Patents

Literature

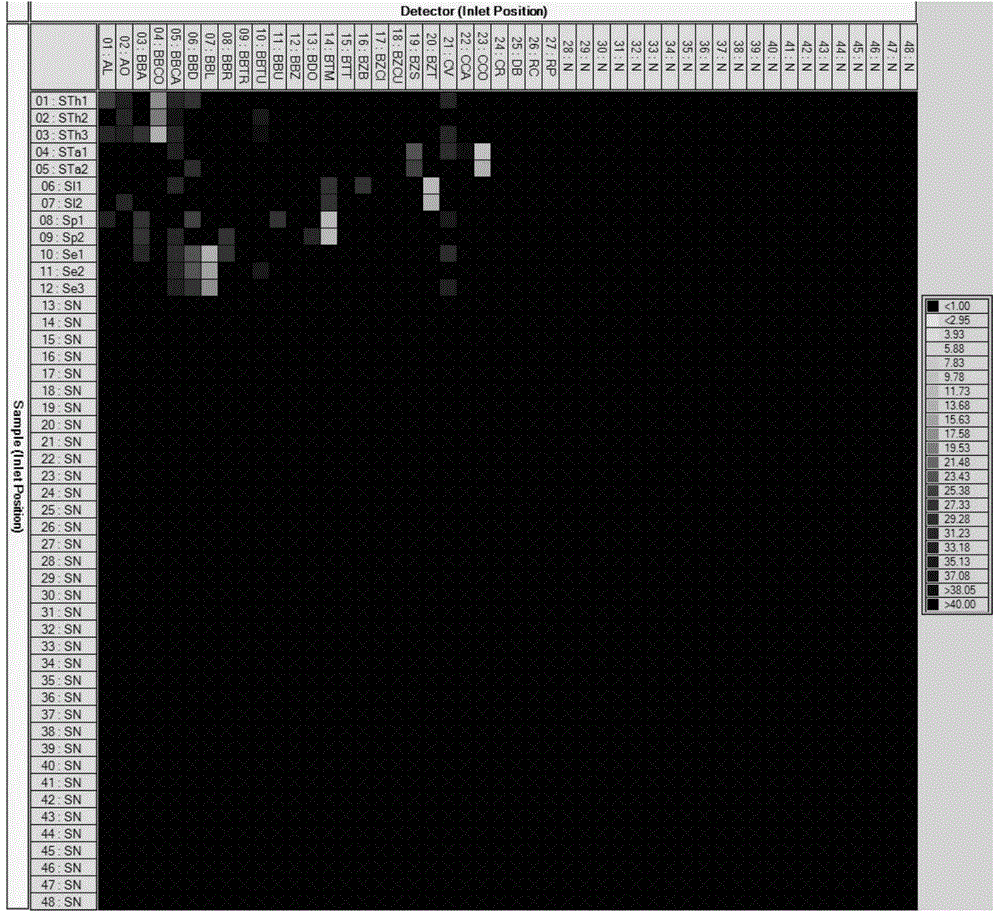

48results about How to "Protect production security" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

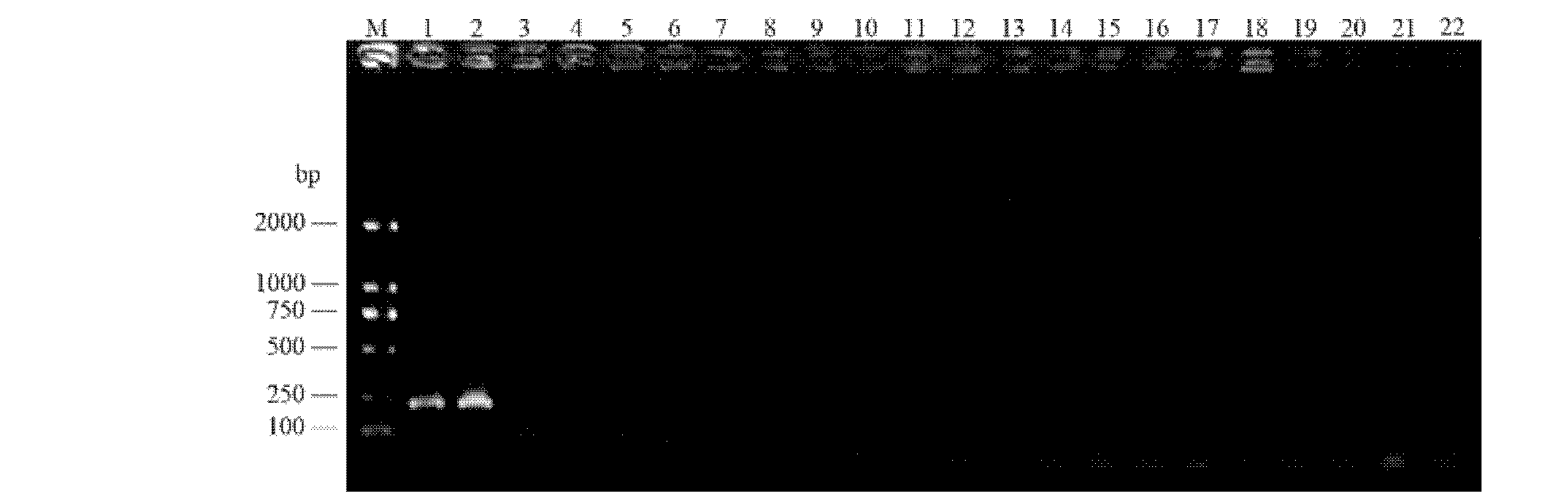

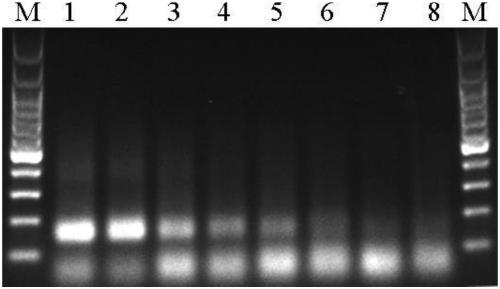

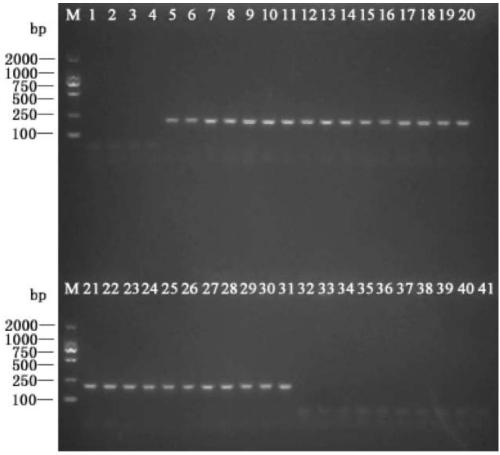

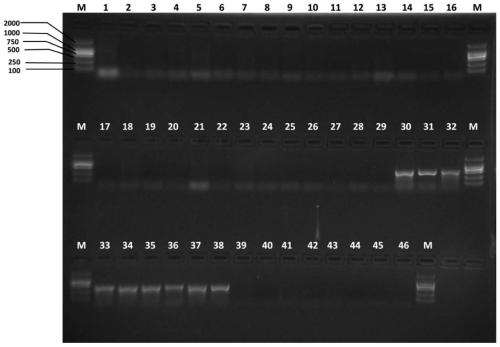

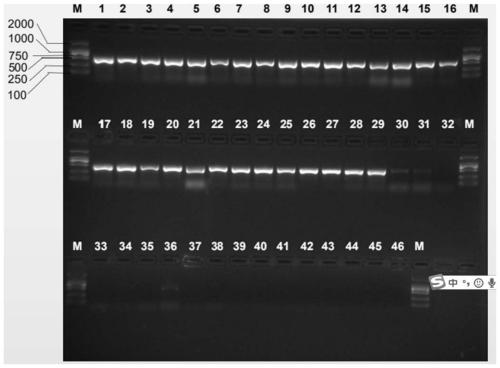

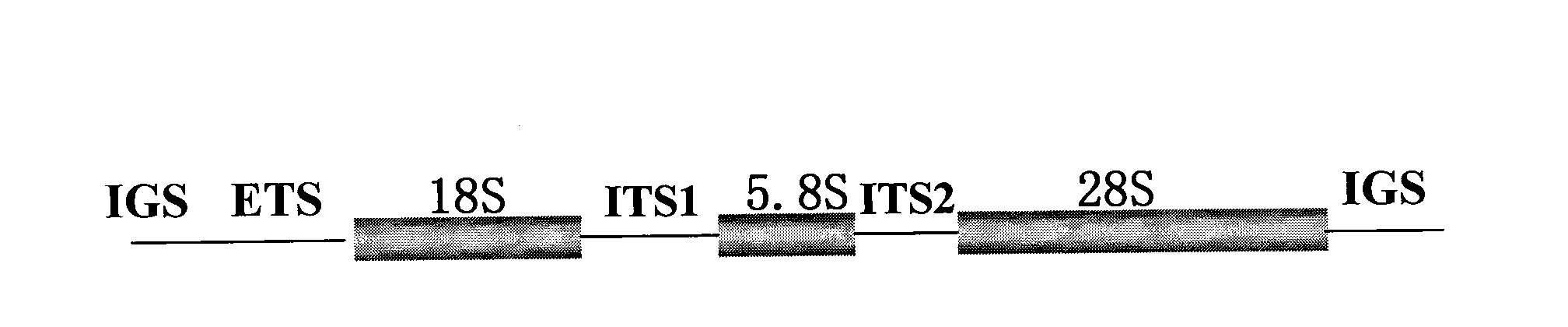

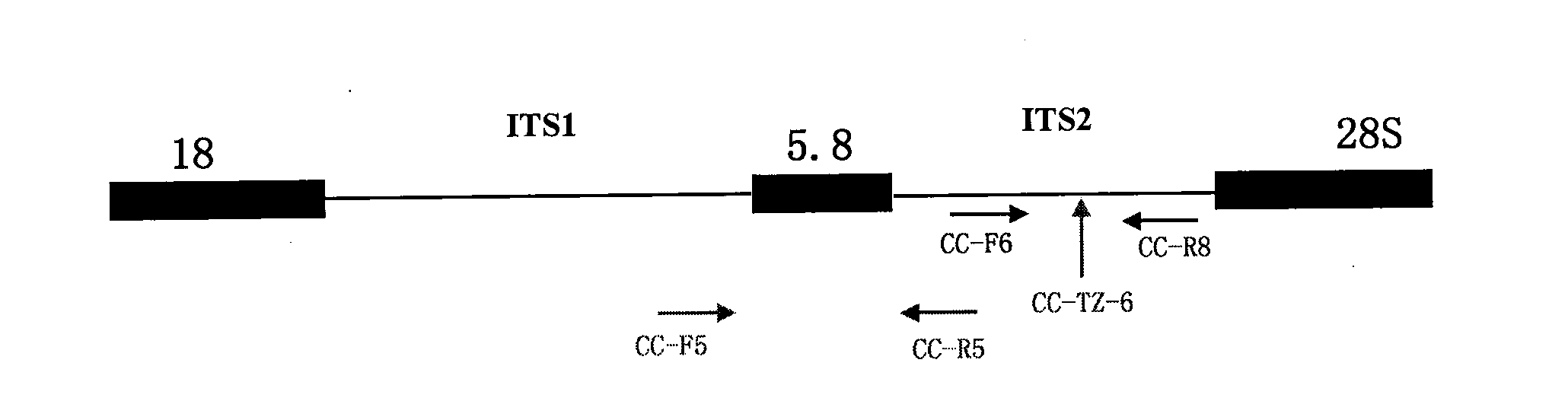

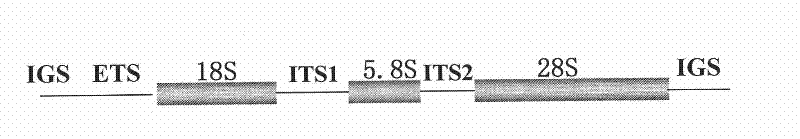

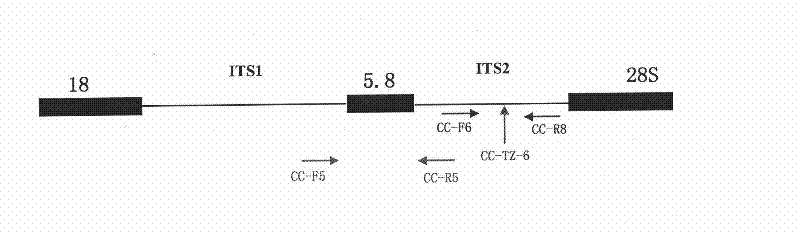

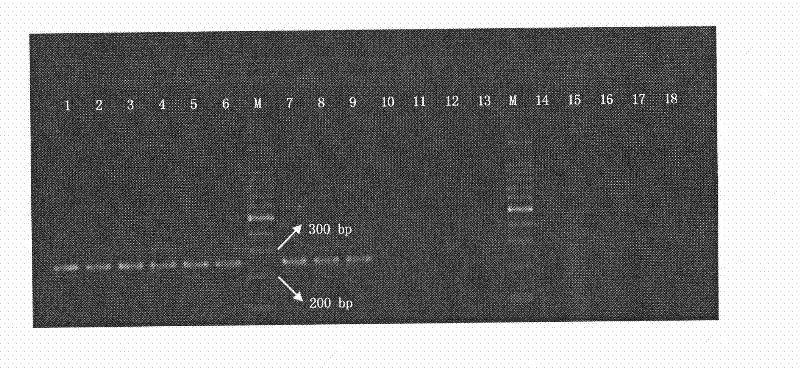

Kit for identifying fruit flies and special primers therefor

InactiveCN102517388AStrong representativeGuaranteed accuracyMicrobiological testing/measurementDNA/RNA fragmentationEcology

Owner:CHINA AGRI UNIV +1

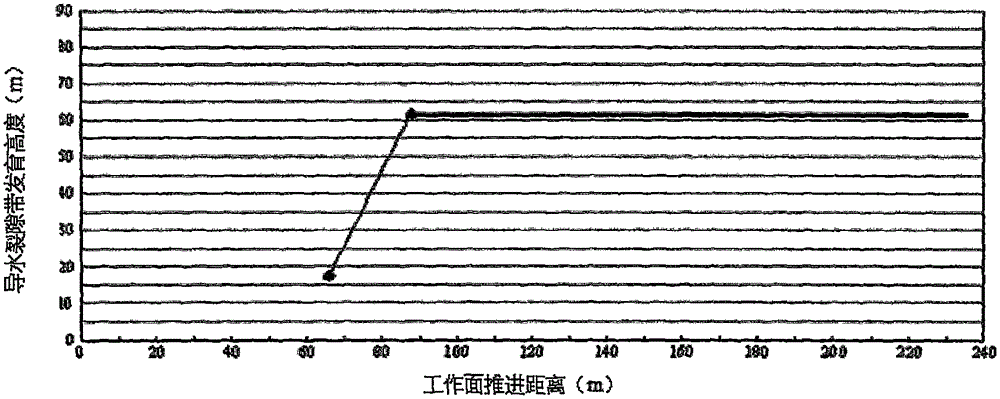

Early warning method of coal mining subsidence

InactiveCN105332738ARealize the goal of water conservation coal miningProtect production securityMining devicesGrowth heightFracture zone

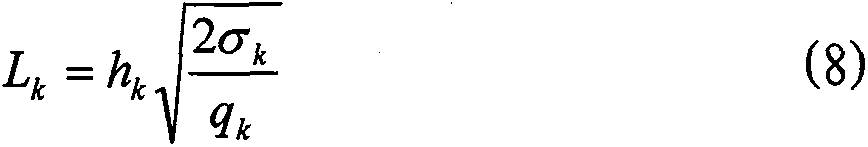

The invention discloses an early warning method of coal mining subsidence. The method is characterized in that the growth height of a water flowing fracture zone is judged according to the ultimate roof breaking interval of a key stratum and soft rock and the growth condition of the height, which grows along with the increasing of working face advancing distance, of a free space on the lower portion of the key stratum and soft rock, the possibility of the coal mining subsidence is evaluated by the height of the water flowing fracture zone, the height of the water flowing fracture zone continuously grows along with the increasing of the working face advancing distance, and an early warning is given out when the height of the water flowing fracture zone approaches a critical height, and coal mining subsidence will occur if the working face distance further increases, or else a coal mine is safe. The early warning method of coal mining subsidence has the advantages that underground water is prevented from fast seeping into a goaf area or deep rock along mining cracks, underground water level lowering is prevented, downhole water burst or mine flooding is prevented, precious coal resources can be produced to the maximum extent, and coal mining safety is guaranteed effectively.

Owner:XIAN UNIV OF SCI & TECH

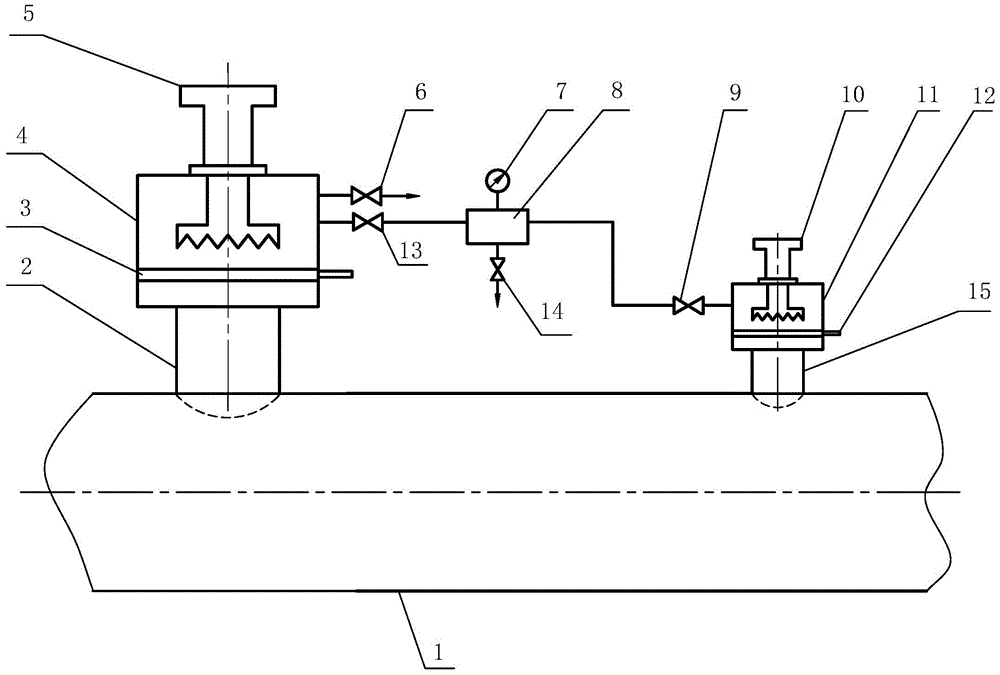

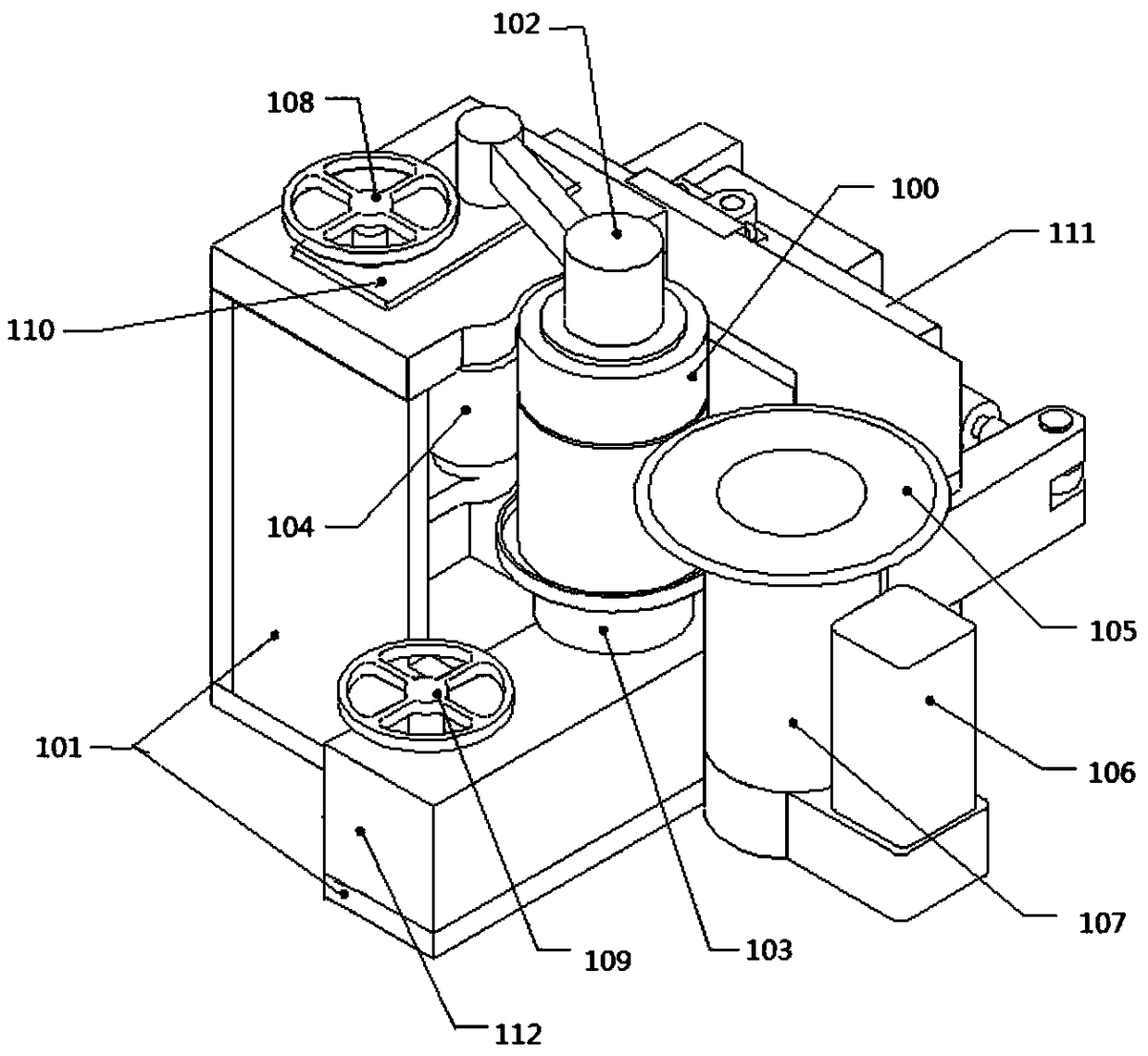

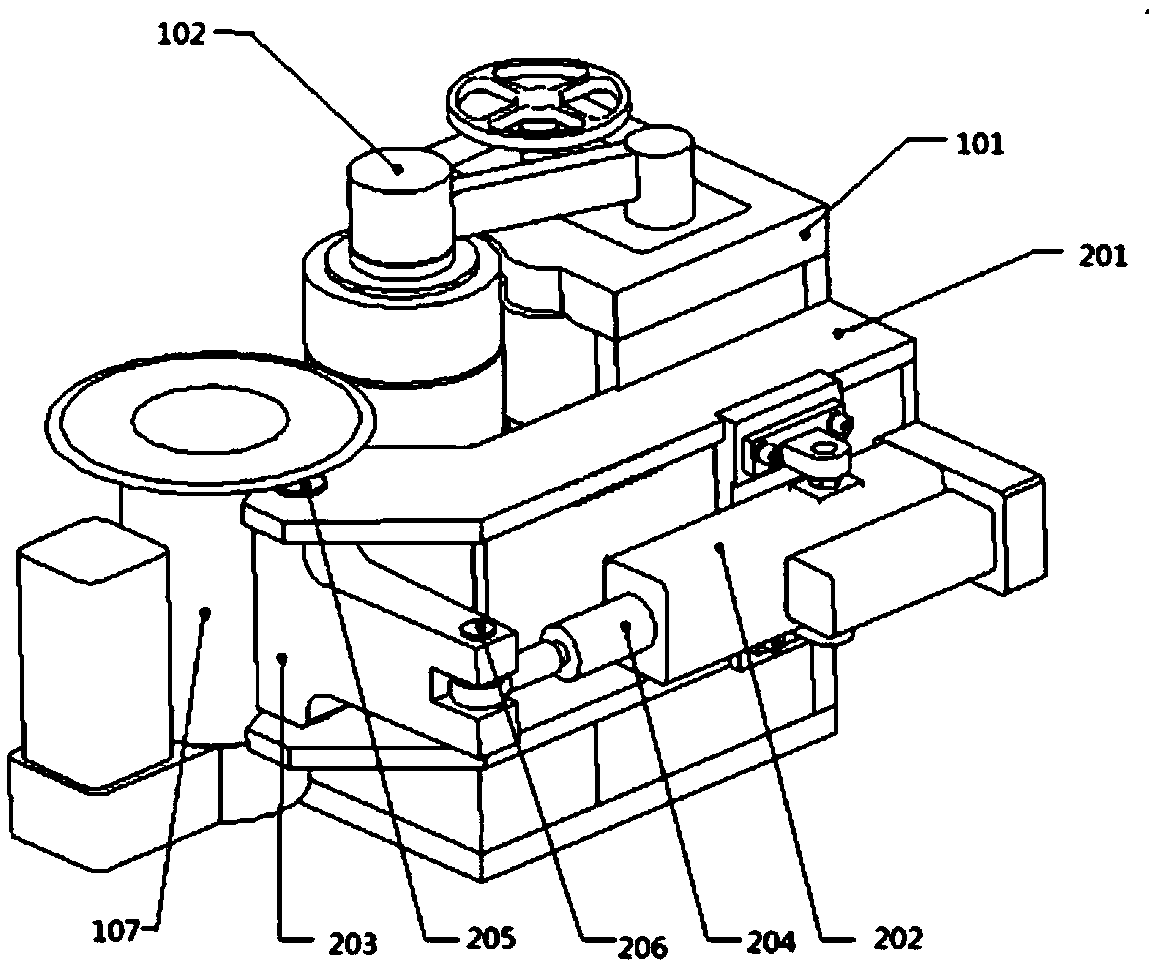

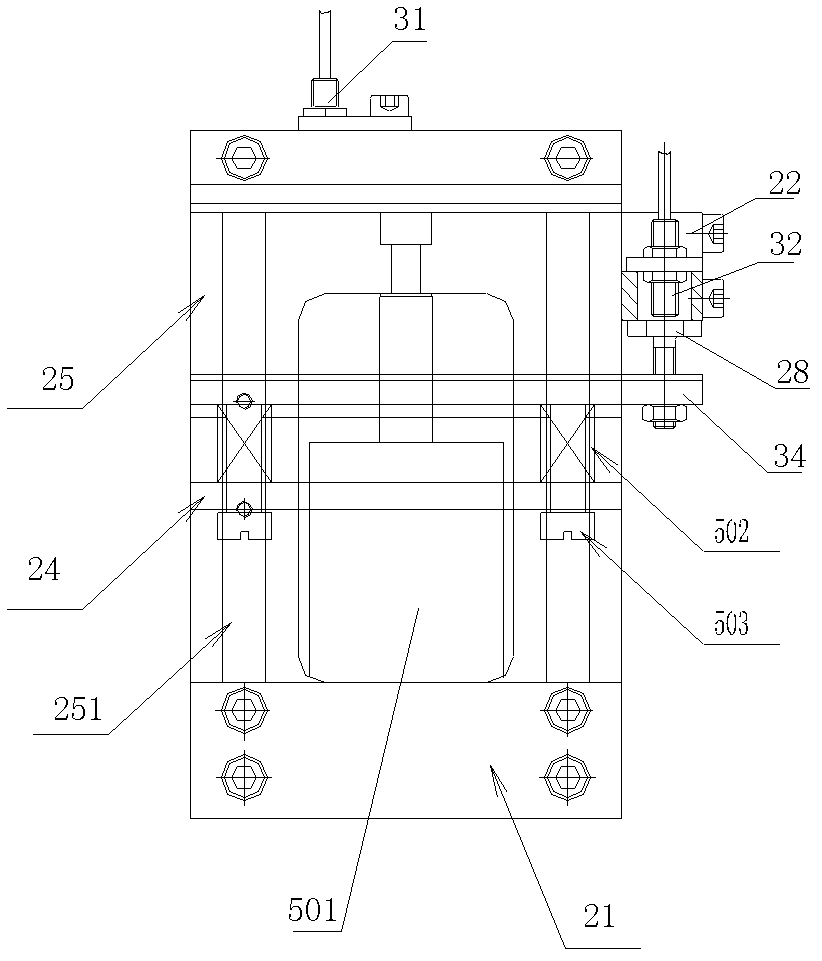

Hot tapping blockage pressure balancing device of fluid pipeline and method of hot tapping blockage pressure balancing device

The invention relates to a hot tapping blockage pressure balancing device of a fluid pipeline and a method of the hot tapping blockage pressure balancing device. The balancing device comprises a connection pipe fitting, a tapping machine, an auxiliary connection pipe fitting, an auxiliary tapping machine and a gas storage tank, wherein a cavity of the connection pipe fitting is a tapping connecting box; the tapping machine and a sandwich valve are arranged in the tapping connecting box; when the sandwich valve is closed, the tapping connecting box is divided into two parts by the sandwich valve; when the sandwich valve is opened, the two parts of the tapping connecting box communicate with each other to form a whole body; a cavity of the auxiliary connection pipe fitting is an auxiliary tapping connecting box; the auxiliary tapping machine and an auxiliary sandwich valve are arranged in the auxiliary tapping connecting box; when the auxiliary sandwich valve is closed, the auxiliary tapping connecting box is divided into two parts by the auxiliary sandwich valve; when the auxiliary sandwich valve is opened, the two parts of the auxiliary tapping connecting box communicate with each other to form a whole body; and the tapping connecting box and the auxiliary tapping connecting box are connected with the gas storage tank through pipes respectively. By the balancing device and the method for tapping a high-pressure gas delivery pipe, severe shock of high pressure in a high-pressure gas pipe to a perforating machine is avoided, so that production safety and safety of operators are ensured.

Owner:BEIJING GAS GRP

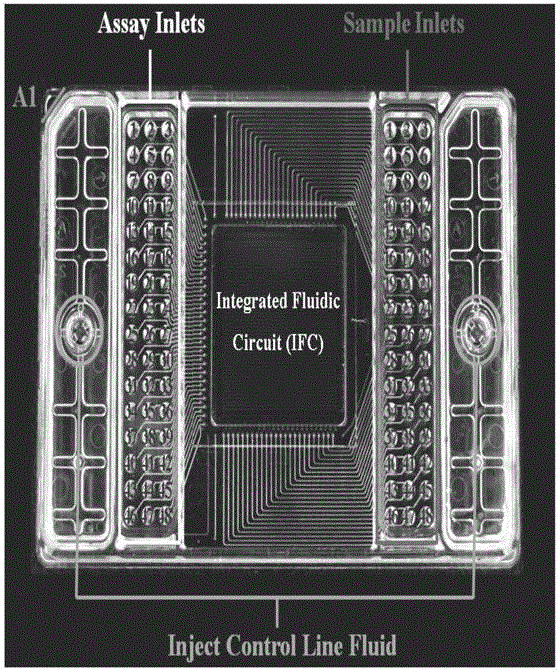

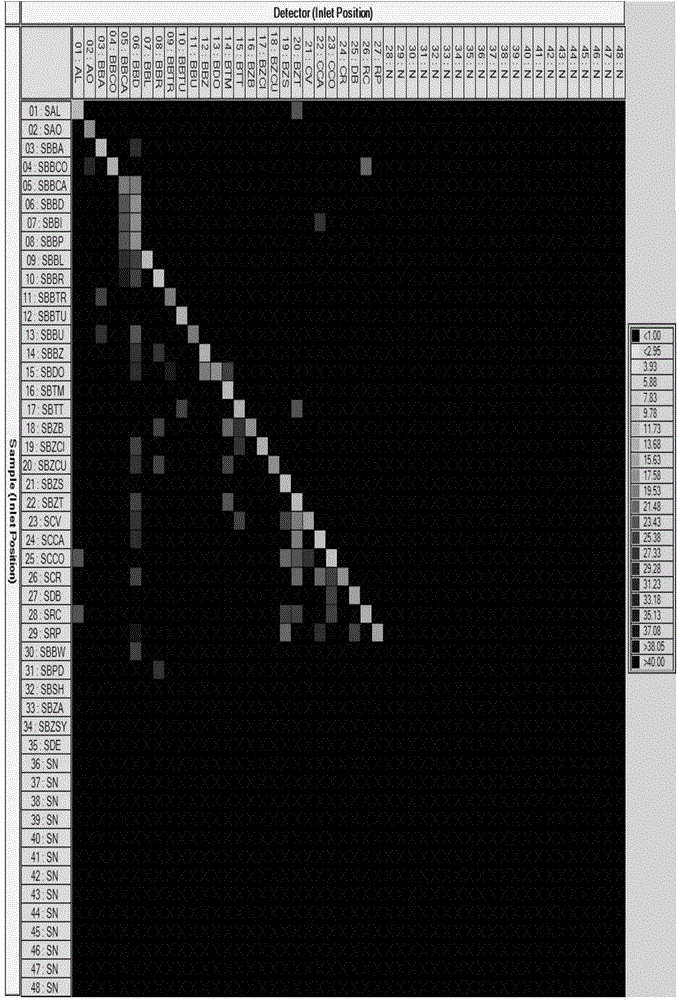

Integrated fluidic chip for identification of fruit fly type and use thereof

ActiveCN104894237AWide varietyMeet needsNucleotide librariesMicrobiological testing/measurementMolecular identificationDiffusion

The invention discloses an integrated fluidic chip for identification of a fruit fly type and a use thereof. The integrated microfluidic chip comprises specific primers for fruit fly type identification and a TaqMan-MGB probe. The invention provides a fruit fly type molecular identification technology utilizing the integrated fluidic chip. A test proves that the integrated microfluidic chip-based molecular identification technology realizes fast identification of a fruit fly type, has good specificity, high flux, a low cost and simple processes, realizes identification of a type of non-adult fruit fly or fruit fly adult residual body, provides a fast identification tool and technology for import and export plant quarantine and nationwide fruit fly epidemic monitoring, effectively prevents invasion and diffusion of dangerous fruit fly, protects agricultural production and ecological safety and promotes trade and economic development in China.

Owner:CHINA AGRI UNIV +1

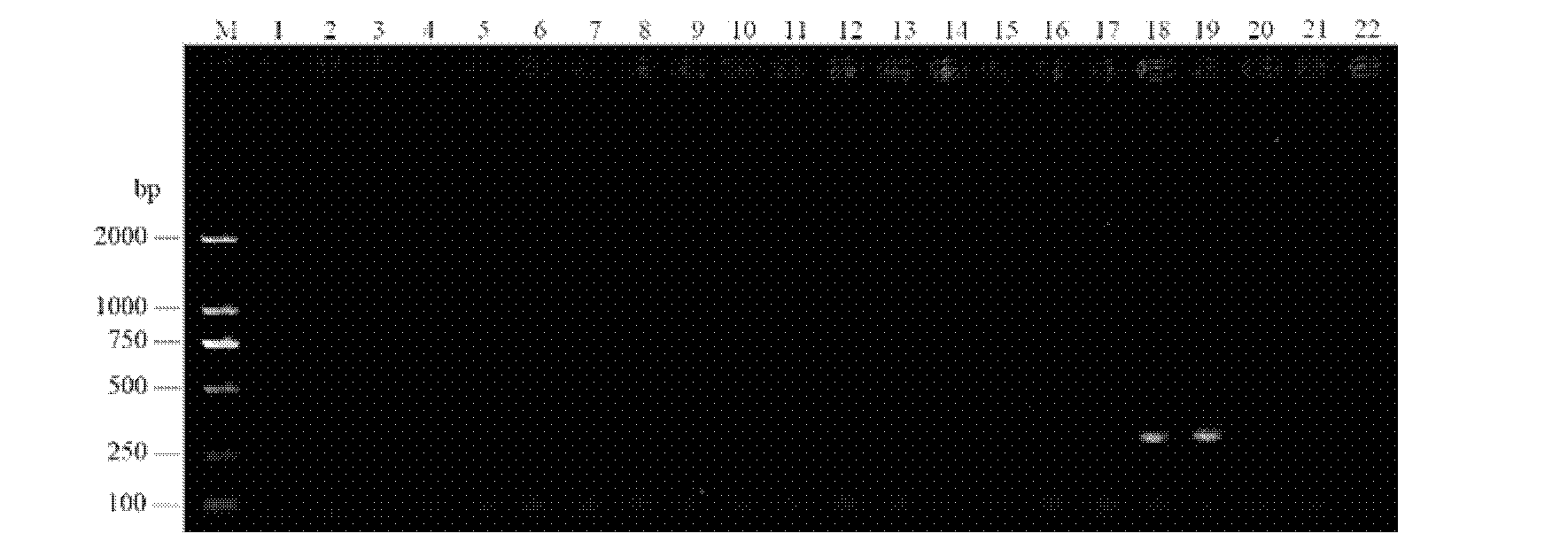

Method of applying RPA technology for detecting suginami root-knot nematode, RPA primer and kit

ActiveCN109486960APrevent intrusionProtect production securityMicrobiological testing/measurementMeloidogyne incognitaRepeatability

The invention provides a RPA primer of applying RPA technology for detecting suginami root-knot nematode and a RPA kit comprising the RPA primer. Sequences of the RPA primer are as follows: upstream primer is MSRPAF:5'-TCCCTTCTCATGGGCTCATTAAGTCTTAAACCG-3', and downstream primer MSRPAR:5'-ACTTTGGTCGTGTAACGGCTAACGCTGGTGTCT-3'. The invention further provides a method utilizing the RPA kit to detect suginami root-knot nematode. The method can detect single or mixed DNA samples of suginami root-knot nematode , is accurate in detection, high in sensitivity, simple in operation, short in time consumption and high in repeatability, can accurately identify suginami root-knot nematode in seedlings coming in border and is of important significance in preventing invasion of non-Chinese species of root-knot nematode and protecting agriculture and forestry production safety of China.

Owner:NINGBO ACAD OF SCI & TECH FOR INSPECTION & QUARANTINE

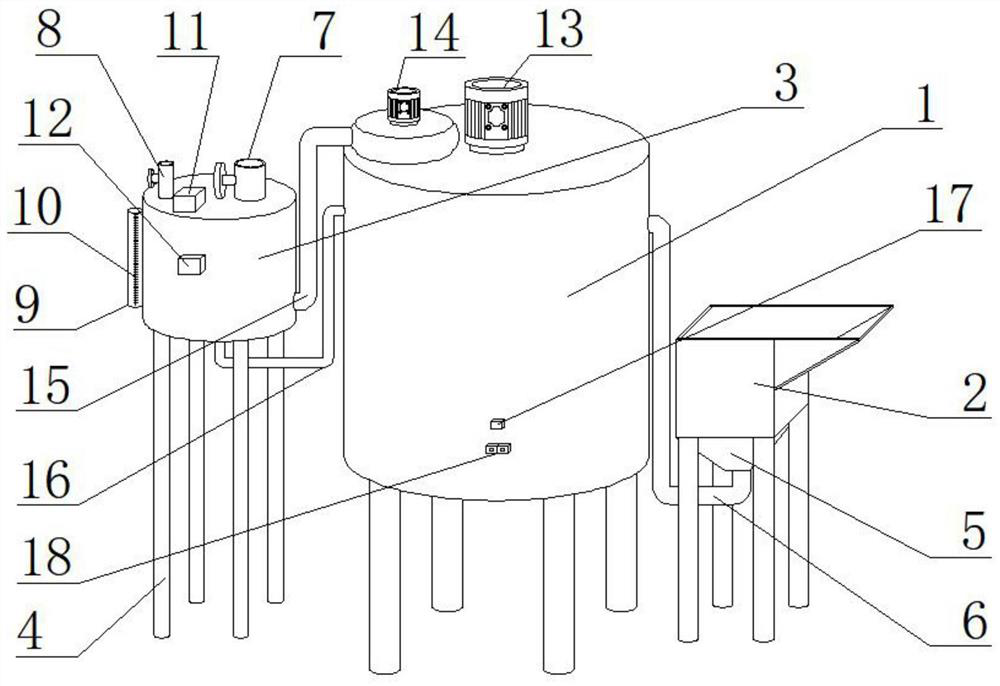

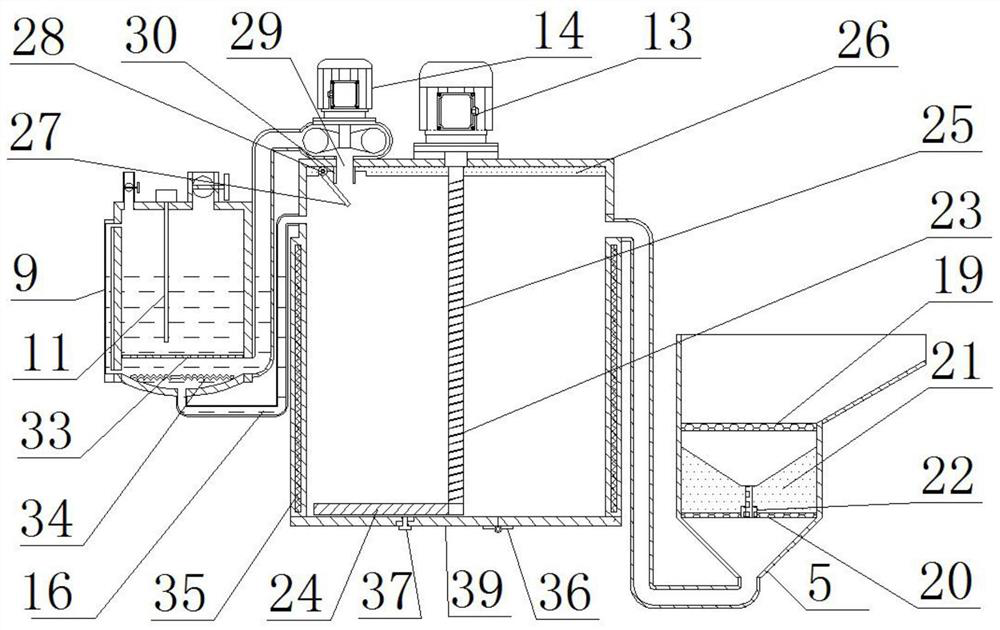

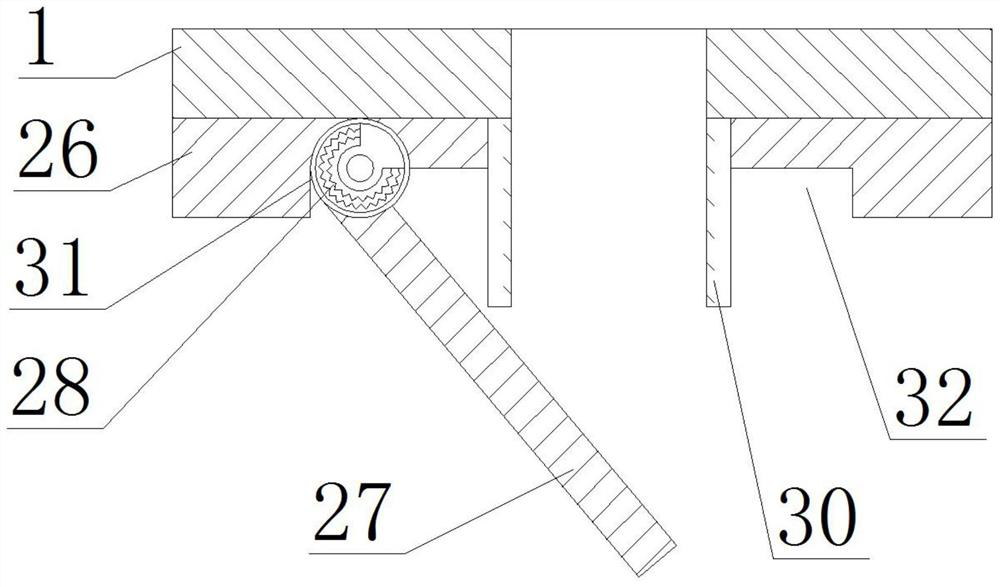

Dustless self discharging type dough mixing equipment for bread making

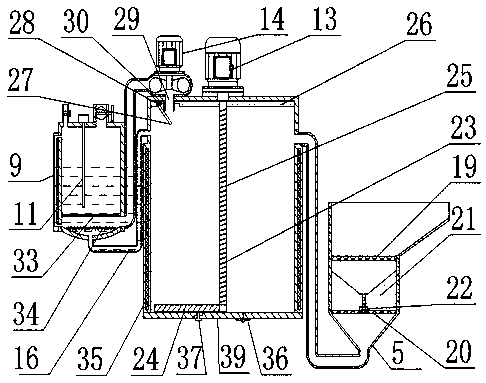

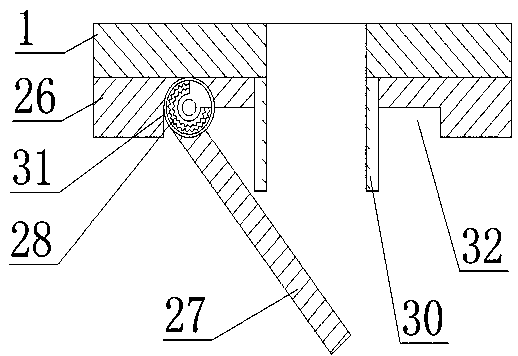

ActiveCN110089531AAvoid pollutionAvoid flyingMixing/kneading structural elementsMixing/kneading with vertically-mounted toolsEngineeringCentrifugal fan

The invention provides dustless self discharging type dough mixing equipment for bread making. The dustless self discharging type dough mixing equipment comprises a dough mixing box, a charging box and a water adding box, wherein the charging box is arranged on one side of the dough mixing box; the water adding box is arranged on the other side of the dough mixing box; brackets are respectively welded to the bottom of the dough mixing box, the bottom of the charging box and the bottom of the water adding box; a funnel is welded to the bottom of the charging box; a sucking pipe is welded to thebottom of the funnel; a wind opening and a water pipe are welded to the top of the water adding box; the water pipe is arranged on one side of the wind opening; a communicating machine is mounted onone side of the water adding box; a volume mark is carved on the communicating machine; a temperature sensor is mounted at the top of the water adding box through bolts; a bidirectional motor and a centrifugal fan are mounted at the top of the dough mixing box through bolts; the centrifugal fan is arranged on one side of the bidirectional motor; and the wind pipe is welded to one side of the centrifugal fan. The dustless self discharging type dough mixing equipment for bread making disclosed by the invention is reasonable in design, and is suitable for dustless automatic dough mixing during bread making.

Owner:豪士(福建)食品有限公司

Method for controlling curculio chinensis chevrolat as camellia oleifera old forest pest

InactiveCN109566241AHealthy growth environmentIncrease productionCultivating equipmentsHorticulture methodsEcological environmentHabit

The invention discloses a method for controlling curculio chinensis chevrolat as a camellia oleifera old forest pest. The method includes the following steps of biological control, physical control and field management. On the basis of the life history and habits of camellia oleifera, different control measures are adopted in different harmful periods of curculio chinensis chevrolat, and curculiochinensis chevrolat larva and imagoes can be effectively killed; through biological control, physical control and a field management method, the land and the ecological environment are protected, andthe production safety of camellia oleifera, the quality safety of camellia oleifera seeds and the ecological environment of cultivation areas are effectively prevented. At the same time, the method greatly reduces the damage of curculio chinensis chevrolat to camellia oleifera fruits, a healthy growth environment is provided for camellia oleifera, and the yield and quality of camellia oleifera canbe effectively improved.

Owner:湖南省林大生物科技有限公司

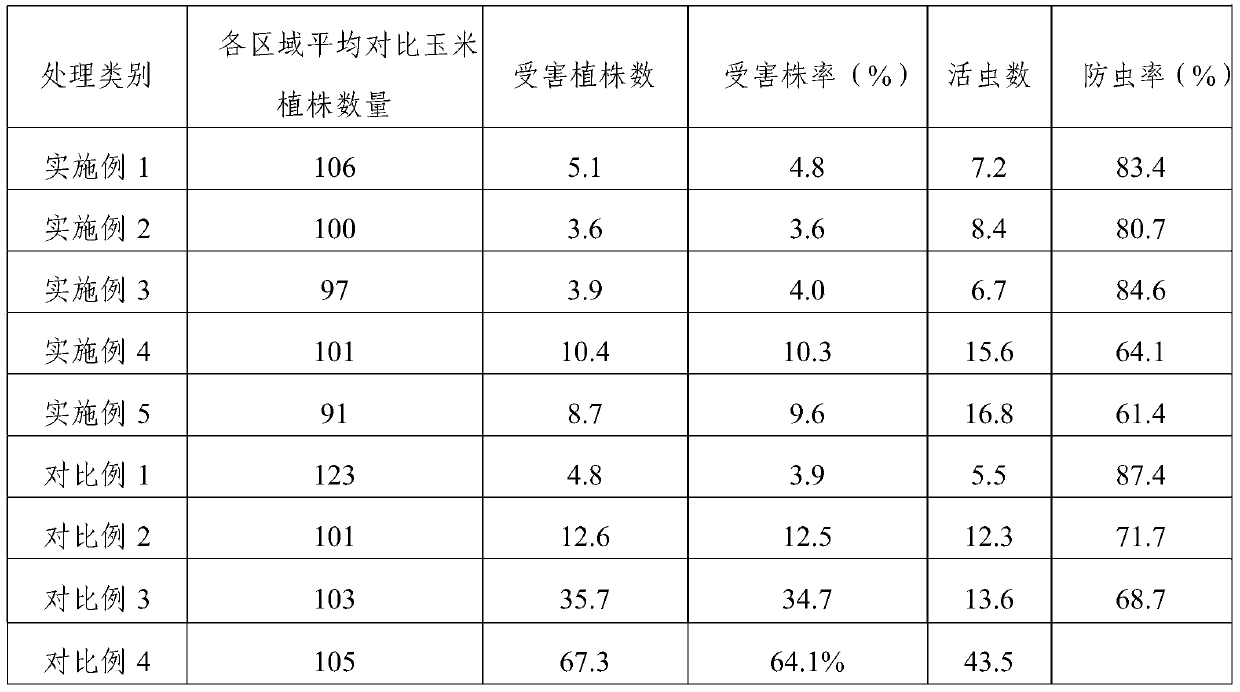

Spodoptera frugiperda insecticide as well as preparation method and application thereof

InactiveCN111493096AGood prevention and control effectHigh fatality rateBiocideAnimal repellantsMicrobial agentNutrition

The invention discloses a spodoptera frugiperda insecticide as well as a preparation method and application thereof. The insecticide comprises at least one microbial agent and at least one synergist,wherein the microbial agent consists of bacillus subtilis and a nutritional agent required by the bacillus subtilis; the synergist comprises at least one plant saponin extract. The preparation methodof the insecticide comprises the steps: mixing and fermenting the microbial agent, the nutritional agent and water, and mixing the obtained fermentation liquor with the synergist according to a certain proportion. In practical application, the insecticide can be sprayed to crops, including foliage spraying, ground spraying, flood irrigation and the like. The method has a good prevention and control effect on field pests (especially spodoptera frugiperda), is free of pesticide addition, does not enable crops to generate drug resistance, and has great significance in preventing and controlling spodoptera frugiperda and protecting grain production safety in China.

Owner:北京泰克美高新技术有限公司

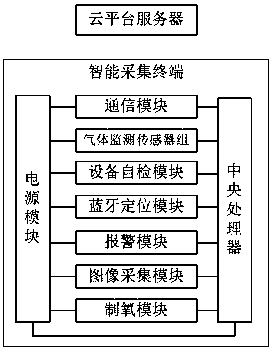

Automated monitoring system of coal mine based on cloud platform

InactiveCN108533321AImprove intelligenceProtect production securityProgramme controlMining devicesMonitoring systemComputer terminal

The invention discloses an automated monitoring system of a coal mine based on a cloud platform. The automated monitoring system comprises a cloud platform server and multiple intelligent acquisitionterminals which scatter around the area of the coal mine. The intelligent acquisition terminals comprise power supply modules, central processors, gas monitoring sensor groups, image acquisition modules, equipment self-check modules, communication modules, alarm modules, oxygen production modules and bluetooth positioning modules. The cloud platform server is in communication connection with the intelligent acquisition terminals. The cloud platform server comprises a data storage module, a data analysis module and a danger prediction module, all of which are orderly connected. The gas monitoring sensor groups, the image acquisition modules, the equipment self-check modules, the communication modules, the alarm modules, the oxygen production modules and the bluetooth positioning modules areall connected with the central processors. The power supply modules are used for providing electric energy. The automated monitoring system of the coal mine based on the cloud platform is conducive to enhancing intelligent level of monitoring of the coal mine.

Owner:成都精灵云科技有限公司

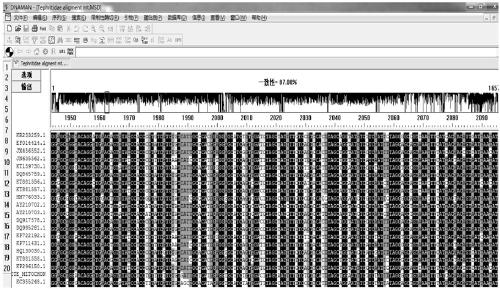

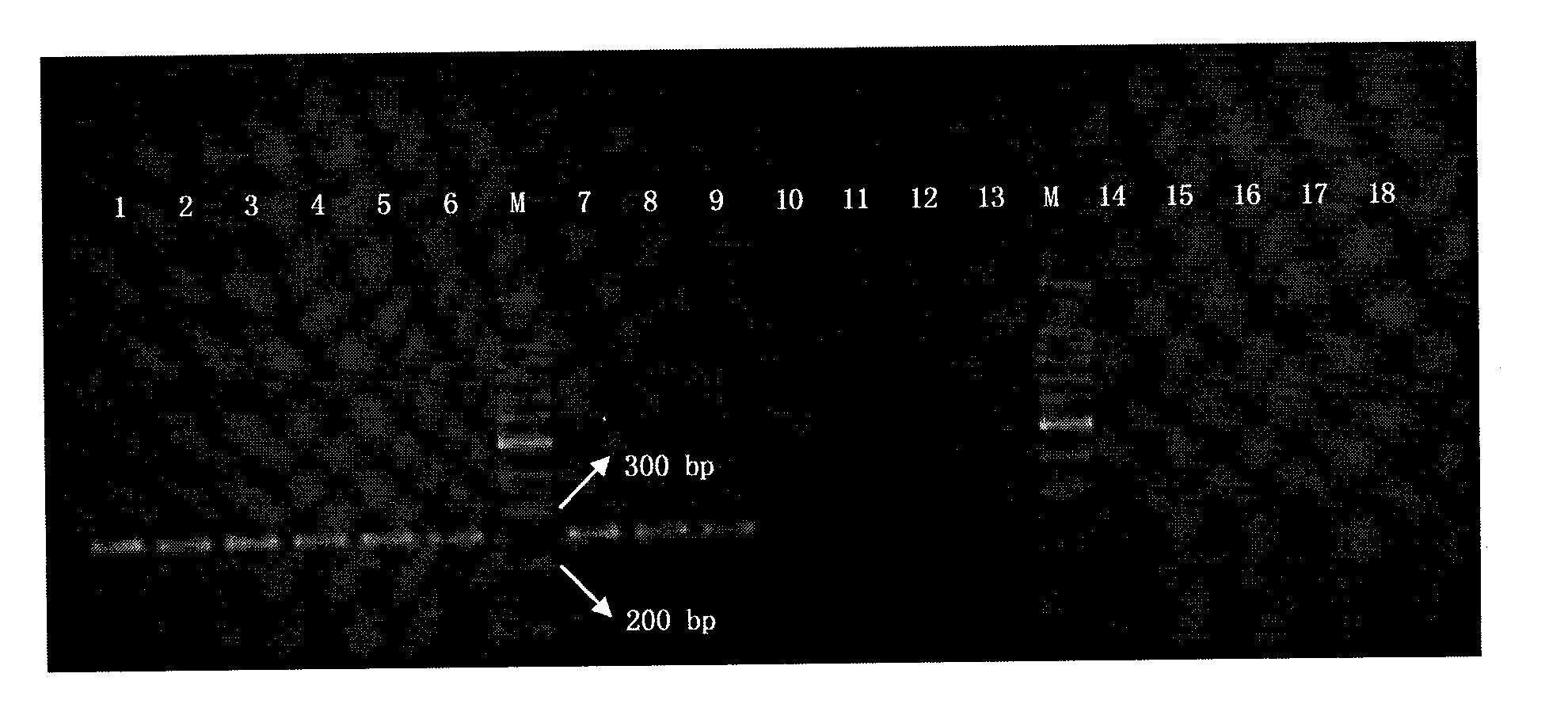

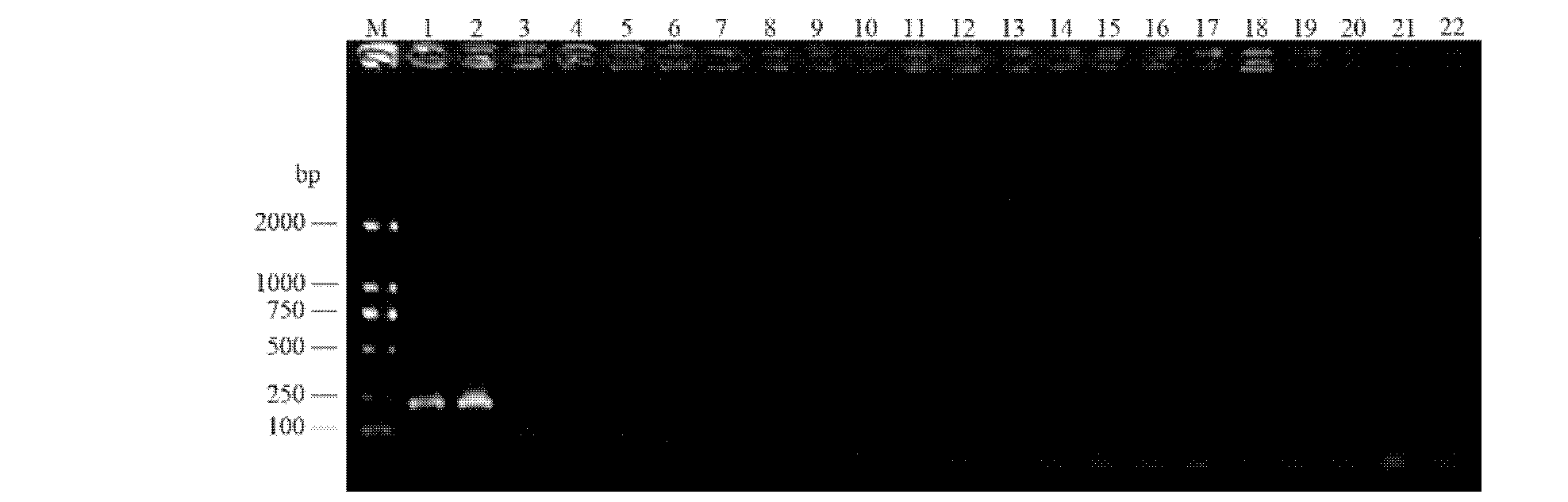

Primers and method used for multi-target fast identification of bactrocera macquart

PendingCN109055572ARapid identificationStrong specificityMicrobiological testing/measurementDNA/RNA fragmentationRhagoletisDacus

The invention relates to the field of fruit fly quarantine technologies, in particular to primers and a method which are used for multi-target fast identification of bactrocera macquart. Nucleotide sequences of the specific primers used for multi-target fast identification of the bactrocera macquart are as shown in SEQ ID NO. 1 and SEQ ID NO. 2; the specific primers can separate the bactrocera macquart from anastrepha schiner, carpomya, ceratitis macleay, dacus, rhagoletis and other diptera species. The specific primers are used for identifying bactrocera macquart species, and have the advantages that the specificity is high, the sensibility is high, and the universality is high.

Owner:CHINESE ACAD OF INSPECTION & QUARANTINE

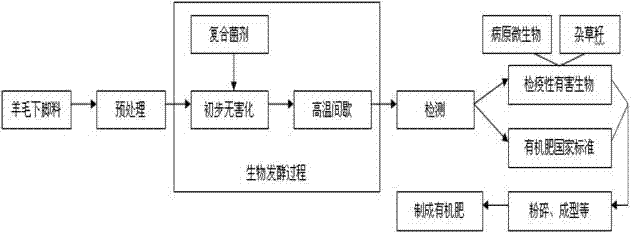

Method for killing quarantine pests in wool processing leftovers through biological fermentation

InactiveCN102924142APromote resource reuseProtect production securityBio-organic fraction processingOrganic fertiliser preparationBiotechnologyLand resources

The invention discloses a method for killing quarantine pests in wool processing leftovers through biological fermentation. The method comprises the steps of (1) preparing complex microbial inoculants, (2) pre-processing the wool processing leftovers, (3) forming a pile body, (4) performing preliminary fermentation and (5) performing high-temperature batch fermentation. Auxiliary materials and high-temperature complex microbial inoculants are added into the leftovers and wastes to perform compost fermentation by means of a biological fermentation method, the heat-producing bacterium effect in the complex microbial inoculants enable the pile body temperature to rise and drop intermittently, and a compost is converted into an organic fertilizer to be reused on the premise that pathogenic microorganism and weed seeds in introduced wool processing leftovers are ensured to be killed or removed. On the one hand, agricultural production safety in our country is ensured, and land resources and environment are protected; and on the other hand, the cost input and energy consumption of manufacturing enterprises are reduced, the using amount of chemical fertilizers used in crop growth is decreased, and organic agriculture development and resource recycling are promoted.

Owner:ZHANGJIAGANG EENTRY EXIT INSPECTION & QUARANTINE BUREAU

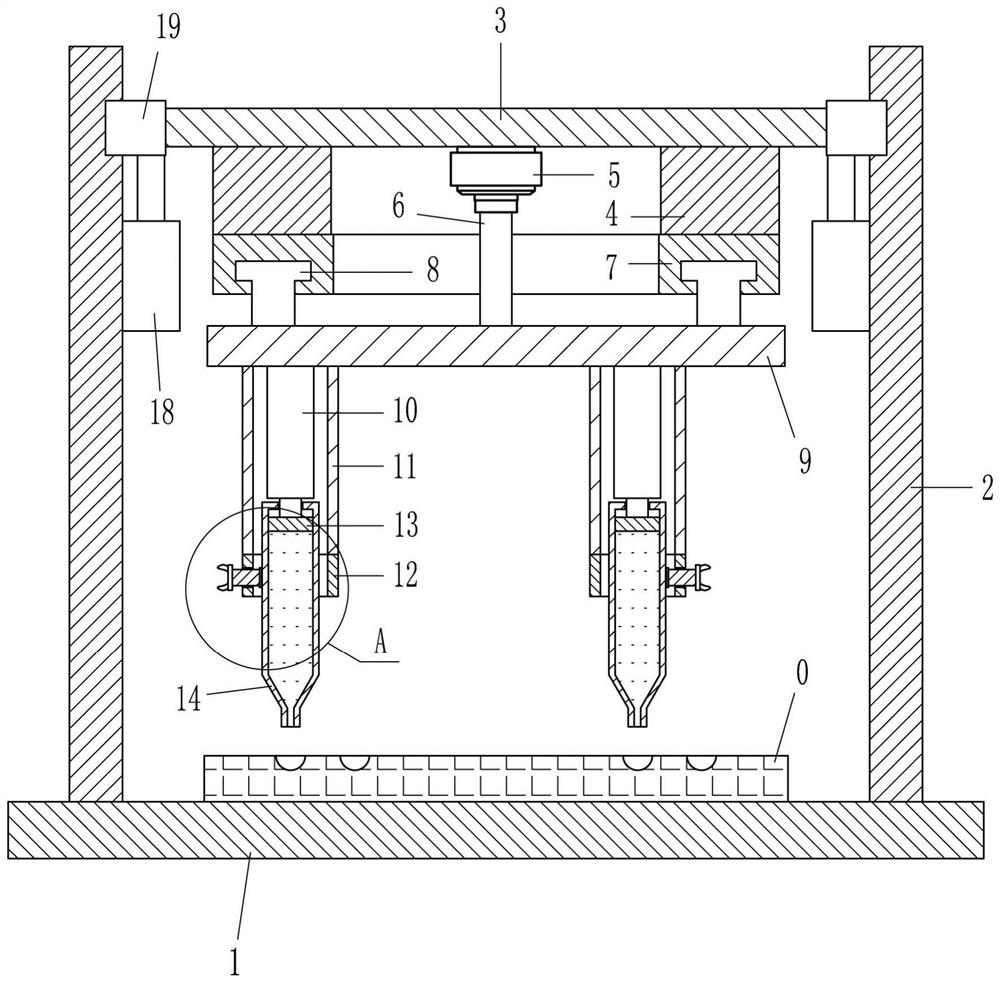

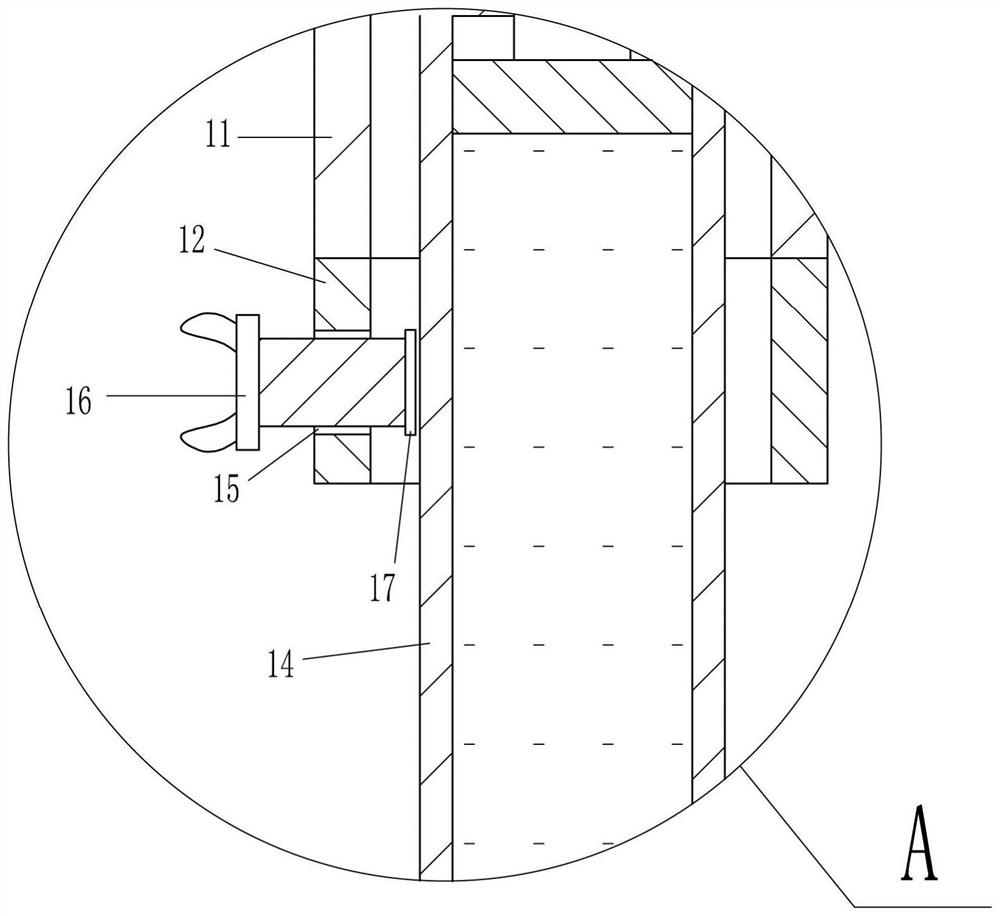

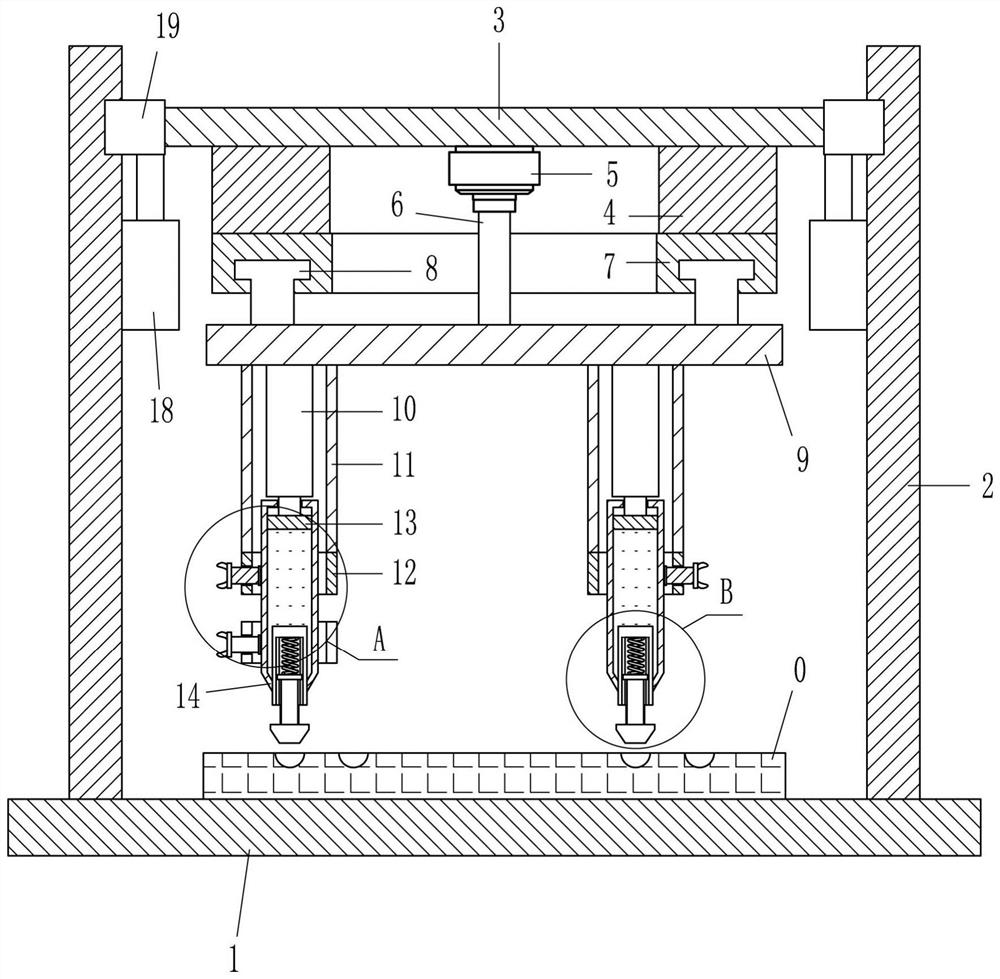

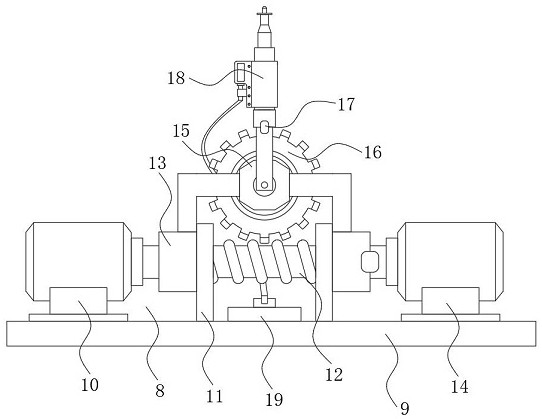

A silicon grease applicator for light source boards for photovoltaic street lamp production

ActiveCN108993832BImprove cooling effectApply evenlyLiquid surface applicatorsCoatingsElectric machineryEngineering

The invention relates to the field of photovoltaic street lamp production, in particular to a light source plate silicon grease coating machine for photovoltaic street lamp production. The light source plate silicon grease coating machine for photovoltaic street lamp production can conveniently coating a large amount of silicon grease and ensures that silicon grease is uniformly smeared. The lightsource plate silicon grease coating machine for photovoltaic street lamp production comprises a mounting plate, supporting sliding rails, a bearing plate, supporting frames, a motor, a first rotatingshaft, annular sliding rails, annular sliding blocks, a rotary table, first electric push rods, connecting frames, first mounting rings, pistons and the like; the two supporting sliding rails are sequentially and fixedly connected to the top surface of the mounting plate; a light source plate is placed on the top surface of the mounting plate; second electric push rods are fixedly connected to the side parts of the sliding rails; and the supporting sliding blocks are in transmission connection with the output ends of the second electric push rods and are in sliding connection with the supporting sliding rails. According to the light source plate silicon grease coating machine, the effect that a large amount of the silicon grease is conveniently smeared and the silicon grease is uniformlysmeared is achieved.

Owner:灵璧县浩翔信息科技有限公司

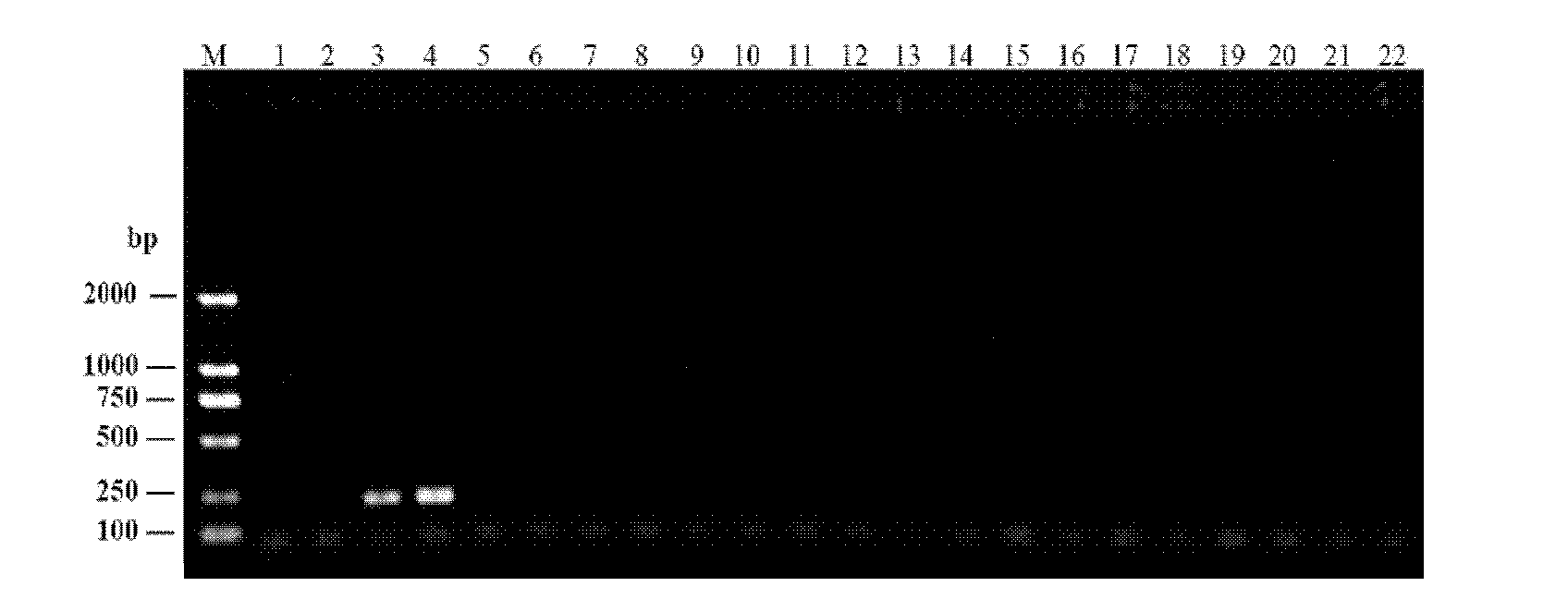

Specific primer pair for identifying tangerine fruit flies and citrus fruit flies and application thereof

ActiveCN109762912ATroubleshoot species identification issuesStrong specificityMicrobiological testing/measurementDNA/RNA fragmentationMolecular identificationAgricultural science

The invention discloses a specific primer pair for identifying tangerine fruit flies and citrus fruit flies and an application thereof. The invention designs a specific primer pair for identifying thetangerine fruit flies and the citrus fruit flies, and develops a molecular identification technology based on conventional PCR. Experiments prove that the molecular identification technology based onthe conventional PCR can achieve the species identification of the tangerine fruit flies and the citrus fruit flies, and has the advantages of strong specificity, high sensitivity, low cost, simple operation and short time consumption. The primer pair not only solves the problem of identifying the species of non-adult fruit flies and residues of the adult fruit flies, but also provides a practical technology and a theoretical basis for monitoring the epidemic situation of the tangerine fruit flies and citrus fruit flies, distributing and invading of the tangerine fruit flies and the citrus fruit flies in main production areas of China, and subsequent plant quarantine and field management. The primer pair is of great significance to effectively prevent further invasion and diffusion of thetangerine fruit flies and citrus fruit flies, protect agricultural production and ecological security, and promote the development of economic and trade in China.

Owner:CHINA AGRI UNIV

Polytene plastic base particle with electromagnetic shielding function

A polyolefine particle with electromagnetic shielding function for plastics is prepared from polyolefine plastics (60-84 wt.%), high-B tourmalinite ore powder (5-15), inorganic filler (5-10), disperser (0.5-1) and aluminium powder (5-15). Said tourmalinite ore powder is the silicate containing B, Al, Si, Mg, Mn, Zn and Ti. The resultant plastics has high effect to shield electromagnetic wave.

Owner:上海金樱环保科技有限公司

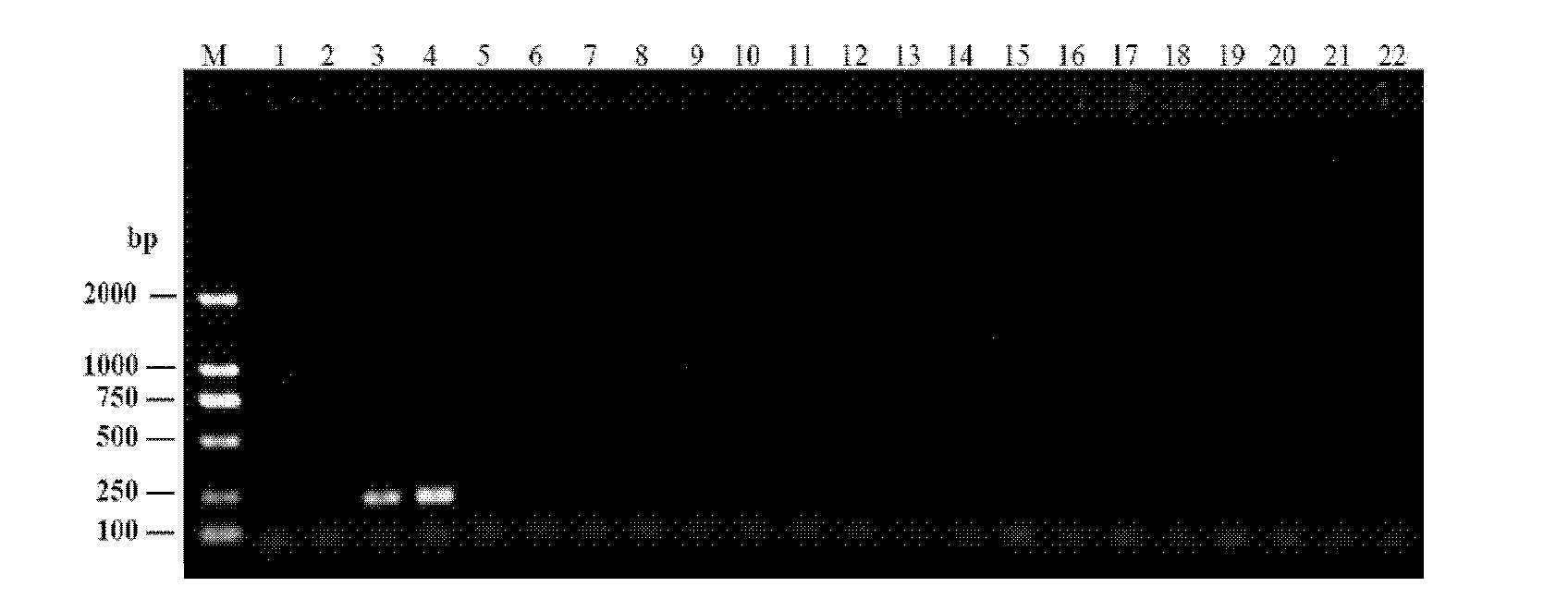

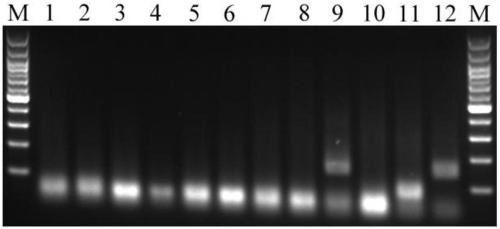

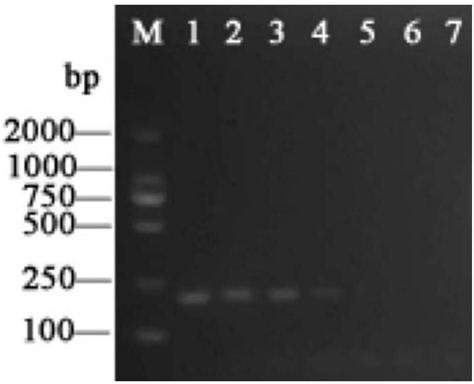

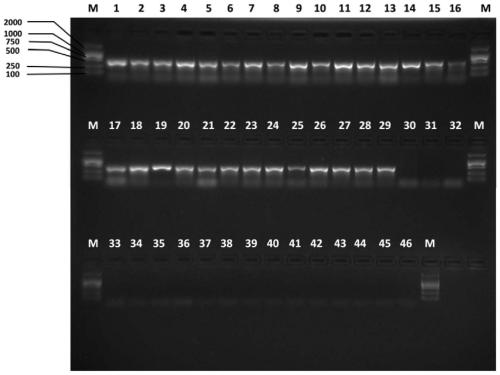

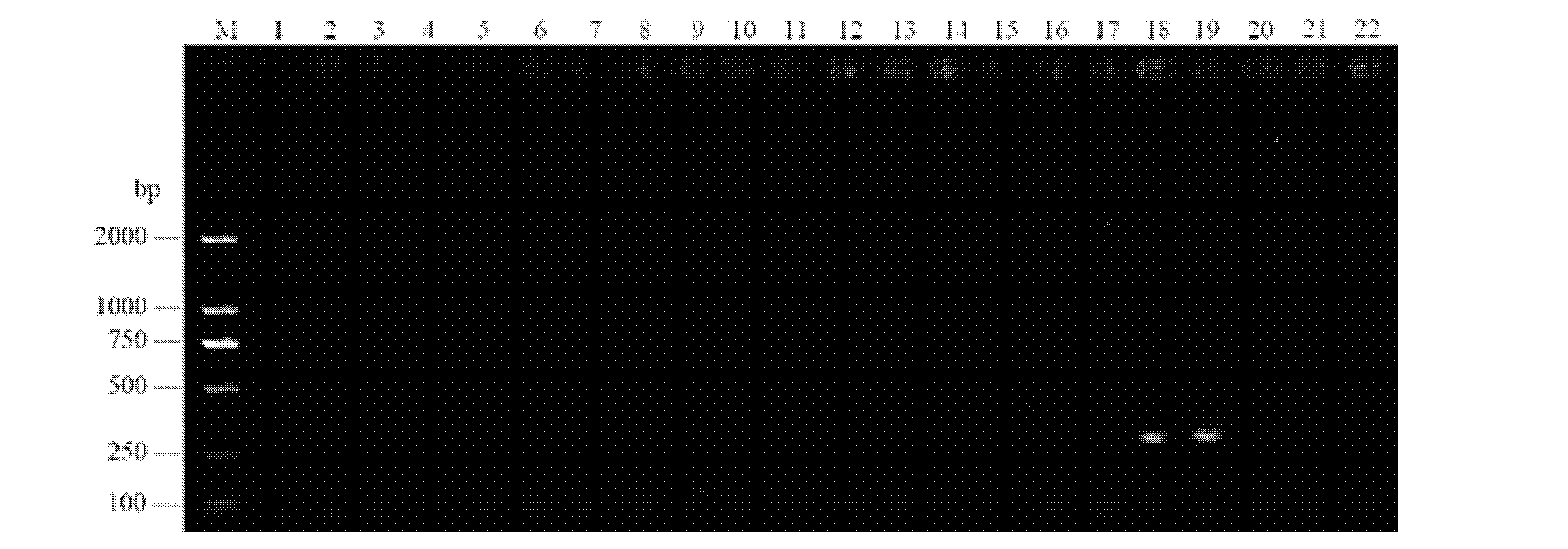

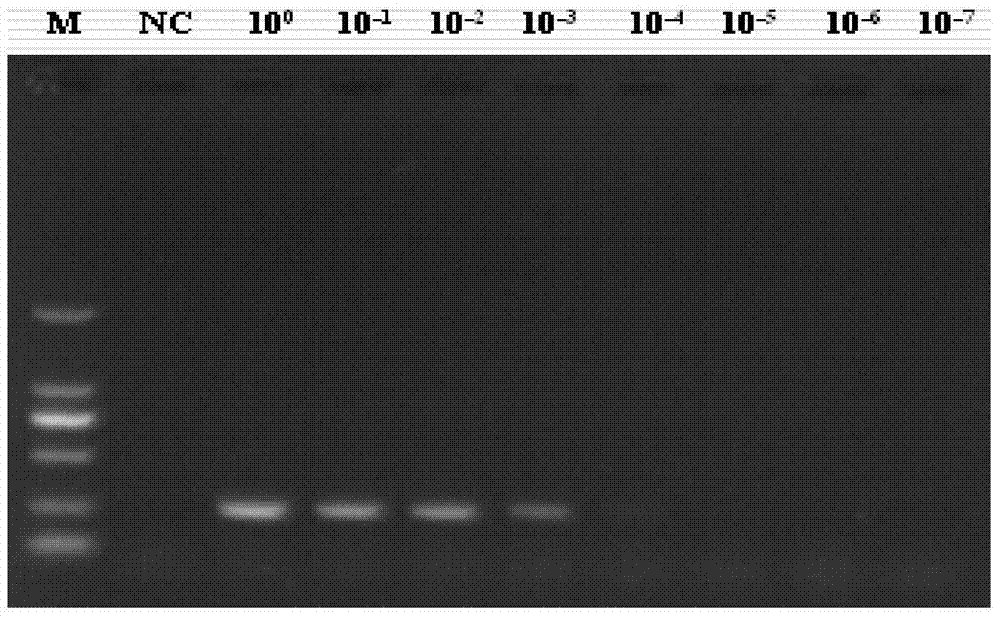

PCR detection method for quickly detecting large coptotermes formosunus

InactiveCN101665828AProtect production securityQuick checkMicrobiological testing/measurementFluorescence/phosphorescenceForest industryFluorescence

The invention discloses a PCR detection method for quickly detecting large coptotermes formosunus, which comprises conventional PCR detection and real-time fluorescence PCR detection. The PCR detection method comprises the following steps: preparing a DNA template for a sample to be detected, designing a specific primer and / or a probe, establishing a PCR reaction system for PCR amplification, andobserving, recording and photographing on a gel imaging system. With the advantage of high speed, stability, reliability and sensitivity, the PCR detection method for quickly detecting large coptotermes formosunus is applied to the detection of different-grade samples of large coptotermes formosunus, and lays a foundation for China's coptotermes formosunus class in molecular classification and therapid identification of sibling species. The result of study can be directly applied to the quarantine identification of large coptotermes formosunus in inward and outward plant quarantine, and has important significance to the production safety protection of agriculture and forestry, biological balance maintenance, public health safety insurance in China.

Owner:中华人民共和国珠海出入境检验检疫局

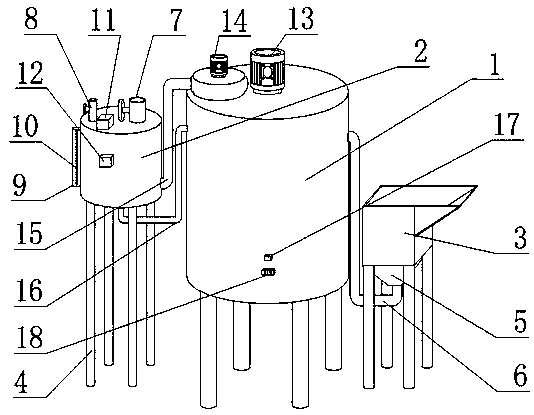

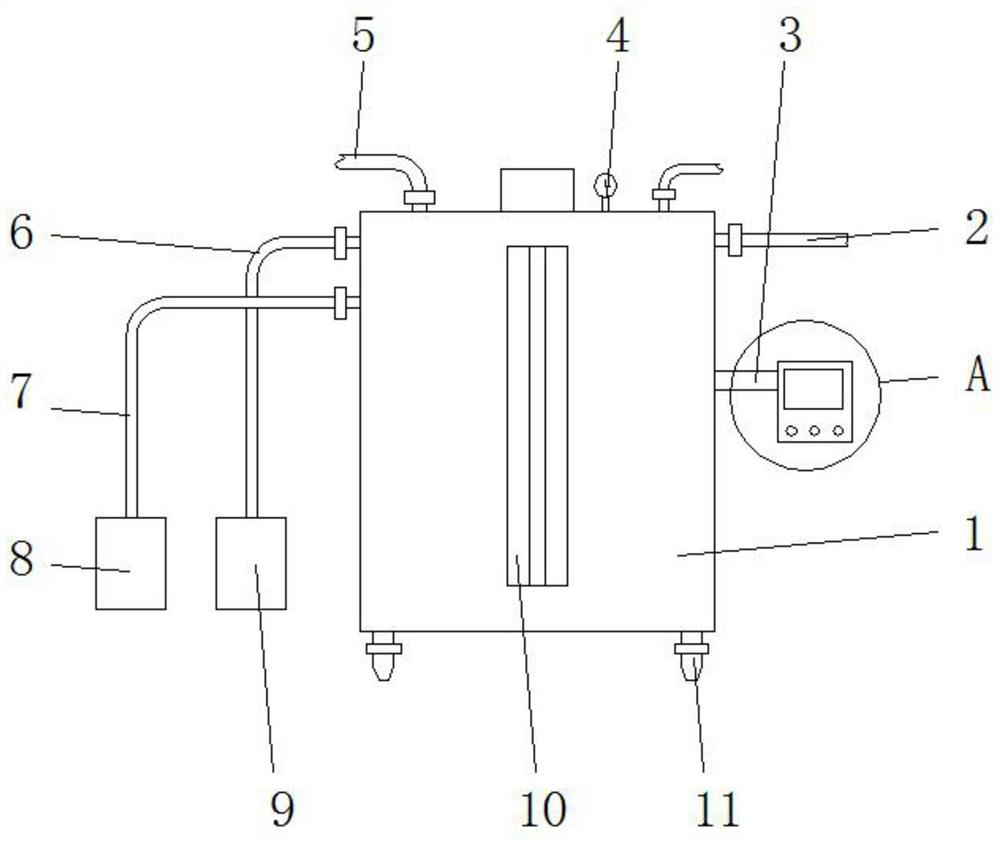

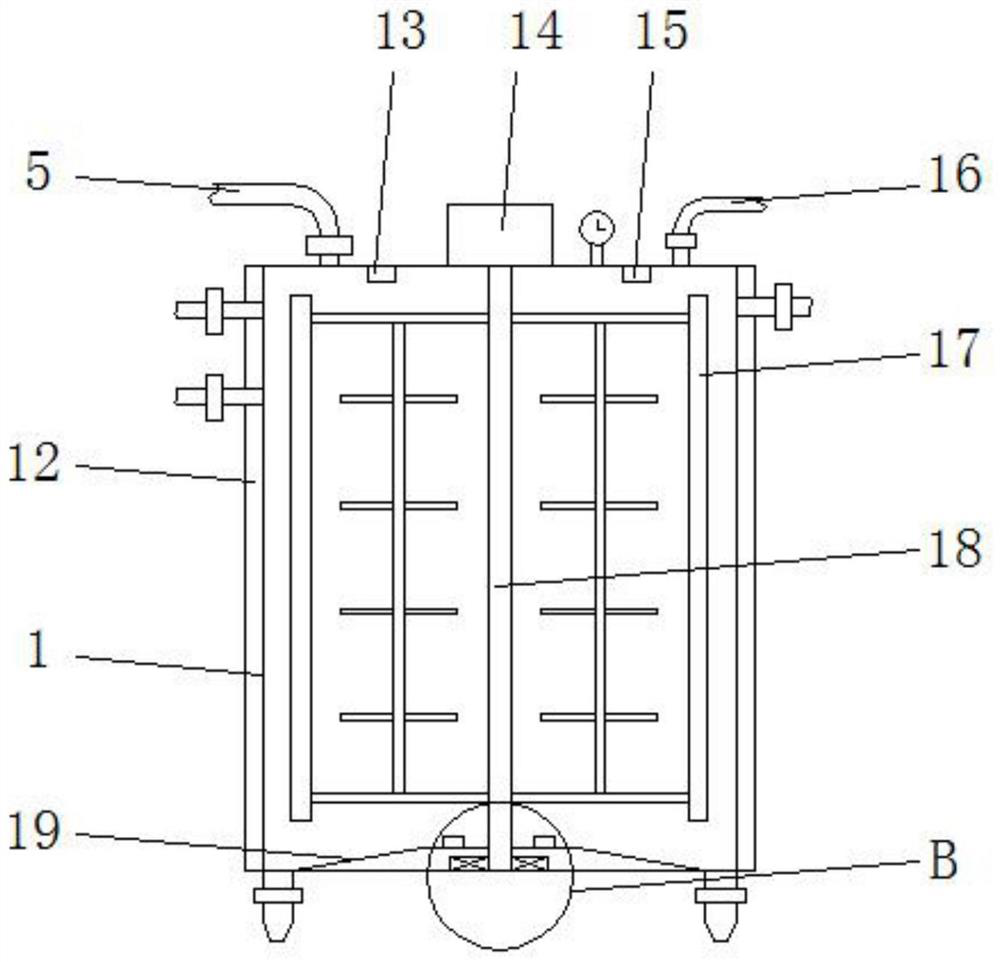

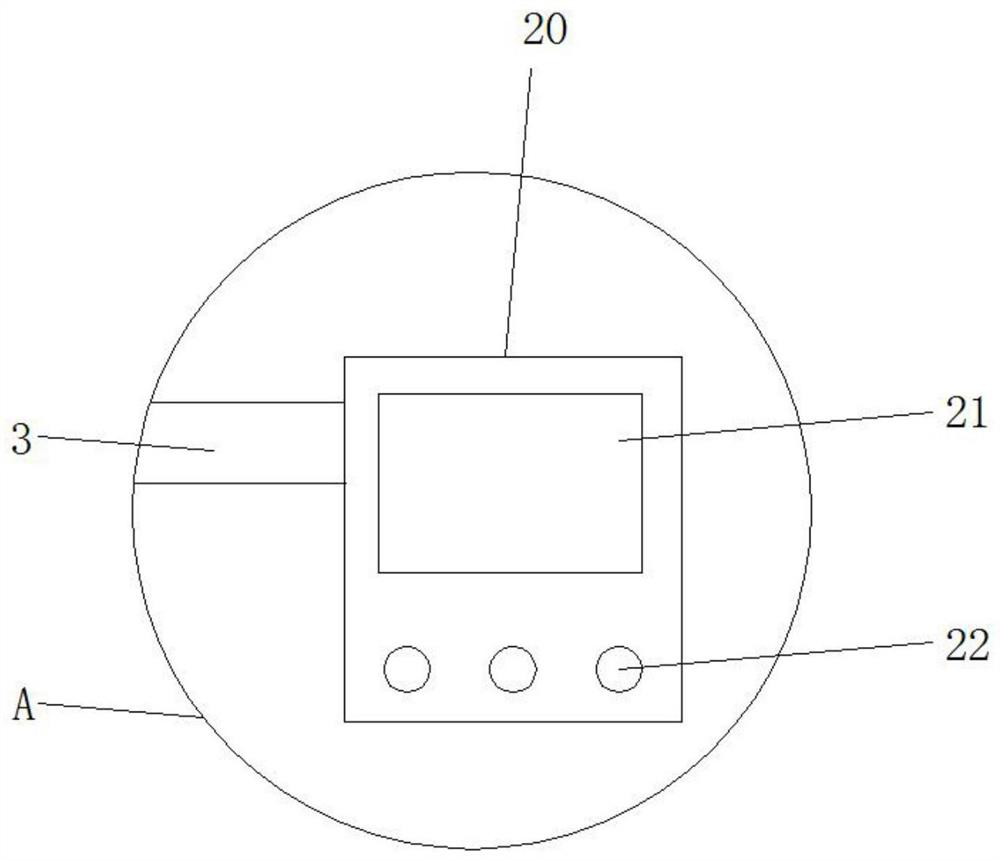

Raw material stirring device with temperature detection function for preparing solid sodium methoxide

PendingCN112156663AImprove solubilityImprove stirring efficiencyTransportation and packagingRotary stirring mixersSodium methoxideEngineering

The raw material stirring device comprises a tank body, a vacuum pump and a heater, a feeding pipe A is installed in the middle of one side of the top end of the tank body, and a feeding pipe B is installed in the middle of the side, away from the feeding pipe A, of the top end of the tank body; the heater is mounted at the top end of one side of the feeding pipe A on the outer surface of the tankbody through a hot air pipe, a vacuum pump is mounted at the lower end of the hot air pipe on the outer surface of the tank body through a vacuum pipe, and a nitrogen inlet pipe is mounted on one side, deviating from the vacuum pipe, close to the top end; a controller is mounted at the lower end of the nitrogen inlet pipe on one side of the tank body through a connecting rod. According to the invention, the problems of fewer temperature detection modules, easiness in causing safety accidents after the detection modules are damaged, simpler stirring structure, poor stirring uniformity and lowdissolving efficiency of the existing device are solved, and the use convenience of the device is improved.

Owner:SHANDONG HUIHAI PHARMA & CHEM

Device and method for cold pressing cutting of tank container in hot chamber

PendingCN108687640ARealize the needs of automated productionReduce labor intensityGrinding carriagesGrinding feed controlEngineeringIdler-wheel

The invention discloses a device for cold pressing cutting of a tank container in a hot chamber and further provides a method for cold pressing cutting of the tank container in the hot chamber. The device comprises a base, an upper pressing disc, a lower tray, positioning idler wheels, a cutterhead and a motor. The upper pressing disc comprises a fixed end, an elongation arm and a rotating disc end; the fixed end is fixed to the base; the elongated arm extends towards the lower tray and fixes the rotating disc end to the position over the lower tray; the bottom face of the rotating disc end isfixedly connected with a rotating disc through a rotating shaft; and the other end of the lower tray is rotatably fixed to the base. The positioning idler wheels and the cutterhead are oppositely arranged on the two sides of the lower tray; the positioning idler wheels are a pair of rotatable cylinders which are mutually parallelly arranged in the base; and the cutterhead is rotatably fixedly connected with a cutterhead box, and the cutterhead box is connected with the motor. The device and method for cold pressing cutting are safe, reliable and stable, manual remote operation is effectivelyreplaced, and the labor intensity of personnel is lowered.

Owner:BEIJING XUANYU INTELLIGENT TECH CO LTD

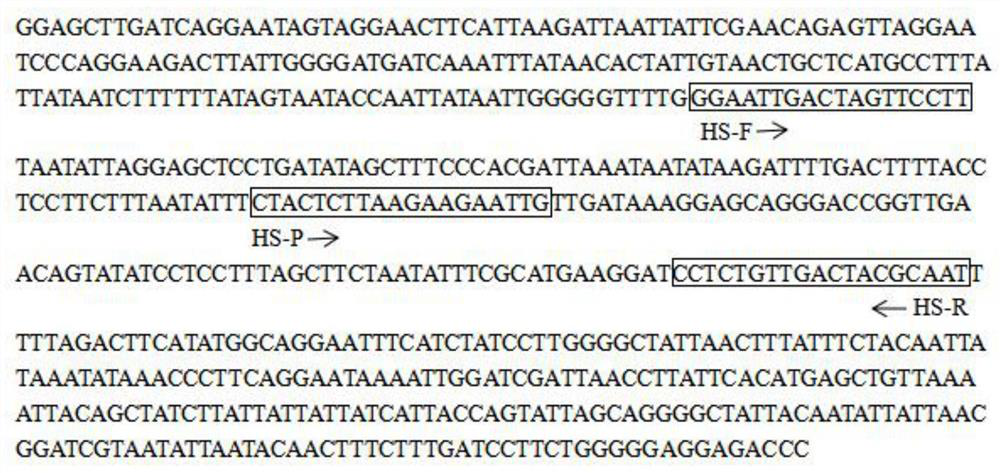

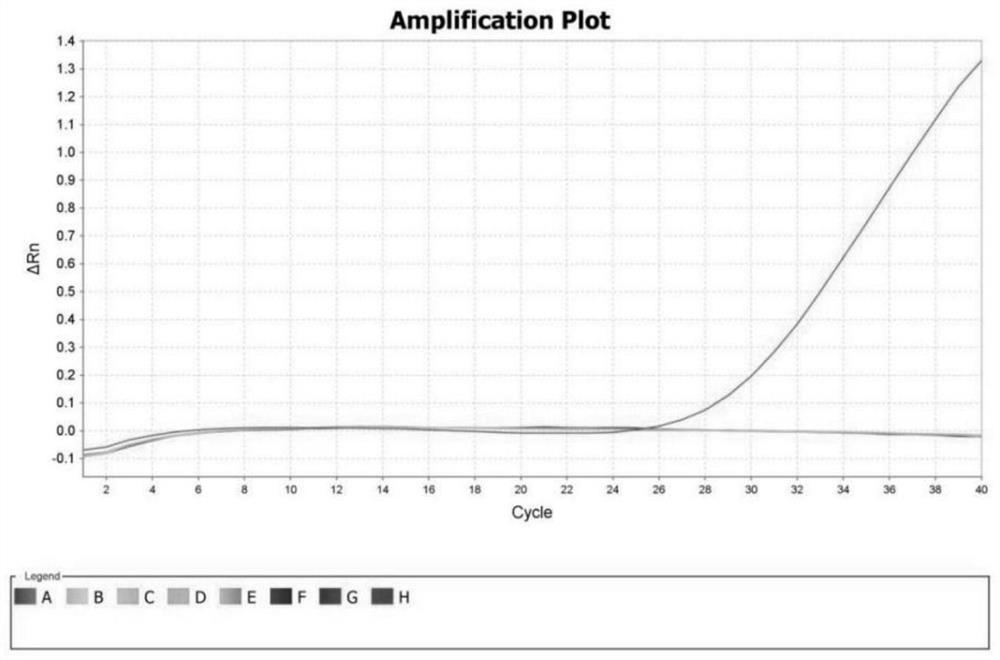

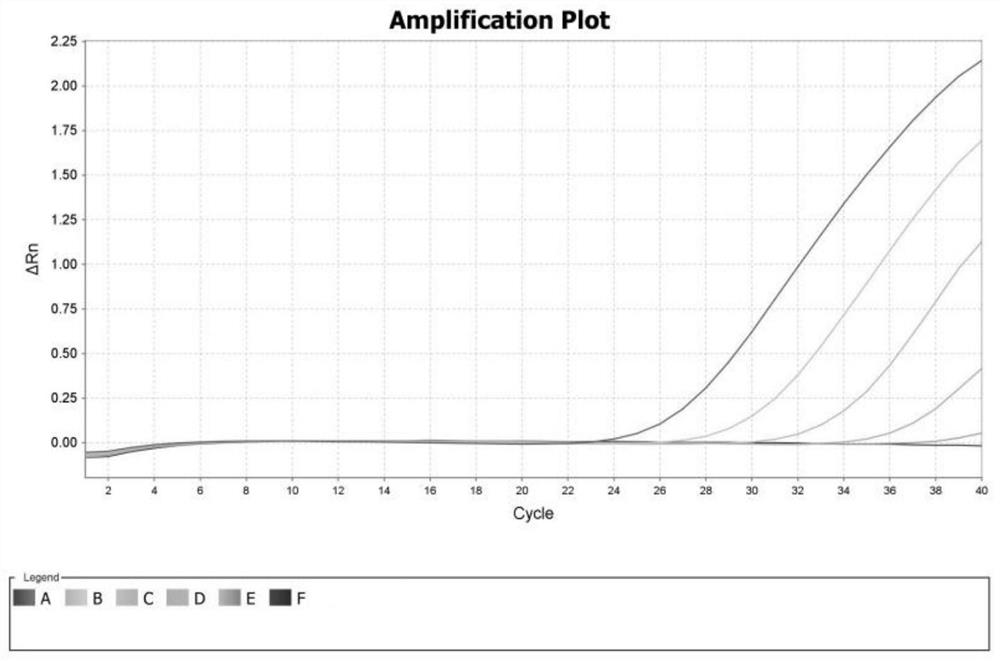

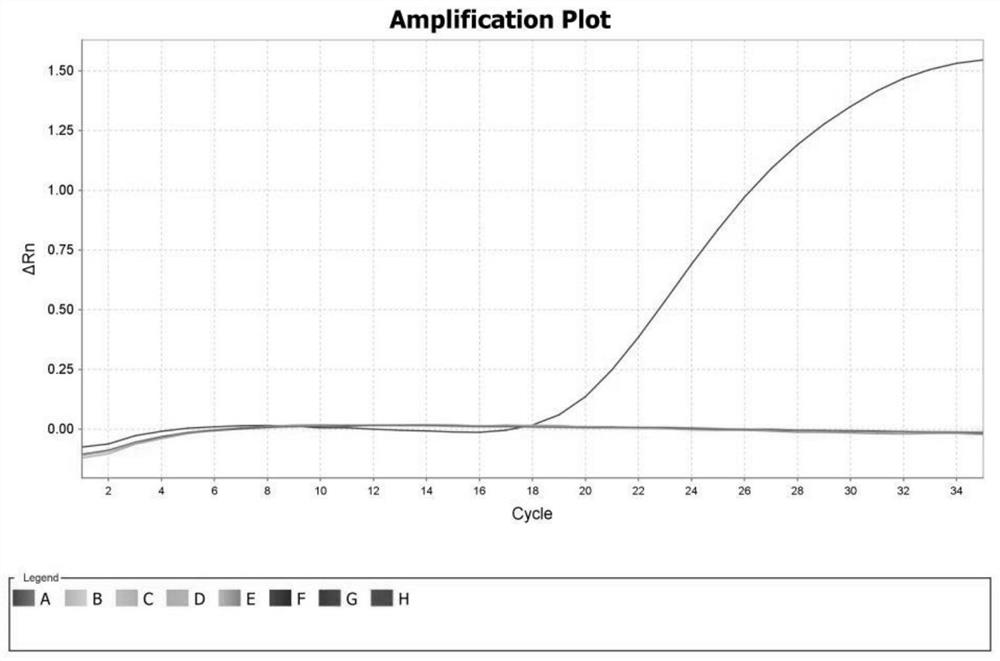

Real-time fluorescent PCR (polymerase chain reaction) detection method for dendroctonus pseudotsugae as well as primers and probe for detection

PendingCN112921106AStrong specificityHigh sensitivityMicrobiological testing/measurementDNA/RNA fragmentationEcological safetyDendroctonus pseudotsugae

The invention provides a method for detecting dendroctonus pseudotsugae. The aim of identifying dendroctonus pseudotsugae can be achieved by combining specific primers (HS-F and HS-R) and a probe (HS-P) which are screened by a test in a Taq-Man real-time fluorescent quantitative PCR (Polymerase Chain Reaction) method. The detection method is suitable for quarantine identification of dendroctonus in different states, the defects of a conventional morphological identification method are overcome, and compared with a DNA bar code identification technology applied in the prior art, the primers and the MGB probe are high in specificity and sensitivity, simple in experimental operation and short in consumed time; the identification result is visual and can be obtained by observing an amplification curve; and the research not only can meet the original rapid customs clearance requirement of entry and exit, improve the detection rate, but also can effectively prevent invasion and diffusion of dangerous dendroctonus, and has important significance on protection of agriculture and forestry production and ecological safety in China.

Owner:海口海关热带植物隔离检疫中心

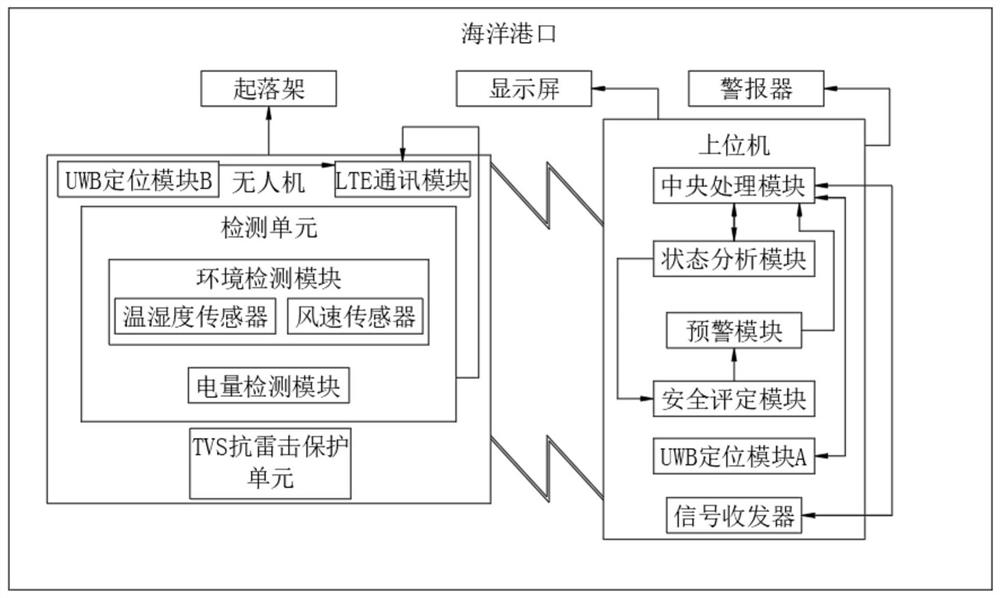

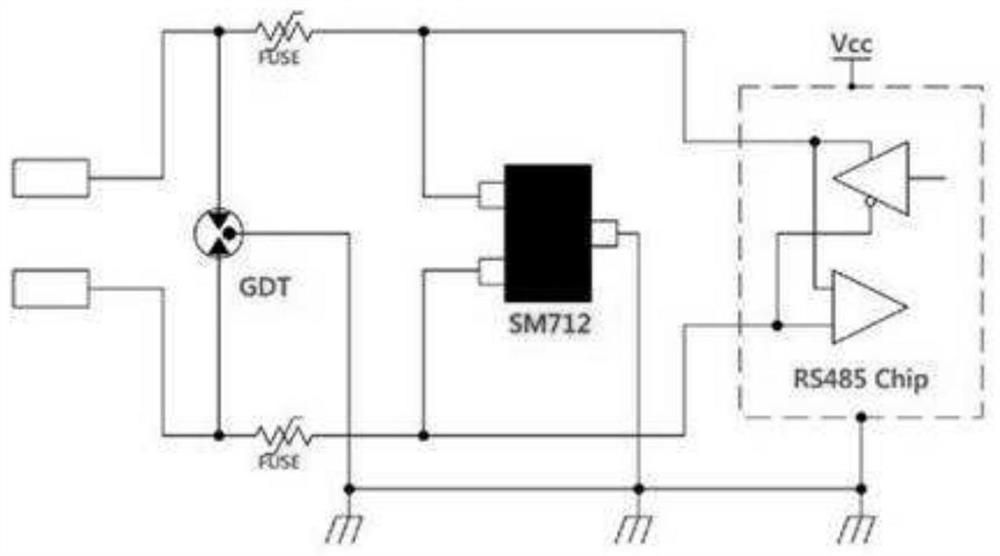

Marine port safety unmanned aerial vehicle detection system

InactiveCN112179401AProtect personal safetyProtect production securityMeasurement devicesTransmission systemsTransceiverMarine engineering

The invention discloses a marine port safety unmanned aerial vehicle detection system. The system comprises an undercarriage arranged at a marine port, a display screen, an alarm, an unmanned aerial vehicle and an upper computer; the unmanned aerial vehicle is in signal connection with the upper computer; the unmanned aerial vehicle comprises an LTE communication module, a UWB positioning module Band a detection unit; the upper computer comprises a central processing module, a state analysis module, an early warning module, a safety evaluation module, a UWB positioning module A and a signal transceiver. The unmanned aerial vehicle is arranged to detect the environment of a marine port, detected data signals are sent to the upper computer through the LTE communication module, the state analysis module in the upper computer analyzes the current state of the marine port, and analyzed data signals are sent to a safety evaluation module; the safety evaluation module evaluates the safety level of the current marine port environment state, gives an alarm to workers in advance, prevents mechanical equipment from being damaged, and protects the personal and production safety.

Owner:TANGSHAN HARBIN SHIP TECH CO LTD +1

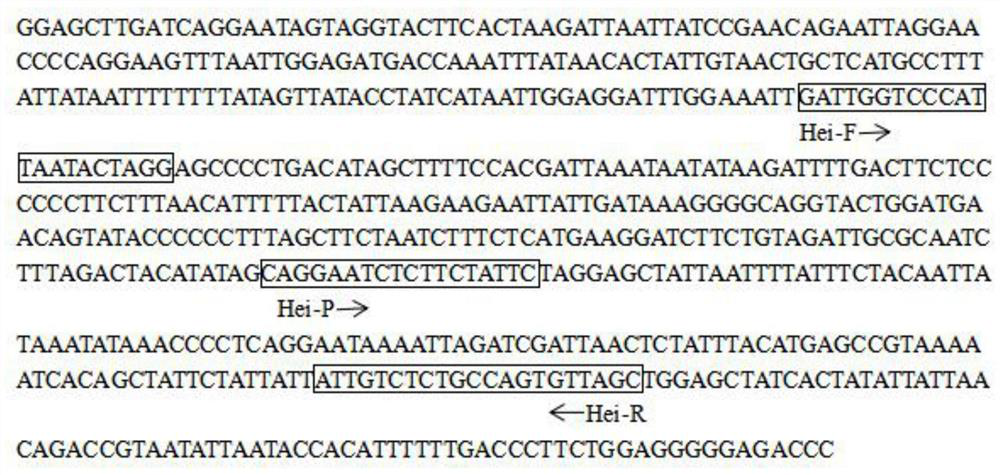

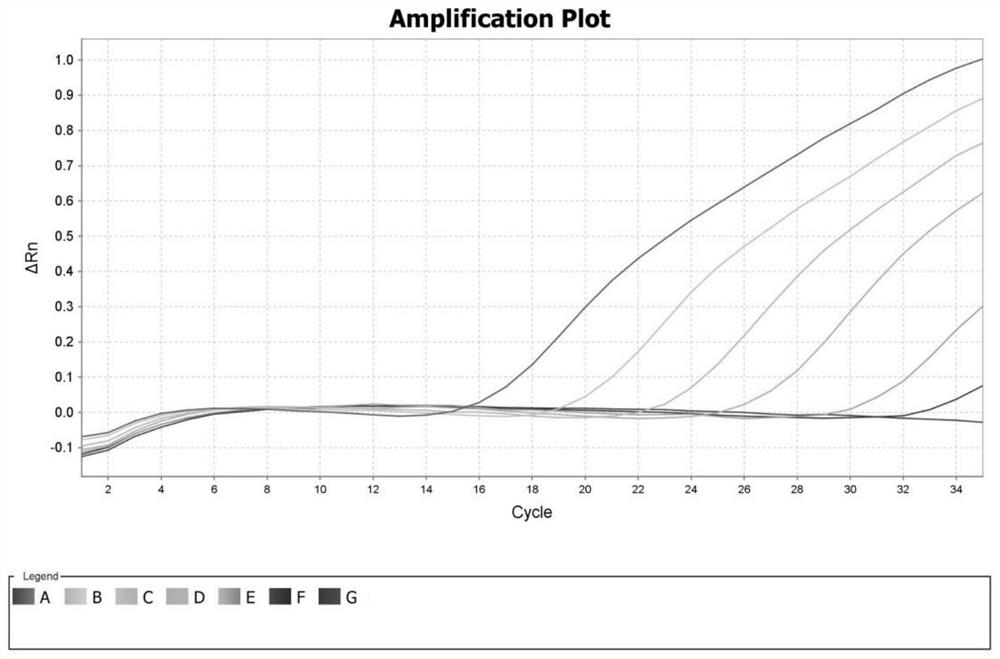

Real-time fluorescent PCR detection method for dendroctonus melanocarpa, primer and probe for detection

PendingCN113025727APrevent intrusionPrevent proliferationMicrobiological testing/measurementDNA/RNA fragmentationEcological safetyMicrobiology

The invention provides a detection method for dendroctonus melanocarpa. The purpose of identifying dendroctonus melanocarpa can be achieved by combining specific primers (Heii-F and Heii-R) and a probe (Heii-P) which are screened by a test in a Taq-Man real-time fluorescent quantitative PCR method. The invention is suitable for quarantine identification of beetles in different states, the defects of a conventional morphological identification method are overcome, and compared with a DNA bar code identification technology applied in the prior art, the primer and the MGB probe are high in specificity and sensitivity, simple in experimental operation and short in consumed time; The identification result is visual and can be obtained by observing an amplification curve. The research not only can meet the original rapid customs clearance requirement of entry and exit, improve the detection rate, but also can effectively prevent invasion and diffusion of dangerous dendroctonus beetle, and has important significance on protection of agriculture and forestry production and ecological safety in China.

Owner:海口海关热带植物隔离检疫中心

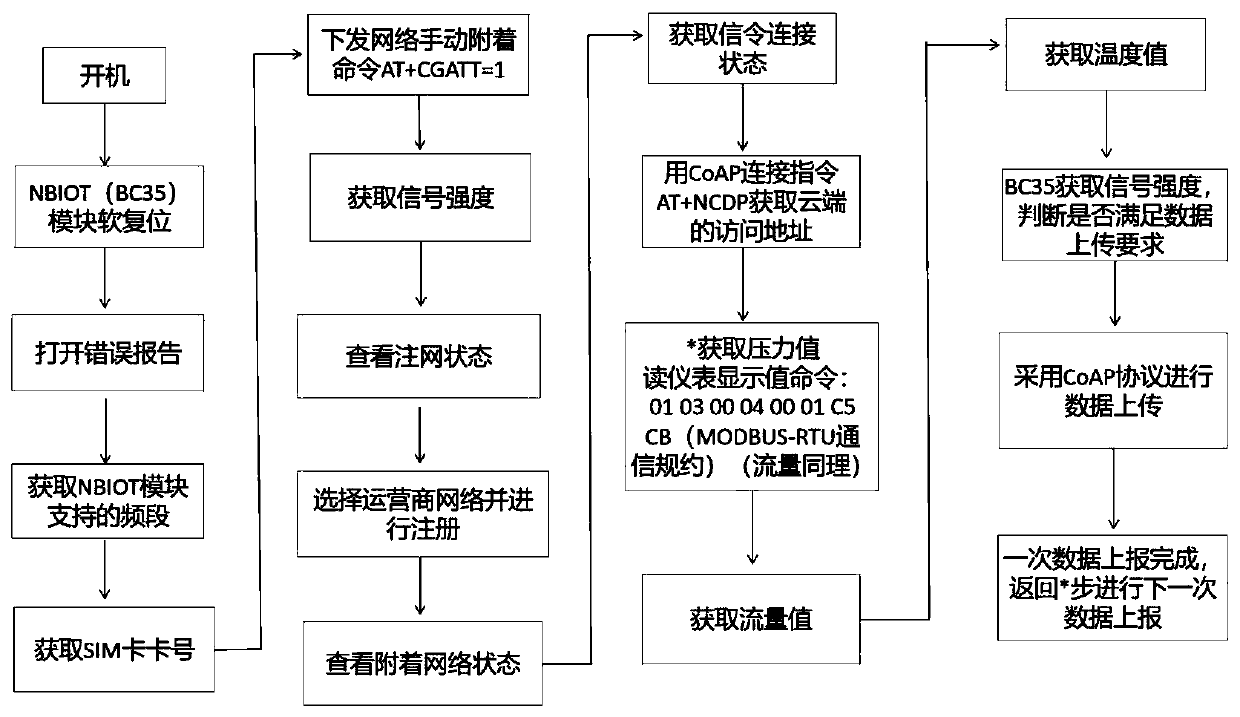

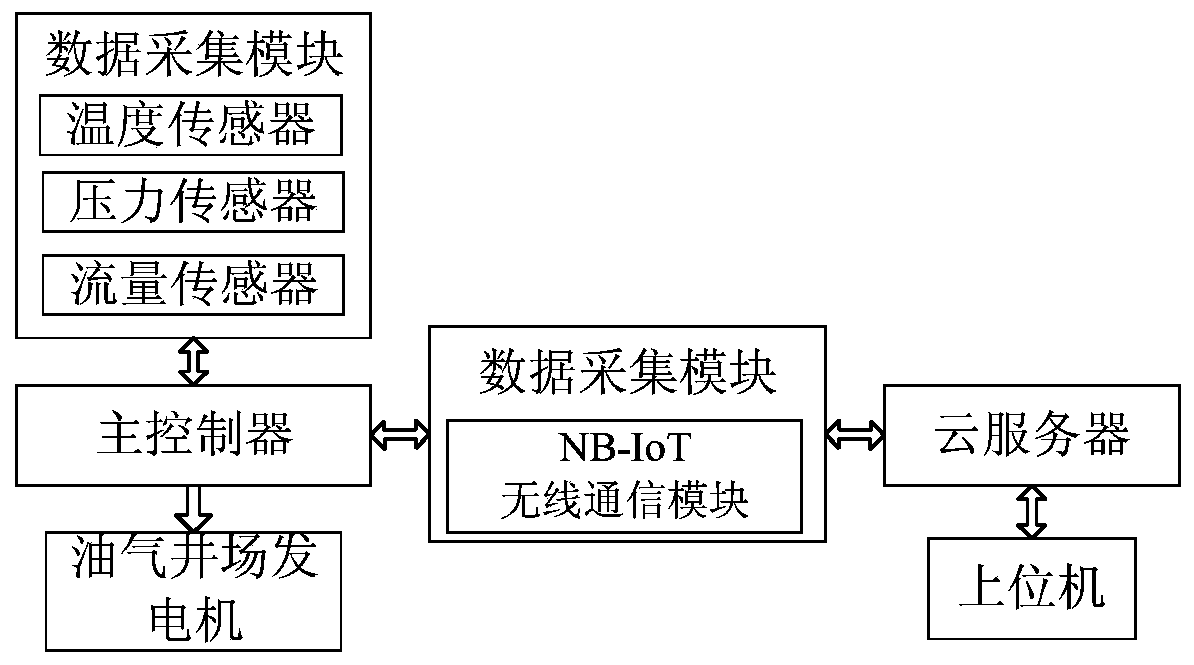

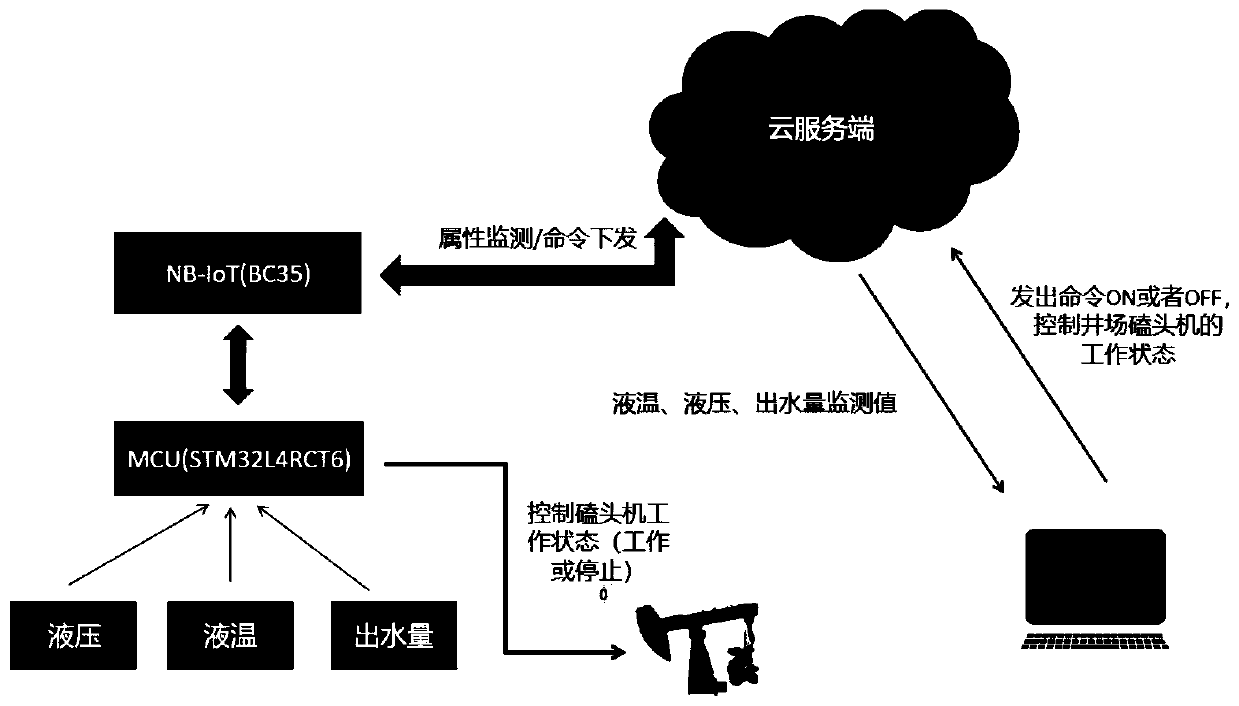

Oil and gas production intelligent monitoring system and method based on NB-IoT

PendingCN110501944ALow costProtect production securityProgramme controlComputer controlTransmission protocolDigitization

The invention provides an oil and gas production intelligent monitoring system and method based on NB-IoT and relates to the oil and gas monitoring technology field. By using the system and the method, data acquired by various digital instruments are transmitted to a cloud server through an advanced NB-IoT wireless communication module at regular intervals by a controller in an oil and gas production field; and a transmission protocol type adopts CoAP, definition and deployment of profile and encoding and decoding plug-ins are completed by the cloud server in advance, the data transmitted by the NB-IoT wireless communication module are analyzed and stored, a client program of an upper computer captures the data from cloud, and oil and gas well attribute data monitoring values are displayedto a user. When the monitored data is abnormal and reaches an alarm value, a manager can send a work stopping instruction to a main controller at an upper computer end, takes the cloud as a relay, and stops working of a generator through controlling the relay so that work of a well site kowtow machine is stopped, and low power consumption and high stability in an oil and gas production monitoringprocess are achieved.

Owner:东北大学秦皇岛分校

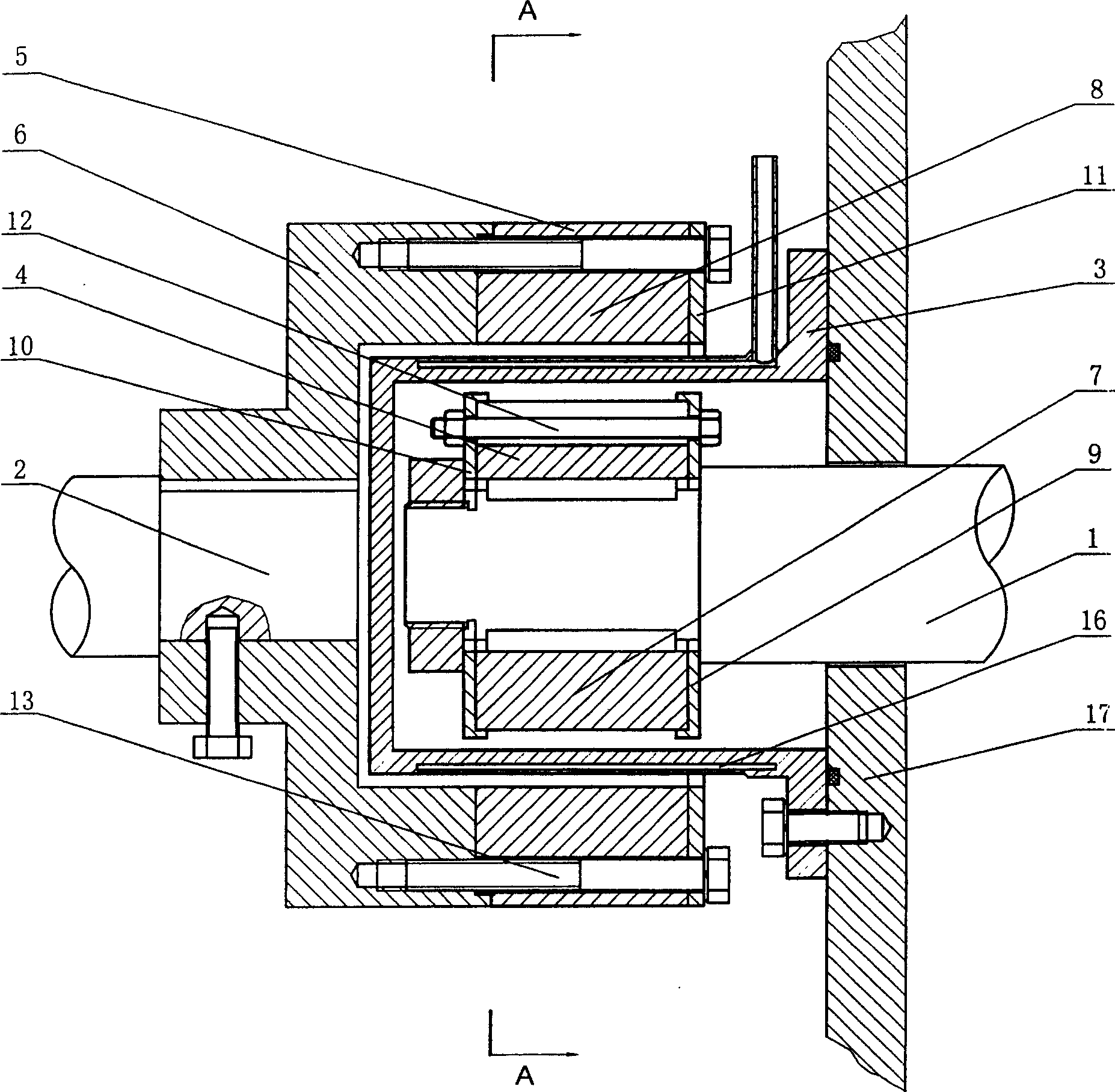

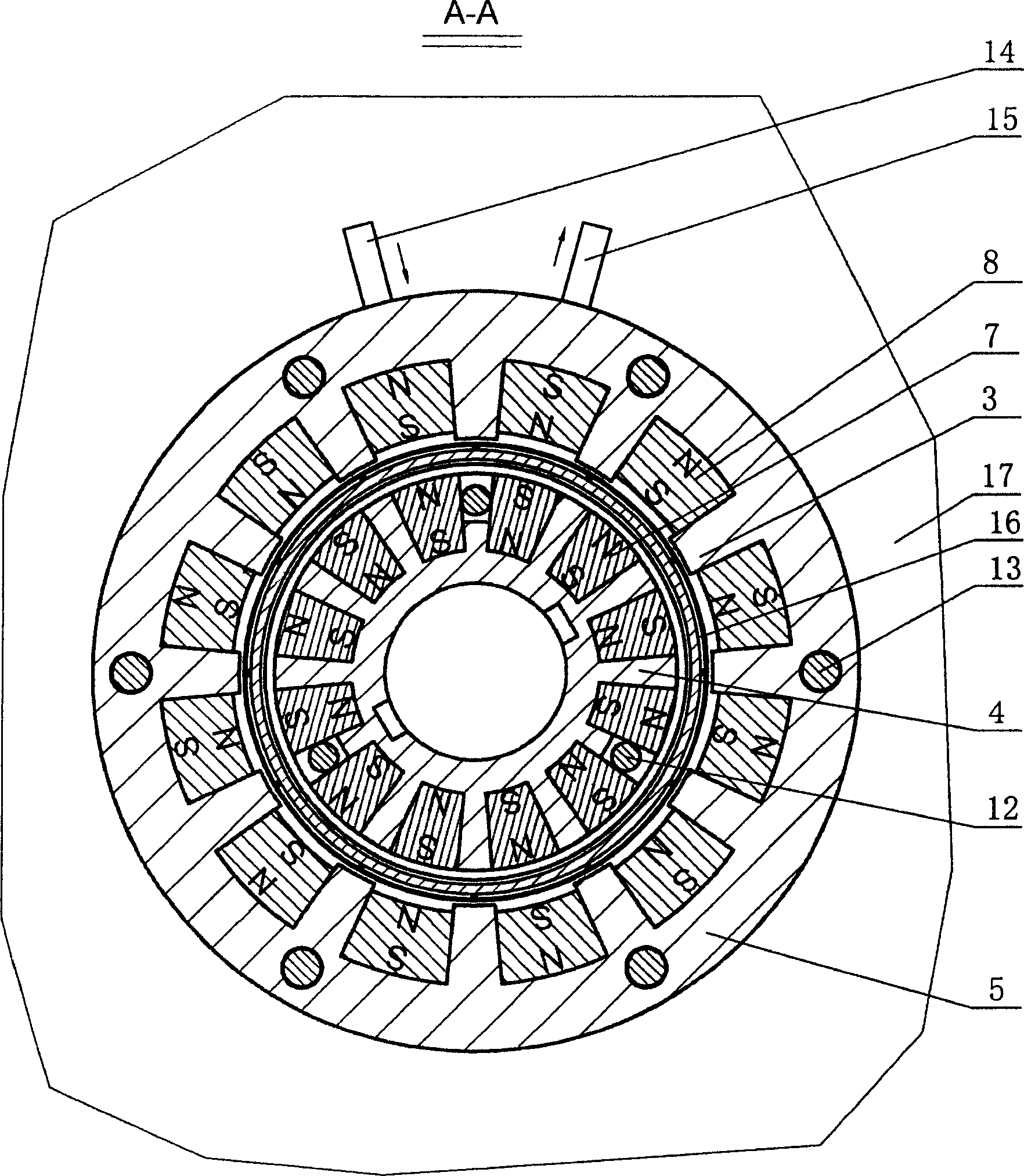

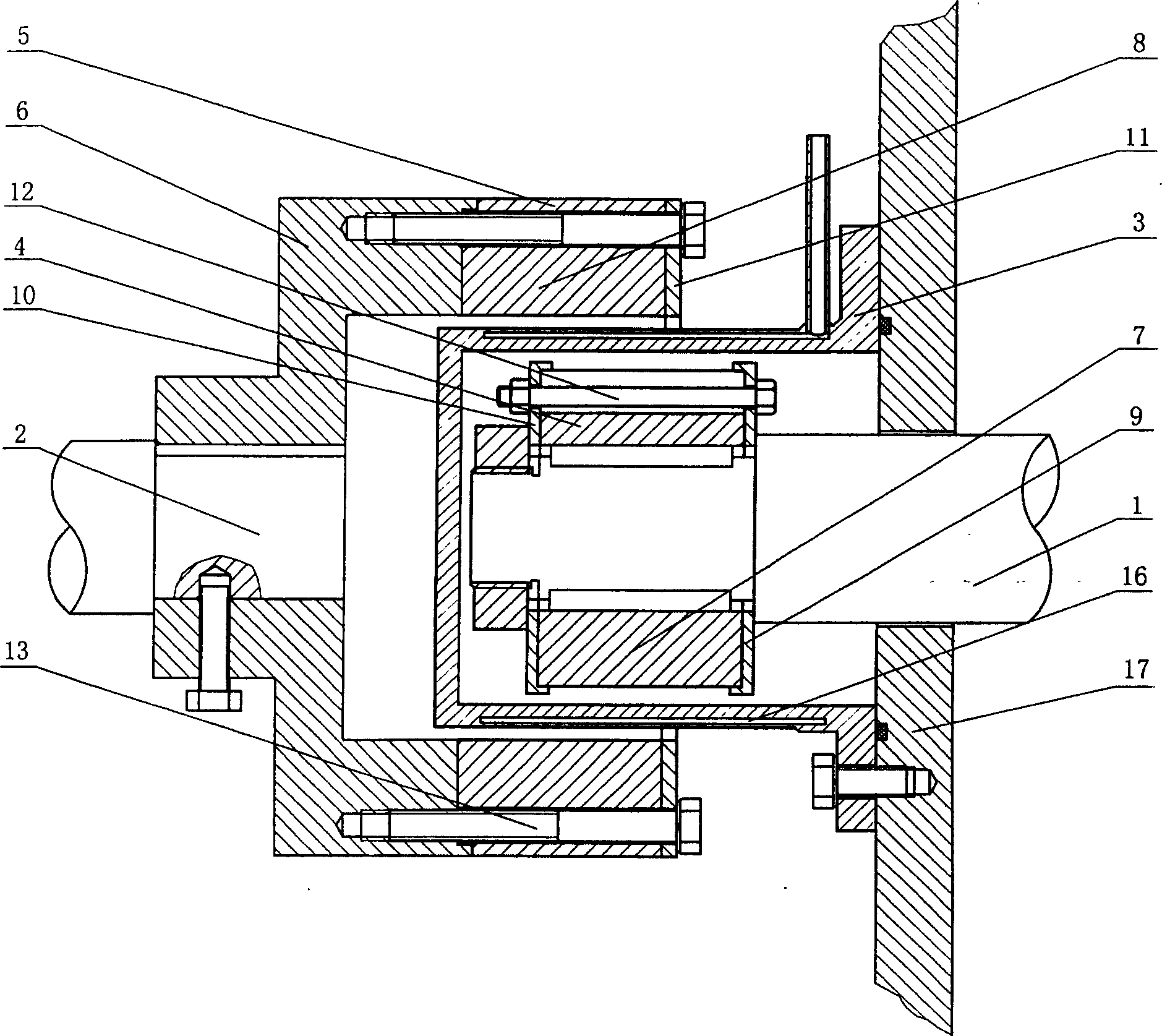

Non contact flexible magnetic coupling for vacuum system

InactiveCN1299019CIncrease the magnetic field strengthHigh torqueYielding couplingPermanent-magnet clutches/brakesCouplingDrive shaft

The present invention relates to a vacuum system non-contacting flexible magnetic coupler, including driven magnetic semi-coupler cover-mounted on the driven shaft, driving magnetic semi-coupler cover-connected on the driving shaft and isolation cover, the driven magnetic semi-coupler is embedded in the interior of driving magnetic semi-coupler, and the isolation cover is placed between the driven magnetic semi-coupler and driving magnetic semi-coupler.

Owner:XIAN UNIV OF TECH

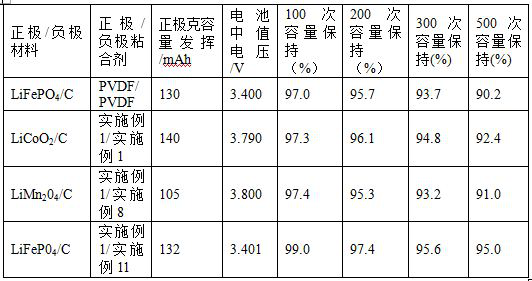

Lithium-ion secondary battery active material binder

ActiveCN108847488BExtended service lifeShorten production timeCell electrodesSecondary cellsHydrophilic monomerElectrical battery

The invention provides a lithium ion secondary battery active material binder. Obtained by two-stage emulsion polymerization: the first stage uses hydrophobic monomers as the main polymerized monomers, and puts hydrophilic monomers, additives and dispersion media together in the reactor for stirring; injects high-purity nitrogen to drive oxygen ; Add the initiation system to start polymerization; the polymerized monomer of the second stage is a hydrophilic monomer, which is added to the polymer of the first stage, and then added to the initiation system for polymerization; the weight percent range of the solid content of the obtained adhesive is 10‑ 50%. The lithium ion secondary battery active material binder prepared by the invention adopts a multi-stage polymerization method, which reduces the residue of toxic volatile organic compounds, improves product safety, and saves manufacturing time and cost. The lithium ion secondary battery prepared by using the binder of the present invention has the characteristics of high capacity of active materials, long battery life in high and low temperature cycles, and the like.

Owner:汕头市鲁汕化工原料有限公司

Kit for identifying fruit flies and special primers therefor

InactiveCN102517388BStrong representativeGuaranteed accuracyMicrobiological testing/measurementDNA/RNA fragmentationEcology

Owner:CHINA AGRI UNIV +1

PCR detection method for quickly detecting large coptotermes formosunus

InactiveCN101665828BProtect production securityQuick checkMicrobiological testing/measurementFluorescence/phosphorescenceForest industryFluorescence

The invention discloses a PCR detection method for quickly detecting large coptotermes formosunus, which comprises conventional PCR detection and real-time fluorescence PCR detection. The PCR detection method comprises the following steps: preparing a DNA template for a sample to be detected, designing a specific primer and / or a probe, establishing a PCR reaction system for PCR amplification, andobserving, recording and photographing on a gel imaging system. With the advantage of high speed, stability, reliability and sensitivity, the PCR detection method for quickly detecting large coptotermes formosunus is applied to the detection of different-grade samples of large coptotermes formosunus, and lays a foundation for China's coptotermes formosunus class in molecular classification and the rapid identification of sibling species. The result of study can be directly applied to the quarantine identification of large coptotermes formosunus in inward and outward plant quarantine, and has important significance to the production safety protection of agriculture and forestry, biological balance maintenance, public health safety insurance in China.

Owner:中华人民共和国珠海出入境检验检疫局

A dust-free self-unloading kneading equipment for bread making

ActiveCN110089531BAvoid pollutionAvoid flyingMixing/kneading structural elementsMixing/kneading with vertically-mounted toolsElectric machineryCentrifugal fan

The invention provides a dust-free self-unloading dough mixing equipment for making bread, which includes a dough mixing box, a feeding box and a water adding box, the feeding box is arranged on one side of the dough mixing box, and the water adding box is arranged on and On the other side of the noodle box, the bottoms of the kneading noodle box, the feeding box and the water adding tank are all welded with brackets, the bottom of the feeding box is welded with a funnel, the bottom of the funnel is welded with a straw, and the top of the water adding box A tuyere and a water pipe are welded, the water pipe is set on one side of the tuyere, a connector is installed on one side of the water tank, and a capacity mark is engraved on the connector, and a temperature sensor is installed on the top of the water tank through bolts , the top of the kneading box is equipped with a two-way motor and a centrifugal fan through bolts, the centrifugal fan is arranged on one side of the two-way motor, and an air duct is welded on one side of the centrifugal fan. The self-unloading dough kneading equipment has a reasonable design and is suitable for dust-free automatic dough kneading during bread making.

Owner:豪士(福建)食品有限公司

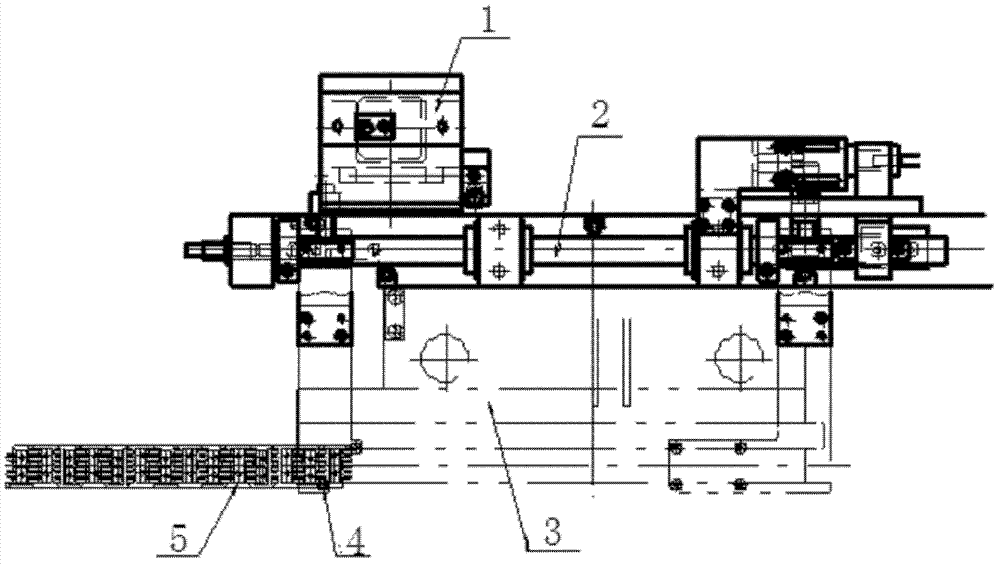

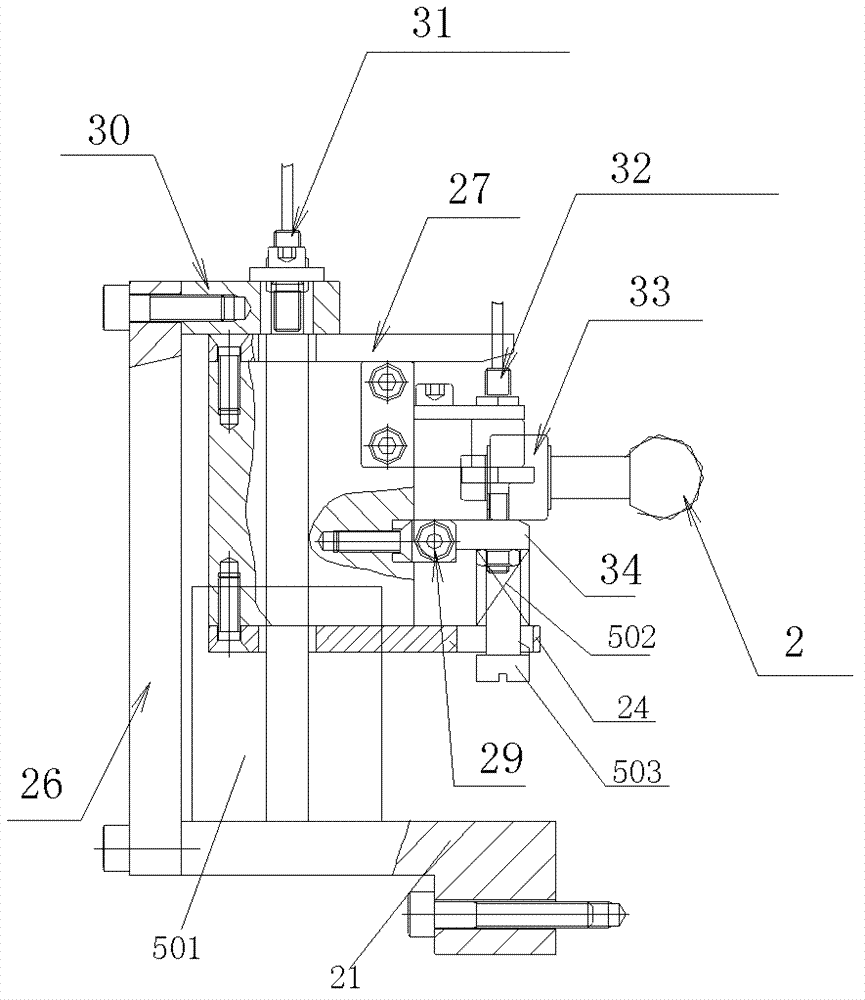

Feeding deflector rod detection device for double in-line package like integrated circuit punching products

The invention discloses a feeding deflector rod detection device for double in-link package (DIP) like integrated circuit punching products, which comprises a fixing plate of a detection plate, a sensor detection plate, a displacement sensor and an adjusting screw, wherein the sensor detection plate is movably connected with the fixing plate of the detection plate, a screw is fixed at the lower side of the sensor detection plate, a spring is sleeved on the screw, a limit plate is fixed below the sensor detection plate, and the spring is pressed on the limit plate; and the adjusting screw is fixed at the end part of the sensor detection plate, the displacement sensor is fixed above the adjusting screw, a short shaft is laterally and fixedly connected onto a deflector rod, the end part of the short shaft is linked with a movable roller, and the roller is placed on the sensor detection plate, and can move along the sensor detection plate back and forth. The feeding deflector rod detection device can realize real-time shutdown, a lead frame is safely taken out, so the invention has the characteristics of real-time detection, accuracy, production safety protection and the like.

Owner:TONGLING SANJIA YAMADA TECH

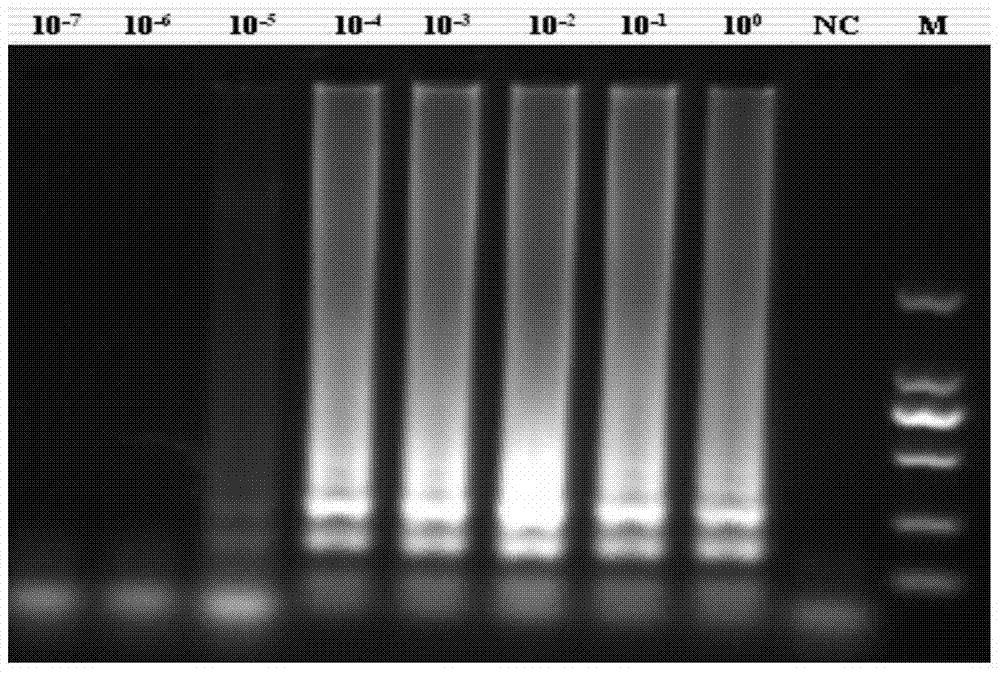

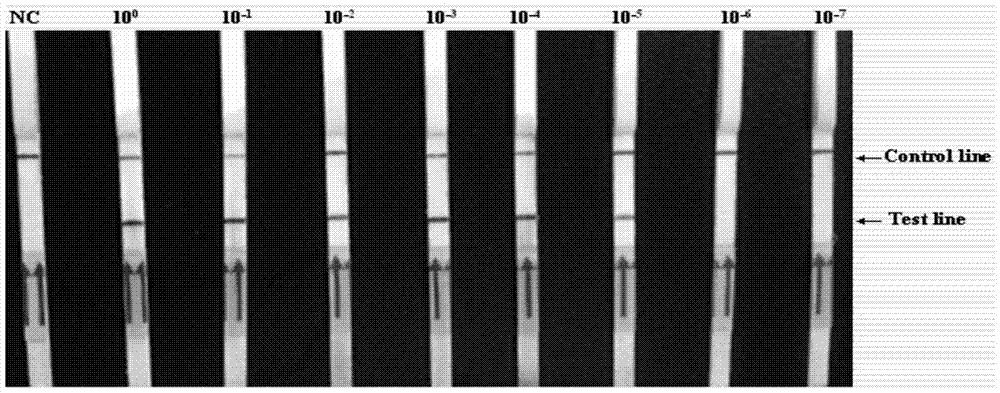

A kind of detection method of rapeseed canker bacterium

InactiveCN104818339BHigh sensitivityLow detection limitMicrobiological testing/measurementDNA/RNA fragmentationLasiodiplodia theobromaeSpecific test

The invention provides a LAMP-LFD (loop-mediated isothermal amplification-lateral flow dipstick) detection method of rape Leptosphaeria maculans, which comprises the following steps: designing three pairs of LAMP primers FIP, BIP, LF, LB, F3 and B3, wherein FIP is a 5'-terminal biotin labeled primer, and LF is a 5'-terminal fluorescein isothiocyanate (FITC) labeled probe; and preparing an LAMP reaction system containing the three pairs of primers and a sample template, amplifying the LAMP reaction system, carrying out LFD detection, and carrying out specificity and sensitivity evaluation. The result shows that the lowest detection line of the LAMP-LFD method for the L.maculans genome DNA (deoxyribonucleic acid) is 114fg / mu L. In the specificity verification experiment, when five related phytopathogens, including Alternaria, Lasiodiplodia theobromae, fusarium and Diaporthe phaseolorum var. caulivora, are used and Diaporthe phaseolorum var. meridionalis and L.maculans are used as specific test strains, the LAMP-LFD detection method only has positive reaction for the L.maculans.

Owner:舟山出入境检验检疫局综合技术服务中心 +2

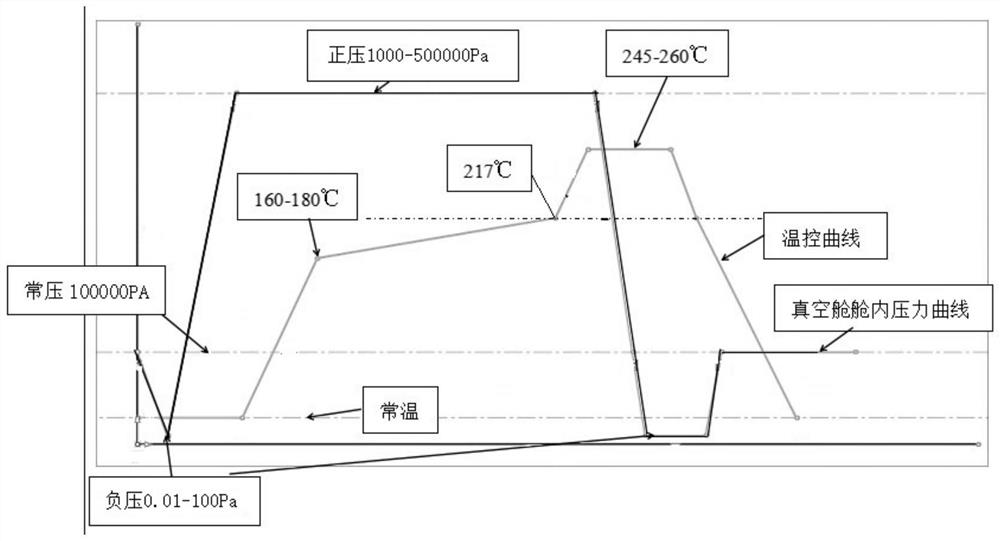

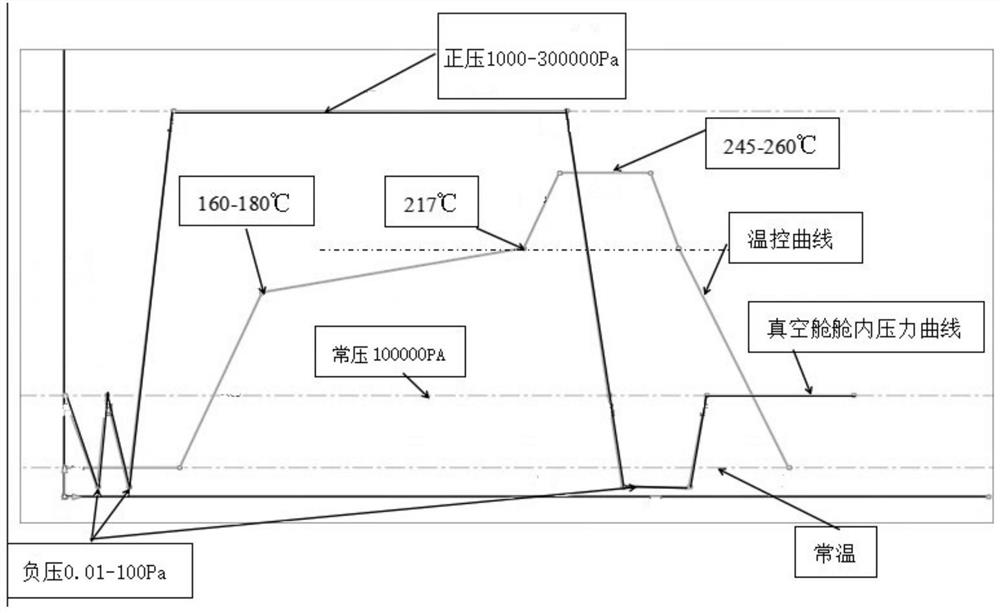

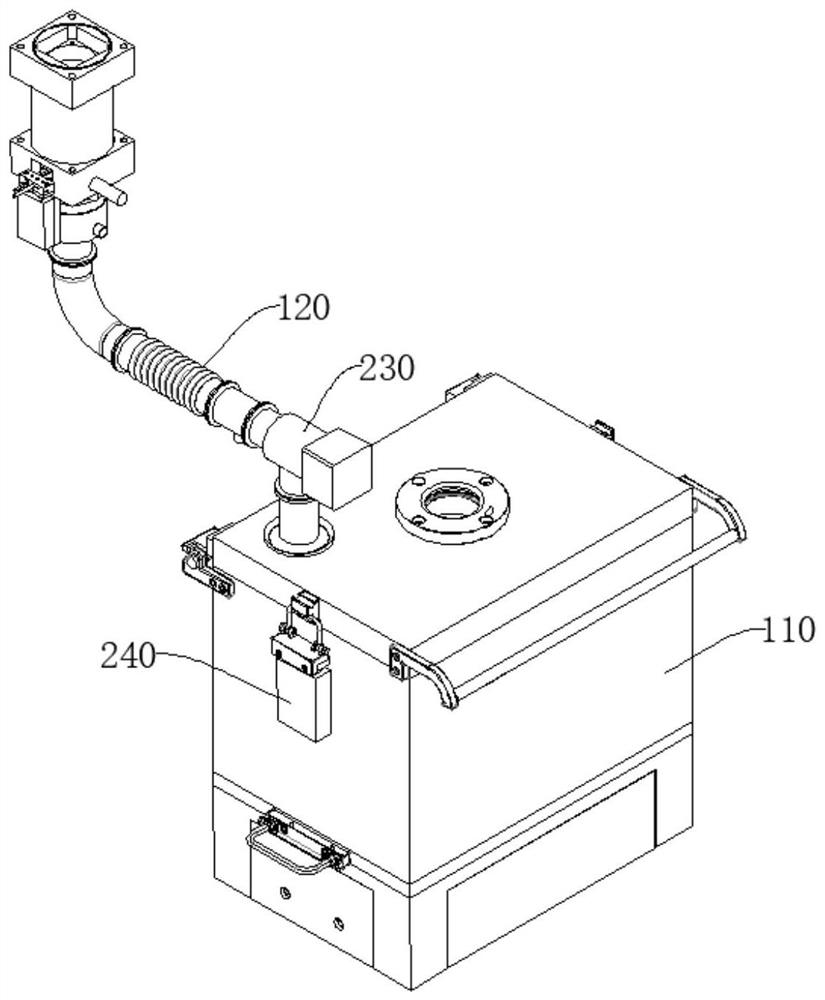

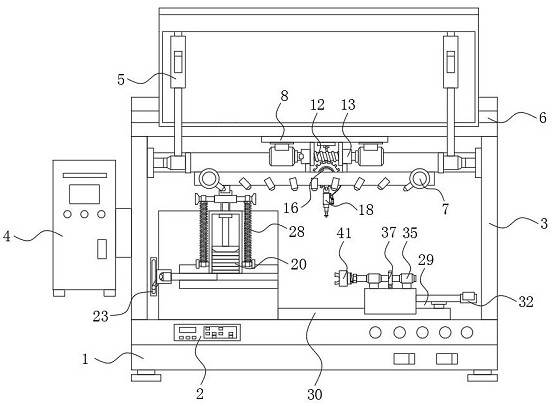

Vacuum reflow soldering positive and negative pressure combined welding process

ActiveCN113385763AReduce void rateExtend discharge timeSoldering apparatusPumping vacuumMaterials science

The invention discloses a vacuum reflow soldering positive and negative pressure combined welding process, and relates to the technical field of vacuum reflow soldering. The process comprises the following steps that debugging preparation is carried out on vacuum cabin equipment; vacuumizing is carried out in a normal temperature state until the pressure in a vacuum cabin is smaller than or equal to a preset pressure value of 0.05-100PA of negative pressure; the vacuum cabin is filled with a reducing agent into in a normal temperature state until the positive pressure is 1000-500000PA; heating is carried out to reach 160-180 DEG C; then heating is carried out to reach the melting point of welding flux of 217 DEG C; then heating is carried out to reach 245-260 DEG C, and the constant temperature is kept for 1-30 seconds; vacuumizing is carried out for 20-30 seconds, and the vacuum degree in the vacuum cabin is maintained at the negative pressure ranging from 0.01 PA to 100 PA; cooling is carried out; the internal pressure of the vacuum cabin reaches normal pressure; and when it is detected that the preset cooling temperature is reached, a weldment is taken out. According to the process, firstly, under the action of positive pressure, bubbles in the welding flux are removed, then when vacuumizing is carried out to reach the negative pressure, the bubbles in the welding flux are removed again, the discharging time of the bubbles is greatly shortened in a positive pressure and negative pressure combined mode, and therefore the voidage of the welding flux is far lower than the voidage in a traditional process.

Owner:成都共益缘真空设备有限公司

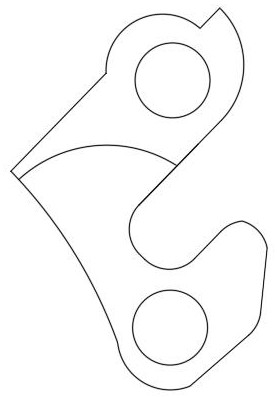

Variable-speed tail hook machining equipment with automatic sand blasting and ash removing functions

PendingCN112809564AFully contactedThe effect of uniform sandblastingBlast gunsAbrasive machine appurtenancesSand blastingReciprocating motion

The invention discloses a variable-speed tail hook machining equipment with automatic sand blasting and ash removing functions and relates to the technical field of special-shaped component machining and detection. The variable-speed tail hook machining equipment specifically comprises a workbench, a controllable variable-direction sand blasting mechanism, a reset intermittent feeding mechanism, a rotary telescopic mechanism and a tenon-and-mortise clamping mechanism. A control end is arranged on one side of the workbench. According to the variable-speed tail hook machining equipment with the automatic sand blasting and dust removing functions, a rotary telescopic mechanism is arranged, a power source is connected with a grooving rack through a transmission crank to form a transmission structure, and a sliding base on one side of the output end of the grooving rack is driven to be located in a rail to do transverse reciprocating motion; and ,meanwhile, a rotating shaft with a gear at the middle end is connected with a rack through shaft sleeves penetrating through two sides of the top end of a sliding seat, and the rack is driven by a sliding sleeve at the surface end of a guide rod to drive the tenon-and-mortise clamping mechanism at the output end of the rotating shaft to rotate, so that full contact between a sand blasting material and each end face of a tail hook component is realized in the rotary telescopic movement process of the mechanism, and the effect of uniform sand blasting is achieved.

Owner:DONGGUAN KAILEDI NUMERICAL CONTROL SCI & TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com