Vacuum reflow soldering positive and negative pressure combined welding process

A welding process and vacuum reflow technology, applied in welding equipment, manufacturing tools, metal processing equipment, etc., can solve problems such as damaged weldments, welding defects, and long air bubble discharge time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

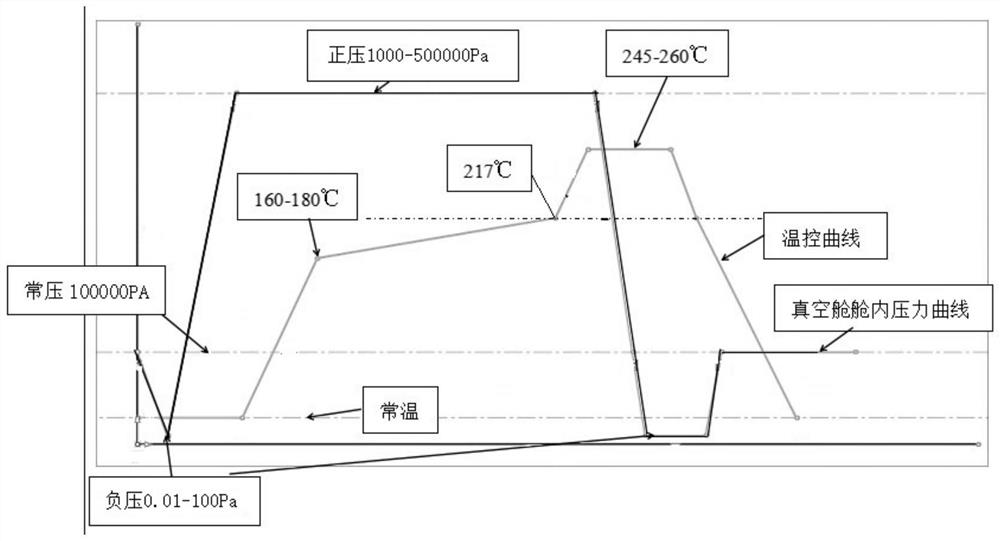

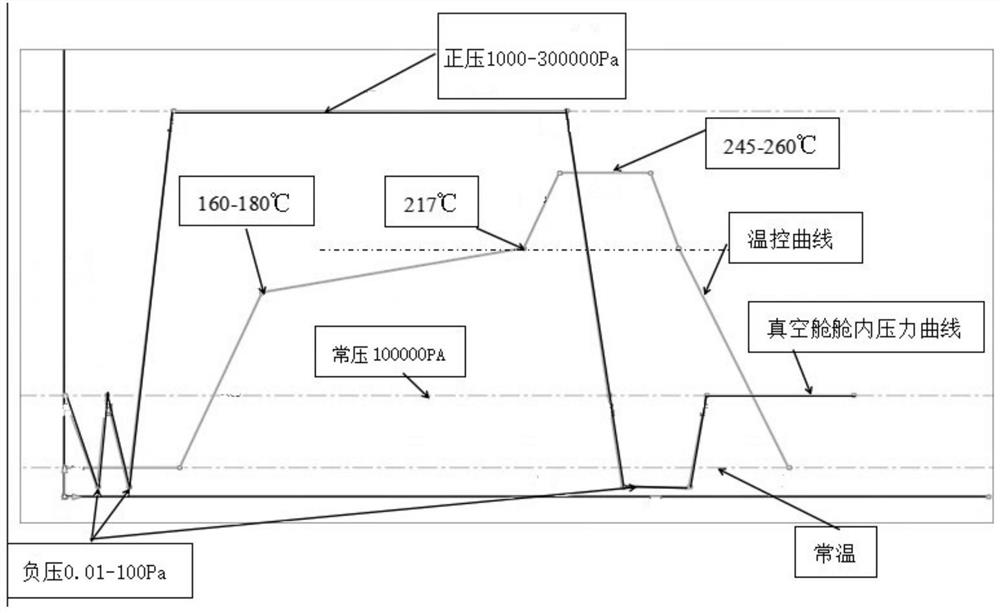

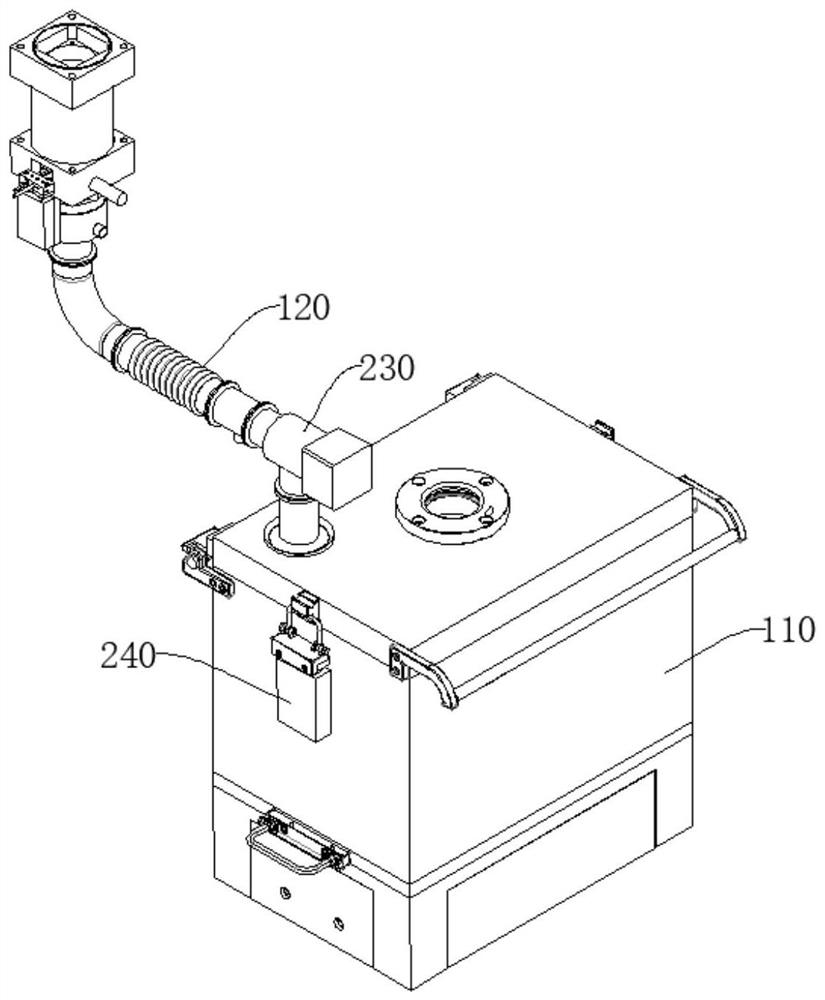

[0065] Such as Figure 1-6 As shown, this embodiment provides a vacuum reflow soldering combined positive and negative pressure welding process, including the following steps:

[0066] Step S1: Prepare for equipment commissioning in the vacuum chamber 110;

[0067] Step S2: The PLC controller controls the vacuum damper valve 230 to open, and starts vacuuming at room temperature. The vacuuming time is 10 to 120 seconds. When the PLC controller detects through the pressure sensor that the pressure in the vacuum chamber 110 is less than or equal to When the preset pressure value of negative pressure is 0.05-100PA, close the vacuum damper valve 230;

[0068] Step S3: Open the reducing agent valve by the PLC controller, and fill the reducing agent into the vacuum chamber 110 at normal temperature to a positive pressure of 1,000-500,000 PA. When the PLC controller detects that the vacuum chamber 110 reaches 1,000-500,000 PA through the pressure sensor When the positive pressure va...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com