A kind of needle coke and preparation method thereof

A needle coke and thermal melting technology, which is used in coke ovens, coking carbonaceous materials, petroleum industry, etc., can solve the problems of high cost, complex needle coke process, and low yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

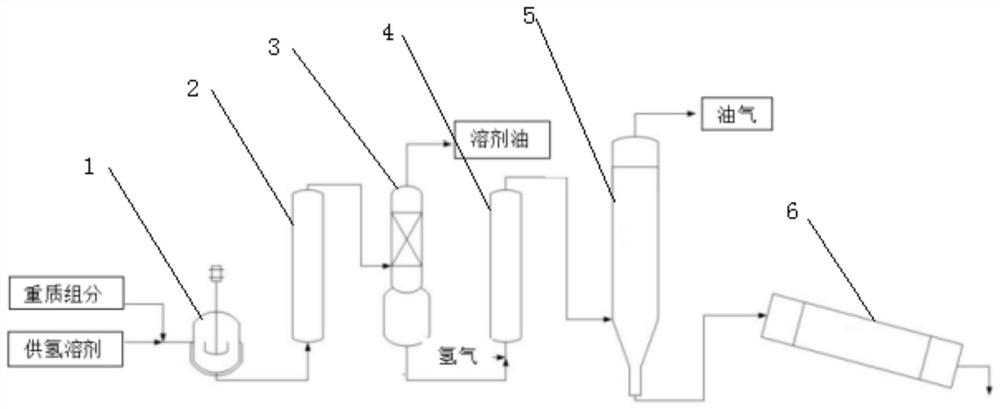

Image

Examples

preparation example Construction

[0032] The heavy product of lignite thermal catalysis process is the by-product produced in the process of lignite preparation of liquid fuel by thermal catalysis: provided by Zhaoqing Shunxin Coal Chemical Technology Co., Ltd.; the specific preparation method includes the following steps, 30~ 50wt% lignite powder, 50-70wt% 1-methylnaphthalene and 0.01-5wt% halide catalyst are fully stirred and mixed to form a coal slurry, and the coal slurry is thermally dissolved and catalyzed to generate a thermally soluble product. The hydrogen temperature is 400-500°C, the pressure is 6-13MPa, the hydrogen-oil volume ratio is 400-600, and the space velocity is 0.2-1.2h -1 , the reaction time is 30 to 60 minutes, and the thermally liquefied product is separated into light hot melt and lignite thermally dissolved catalytic heavy component, wherein the separation method includes normal pressure separation or reduced pressure separation, and the light hot melt is For the front fraction lower ...

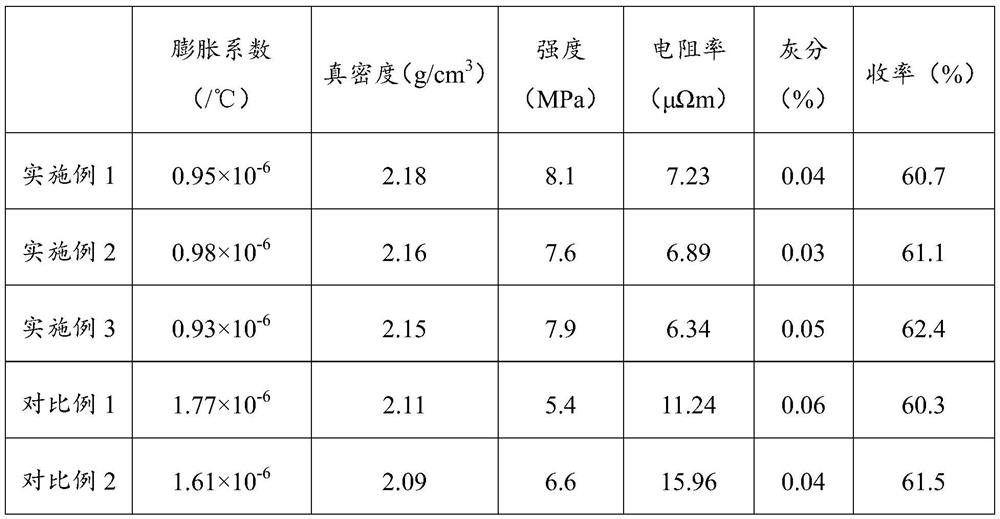

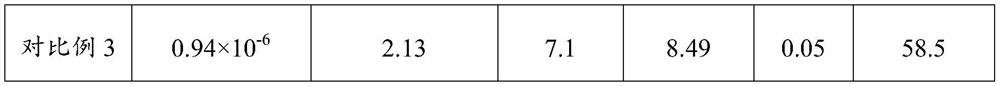

Embodiment 1

[0038] 30wt% lignite powder, 65wt% 1-methylnaphthalene and 0.05wt% zinc iodide catalyst are fully stirred and mixed to form a coal slurry, and the coal slurry is thermally dissolved and catalyzed to generate a thermally soluble product. The hydrogenation temperature is 420°C and the pressure is 6MPa , the volume ratio of hydrogen to oil is 500, and the space velocity is 1h -1 , separating the obtained thermal solution product through vacuum distillation to obtain lignite thermally soluble catalytic heavy components with a boiling point between 450 and 500°C;

[0039] Take 1 ton of the heavy product of the lignite hot-melt catalytic process with a boiling point between 450 and 500°C and add 1 ton of tetralin as a hydrogen-donating solvent to dissolve it. is 5MPa, and the reaction time is 1 hour to obtain a hydrogenated asphalt mixture. Then the hydrogenated bitumen mixture is transported into the flash tower, the flash temperature is controlled to be 320°C, the top pressure of...

Embodiment 2

[0041] Fully stir and mix 45wt% lignite powder, 58.3wt% 1-methylnaphthalene and 1wt% zinc iodide catalyst to form a coal slurry. The coal slurry is hot-dissolved and catalyzed to generate a hot solution product. The hydrogenation temperature is 500°C and the pressure is 10MPa , The volume ratio of hydrogen to oil is 450, and the space velocity is 0.5h -1 , separating the obtained thermally liquefied product through vacuum distillation to obtain lignite thermally soluble catalytic heavy components with a boiling point between 480 and 510°C;

[0042] Take 2 tons of heavy products of the lignite hot-melt catalytic process with a boiling point between 480 and 510°C and 16 tons of hydrogen-donating solvent hot-melt catalytic light oil for dissolution, and transport the dissolved materials into the hydrogenation tower, and control the reaction temperature to 360°C. The reaction pressure was 9 MPa, and the reaction time was 2 hours to obtain a hydrogenated bitumen mixture. Then the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com