Method for preparing ceramic copper-clad plate by hot-pressing active brazing method

A ceramic copper clad laminate and active brazing technology, applied in welding equipment, welding media, manufacturing tools, etc., can solve the problems of low pulling force, multi-solder, high welding void rate, and achieve high pulling force and high production efficiency. , the effect of low voiding rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

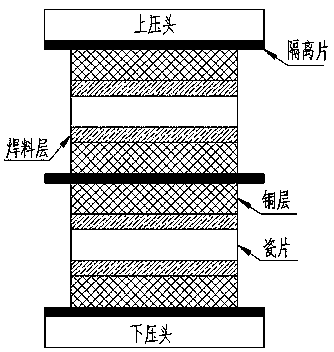

[0023] Embodiment 1, see Figure 1-3 , the present invention provides a technical solution: a method for preparing a ceramic copper-clad laminate by hot-pressing active brazing, comprising the following steps;

[0024] Step 1: Clean the tiles with pure water at 70°C for 8 minutes and then dry them in an oven at 100°C;

[0025] The tiles include: aluminum nitride, silicon nitride, aluminum oxide, ZTA and other ceramic tiles commonly used in copper clad laminates;

[0026] Step 2. Evenly coat both sides of the dried tiles with silver-copper solder containing active metal components, and dry them in an oven at 85°C;

[0027] The active metal components of the silver-copper solder include: one or more combinations of nickel, titanium, chromium, vanadium, zirconium and hafnium;

[0028] In the active solder, silver accounts for 50%, copper accounts for 48%, and active metal accounts for 2%;

[0029] Step 3. Set the copper sheet on both sides of the ceramic sheet coated with sold...

Embodiment 2

[0034] Example 2, see Figure 1-3 , the present invention provides a technical solution: a method for preparing a ceramic copper-clad laminate by hot-pressing active brazing, comprising the following steps;

[0035] Step 1: Clean the tiles with pure water at 70°C for 9 minutes and then dry them in an oven at 100°C;

[0036] The tiles include: aluminum nitride, silicon nitride, aluminum oxide, ZTA and other ceramic tiles commonly used in copper clad laminates;

[0037] Step 2: Evenly coat both sides of the dried tiles with silver-copper solder containing active metal components, and dry them in an oven at 75°C;

[0038] The active metal components of the silver-copper solder include: one or more combinations of nickel, titanium, chromium, vanadium, zirconium and hafnium;

[0039] In the active solder, silver accounts for 48%, copper accounts for 49.5%, and active metal accounts for 2.5%;

[0040] Step 3. Set the copper sheet on both sides of the ceramic sheet coated with sol...

Embodiment 3

[0045] Example 3, see Figure 1-3 , the present invention provides a technical solution: a method for preparing a ceramic copper-clad laminate by hot-pressing active brazing, comprising the following steps;

[0046] Step 1: Clean the tiles with pure water at 70°C for 10 minutes and then dry them in an oven at 100°C;

[0047] The tiles include: aluminum nitride, silicon nitride, aluminum oxide, ZTA and other ceramic tiles commonly used in copper clad laminates;

[0048] Step 2. Evenly coat both sides of the dried tiles with silver-copper solder containing active metal components, and dry them in an oven at 85°C;

[0049] The active metal components of the silver-copper solder include: one or more combinations of nickel, titanium, chromium, vanadium, zirconium and hafnium;

[0050] In the active solder, silver accounts for 53%, copper accounts for 44%, and active metal accounts for 3%;

[0051] Step 3. Set the copper sheet on both sides of the ceramic sheet coated with solder...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com