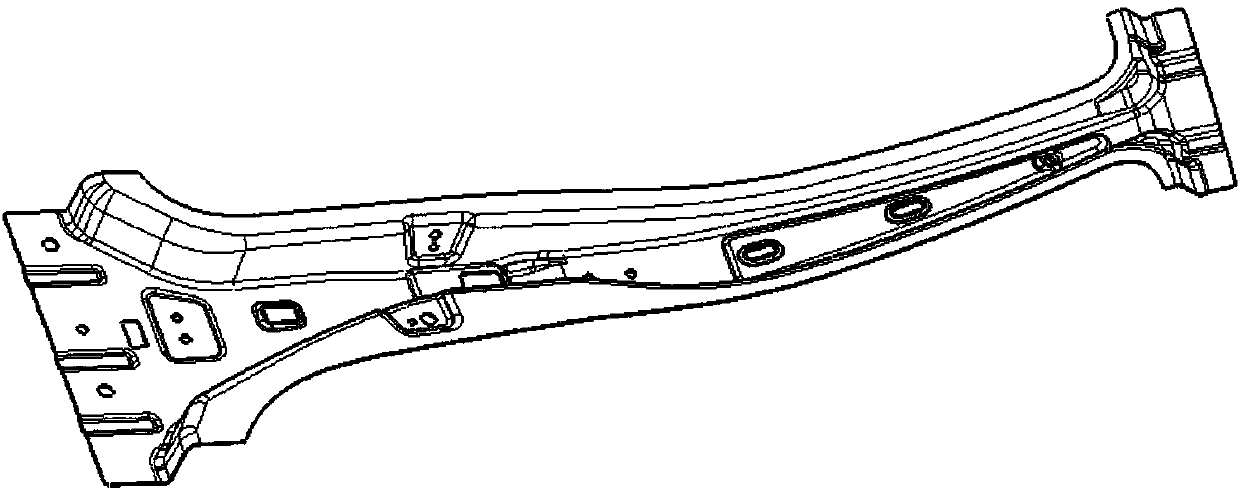

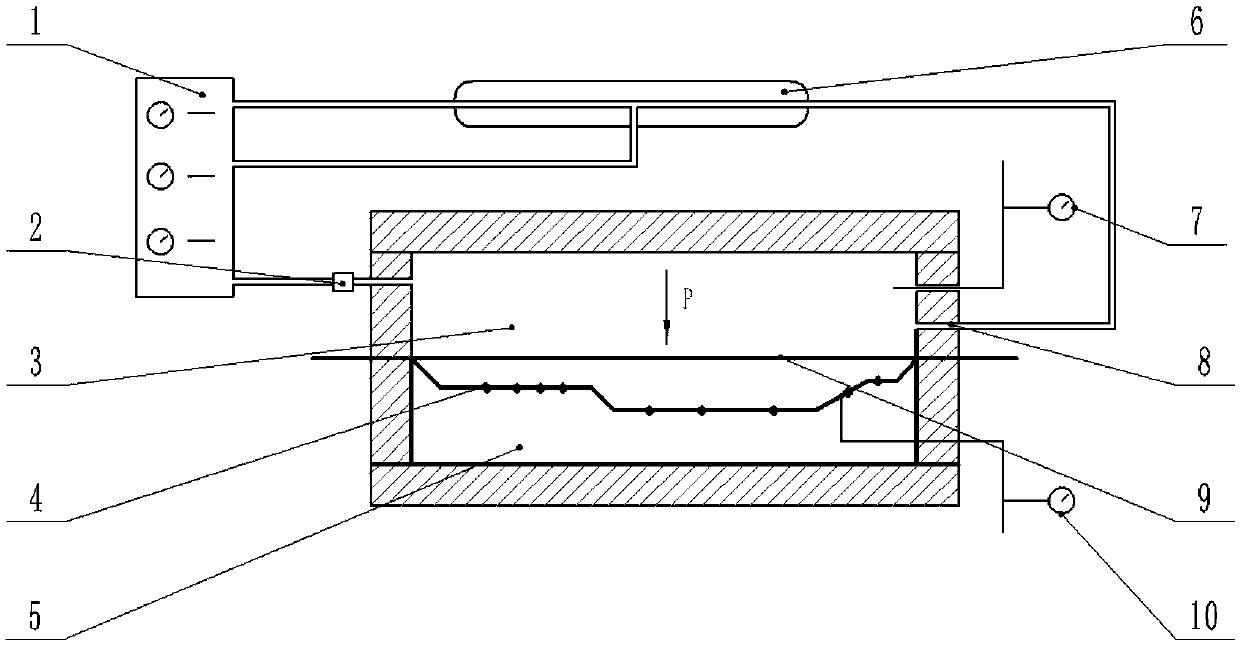

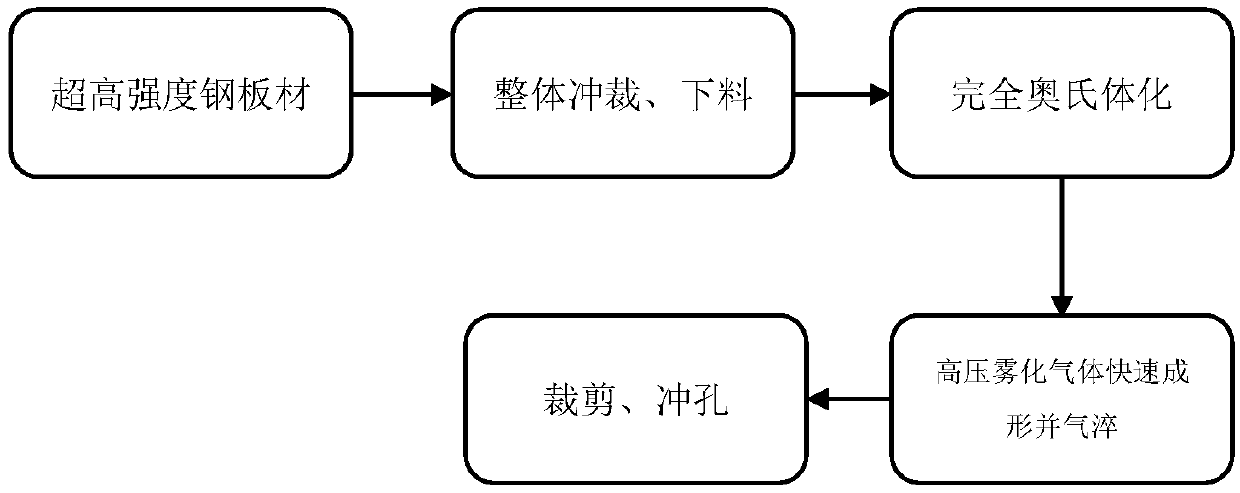

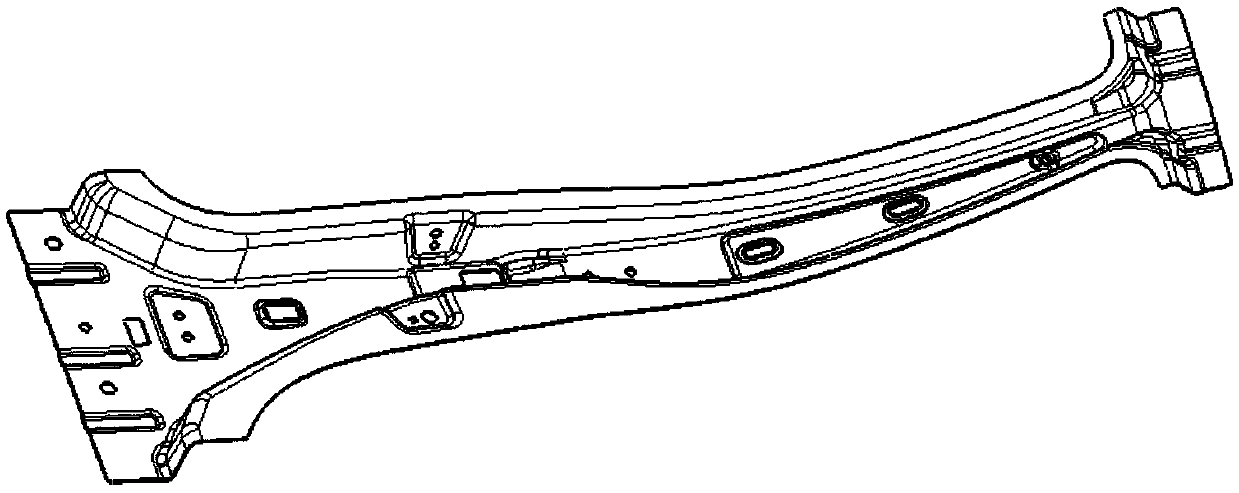

Pneumatic hot forming-quenching method and device for ultrahigh-strength steel complex component

ActiveCN107597966AStable quenchingStable realization of rapid quenching of ultra-high-strength steelShaping toolsFurnace typesControl systemHigh pressure

The invention discloses a pneumatic hot forming-atomization quenching method and device for an ultrahigh-strength steel complex component, and belongs to the technical fields of advanced metal manufacturing and plastic forming. The method comprises the steps that firstly, a punched plate is heated until austenization is complete; secondly, the punched plate is placed in a pneumatic forming device,a mold is closed, the plate and a female mold body are completely attached by gradually increasing the air pressure, and pressure maintaining is conducted for a period of time; thirdly, high-pressureatomized gas flowing at a high speed is formed in stamping equipment by atomizing supercooled liquid drops with circulating protection gas in a matched mode through a gas circulating control system,quick and uniform quenching is conducted on the ultrahigh-strength steel plate, and the complete Martensite structure is obtained; and lastly, cutting operation, punching operation and the like are conducted. According to the method, the non-uniform quenching phenomenon generated in the ultrahigh-strength steel cooling process can be effectively solved, the service life of the mold can be prolonged, the processes can be reduced, and the product surface quality can be improved; the forming efficiency of ultrahigh-strength steel can be improved, the cost can be reduced, and the high engineeringapplication value is achieved.

Owner:NANJING INST OF TECH

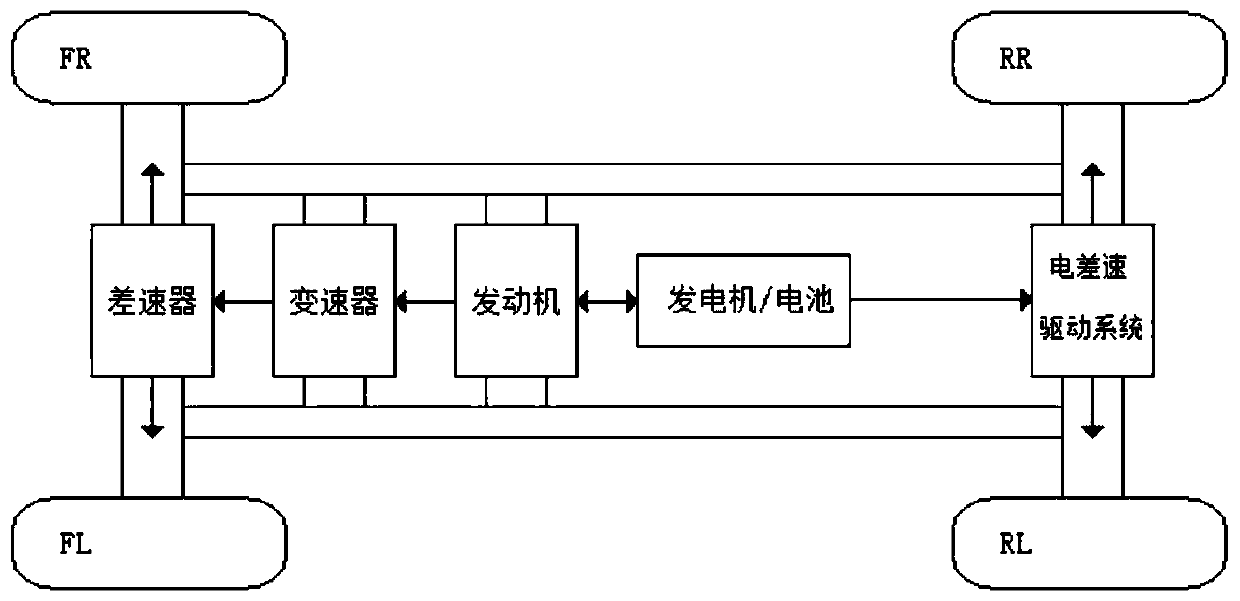

Coaxial opposite rotor differential motor and new energy automobile

InactiveCN111509937AStrong durabilityStrong technical versatilityHybrid vehiclesSpeed controllerMagnetic coreDrag torque

A coaxial opposite rotor differential motor belongs to the electromechanical technology and automobile technology field, and comprises a motor housing, a stator, and a first rotor and a second rotor which are coaxially assembled and opposed to each other. The stator, the first rotor and the second rotor are all stator and rotor structures of an asynchronous motor. Electrical parameters of the first rotor and the second rotor are the same. The stator comprises a stator magnetic core and a stator winding, the sum of effective magnetic core lengths of the first rotor and the second rotor is equalto the length of the stator magnetic core, and a magnetic field generated by the stator winding is shared by the first rotor and the second rotor; the first rotor is provided with a first output shaft, the second rotor is provided with a second output shaft, flexible and free operation is allowed between the first rotor and the second rotor, and the two rotors are axially clamped by the two end covers; when the stator winding is connected with an alternating current power supply, the three-phase rotating magnetic field in the vertical direction of the coil is axially segmented according to the electromagnetic principle, so that the first output shaft and the second output shaft face different resistance moments to achieve the differential effect.

Owner:佛山中锦微电科技有限公司

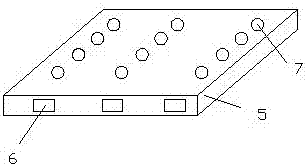

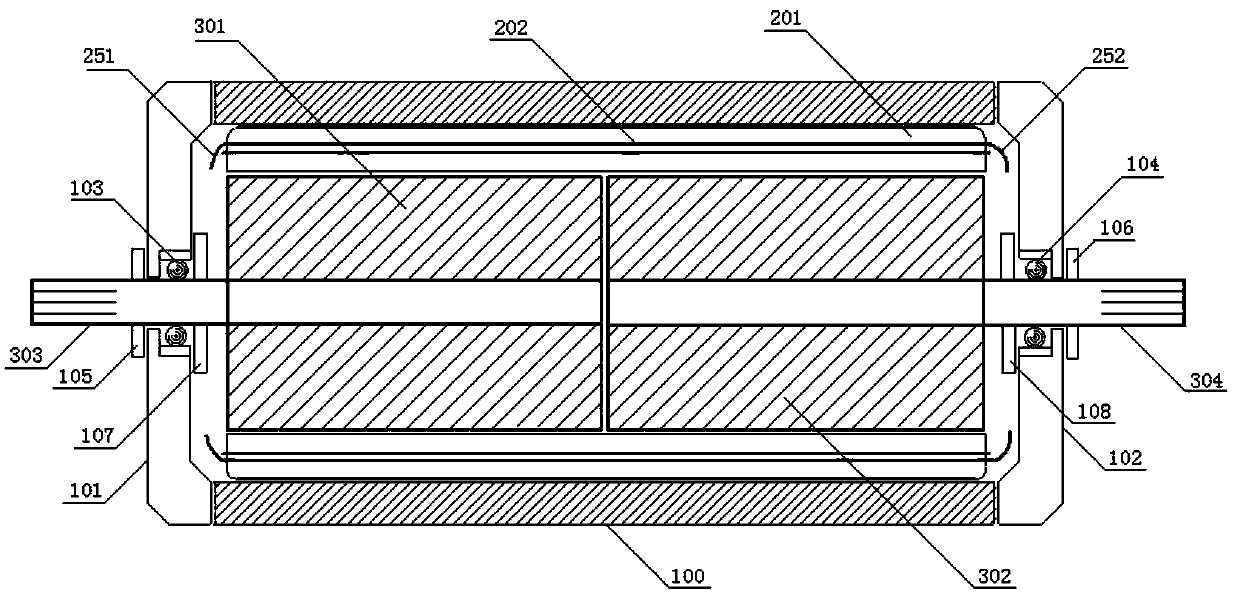

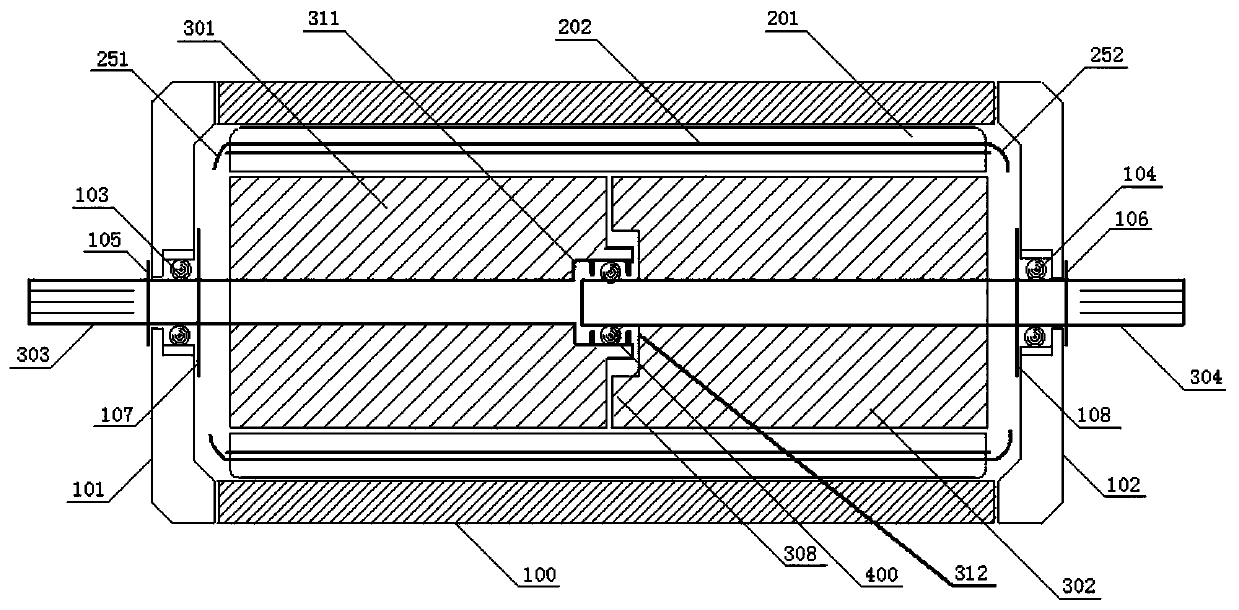

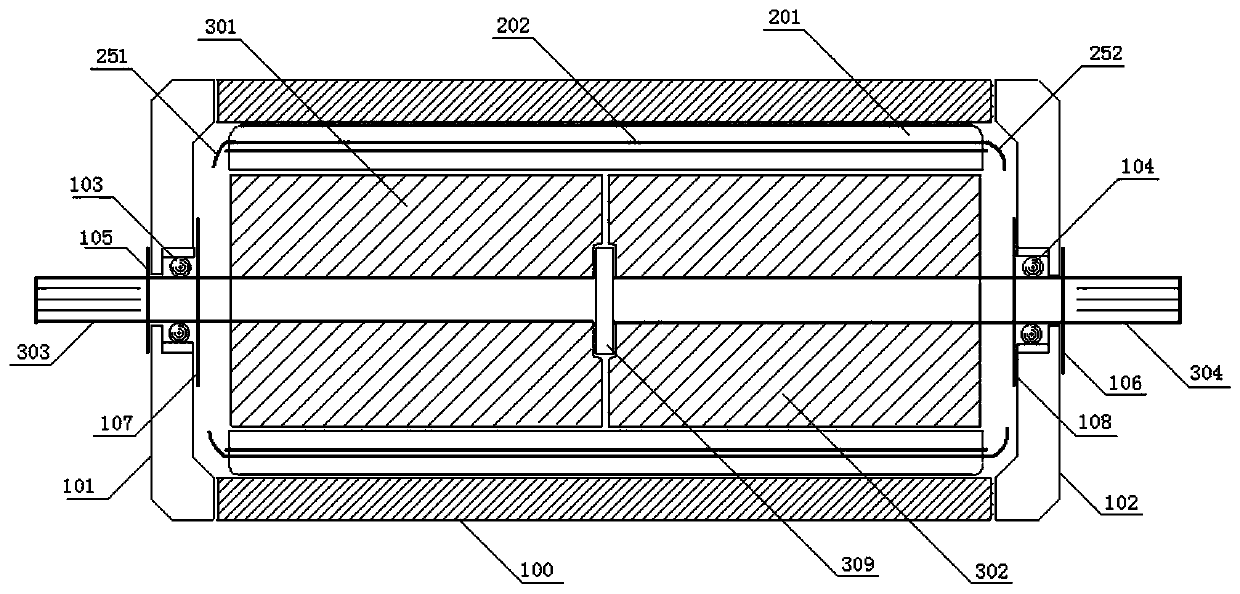

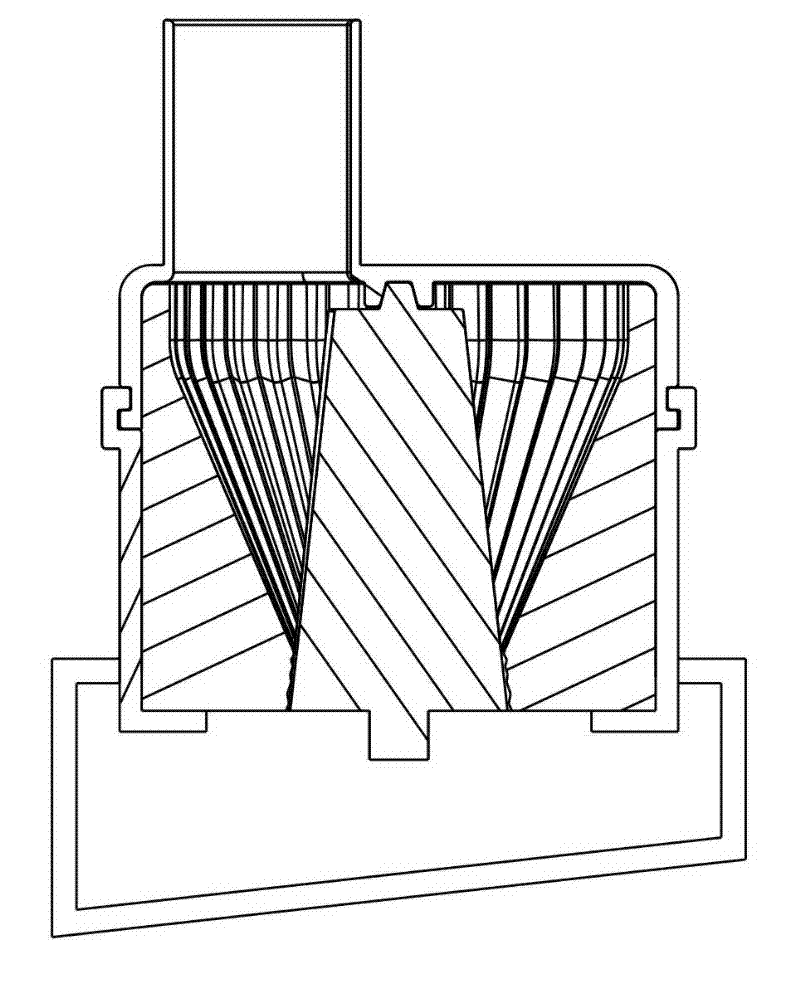

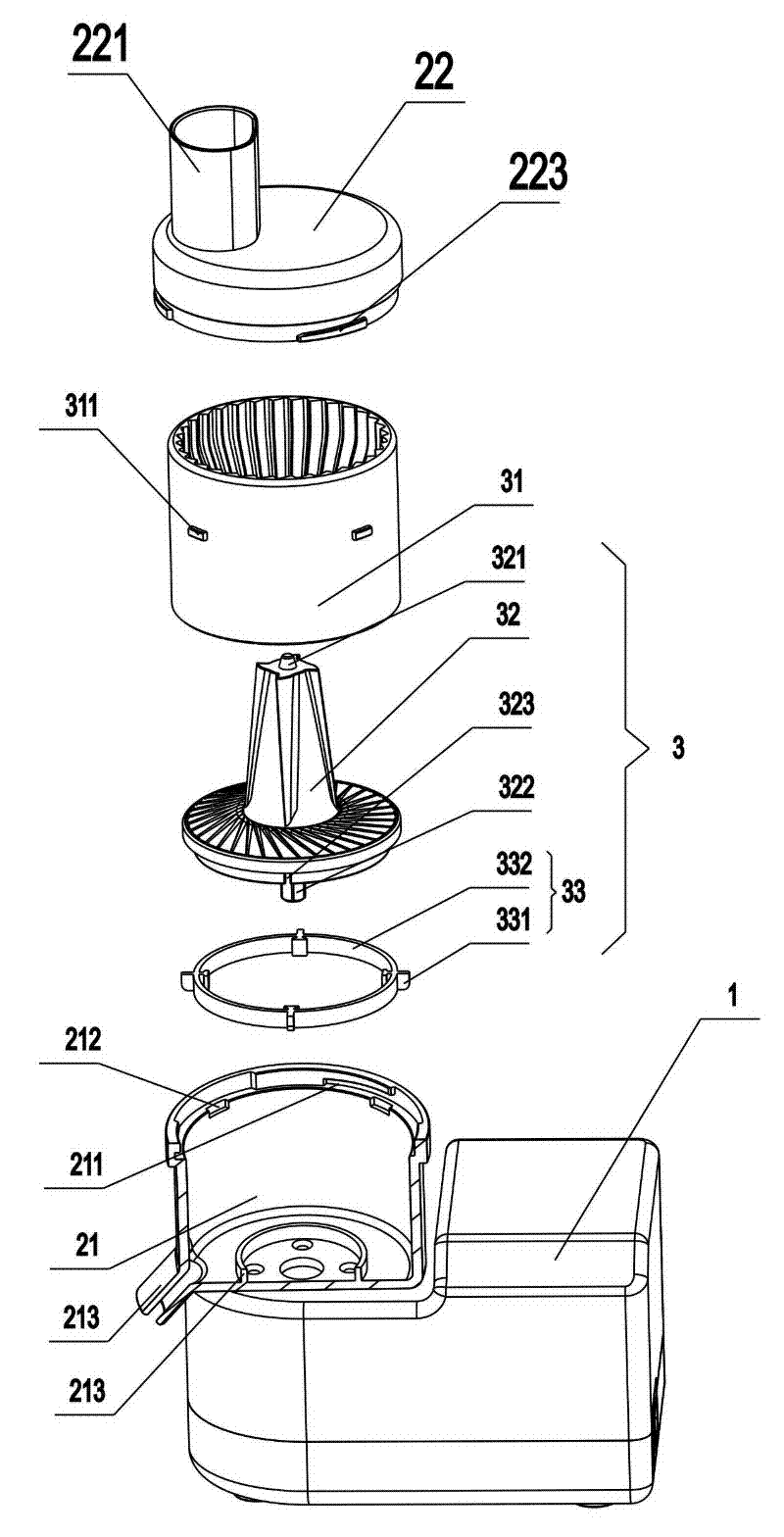

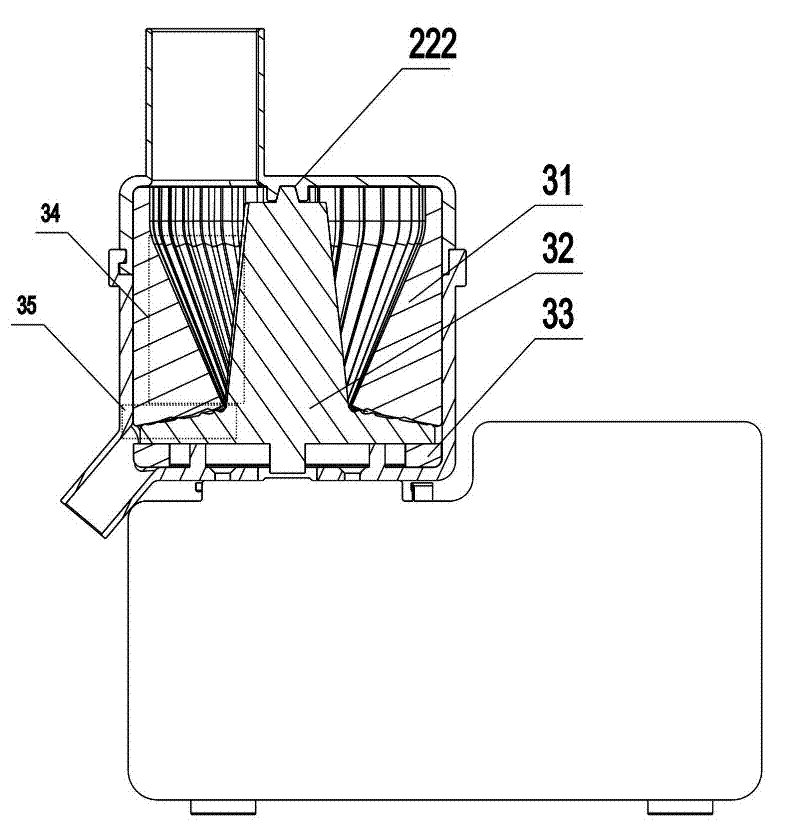

Grinder convenient for discharge

ActiveCN102362789AStrong technical versatilityEasy to implementCoffee millsSpice millsEngineeringMechanical engineering

The invention provides a grinder convenient for discharge. The grinder comprises a host, a material container and a grinding assembly, wherein the grinding assembly is arranged in the material container and is driven by a driving part arranged on the host. The grinder is characterized by also comprising a discharge port on the material container and a material sweeping device arranged in the material container and used for pushing material to go out of the discharge port. Through the arrangement of the discharge port and the material sweeping device, the grinder can realize automatic discharge and the material is discharged intensively and can be collected conveniently. Through the arrangement of the material sweeping device, the material container can be cleaned up and high hygiene degree is achieved; and the material sweeping device is applicable to various grinders, has high technical generality and low production cost, and is convenient to implement.

Owner:JOYOUNG CO LTD

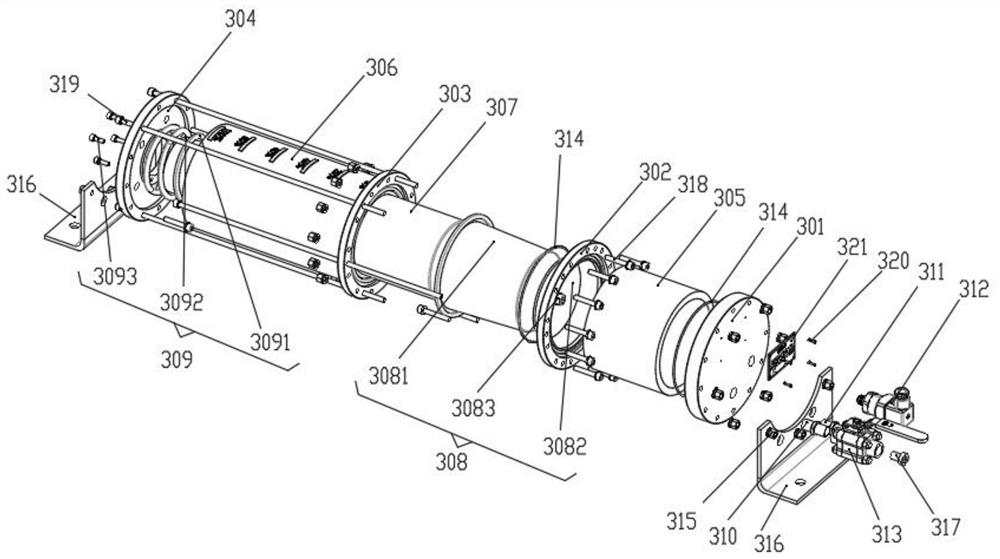

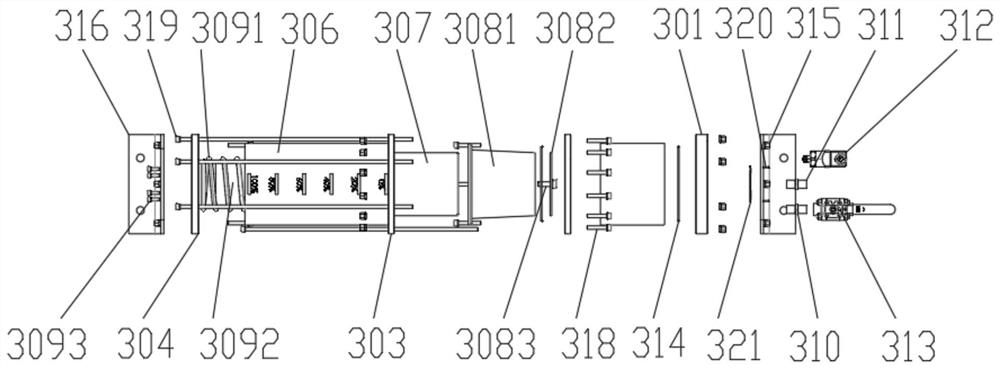

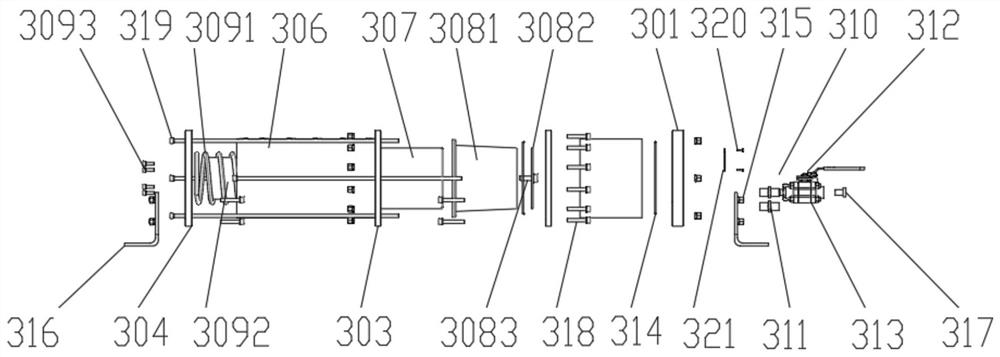

Differential pressure compensator of underwater hydraulic system

PendingCN112594256AReduce manufacturing costChange the pre-pressure at any timePipeline expansion-compensationFluid-pressure actuator componentsMiniaturizationPlunger

The invention discloses an underwater hydraulic system differential pressure compensator which is arranged in an installation cabin of a desilting robot and comprises a hydraulic oil side sealing cover, a hydraulic oil side telescopic leather bag sealing flange, a water passing side telescopic leather bag sealing flange and a base, a hydraulic oil side PC sleeve is arranged on the side wall of thehydraulic oil side telescopic leather bag sealing flange and the side wall of the hydraulic oil side sealing cover, the hydraulic oil side telescopic leather bag sealing flange is fixedly connected with the water passing side telescopic leather bag sealing flange, and a water passing side PC sleeve is arranged on the side wall of the water passing side telescopic leather bag sealing flange and the side wall of the base, sliding plungers are connected with the hydraulic oil side PC sleeve and the water passing side PC sleeve in a sliding mode, the invention provides a series of products with the random volume compensation from 2L to 16L, the pre-pressure can be changed at any time, the structure is simple, the manufacturing cost is low, the size is small, the technical universality is high, batch production can be achieved through a prefabricated grinding tool, the product quality is reliable, and the production efficiency is high, and the requirements of integration and miniaturization are achieved.

Owner:POWERCHINA XIBEI ENG +1

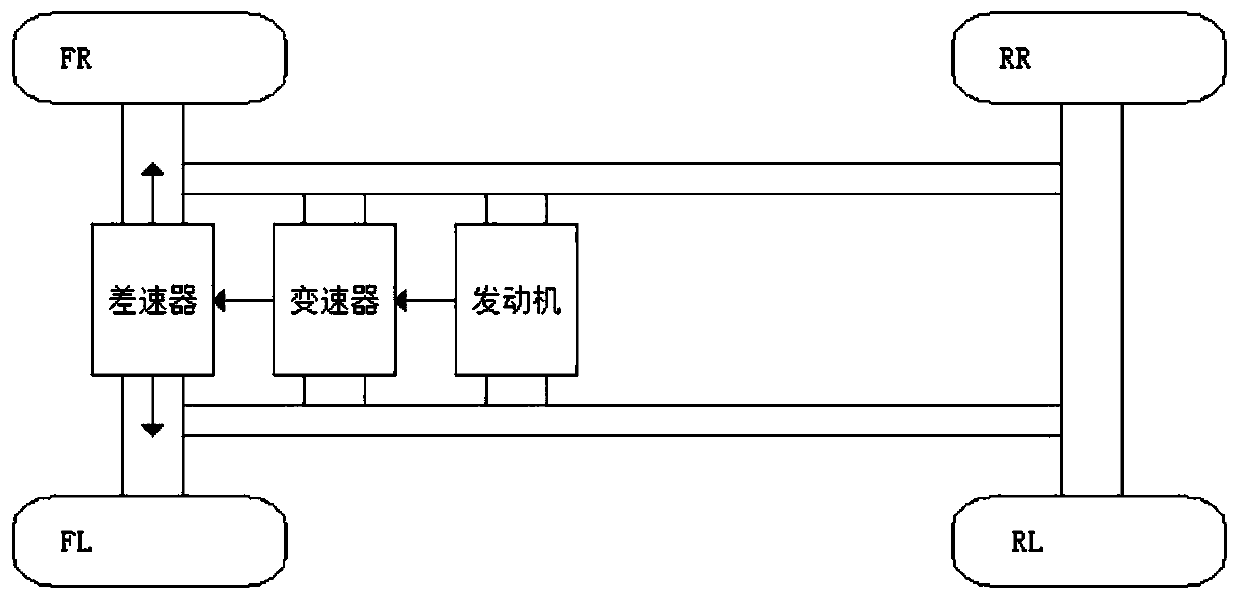

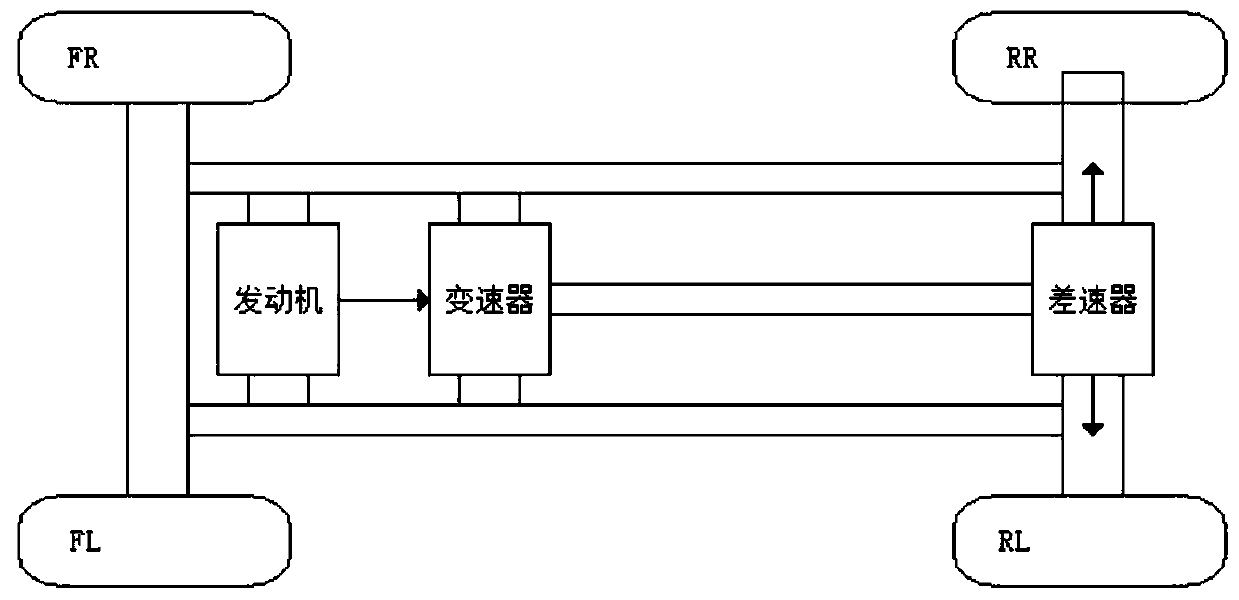

Hybrid power four-wheel drive configuration method for electrifying internal combustion power vehicle

InactiveCN111546884APromote maturityStable structureHybrid vehiclesSpeed controllerElectric machineryControl theory

The invention discloses a hybrid power four-wheel drive configuration method for electrifying a fuel vehicle. The method is characterized in that an electric differential drive system which is composed of two alternating current motors and has an electric differential and differential lock drive function is configured; when the two front wheels of the vehicle are driven by internal combustion power, the electric differential driving system is configured to provide power for the two rear wheels of the vehicle; when the two rear wheels of the vehicle are driven by internal combustion power, theelectric differential driving system is configured to provide power for the two front wheels of the vehicle; an internal combustion power vehicle is electrically driven, four-drive-force split-axle configuration is achieved through hybrid power, a mechanical differential mechanism is omitted, and differential lock and even differential rate control is achieved; the starting and accelerating performances of the vehicle are improved; performance improvement of an electric differential system in the aspects of differential, anti-skid driving, trafficability, controllability, safety, light weightand energy conservation is fully utilized, great technical breakthrough and innovation in the aspects of high-performance four-wheel drive, environmental protection, cost reduction and the like of thevehicle are achieved, and the four-wheel drive technology and market value are huge.

Owner:佛山中锦微电科技有限公司

Kit for identifying fruit flies and special primers therefor

InactiveCN102517388BStrong representativeGuaranteed accuracyMicrobiological testing/measurementDNA/RNA fragmentationEcology

Owner:CHINA AGRI UNIV +1

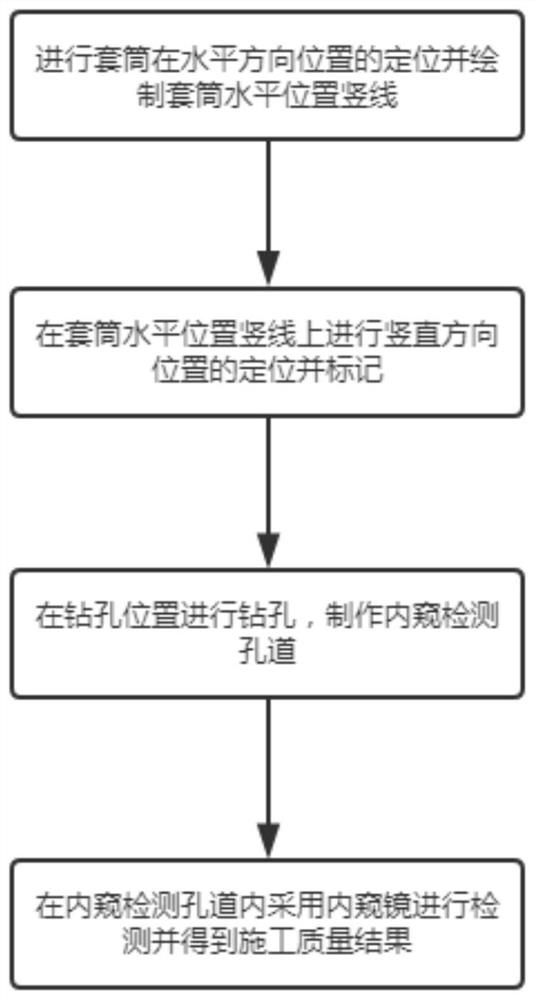

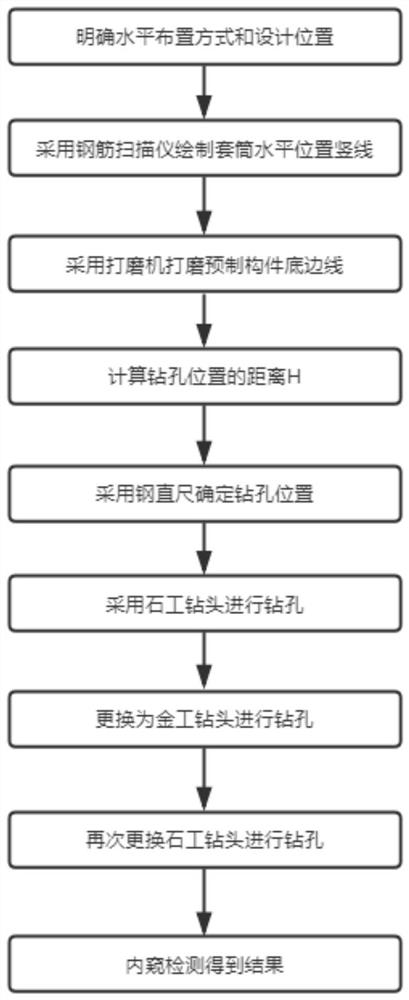

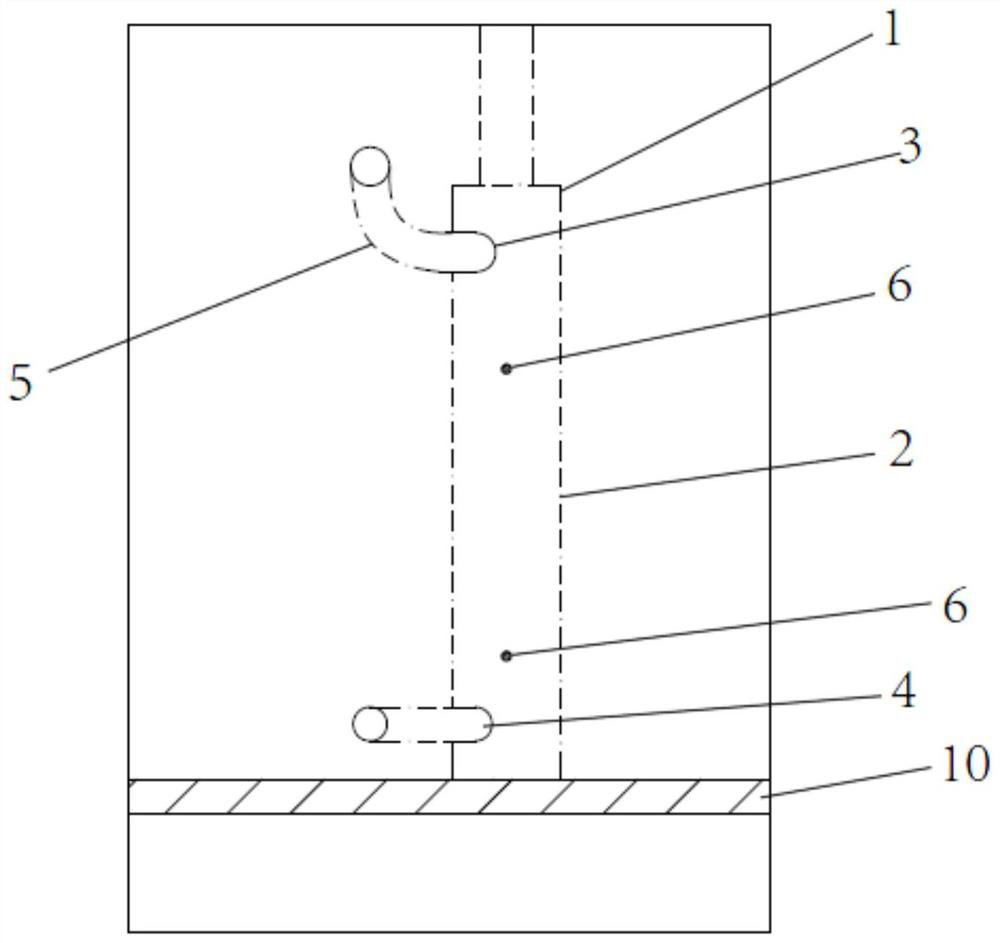

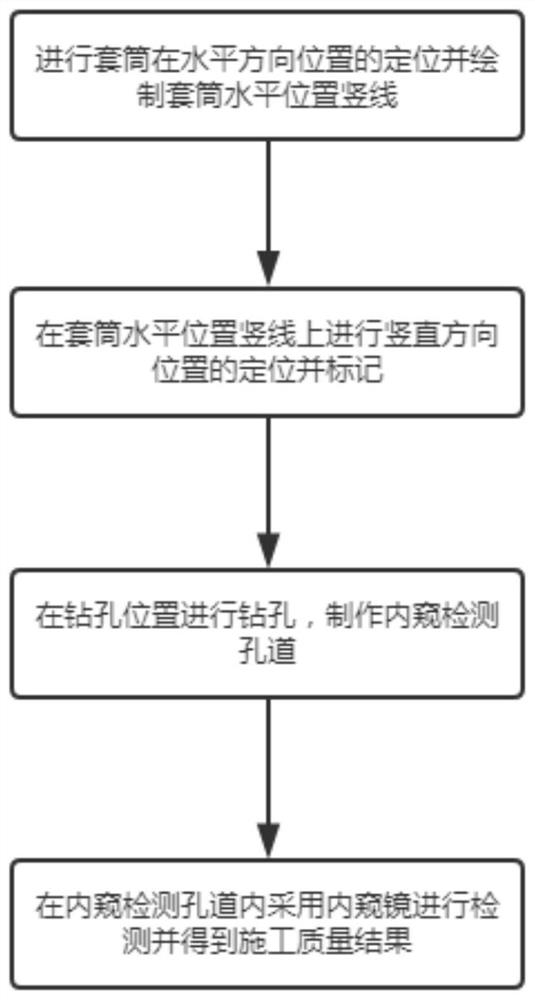

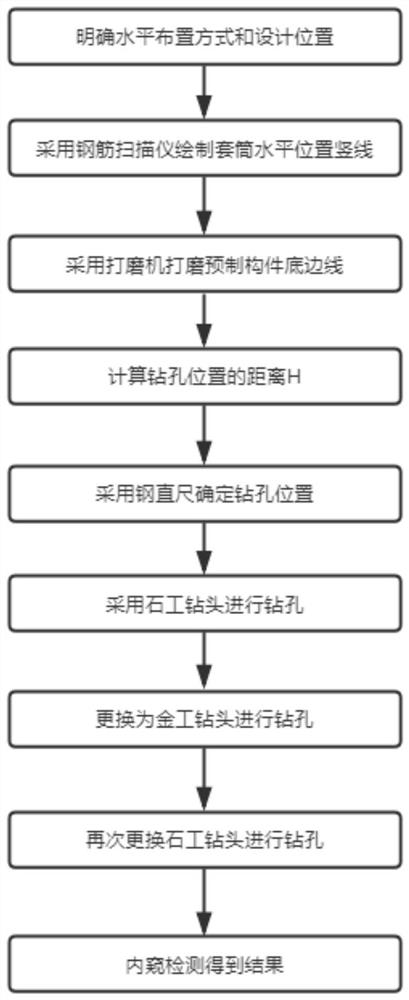

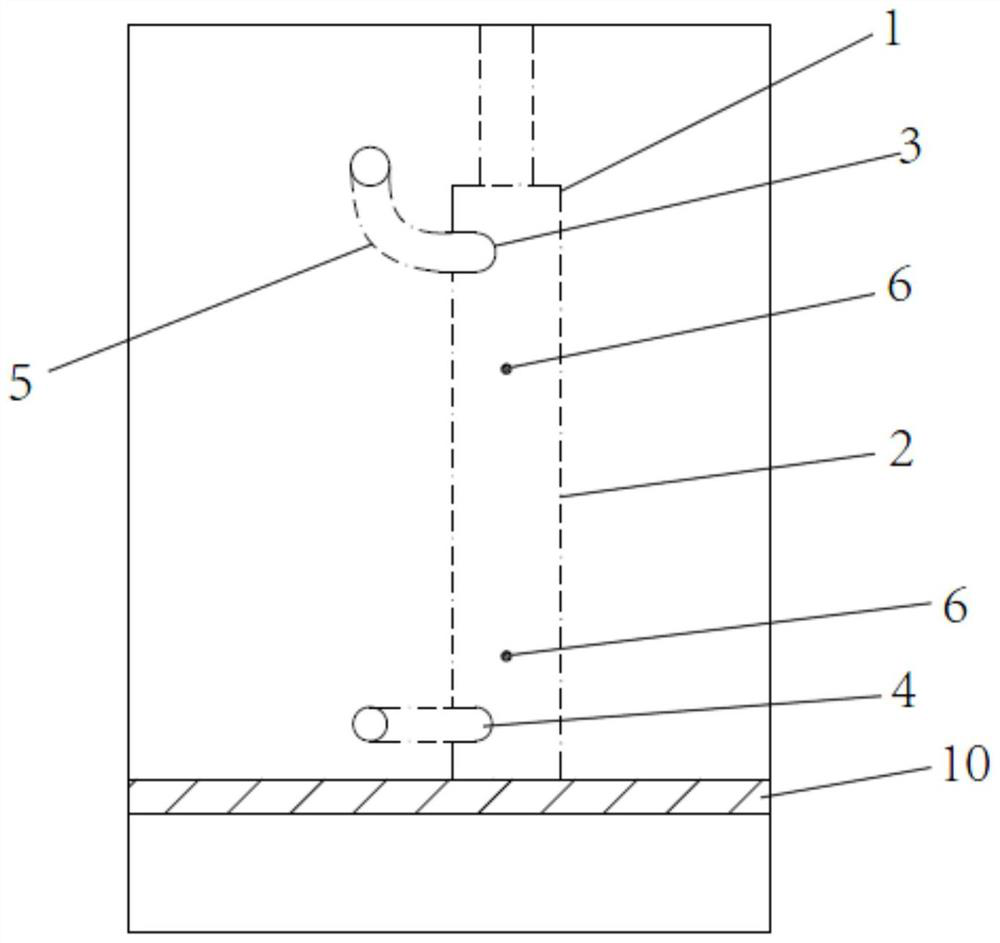

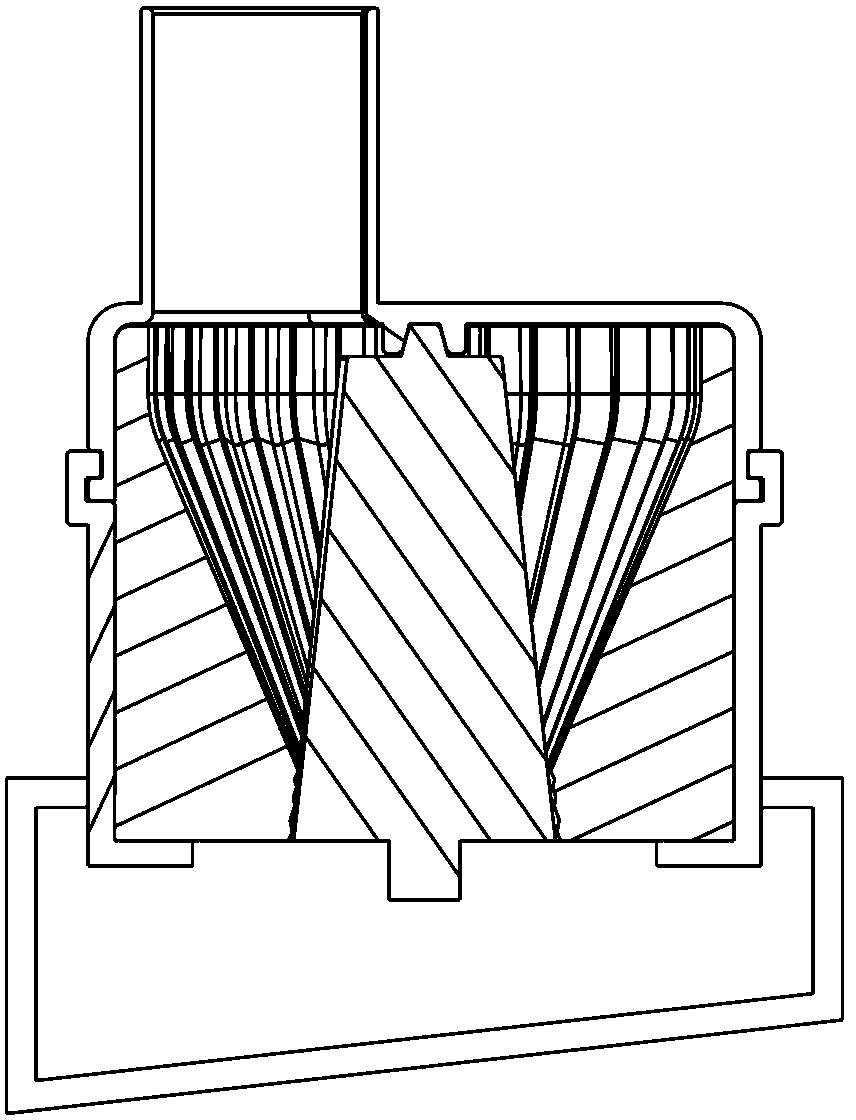

A preparation method of endoscopic tunnel for sleeve grouting connection construction quality inspection

ActiveCN113492461BPrecise positioningHigh precisionEdge grinding machinesMaterial analysis by optical meansRebarHorizontal orientation

The invention discloses an endoscopic tunnel preparation method for the quality inspection of sleeve grouting connection construction. First, the position of the sleeve in the horizontal direction is positioned and the vertical line of the horizontal position of the sleeve is drawn, and a steel bar scanner is used to scan the inspected sleeve. Accurately locate the horizontal position of the sleeve, locate at least 2 points in the vertical direction, connect them into a straight line, mark the straight line as the vertical line of the horizontal position of the sleeve, and then perform positioning in the vertical direction on the vertical line of the horizontal position of the sleeve to determine The drilling position is marked, and the hole is drilled at the drilling position to make an endoscopic inspection channel; finally, an endoscope is used to detect in the endoscopic inspection channel and the construction quality result is obtained. The invention can quickly and accurately locate the position of the rotating hole, and can drill the hole efficiently and safely, thereby greatly improving the accuracy of the detection result.

Owner:KUNSHAN CONSTRUCT ENG QUALITY TESTING CENT

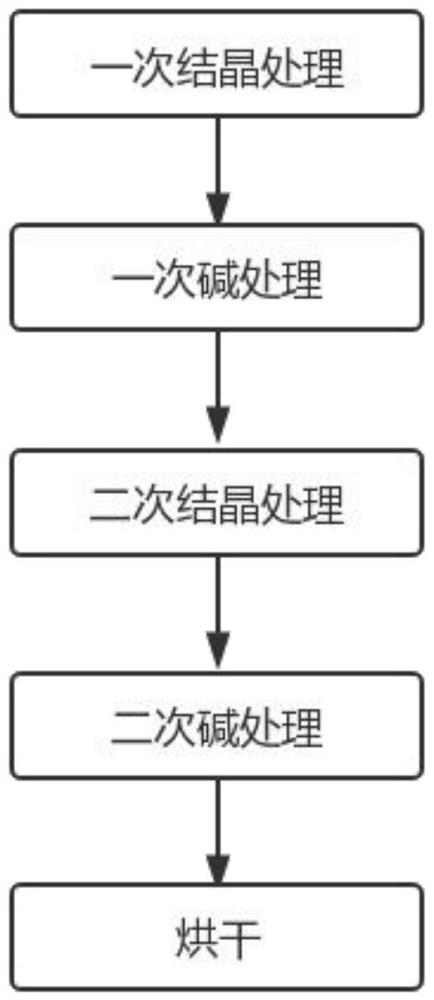

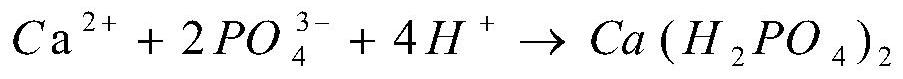

Gypsum-based building material product moisture-proof treatment process using industrial waste acid

PendingCN113248280AStrong technical versatilityThe process technology route is simpleO-Phosphoric AcidToxic industrial waste

The invention discloses a moisture-proof treatment process for a gypsum-based building material product by utilizing industrial waste acid, and belongs to the field of building materials. Aiming at the characteristics that the gypsum-based building material product is not resistant to water and low in softening coefficient, a process route of soaking in a phosphoric acid solution twice and soaking in saturated lime water twice is adopted, and a layer of insoluble calcium phosphate crystals is generated in pores and the surface of the gypsum-based building material product. On one hand, insoluble calcium phosphate crystals can hinder the dissolution effect of water on calcium sulfate, and on the other hand, gypsum pores can be filled, so that the aim of improving the strength and water resistance of gypsum is achieved. The technical route is simple, the raw materials are mainly industrial waste acid, the method is green and environment-friendly, the economic benefit is prominent, and the water resistance of the gypsum-based building material product can be effectively improved.

Owner:云南凝创环保科技有限公司

Quasi-differential lock control system, differential rate control system and method and automobile

ActiveCN111509936AStable structureIncreased durabilityHybrid vehiclesSpeed controllerPhase splittingElectric machine

All windings of n three-phase alternating-current motors are connected end to end according to a motor sequence after phase splitting to obtain three edges belonging to three phases; the three edges are connected end to end to form a large triangle; the end-to-end connection points of the adjacent windings in each side are n equal division points of the side; each vertex of the large triangle is electrically connected with one n equal division point corresponding to the opposite side to form an equal division center line, two parts cut from the large triangle are equivalent to two new small triangles in electrical connection relation after the three equal division center lines are connected, and the vertexes of the small triangles coincide with the three vertexes of the large triangle; three vertexes are connected with a three-phase alternating current power supply, the motors in the small triangles are still kept in the same rotating direction when the large triangle runs, the three equal division center lines are connected to realize a quasi differential lock function among the motors, the differential function of back-load inductive voltage distribution is realized when the three equal division center lines are disconnected, and the phase sequence connection relationship is called as a neutral line theorem of the three-phase alternating current motor; and the difference rategamma can be modulated through the on-line switch conduction rate Cy.

Owner:佛山中锦微电科技有限公司

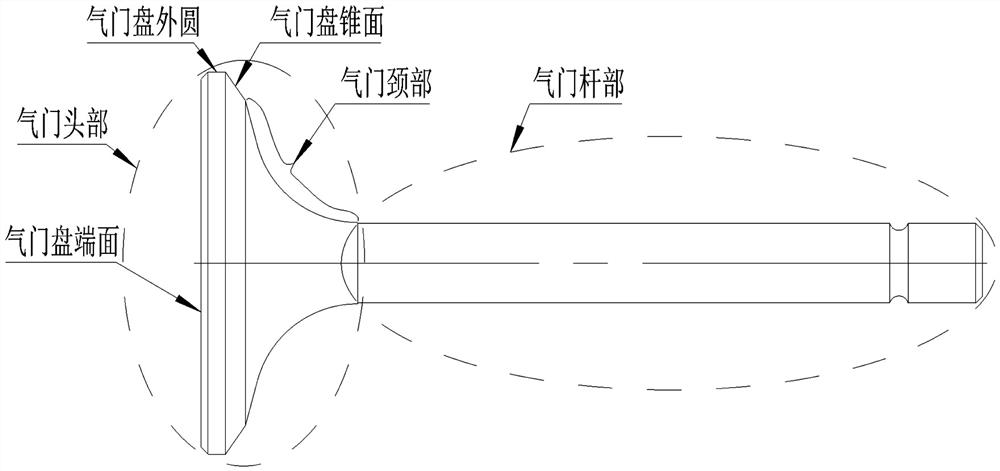

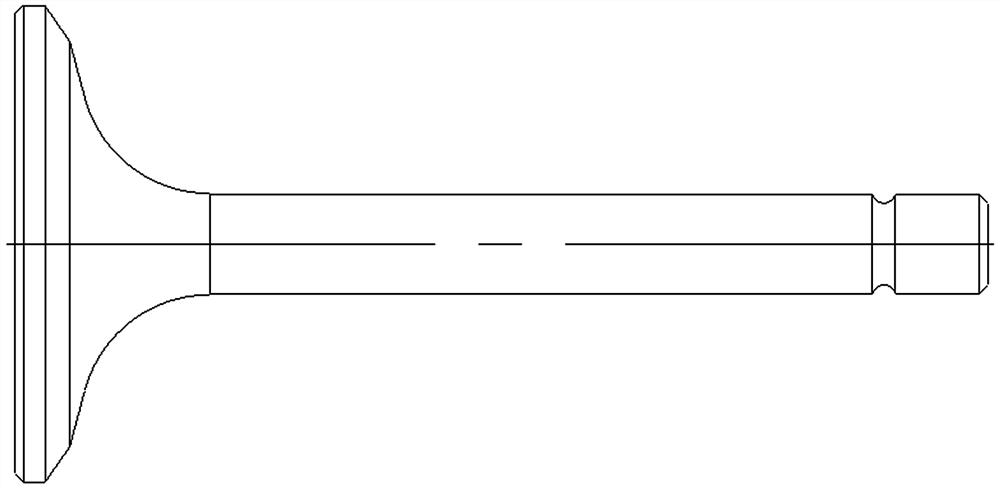

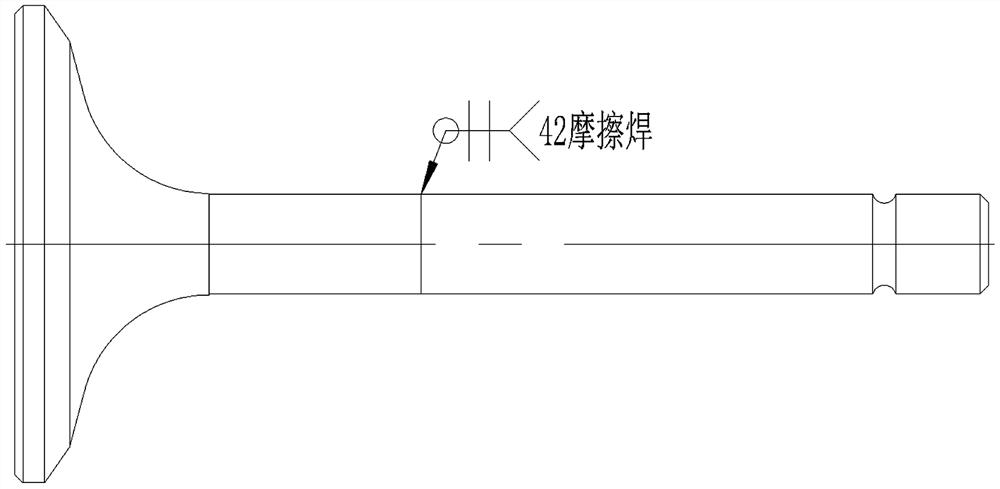

Multi-metal structure valve

PendingCN111663976AMeet wear and corrosion resistance requirementsGood work reliabilityMachines/enginesLift valveCircular discFriction welding

The invention provides a multi-metal structure valve. The multi-metal structure valve is composed of a valve head and a valve rod. The valve head comprises a valve disc part and a valve neck part. Thevalve disc part comprises a disc end face, a disc outer circle and a disc conical face. The valve head can be divided into a small disc and an outer circular ring in the annular direction. The smalldisc and the outer circular ring are made of different metal materials and are tightly combined. The disc outer circle, the disc conical face and the disc end face are partially located on the outer circular ring. The multi-metal structure valve can meet the requirements for abrasion resistance and corrosion resistance of the valve conical face and the requirements for tensile strength, yield strength and fatigue strength of the valve neck part in a high-temperature state, and better work reliability is achieved. The multi-metal structure valve can be adopted in existing common single-metal integral material structure valves, double-metal friction welding structure valves, surface treatment valves, hollow sodium-cooled double-metal valves and the like in the valve blank stage.

Owner:HUNAN TYEN MACHINERY

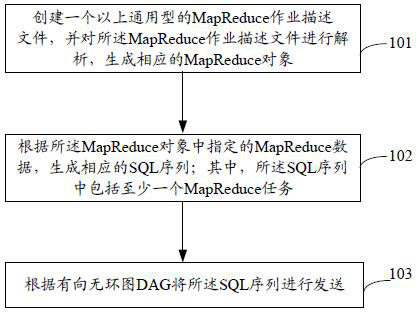

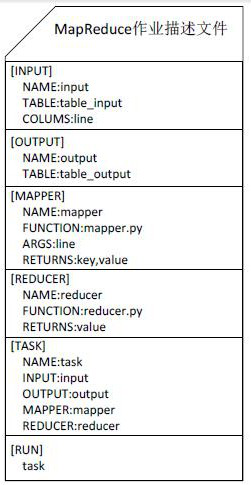

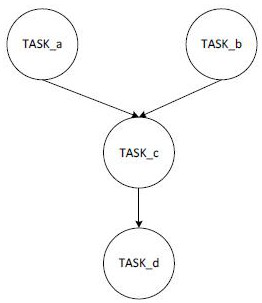

A method, device and system for running mapreduce jobs

ActiveCN108614731BComplies with the way of writingUnlimited mapping relationshipProgram initiation/switchingSoftware engineeringParallel computingTheoretical computer science

The invention discloses a method for running a MapReduce job. The method includes: creating more than one general-purpose MapReduce job description file, and parsing the MapReduce job description file to generate a corresponding MapReduce object; according to the MapReduce object Generate the corresponding Structured Query Language (SQL) sequence for the MapReduce data specified in ; wherein, the SQL sequence includes at least one MapReduce task; and send the SQL sequence according to a Directed Acyclic Graph (DAG). The invention also discloses a device and system for running MapReduce jobs at the same time.

Owner:CHINA MOBILE SUZHOU SOFTWARE TECH CO LTD +1

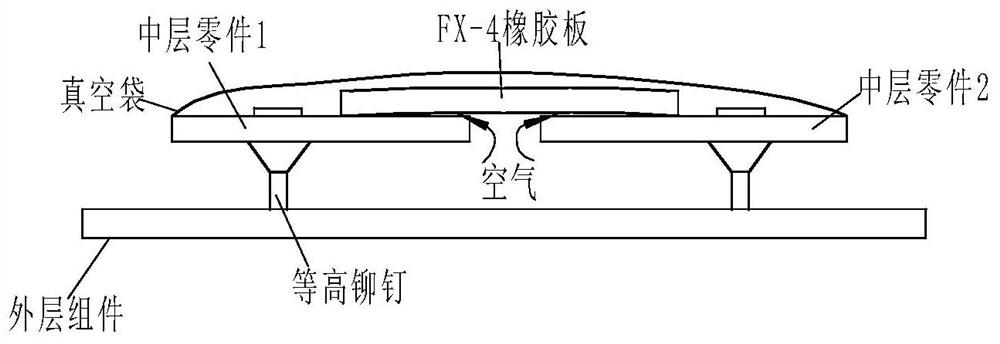

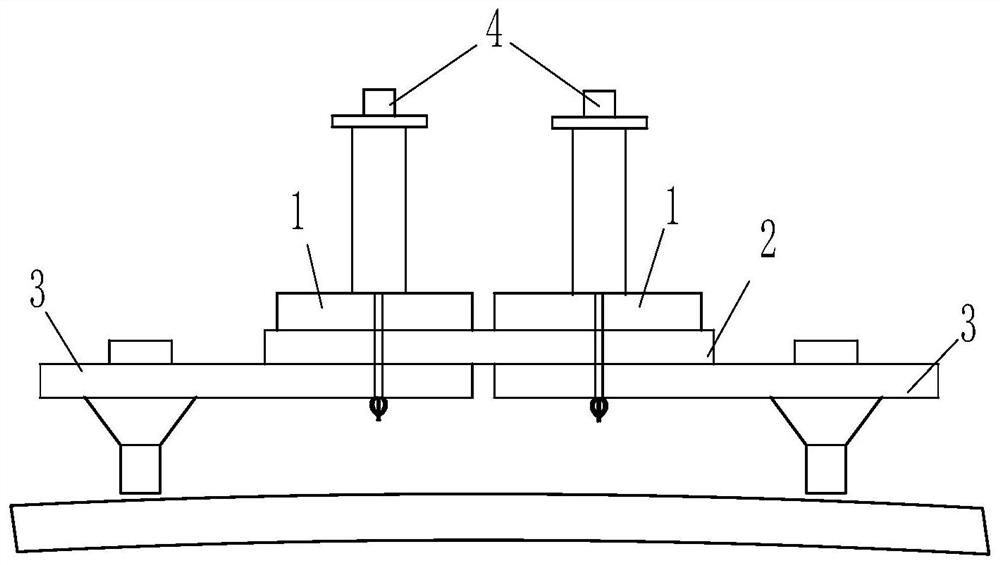

Fluororubber plate cementing, pressurizing and curing method and device

PendingCN114131940ASolve the technical difficulties of bondingEasy to operateMetal working apparatusAdhesiveMechanical engineering

The invention provides a method and a device for gluing, pressurizing and curing a fluororubber plate. The method comprises the following steps of: adhering the fluororubber plate (2) on the respective adhering surfaces of a first part and a second part to be adhered by adopting an adhesive; the first pressing plate and the second pressing plate are arranged on the two sides of the fluororubber plate (2) respectively; auxiliary holes are pre-formed in the first pressing plate and the second pressing plate; auxiliary holes are drilled in the fluororubber plate (2), the first part and the second part in a matched mode according to preset auxiliary holes, and a spring clamp (4) is arranged in each pair of auxiliary holes; after the fluororubber plate is pressurized and cured, the spring clip (4) and the pressing plate are taken down; and the auxiliary hole is plugged by adopting an adhesive. By designing and manufacturing a pressing plate consistent with a bonded curved surface in curvature change, after the fluororubber plate is bonded, the pressing plate is fixed on the fluororubber plate, then a fabrication hole is formed, and a spring clip pressurizing and curing mode is adopted through the fabrication hole, so that the technical difficulty of pressurizing and curing in the gluing process of the fluororubber plate on a multi-curved-surface complex part with a cavity structure is solved.

Owner:CHINA HELICOPTER RES & DEV INST +1

Preparation method of endoscopic hole channel for sleeve grouting connection construction quality detection

ActiveCN113492461APrecise positioningHigh precisionEdge grinding machinesMaterial analysis by optical meansEngineeringRebar

The invention discloses a preparation method of an endoscopic hole channel for sleeve grouting connection construction quality detection, which comprises the following steps of: positioning a sleeve in the horizontal direction, drawing a vertical line of the horizontal position of the sleeve, accurately positioning the horizontal position of the detected sleeve by adopting a steel bar scanner, positioning at least two points in the vertical direction, connecting the two points into a straight line, marking the straight line as a horizontal position vertical line of the sleeve, then, positioning the position in the vertical direction on the horizontal position vertical line of the sleeve, determining and marking a drilling position, performing drilling at the drilling position, and manufacturing an endoscopic detection hole channel; and finally, adopting an endoscope for detection in the endoscopic detection hole channel to obtain a construction quality result. According to the invention, the drilling position can be rapidly and accurately positioned; efficient and safe drilling can be achieved; and the precision of a detection result is greatly improved.

Owner:KUNSHAN CONSTRUCT ENG QUALITY TESTING CENT

Grinder convenient for discharge

ActiveCN102362789BRealize automatic dischargeEasy to collectCoffee millsSpice millsEngineeringMechanical engineering

The invention provides a grinder convenient for discharge. The grinder comprises a host, a material container and a grinding assembly, wherein the grinding assembly is arranged in the material container and is driven by a driving part arranged on the host. The grinder is characterized by also comprising a discharge port on the material container and a material sweeping device arranged in the material container and used for pushing material to go out of the discharge port. Through the arrangement of the discharge port and the material sweeping device, the grinder can realize automatic discharge and the material is discharged intensively and can be collected conveniently. Through the arrangement of the material sweeping device, the material container can be cleaned up and high hygiene degree is achieved; and the material sweeping device is applicable to various grinders, has high technical generality and low production cost, and is convenient to implement.

Owner:JOYOUNG CO LTD

A filter dust removal reminder method, reminder device and air conditioner

ActiveCN111649450BJudging the degree of dirtinessStrong technical versatilityMechanical apparatusSpace heating and ventilation safety systemsElectrical resistance and conductanceDust control

The invention relates to a filter net dedusting reminding method, a reminding device and an air conditioner, which reflects the dirty and clogged state of the filter net by monitoring the resistance value change of the resistance strain gauge, and when the filter net is dirty and clogged to a certain degree, the dust removal reminder is carried out by The resistance value R of the resistance strain gauge under normal working conditions i The resistance value R of the resistance strain gauge after the cleaning operation with the filter a For comparison, identify whether it is working normally and distinguish the dirty and clogged state of the filter screen, which has a good distinction and prompt effect, and this scheme does not change the existing structure of the air conditioner, only the filter screen and the filter screen limit card of the middle frame Just buckle up and arrange resistance strain gauges, which has the technical effect of strong technical versatility and simple later inspection and maintenance.

Owner:NINGBO AUX ELECTRIC +1

Primer pair and kit for identifying or assisting identification of stored bean weevil

ActiveCN104498593BIdentification achievedLower requirementMicrobiological testing/measurementDNA/RNA fragmentationBiotechnologyGenetics

Owner:INST OF FOOD CROPS HUBEI ACAD OF AGRI SCI

A quenching method for aerodynamic thermoforming of complex components of ultra-high-strength steel

ActiveCN107597966BStable quenchingStable realization of rapid quenching of ultra-high-strength steelShaping toolsFurnace typesControl systemProduct gas

Owner:NANJING INST OF TECH

Method for measuring absolute position of rotor in motor servo system

ActiveCN102829742BSimple mechanical structureReduce volumeMeasurement devicesSignal processing circuitsCoupling

The invention discloses a method for measuring the absolute position of a rotor in a motor servo system, comprising the steps of: integrally combining the motor and a position sensor; and by utilizing position information provided by a predetermined position as well as relative position information and pitch information provided by the sensor, and recombining the position information through using a proper method so as to obtain absolute position information of the motor rotor. According to the method, a zero position indicator is not required; after outage, the absolute position of a zero position of a relative system of the motor rotor can be obtained through the predetermined position of the motor rotor; compared with a coarse / fine coupling double-speed rotary transformer system, the high-precision absolute position information is obtained by using the simple and reliable sensor, so that the structure of the integrated high-performance servo motor is simplified and decreased, then the structure is more compact and the volume is decreased; and at the same time, a signal processing circuit and coarse / fine coupling operation are decreased, so that compared with the coarse / fine coupling double-speed rotary transformer system, the performance-price ratio is improved and the complexity level is reduced.

Owner:BEIJING PULIMEN ELECTRO MECHANICAL HIGH TECHN CO

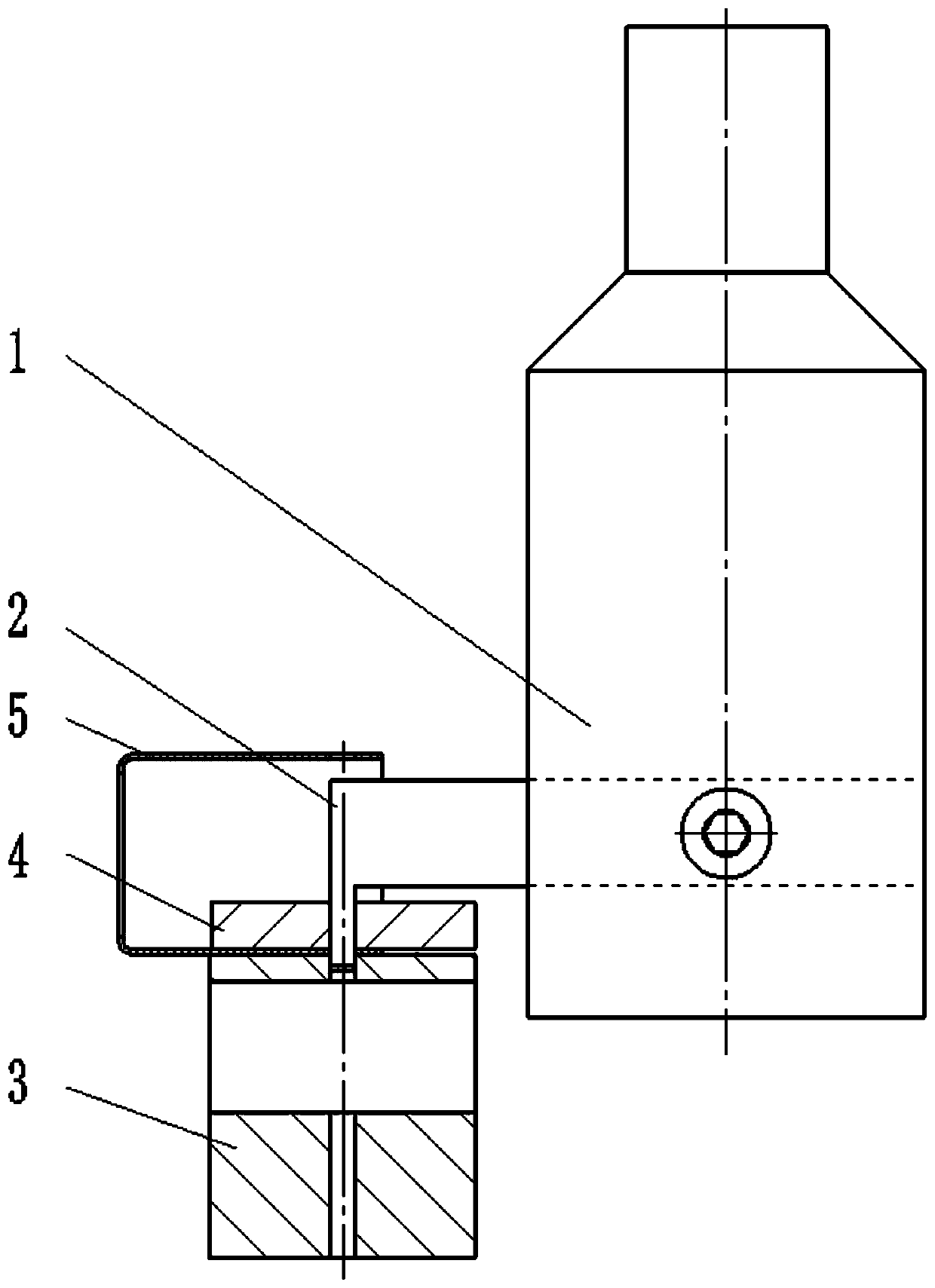

Punching die structure of side face side wall hole

The invention provides a punching die structure of a side face side wall hole. The punching die structure comprises a male die fixed block and a female die, the upper end of the male die fixed block is provided with a die handle, and is connected with the bottom of the upper end of a driving mechanism, the lower end side face of the male die fixed block is connected with a male die, a positioninggroove used for positioning the outer side face of a shell part is formed in the upper end face of the female die, material leaking large square holes are formed in the bottom of the positioning groove and the side face of the female die, guide positioning grooves are formed in the two sides of a concave hole, a protrusion is arranged on the lower end face of a positioning discharging plate, the protrusion of the positioning discharging plate corresponds to the positioning groove of the female die, a gap is formed, the gap forms the shell part inner and outer cavity shape, the punching manneris novel, the die structure design is reasonable and ingenious, through the production practice, the punching quality and precision are high, it is ensured that the inner and outer dual face punchingedges of the shell part are smooth, flat and free of burrs, and quality needs of part practical production can be met.

Owner:GUIZHOU ZHENHUA HUALIAN ELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com