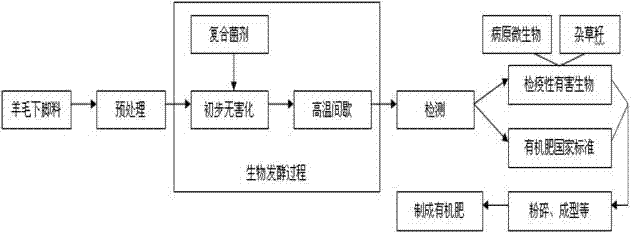

Method for killing quarantine pests in wool processing leftovers through biological fermentation

A technology of biological fermentation and harmful organisms, applied in the treatment of biological organic parts, the preparation of organic fertilizers, organic fertilizers, etc., can solve the problems of inappropriate direct composting and fermentation, small particle size of wool waste, and inability to guarantee the fermentation temperature, etc., to achieve The effect of promoting development and resource reuse, reducing cost input, and protecting agricultural production safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Taking the treatment process of wool processing waste from a wool washing enterprise as an example, the paper focuses on the description of the microbial fermentation treatment process, and tests the effect of harmless treatment on quarantine harmful organisms in the waste, as well as the relevant indicators in accordance with the national standards for organic fertilizers. After processing, waste materials are verified:

[0026] 1) Preparation of compound bacterial agent: 1.5mL of corn extract, 1mL of honey, 1.5g of starch, 1g of beef extract, 1.5g of sodium chloride, 5g of peptone and 16g of nutrient agar plus 1000mL of distilled water were used to make a compound bacterial medium;

[0027] Inoculate 9 kinds of bacteria including 3g of fungi, 3g of actinomycetes, 3g of yeast, 3g of Bacillus subtilis, 4g of Bacillus licheniformis, 1g of nitrogen-fixing bacteria, 1g of phosphorus-solubilizing bacteria, 1g of potassium-solubilizing bacteria, and 1g of photosynthetic bacte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com