Process method for vacuum reflow eutectic welding

A vacuum reflow and eutectic welding technology, applied in the manufacture of electrical components, electrical solid devices, semiconductor/solid state devices, etc., can solve the problems of uneven temperature distribution, slow heating speed, etc., to achieve versatility, increase absorption, reduce The effect of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

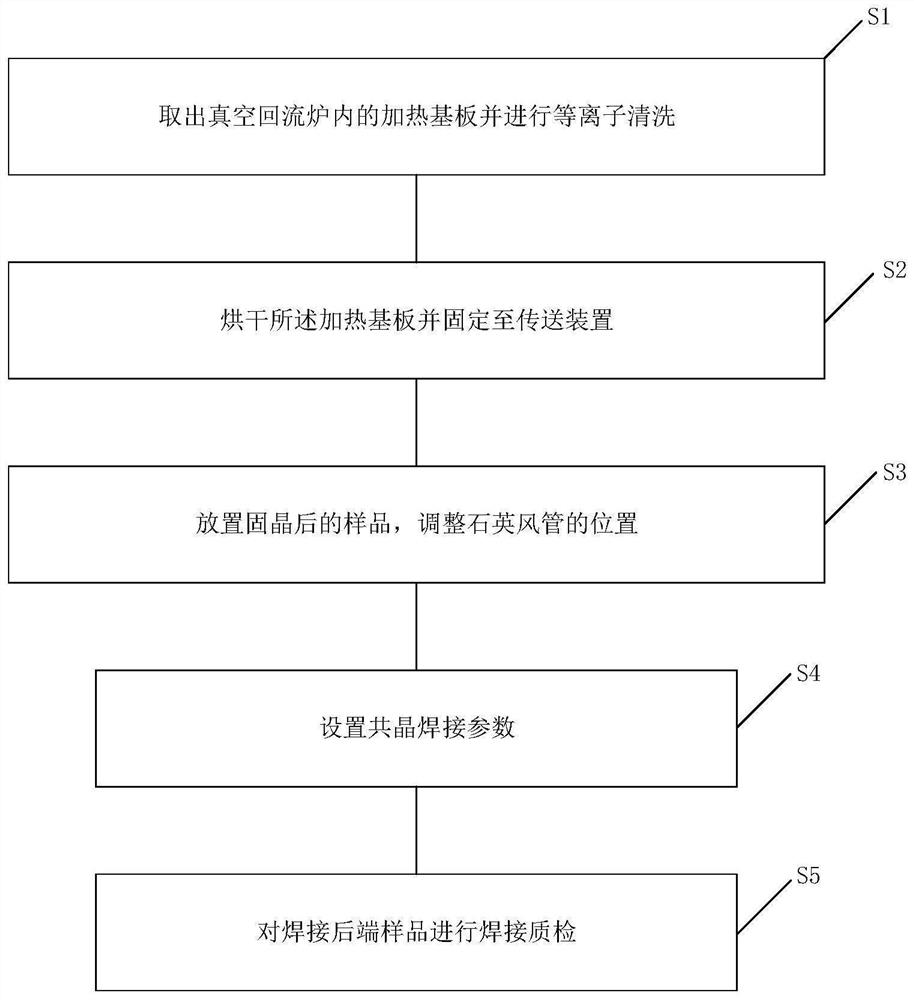

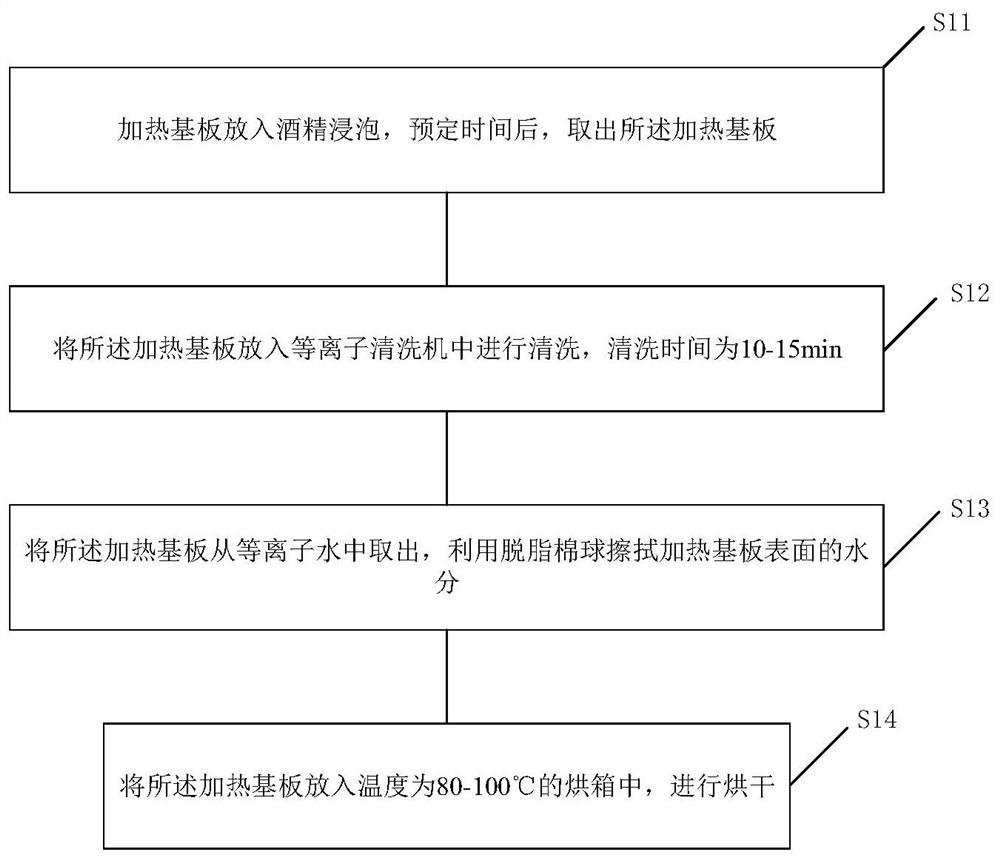

[0060] Select the LED chip as the welding sample chip, and use the above-mentioned vacuum reflow furnace and welding process to carry out four sets of welding experiments. The welding process flow chart can be found in figure 1 and figure 2 , the heating curves of the four sets of welding experiments can be found in Figure 7 . Among them, the size specification of the substrate: 4*8*0.2mm, the size specification of the solder preform: 4*3.2*0.0254mm, and the size specification of the sample chip: 4*3.2*0.10mm.

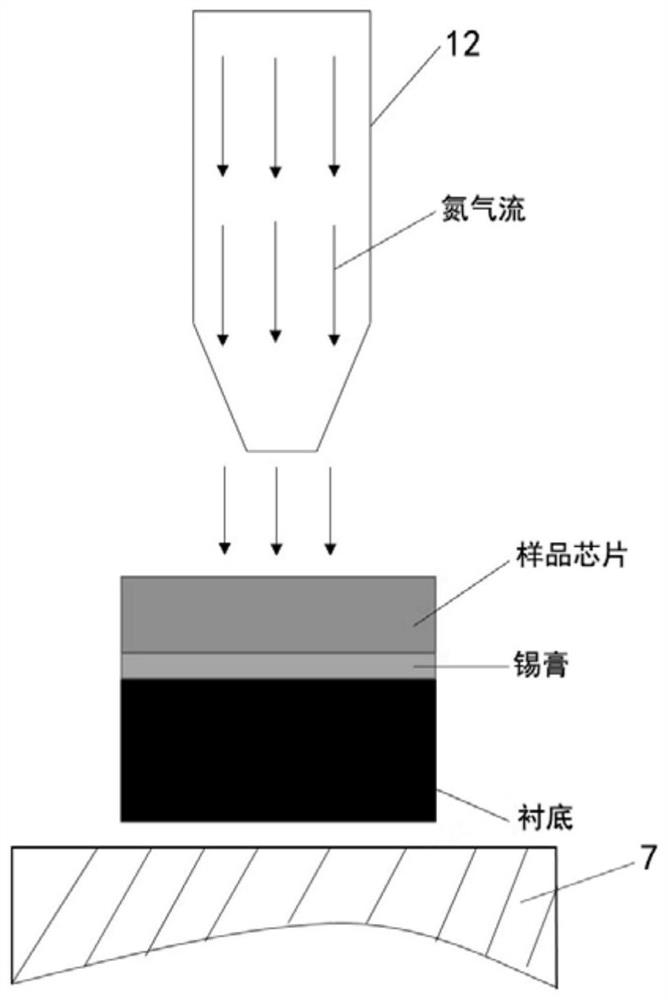

[0061] The first group: set the preheating temperature of the conveyor belt 3 and the heating substrate 7 to 285°C, provide 60% hot air + 40% radiation for basic heating, set the temperature of the hot nitrogen flow in the vacuum area to 280°C, and set the hot nitrogen flow time to 30 Seconds, once the temperature in the vacuum chamber reaches the preset temperature of 350°C, the nitrogen flow will be automatically closed. After the welding is completed, the void ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com