Grinder convenient for discharge

A grinder and convenient technology, applied in the field of food processing, can solve the problems of moldy food, unfavorable discharge and collection, poor hygiene, etc., and achieve the effects of strong technical versatility, wide application range and low production cost

Active Publication Date: 2013-11-06

JOYOUNG CO LTD

View PDF3 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] 1. Since the grinding assembly that mainly completes the processing is usually set in the shape of a disc or shaft, the output of the grinding assembly will wrap around the surrounding of the grinding assembly, and rely on automatic blanking to achieve collection. It is necessary to set a larger collection container so that the The increased volume of the grinder makes the grinder inconvenient to use and increases the manufacturing cost

[0006] 2. Since the grinder needs to process various materials, the shapes of various materials are different after processing, such as processing dry materials and wet materials, the dry materials can be automatically discharged, and because the wet materials have a certain viscosity, It will stick to the grinding assembly and collection container, which is not conducive to normal discharge and collection

[0007] 3. Due to relying on the material diversion groove to realize the discharge, it is inevitable that some food cannot be completely discharged and needs to be cleaned manually, which increases the operating time and difficulty of the user; or, because the food is not cleaned in time, and Cause food moldy, etc., poor sanitation

[0008] 4. Relying on wind blowing or throwing out to collect food will blow food everywhere, and when processing powdery food, wind blowing will not be able to collect

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0035] The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

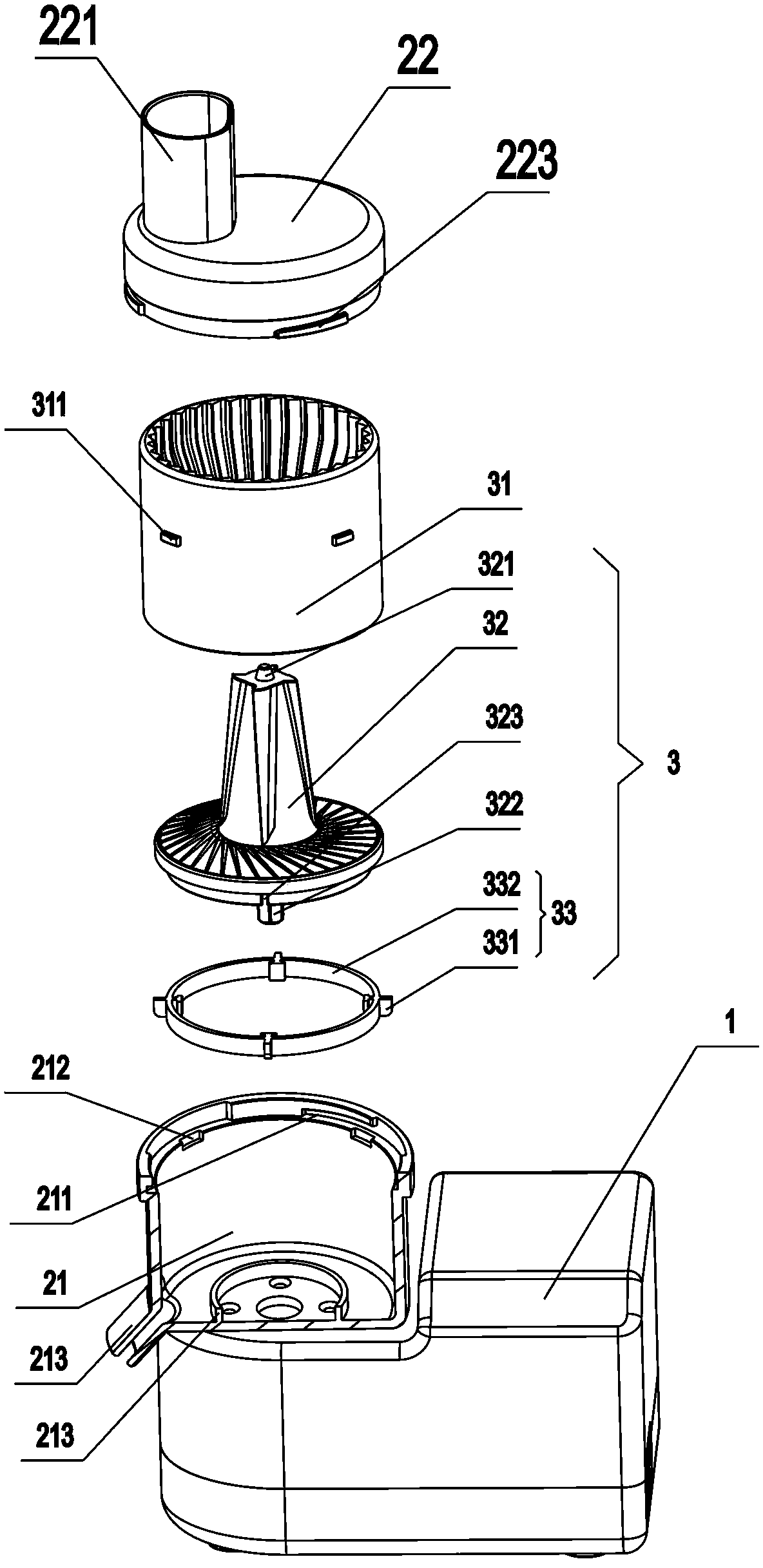

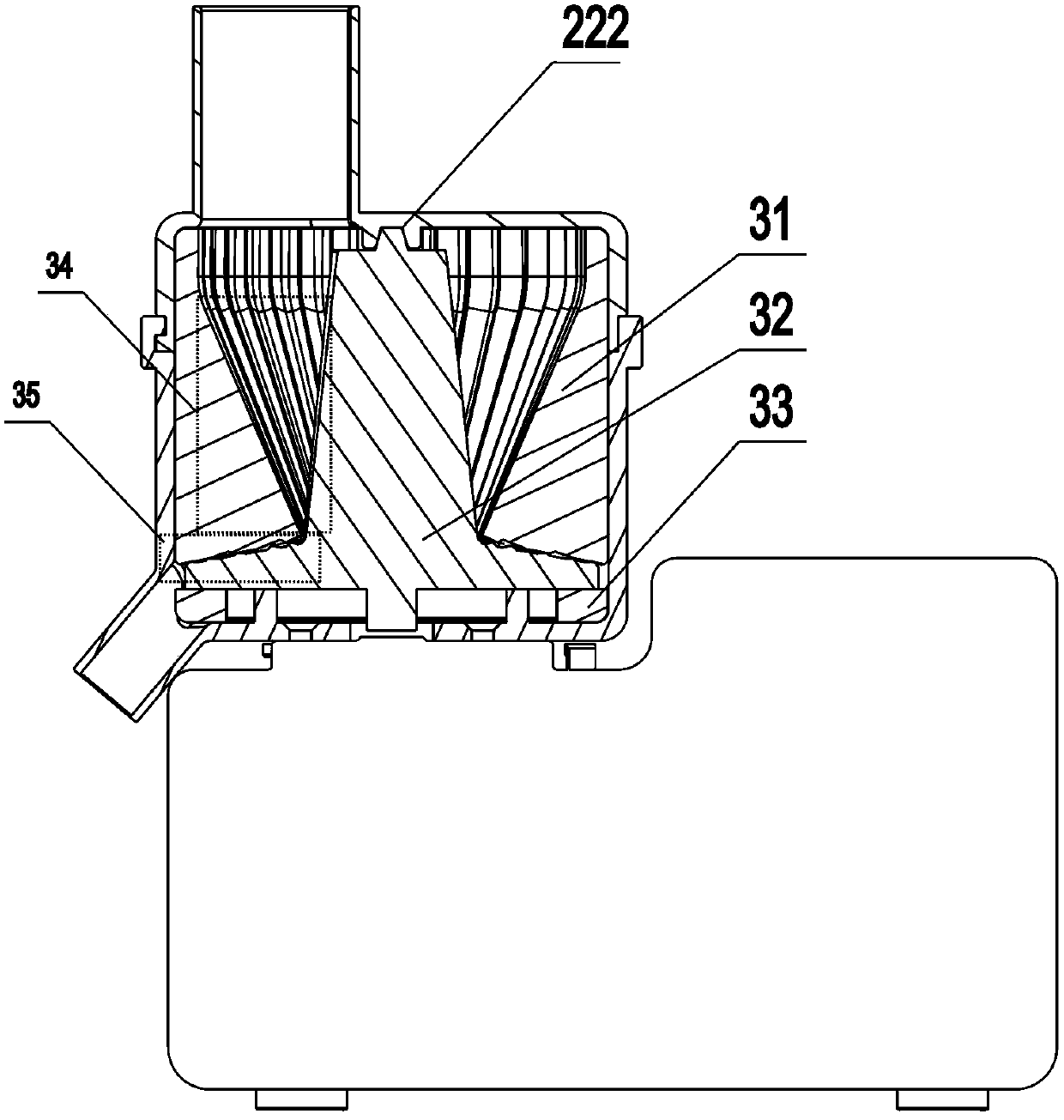

The invention provides a grinder convenient for discharge. The grinder comprises a host, a material container and a grinding assembly, wherein the grinding assembly is arranged in the material container and is driven by a driving part arranged on the host. The grinder is characterized by also comprising a discharge port on the material container and a material sweeping device arranged in the material container and used for pushing material to go out of the discharge port. Through the arrangement of the discharge port and the material sweeping device, the grinder can realize automatic discharge and the material is discharged intensively and can be collected conveniently. Through the arrangement of the material sweeping device, the material container can be cleaned up and high hygiene degree is achieved; and the material sweeping device is applicable to various grinders, has high technical generality and low production cost, and is convenient to implement.

Description

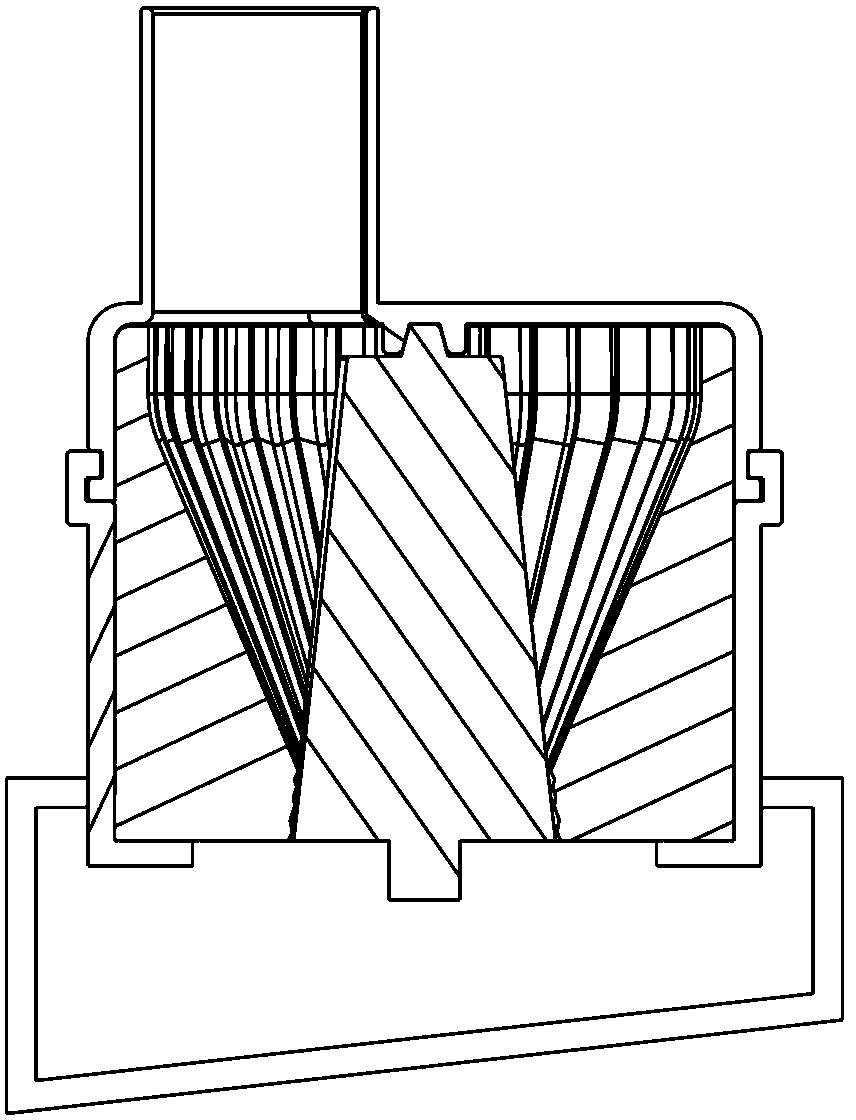

technical field [0001] The invention relates to the field of food processing, in particular to a food grinder. Background technique [0002] As a food auxiliary processing tool in people's daily life, the grinder is usually equipped with a feeding port and a discharging port. The food enters from the feeding port, is processed by the grinder, and then is discharged and collected from the discharging port. [0003] There are usually two ways of collecting materials in the existing grinder: one such as figure 1 As shown, there is a large volume receiving container at the lower end of the grinding assembly, the receiving container closes the discharge opening, and the processed materials fall into the receiving container by their own weight to realize collection; another One way is to use wind blowing or throwing out to achieve collection. [0004] However, the existing technology has the following problems: [0005] 1. Since the grinding components that mainly complete the ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): A47J42/00A47J42/40

Inventor 王旭宁万军

Owner JOYOUNG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com