A kind of mesophase pitch and preparation method thereof

A technology of mesophase pitch and reaction time is applied in the preparation of liquid hydrocarbon mixture, the processing of tar pitch/petroleum pitch/natural pitch, and the melting processing of tar pitch/petroleum pitch/natural pitch, etc. The problems of poor stability and high cost can achieve the effect of simplifying the preparation method, reducing the content and promoting the transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

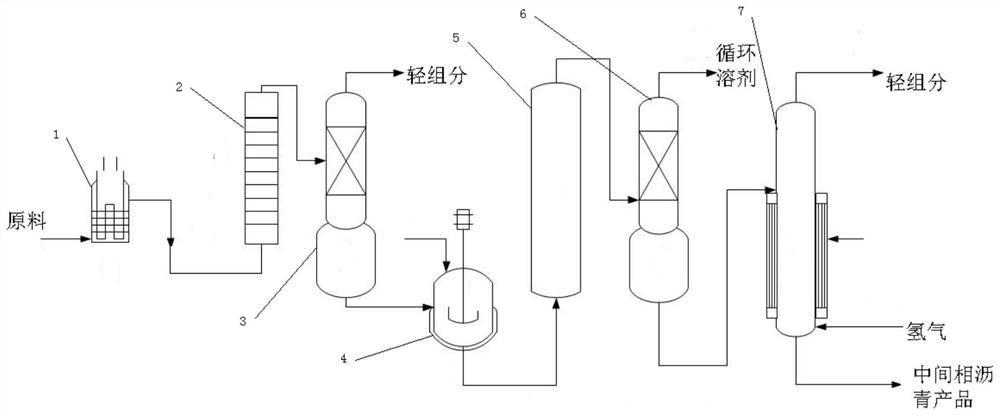

Method used

Image

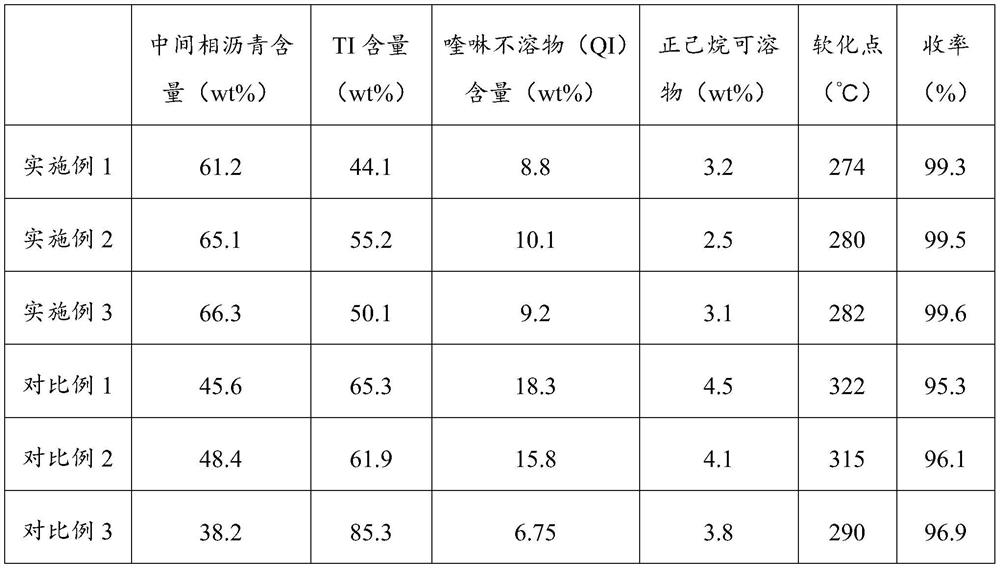

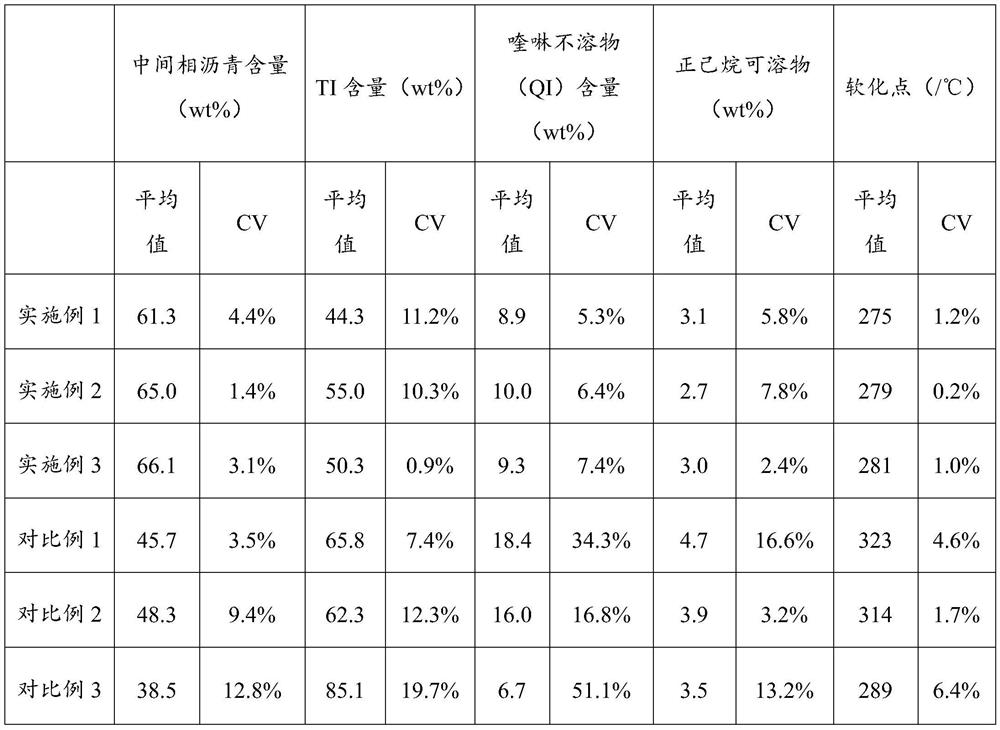

Examples

preparation example Construction

[0031] The heavy product of the lignite thermolysis catalytic process is the by-product produced in the process of lignite preparation of liquid fuel by thermolysis catalytic method: provided by Zhaoqing Shunxin Coal Chemical Technology Co., Ltd. The specific preparation method includes the following steps: 30~50wt % lignite powder, 50-70wt% 1-methylnaphthalene and 0.01-5wt% halide catalyst are fully stirred and mixed to form a coal slurry, and the hot-melt catalytic reaction of the coal slurry generates a hot-solubilized product, wherein the hydrogenation of the hot-melt catalytic reaction process is controlled The temperature is 400-500°C, the pressure is 6-13MPa, the hydrogen-oil volume ratio is 400-600, and the space velocity is 0.2-1.2h -1 , the reaction time is 30 to 60 minutes, and the thermally liquefied product is separated into light hot melt and lignite thermally dissolved catalytic heavy component, wherein the separation method includes normal pressure separation or...

Embodiment 1

[0037] Fully stir and mix 45wt% lignite powder, 58.3wt% 1-methylnaphthalene and 1wt% zinc iodide catalyst to form a coal slurry. The coal slurry is hot-dissolved and catalyzed to generate a hot solution product. The hydrogenation temperature is 500°C and the pressure is 10MPa , The volume ratio of hydrogen to oil is 450, and the space velocity is 0.5h -1 , separating the obtained thermal solution product through vacuum distillation to obtain lignite thermally dissolved catalytic heavy components with a boiling point between 350°C and 370°C;

[0038] Take 0.5 tons of the heavy product of the lignite hot-melt catalytic process with a boiling point between 350 and 370°C and preheat it to 120°C, and then use a high-temperature metering pump to input it into an electromagnetically heated circulating thermal polycondensation reactor. Thermal polycondensation reaction is carried out at 1MPa, react for 30min, and then enter the internal and external heating distillation tower, control...

Embodiment 2

[0041] 50wt% lignite powder, 55wt% 1-methylnaphthalene and 5wt% zinc iodide catalyst are fully stirred and mixed to form a coal slurry, and the coal slurry is thermally dissolved and catalyzed to generate a thermally soluble product. The hydrogenation temperature is 450°C and the pressure is 13MPa. The volume ratio of hydrogen to oil is 600, and the space velocity is 0.2h -1 , separating the obtained thermally liquefied product through vacuum distillation to obtain lignite thermally soluble catalytic heavy components with a boiling point between 350 and 410°C;

[0042] Take 0.5 tons of the heavy product of the lignite hot-melt catalytic process with a boiling point between 350 and 410°C and preheat it to 140°C, and then use a high-temperature metering pump to input it into an electromagnetically heated circulating thermal polycondensation reactor. Thermal polycondensation reaction is carried out at 2MPa, react for 20min, and then enter the internal and external heating distill...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com