Dustless self discharging type dough mixing equipment for bread making

A self-unloading and bread technology, which is applied in the directions of mixing/kneading, application, dough mixer, etc. with vertical installation tools, can solve the problems of increasing economic expenditure, consuming a lot of manpower, reducing work efficiency, etc., to avoid air pollution, protect The effect of production safety and equipment capital saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

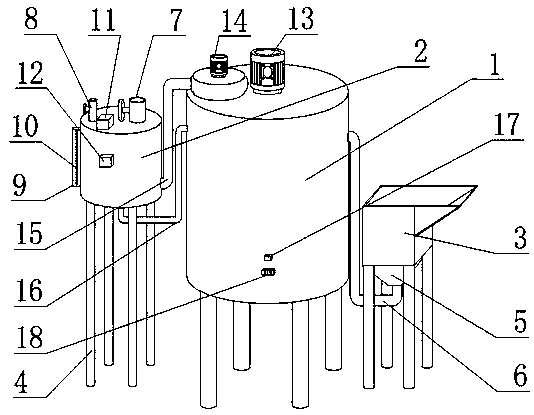

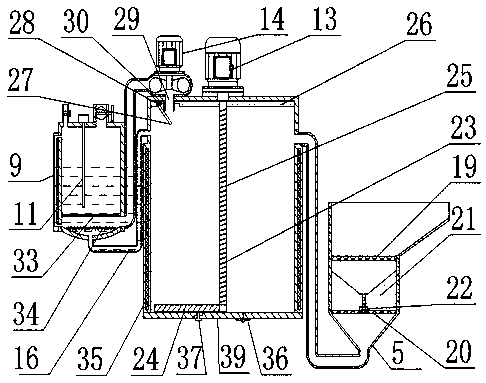

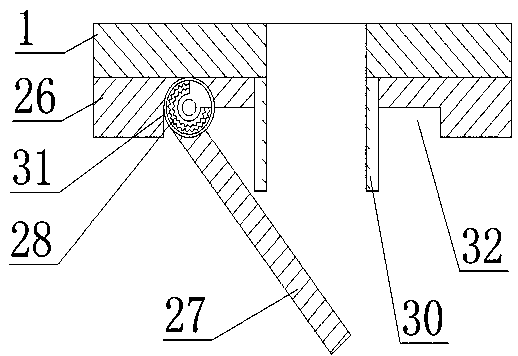

[0035] As a preferred embodiment of the present invention, the centrifugal fan 14 includes a motor and two blades, the two blades are mounted on the output shaft of the motor through bolts, and the top of the main shaft 23 passes through the kneading box 1 The top is also welded on the output shaft of the two-way motor 13, and the inboards of the tuyere 7 and the water pipe 8 are equipped with valves.

[0036] Working principle: The device provides the required electric energy for all the electrical equipment of the device through an external power supply. When the device is in use, connect the water pipe 8 to the water supply pipe, open the valve on the water pipe 8, and know how to add the water tank through the connector 9 3, when the water volume is equal to the required water volume, close the valve on the water pipe 8, open the switch 17, the centrifugal fan 14 will pump the air into the water inlet tank 3 through the air pipe 15, and then make the kneading box 1 pass thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com