Patents

Literature

69results about How to "Save solder" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

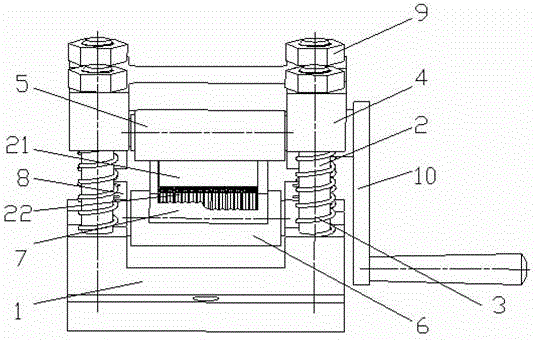

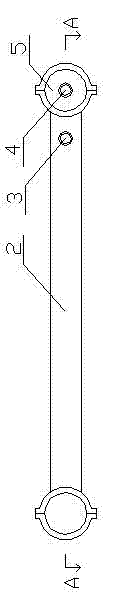

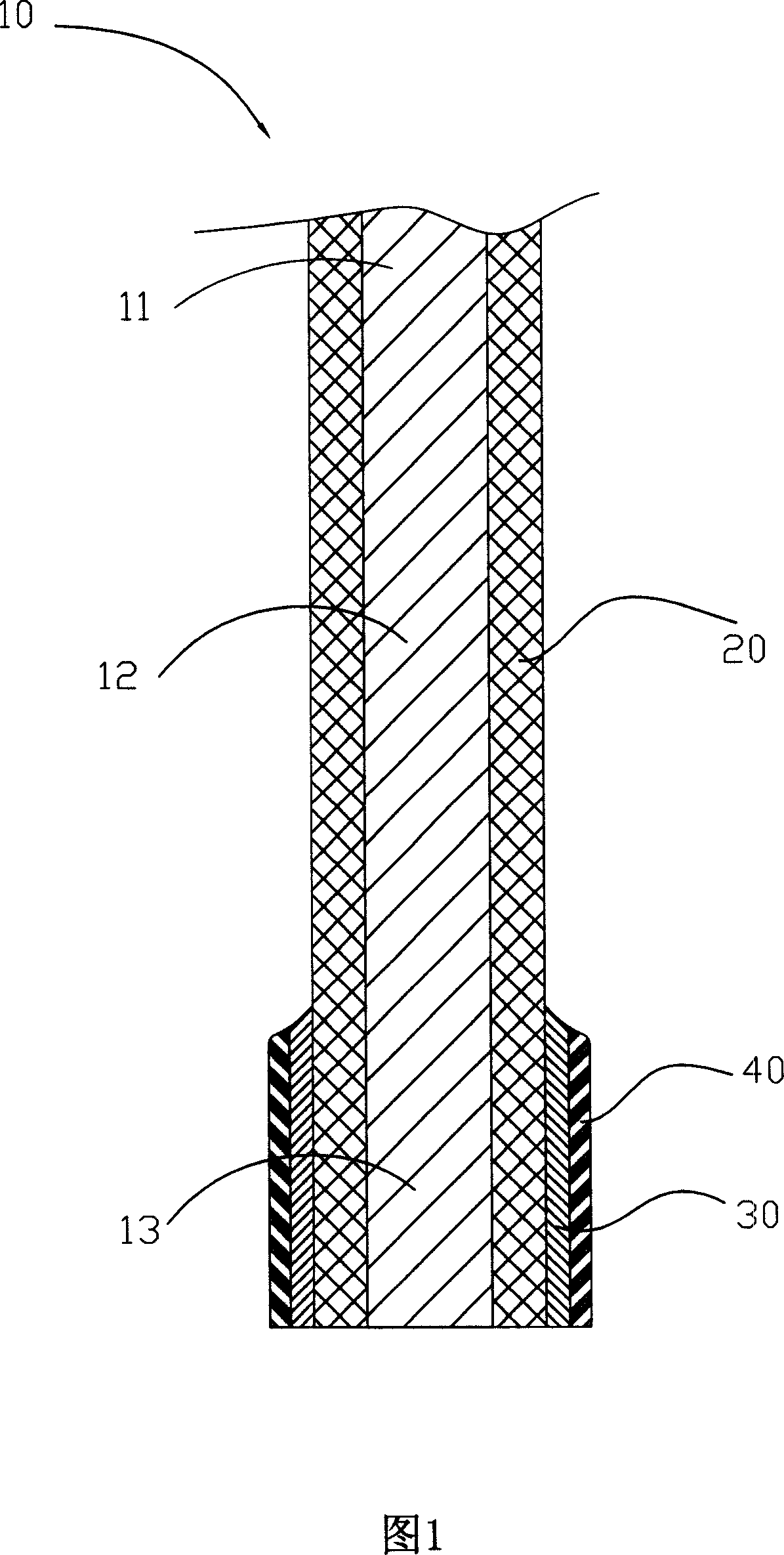

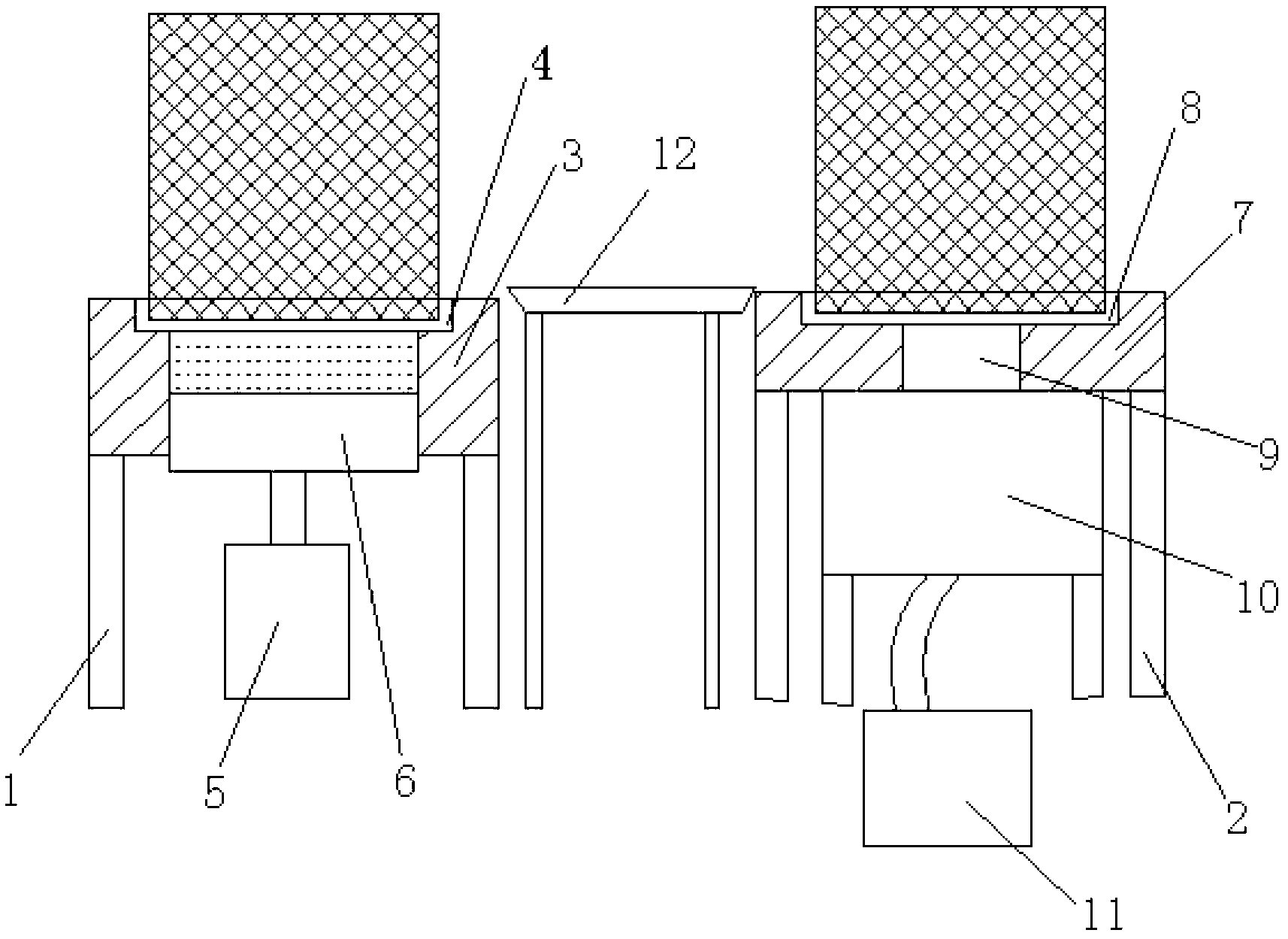

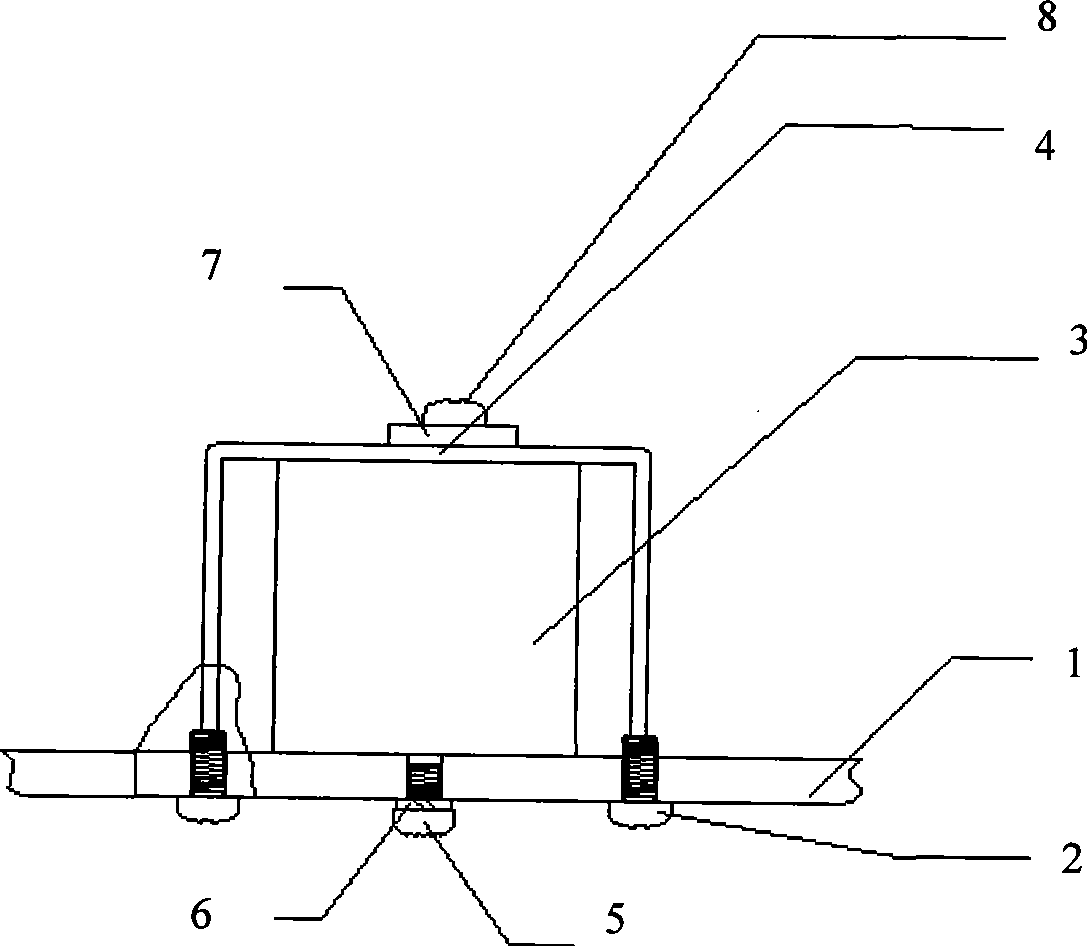

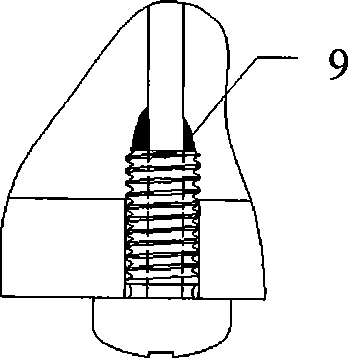

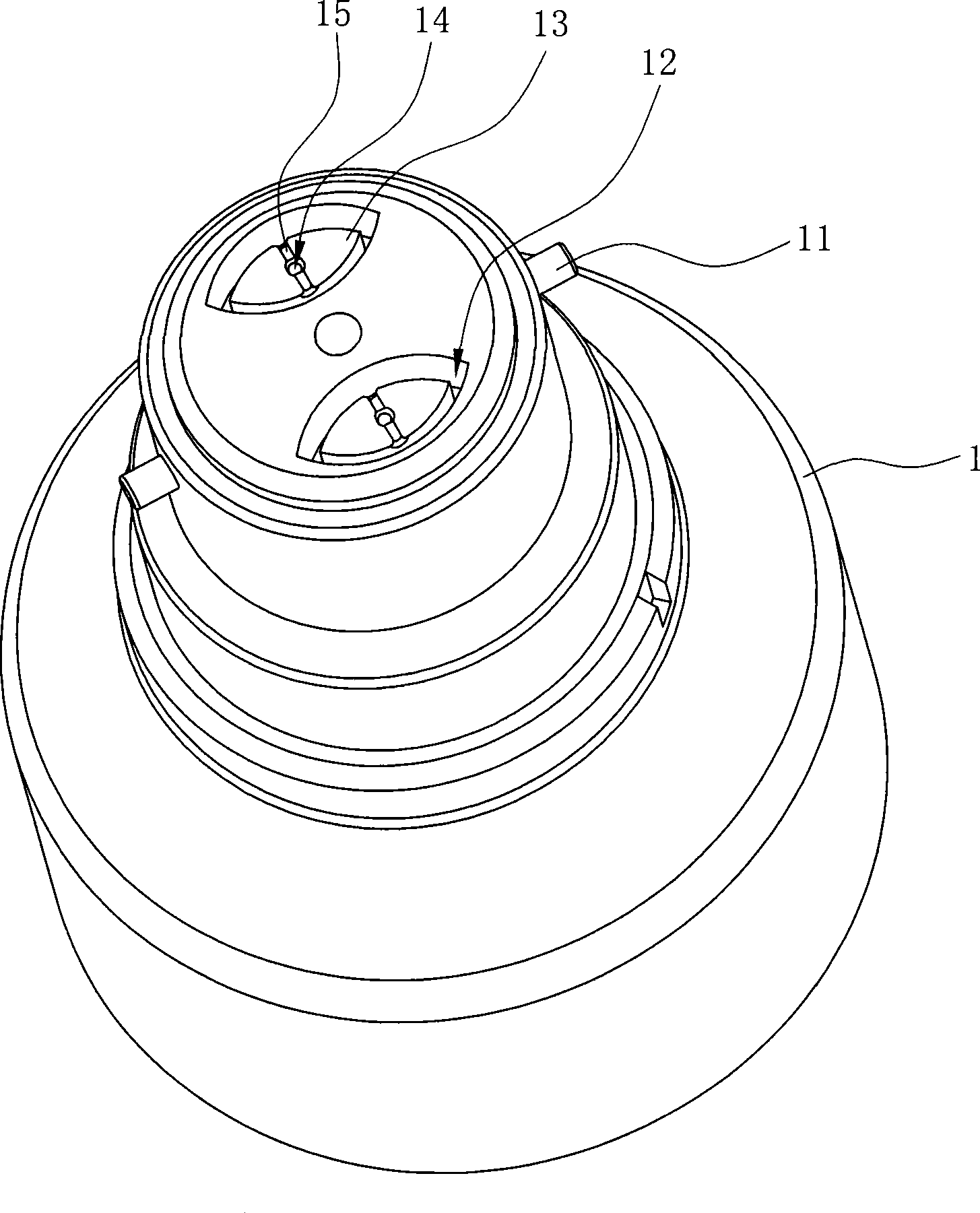

Method and special device for preplacing adhesive tape brazing filler metal for honeycombs

ActiveCN102909454AConsistent thicknessExcellent and stable brazing qualitySoldering auxillary devicesHoneycombScrew cap

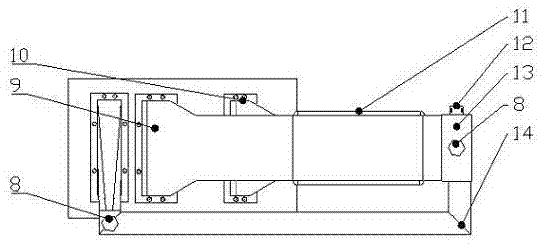

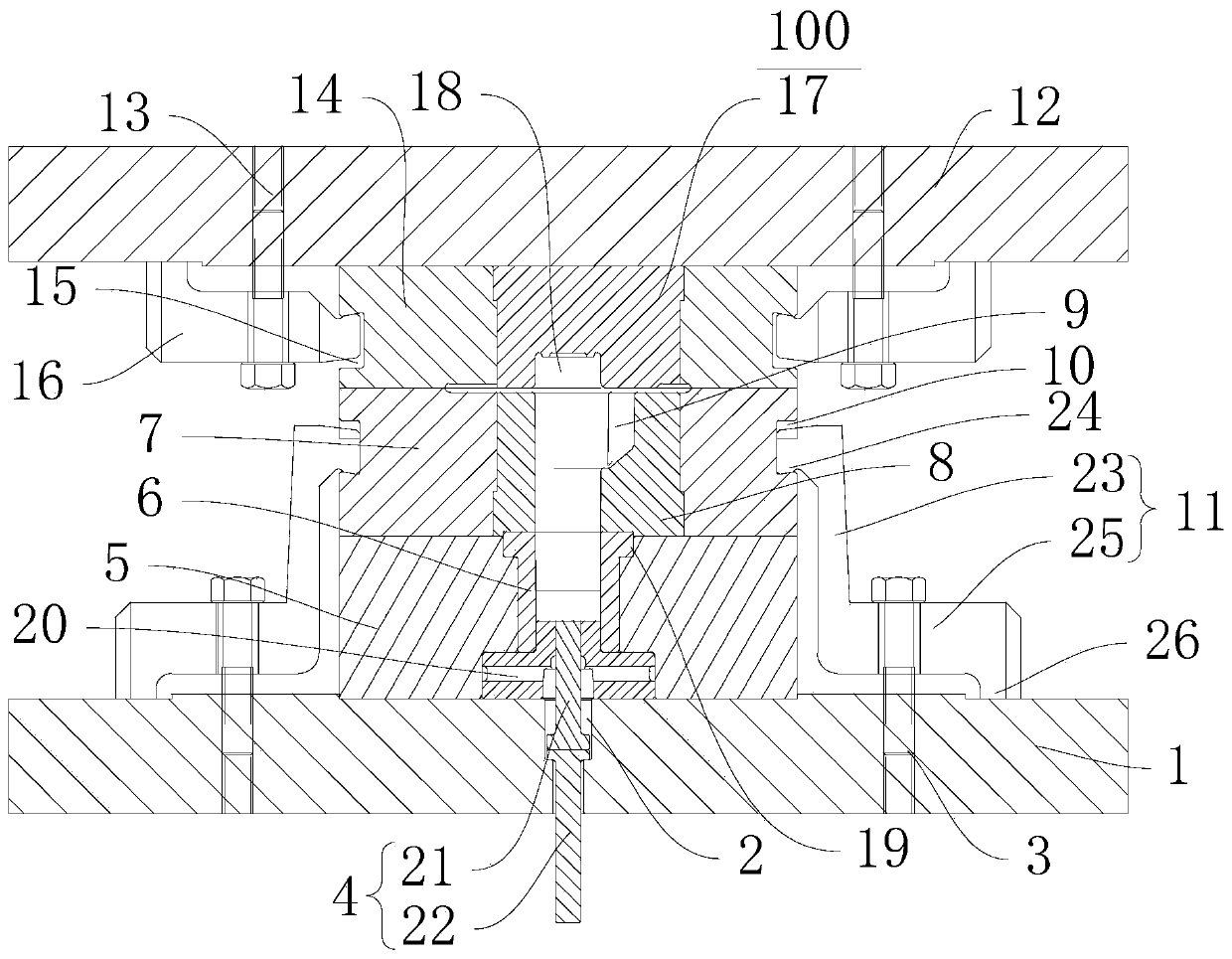

The invention relates to a method for preplacing adhesive tape brazing filler metal for honeycombs. The method comprises the step of pressing the adhesive tape brazing filler metal (21) that is placed on a honeycomb baseplane into honeycomb core grids with a special device by a rolling method. The special device consists of a base (1), guide posts (2), four springs (3), a pressing plate (4), an upper roller (5), a lower roller (6), a supporting plate (7), four locking plates (8), four compression nuts (9) and a rocker arm (10). The method further relates to a special device for preplacing the adhesive tape brazing filler metal for the honeycombs. The method and the special device are applicable to the sector honeycombs 22 and the circular honeycombs 30 in different core grid dimensions. The adhesive tape brazing filler metal 21 can be pressed into the honeycomb core grids without crushing the honeycombs, and the preplaced brazing filler metal is consistent in thickness and clean and is firmly bonded with the core grids, so that each core grid is provided with the adequate brazing filler metal, and good and stable brazing quality is achieved; and in addition, the brazing filler metal can be saved, the cost can be lowered, and the working efficiency can be improved by more than 2 times.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

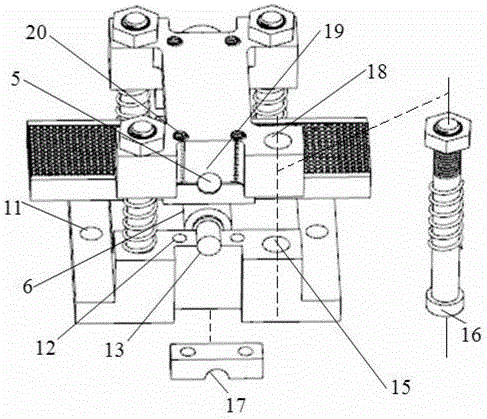

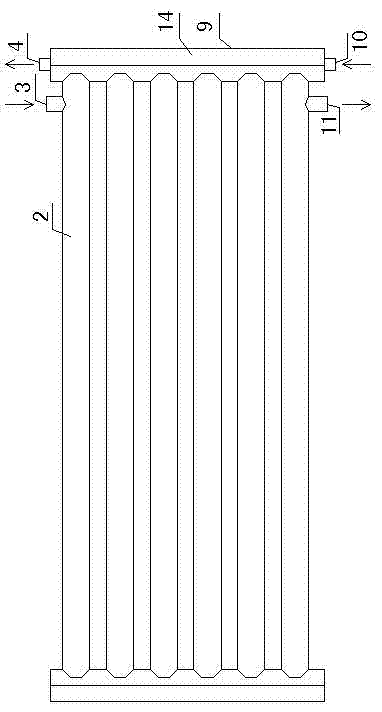

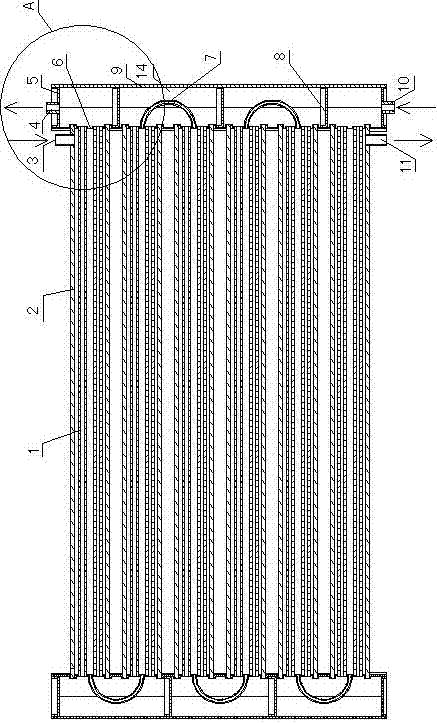

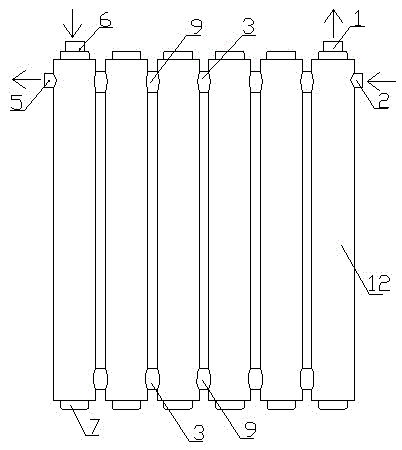

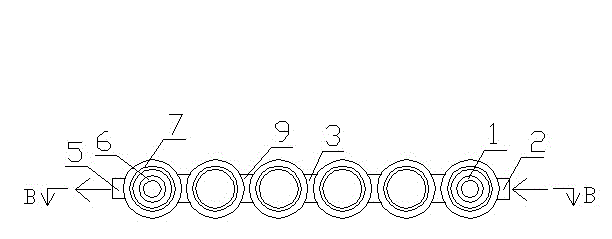

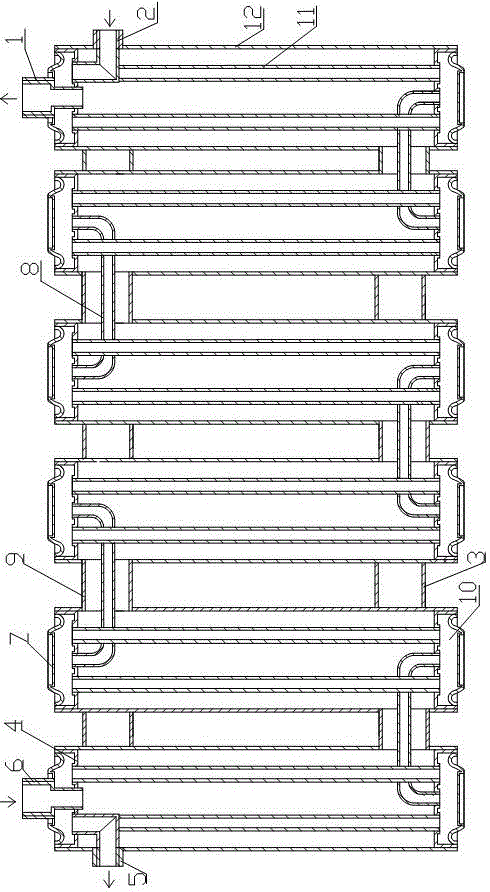

Header cold water pipe open communication heat absorption heat exchanger and manufacturing process thereof

ActiveCN102927604AReduce cloggingReduce heat lossLighting and heating apparatusSpace heating and ventilation detailsWater channelMetallic materials

The invention discloses a header cold water pipe open communication heat absorption heat exchanger and a manufacturing process of the header cold water pipe open communication heat absorption heat exchanger. The header cold water pipe open communication heat absorption heat exchanger at least comprises two heat supply pipes, wherein two ends of the heat supply heats are respectively welded with a header, at least one cold water channel is arranged inside a heat supply pipe cavity, ports at two ends of the cold water pipe channel are communicated in open cavity mode, and deposited scales in a cold water pipe can be conveniently cleaned by poured acid liquor. The cold water pipe stores water and absorbs heat, effective heat sources can be fully utilized, the heat is quickly absorbed through multiple dividing walls, the heat is transmitted in step mode, a heat absorption area is enlarged, and due to the fact that water is stored in the headers, the length of flow path of cold liquor is increased, the time of heat exchange is prolonged, heat loss is reduced, and heat exchange efficiency is improved. Longitudinal or transverse flexible installation is achieved by reasonable utilization of space, requirements of users can be met, materials are saved, and production cost is reduced. Product quality is stable and reliable, and service life is prolonged. The same kind of metal material is adopted, the weight is light, transportation is convenient, and logistics transportation cost is saved.

Owner:ZAOZHUANG LINENG WATER HEATER FACTORY

Cast-welding method for lead-acid storage battery tabs

InactiveCN105290378ARealize quantitative feedingSave solderEnvironmental resistanceElectrical battery

The invention discloses a cast-welding method for lead-acid storage battery tabs. The cast-welding method comprises the following steps that a storage battery pole plate is placed on a cast-welding mold which is at least provided with a mold cavity; a certain amount V of molten lead liquid is injected to the side face or the bottom of the mold cavity through a communicating tube, and the lead liquid amount V is the lead liquid amount needed for tab welding in the cast-welding mold; a lead rod and an induction heating device are arranged at an inlet of the communicating tube; the induction heating device quickly heats a section of lead rod to form lead liquid, and the lead liquid drops into the communicating tube and injected into the mold cavity; and then tab cast-welding operation is conducted. According to the cast-welding method for the lead-acid storage battery tabs, cast-welding lead liquid is supplied quantitatively through pipeline lead supplying, and the requirement for the lead liquid amount for cast-welding of a set of battery tabs in the mold is met; lead rod induction heating is used for lead liquid conveying, and quantitative material supply is achieved, so that the method has the advantages of power saving, environmental protection, welding material saving and the like.

Owner:厦门华海大正电池装备有限公司

Technique of double wire hidden arc welding

ActiveCN101092003AImprove welding efficiencyImprove welding qualityArc welding apparatusWelding/cutting media/materialsEngineeringVoltage

The invention relates to a double thread submerged arc welding technology that includes the following steps: selecting primary welding parameter: adopting double thread submerged arc welding method; selecting welding method according to leg height k; selecting welding thread diameter phi according to k, selecting 2mm B23K 9 / 18 B23K 9 / 095 B23K 35 / 04 0 3 2 2006 / 6 / 20 101092003 2007 / 12 / 26 000000000 Xidian Transformers Co., Ltd., Xi'an Xi-an 710077 Zhai Weidong You Yu xubeng 61211

Owner:XIAN XIDIAN TRANSFORMER

Heat radiation structure of LED lamp backlight device

InactiveCN101413655AGuaranteed image qualityExtended service lifePoint-like light sourceSemiconductor/solid-state device detailsLiquid-crystal displayImaging quality

The invention aims at providing a heat dissipation structure of an LED lamp backlight device, and an LED lamp which has the heat dissipation structure has the advantages of the prolonged service life, the improved luminous efficiency and the ensured imaging quality of a liquid-crystal display panel. In the heat dissipation structure of the LED lamp backlight device, the LED lamp backlight device comprises a lamp strip which is provided with at least one LED lamp as well as a positive pin and a negative pin that are used for supplying power for the LED lamp; the positive pin and the negative pin of the heat dissipation structure are connected with a heat conducting part by material which can conduct heat, but is insulative.

Owner:NANJING NEW LANDMORE DISPLAY TECH

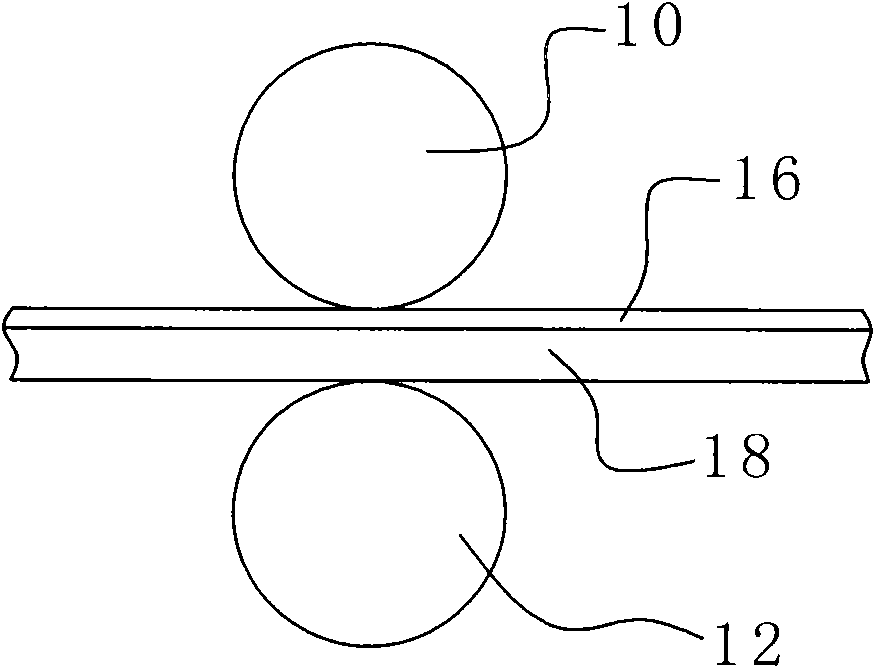

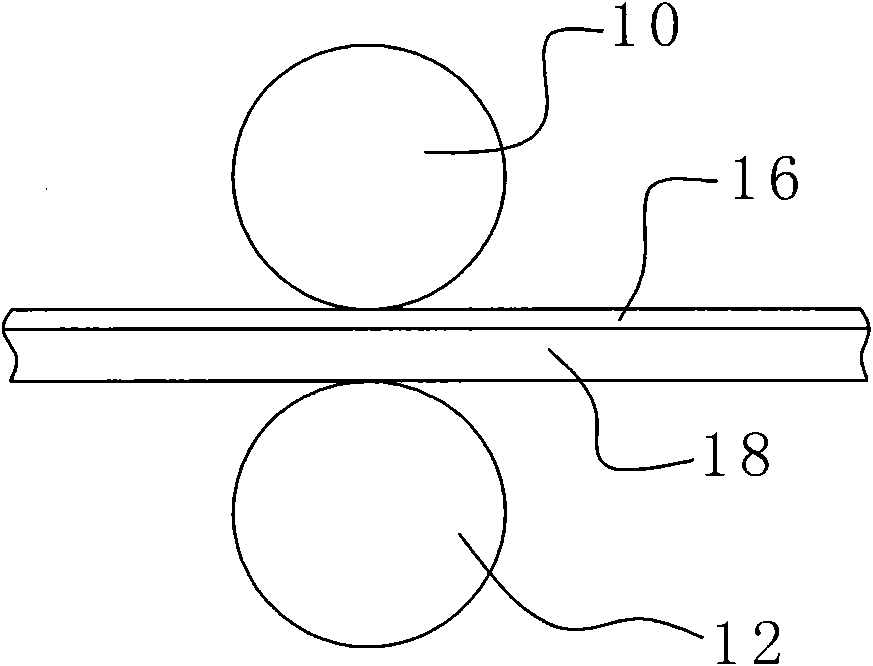

Special seam welding technique for continuous electric resistance welding of silver strips and copper strips

InactiveCN101829842AGood thermal conductivityHigh resistivityWelding with roller electrodesWelding/cutting media/materialsElectrical resistance and conductanceCopper electrode

The invention discloses a special seam welding technique for continuous electric resistance welding of silver strips and copper strips, which comprises following steps of: a, flatting whole rolls of the copper strips and aligning the copper strips to joint with the silver strips; b, towing the copper strips and sliver strips to pass through a clearance between a first electrode wheel and a second electrode wheel of the seam welding machine, wherein the first electrode wheel is a molybdenum electrode wheel or a tungsten electrode wheel, and the second electrode wheel is an alloy copper electrode wheel; c, clamping the copper strips and the sliver strips by using the first electrode wheel and the second electrode wheel to make the first electrode wheel contact with the silver strips and the second electrode wheel contact with the copper strips; d, towing the silver strips and copper strips to move continuously and introducing welding current for electric resistance welding between the first electrode wheel and the second electrode wheel. The contact surfaces of the copper strips and the silver strips can be fused at the same time by using the technique of the invention so as to form favorable molten area for welding. Then the seam welding between copper strips and sliver strips can be implemented. Welding parts of the copper strips and the silver strips are firm, stable and non-deforming, thereby the welding quality is ensured, soldering flux is ensured, and the welding effect is improved.

Owner:HERON INTELLIGENT EQUIP CO LTD

Heat exchanger with open-type, communicated and heat-absorbing cooling water pipe

ActiveCN102914187AReduce difficultySolve technical problems of fatigue lifeStationary conduit assembliesHeat exchanger casingsWater storageEngineering

The invention discloses a heat exchanger device with a open-type, communicated and heat-absorbing cooling water pipe, which can be used not only for heating and heat radiation, but also for replacing bathing hot water. The heat exchanger has a compact structure and is simple in manufacturing technique; water storage communicated flow splitting chambers are respectively arranged in sealing heads at two ends of each heating pipe; the inner chambers of the heating pipes and the water storage communicated flow-dividing chambers are isolated by welding separating walls; at least one cooling water pipe penetrates each heating pipe; mouths of two ends of each cooling water pipe are arranged on the corresponding separating walls and communicated with the water storage communicated flow-dividing chambers; the mouths of two ends of each cooling water pipe are communicated with the water storage communicated flow-dividing chambers in an open manner, so as to bring convenience for filling acid liquor to clean deposited dirt in the cooling water pipes; the cooling water pipes can be used for water storage and heat absorption, and the effective heat source can be fully utilized; dividing walls can quickly absorb heat; the heat is transferred in a stepped manner to increase the heat-absorbing area; and the cooling water, which is stored in the water storage communicated flow-dividing chambers, is used for heat absorption. According to the invention, as the water is stored in the device, the process length of the cold fluid is increased, the heat exchange time is prolonged, the heat loss is reduced, the heat exchange efficiency is improved, and the manufacturing cost is reduced.

Owner:ZAOZHUANG LINENG WATER HEATER FACTORY

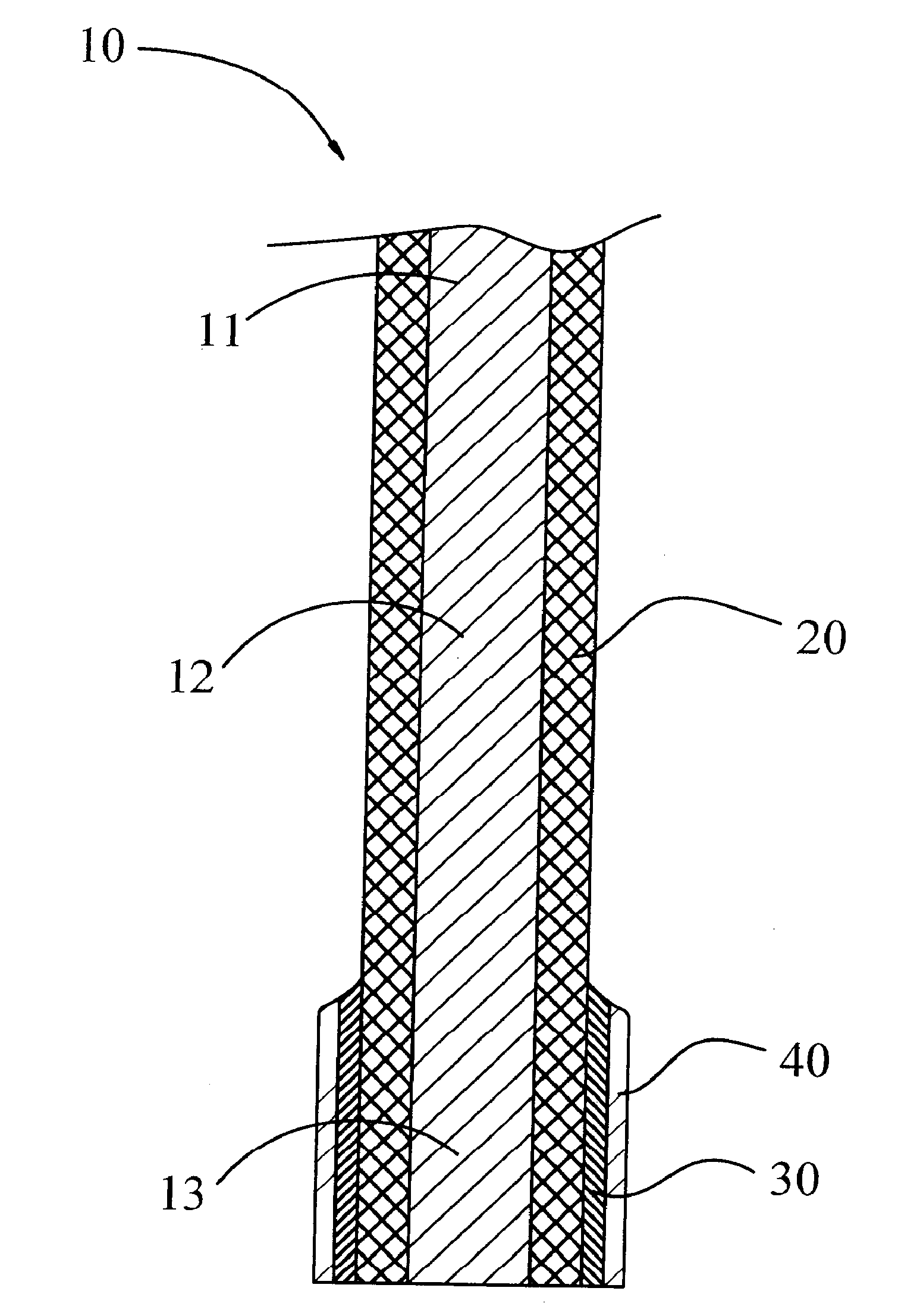

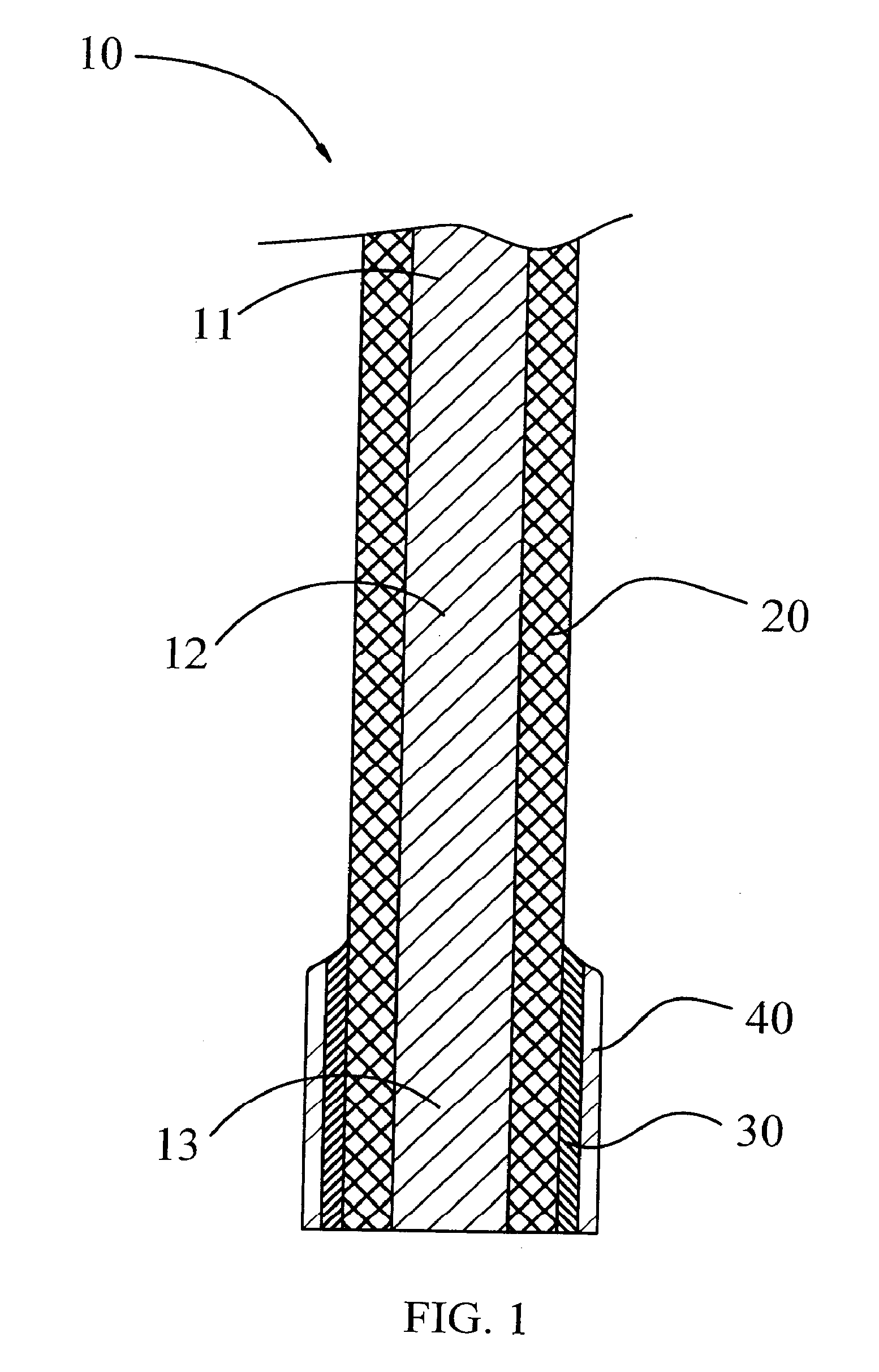

Method for siphon prevention of the terminal and the terminal made by this method

InactiveCN101009409APrevent siphonPrevent empty welding phenomenonContact member manufacturingElectrically conductive connectionsSiphonCopper oxide

The invention discloses an anti-siphonage method of ends, the ends includes guiding connection part which is welded with the outer element by solder, and connection part which is extended by the guiding connection part, the surface of the connection part is naked and made of copper, the copper is oxidized to form oxide. The ends of the invention includes connection part and guiding connection part, thereinto, the connection par extends to form the guiding connection part, the guiding connection part can be connected with outer element by solder, the connection part is made of copper which can be oxidized and naked. Because the invention comprises copper which can be oxidized and naked, the copper is oxidized to form oxide, the oxide such as copper-oxide can avoid the solder siphoned from the guiding connection part to the ends connection part during the welding, it can save the solder and avoid the phenomenon of empty welding, the quality of welding can be guaranteed and the cost is saved.

Owner:DEYI PRECISION ELECTRONIC IND CO LTD PANYU

Vacuum brazing paste solder free of brazing flux, preparing method and using method of solder

ActiveCN111299898AImprove stabilityIncrease productivityWelding/cutting media/materialsSoldering mediaWeld seamElectrochemical corrosion

The invention discloses a vacuum brazing paste solder free of brazing flux, a preparing method and a using method of the solder, relates to a paste solder free of brazing flux for vacuum brazing aluminum matrix composites, a preparing method and a using method of the solder, and aims at solving the problems that it is difficult to weld and operate members in a complex shape with a foil solder, automatic production is hindered, and the brazing flux of the existing paste solder is stacked in brazing seams and cannot be discharged out, resulting in electrochemical corrosion at welding beams and lowering of performance of welded joints. The paste solder is prepared by mixing solder alloy powder and a binding agent and is free of brazing flux. The preparing method comprises the steps of preparing the solder alloy powder and the binding agent, and mixing the solder alloy powder and the binding agent in a proportion to obtain the vacuum brazing paste solder free of brazing flux. The using method comprises the steps of adopting a brush for brushing the paste solder onto the surface of a composite, and then putting the composite in a vacuum furnace for welding. According to the vacuum brazing paste solder, the preparing method and the using method, in addition to the reduction of cost and simplification of operation, the intensity, air impermeability and safe reliability of the welded joints are also improved.

Owner:허난징타이에어로우스페이스하이테크머터리얼스테크놀로지컴퍼니리미티드 +1

Method for preventing siphoning effect in terminal and terminal manufactured using the same

InactiveUS20080179076A1Save solderSaving of production costNon-insulated conductorsElectrically conductive connectionsCopper oxideWelding

The invention relates to a method for preventing siphoning effect in a terminal. The terminal of the invention comprises a conductive portion connected to an external component by a solder and a connecting portion extended to form the conductive portion. An exposed and easily oxidized copper is attached on the surface of the connecting portion, and the copper can be further oxidized to form oxide of copper. Since the copper is attached on the connecting portion of the terminal, and the copper can be oxidized to form oxide of copper, the oxide of copper, such as copper oxide, can prevent the siphoning of the solder from the conductive portion to the connecting portion during the soldering process. Accordingly, the solder can be saved, and the phenomenon of false welding can be avoided, such that the quality of soldering can be maintained well and the production cost can be reduced.

Owner:LOTES

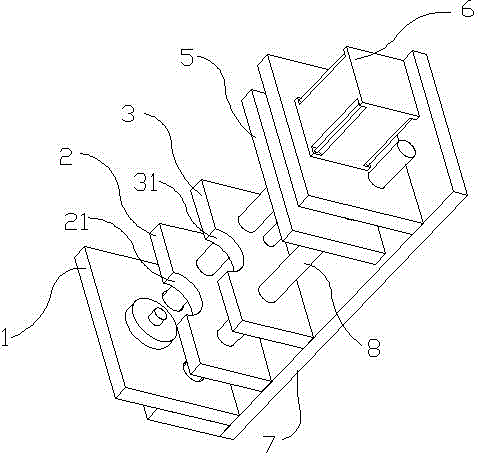

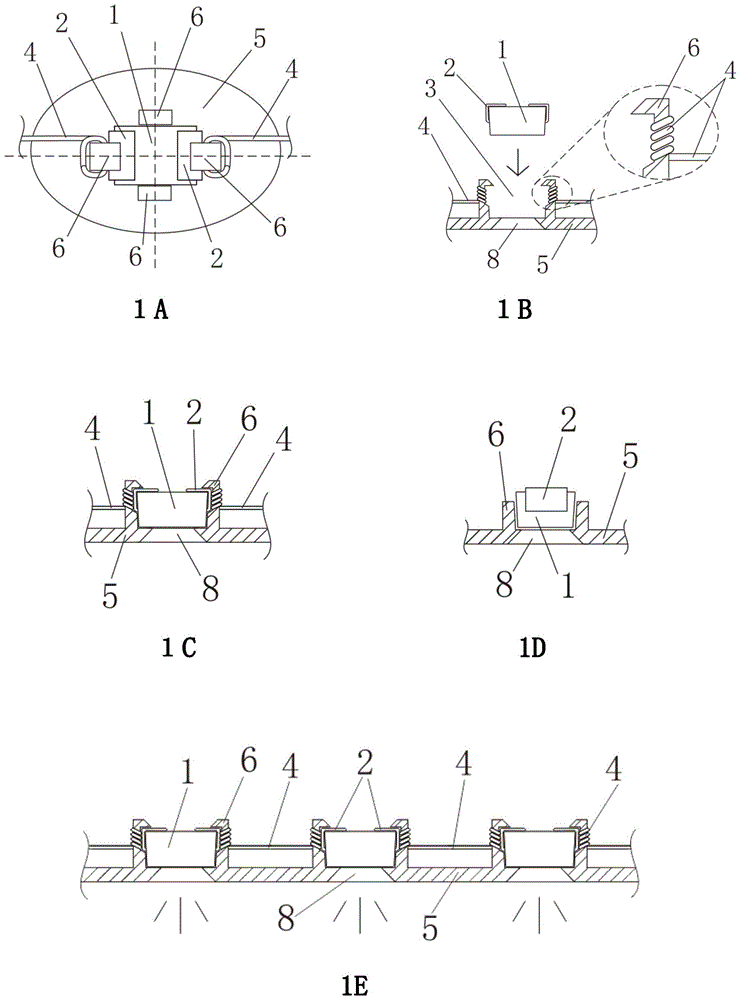

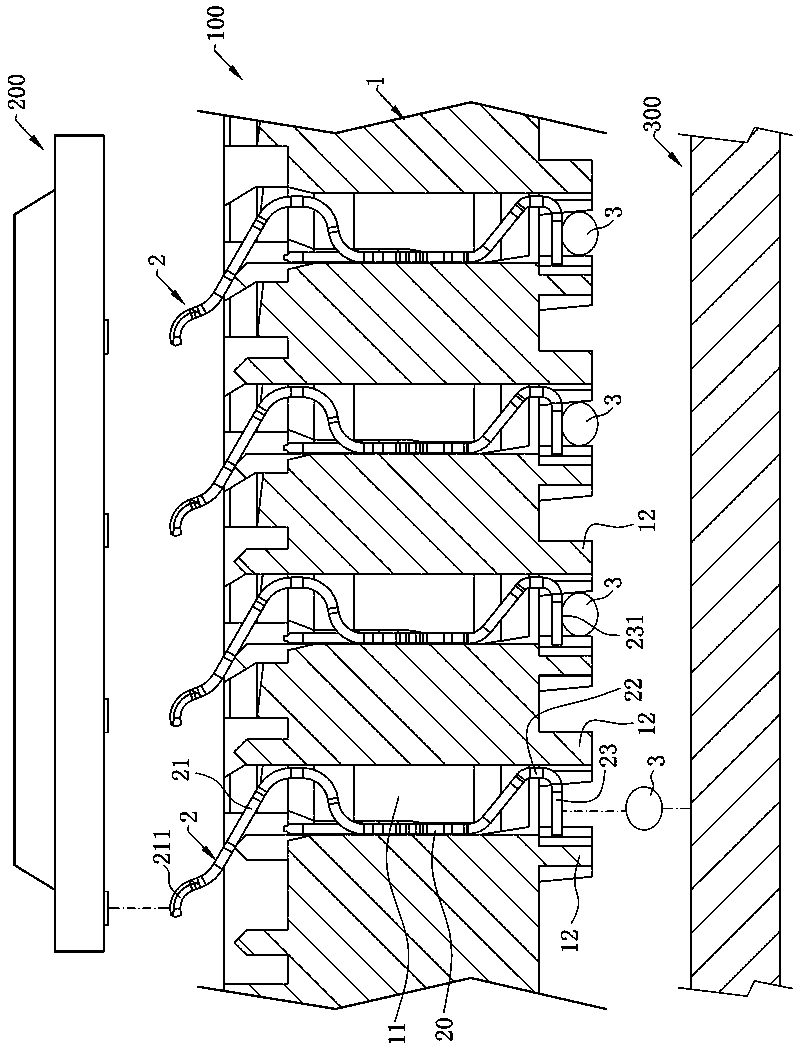

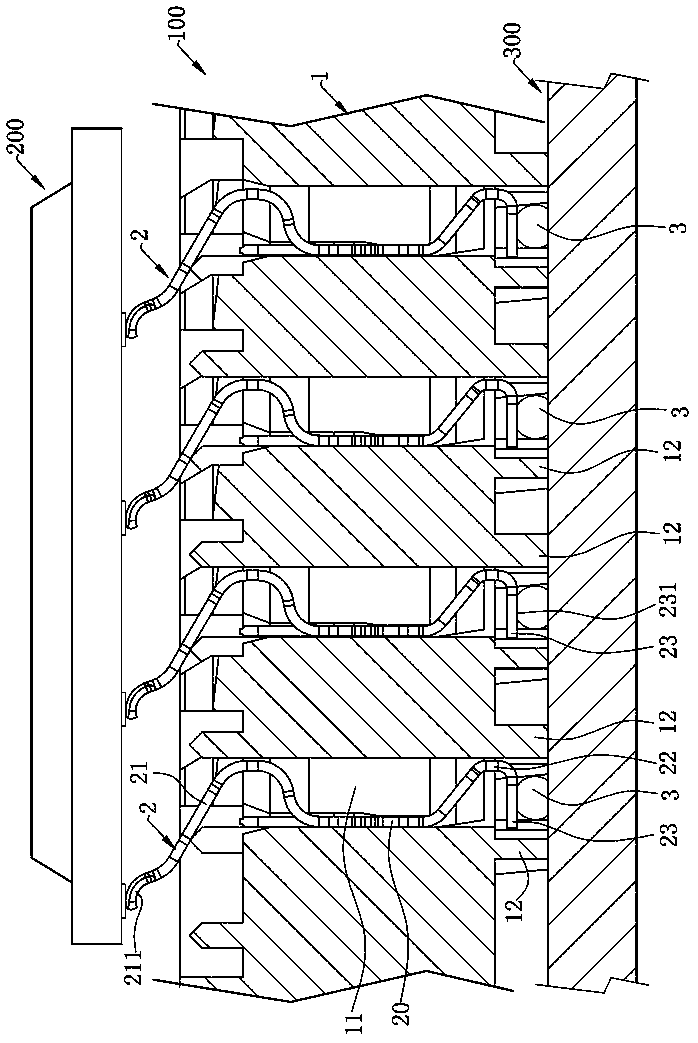

Device and method for uploading soldering paste of metal honeycomb carrier

ActiveCN103212766AAchieve reasonable utilizationReasonable structural designSoldering auxillary devicesHoneycombAtmospheric pressure

The invention discloses a device and method for uploading a soldering paste of a metal honeycomb carrier. The device comprises an air pressure propelling device used for uploading the soldering paste, and a soldering paste negative pressure recovery device. The method is a method that brazing is carried out by coating the soldering paste after rolling and forming, and the method comprises the following steps: rolling a flat wave strip into the metal honeycomb carrier; placing the formed metal honeycomb carrier on the air pressure propelling device used for uploading the soldering paste, so as to push the soldering paste into the metal honeycomb carrier; placing the metal honeycomb carrier filled with the soldering paste upside down to be delivered into the soldering paste negative pressure recovery device to recycle redundant soldering paste; and finally placing the metal honeycomb carrier containing small amount of soldering paste in clearance into a vacuum brazing room to be welded. The device for uploading the soldering paste of the metal honeycomb carrier is reasonable in structure design, and the method is simple and feasible, so that not only the soldering paste cannot generate plugged holes in a carrier pore canal, but also the condition that the soldering paste is discharged and pressed can be reduced, and soldering flux is saved, thereby rational utilization of resources can be achieved, and meanwhile, the welding strength is improved, and the quality of products is guaranteed.

Owner:浙江欧信环保科技有限公司

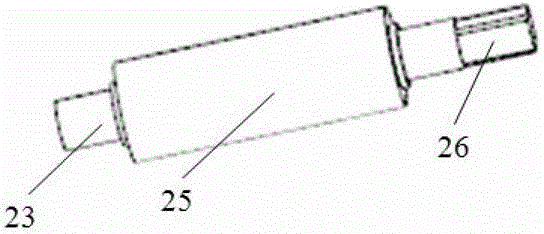

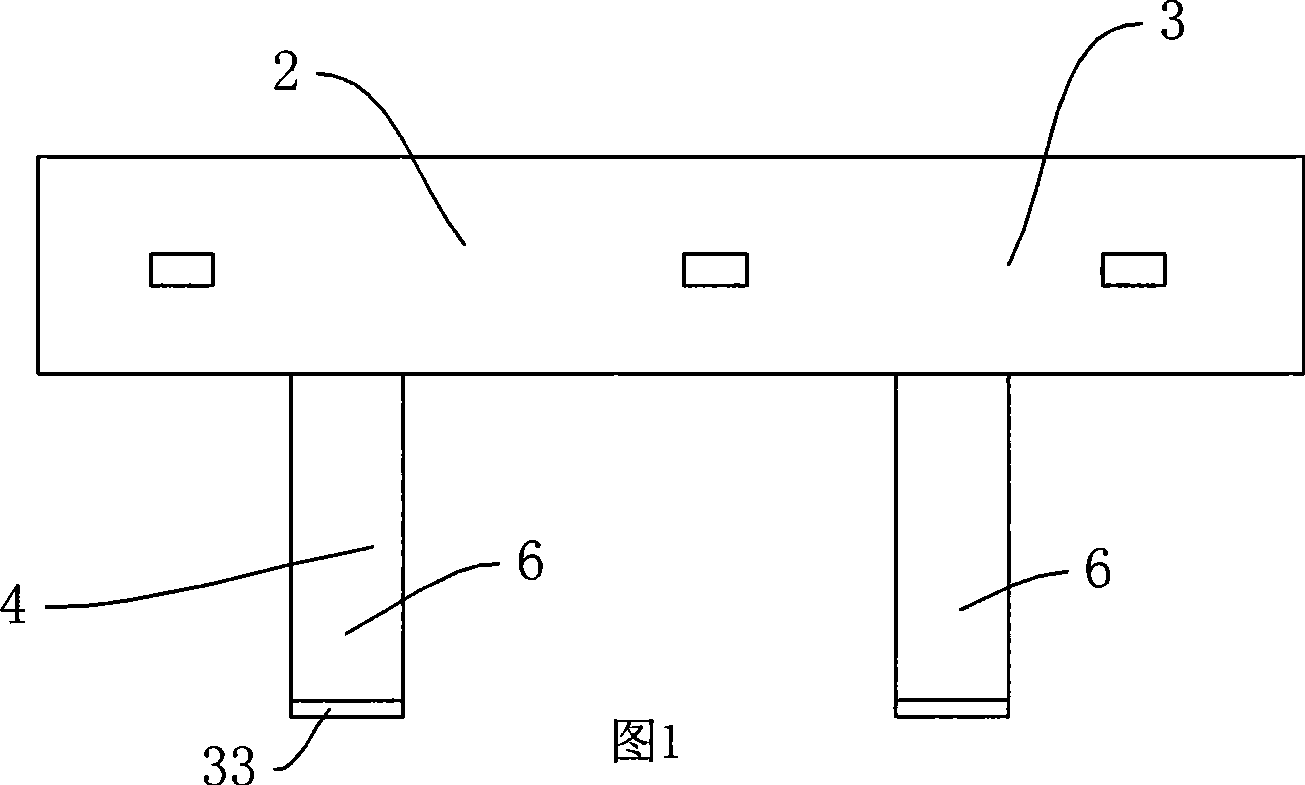

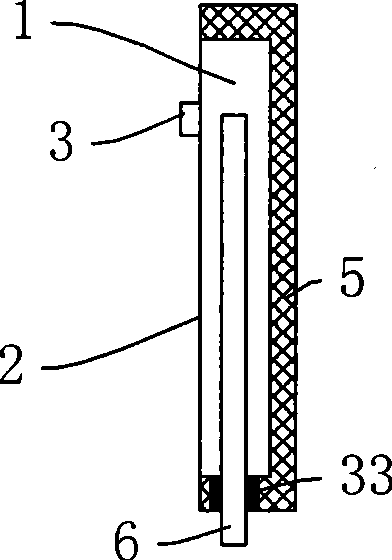

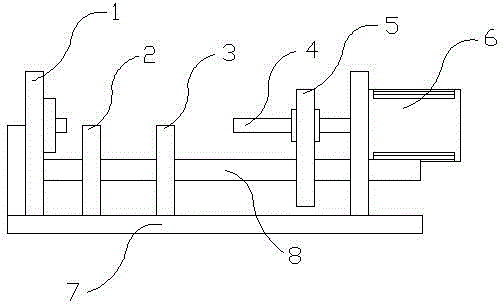

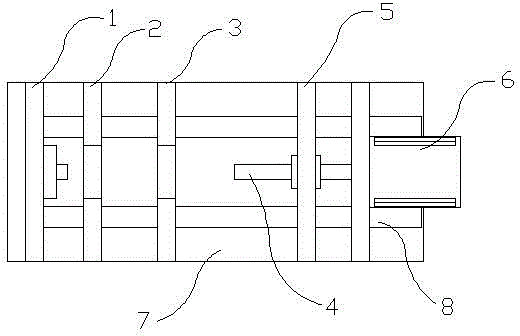

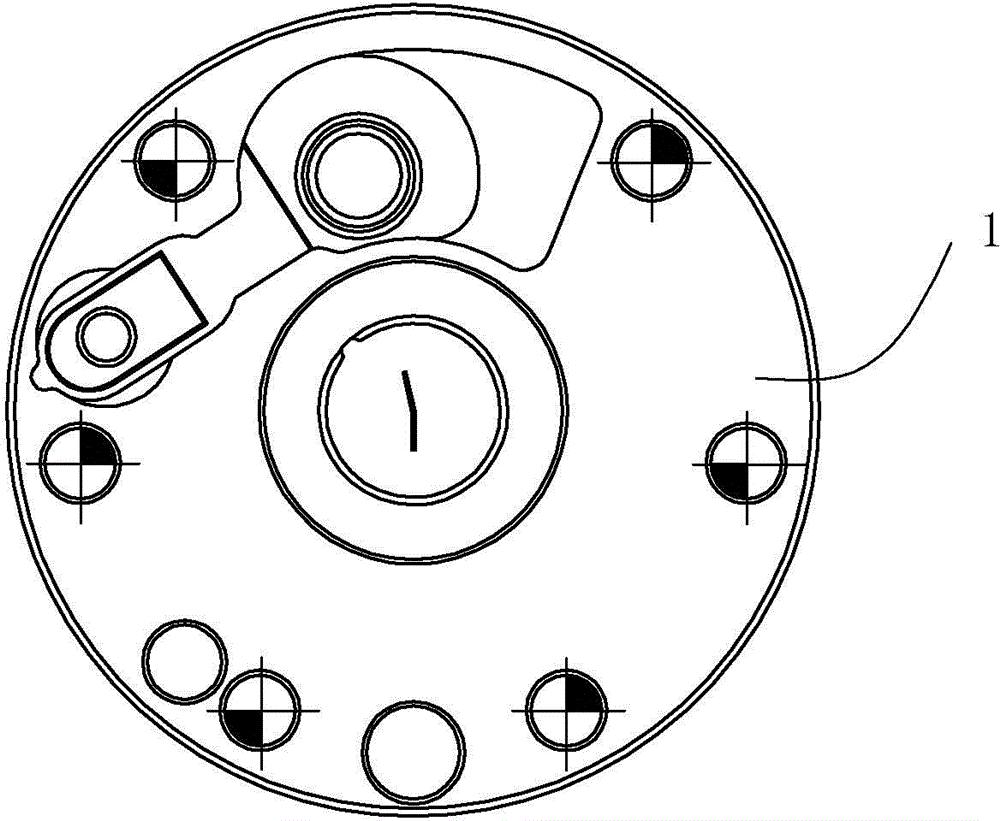

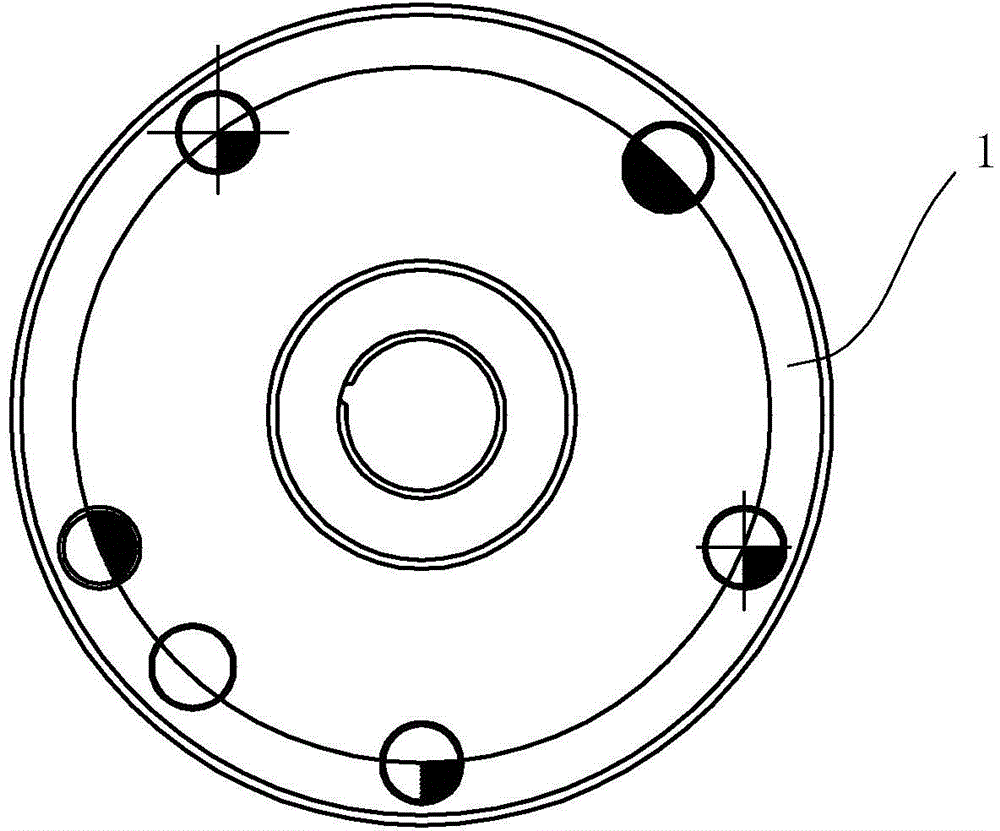

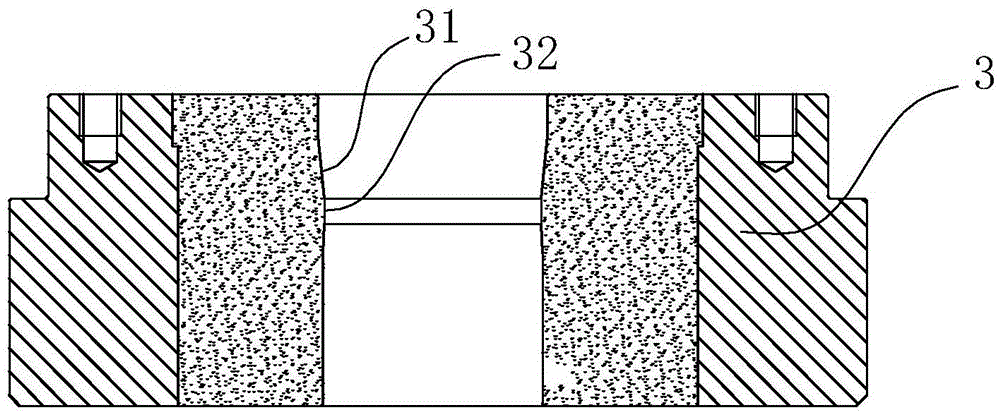

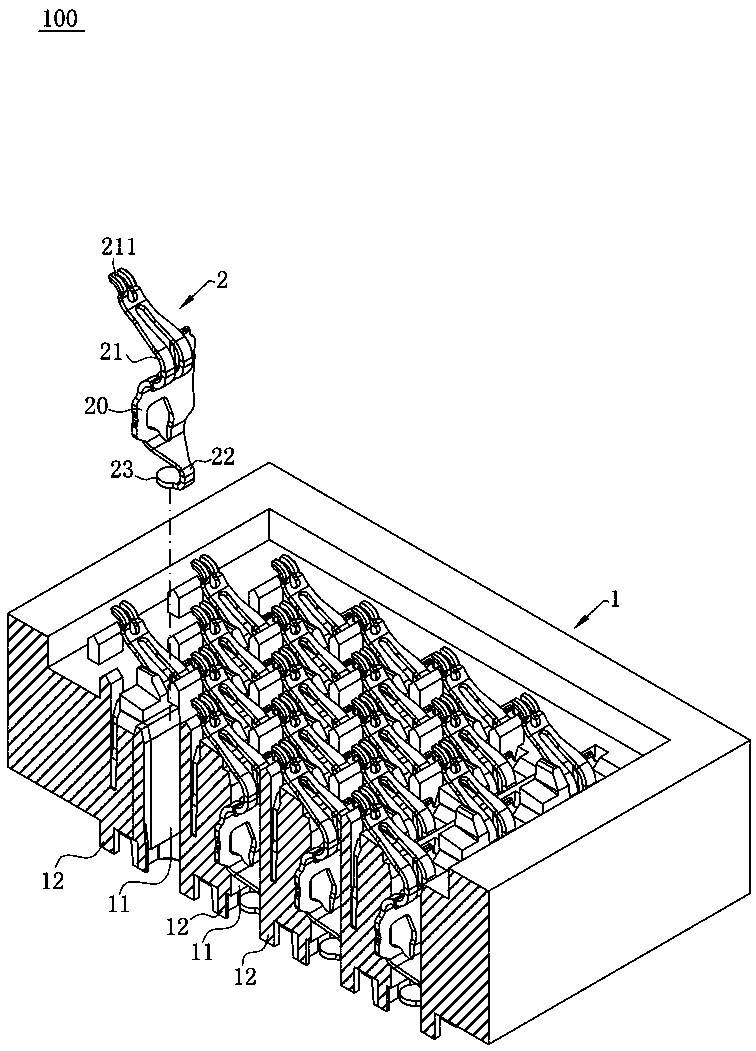

Silencer assembling device

ActiveCN103147958AFast stuffingReduce voidsPositive displacement pump componentsPositive-displacement liquid enginesSlide plateFiller metal

The invention discloses a silencer assembling device and belongs to the field of machining machines of silencers. The silencer assembling device comprises a baffle plate and a base and further comprises a first bearing plate, a second bearing plate, a telescopic rod, a sliding plate, a hydraulic device and a fixing rod, wherein the hydraulic device is fixedly arranged on the base through the fixing plate, and the baffle plate, the first bearing plate, the second bearing plate, the sliding plate and the hydraulic device are sequentially arranged on the base; the fixing rod is in parallel with the base and sequentially passes through the baffle plate, the first bearing plate, the second bearing plate, the sliding plate and the fixing plate of the hydraulic device; and after the telescopic rod passes through the sliding plate, one end of the telescopic rod is connected with the hydraulic device. According to the silencer assembling device with ribs disclosed by the invention, an air charging inner tube of the silencer can be quickly plugged into an expansion pipe so that a space between the air charging inner tube and the expansion pipe is small, the brazing filler metal is saved, the welding speed is quick, the efficiency is high, the realization of automation is facilitated, the welding cost is reduced, the connection effect is good, the appearance is attractive and the device is wearable.

Owner:ANHUI ZHONGHUI REFRIGERATION

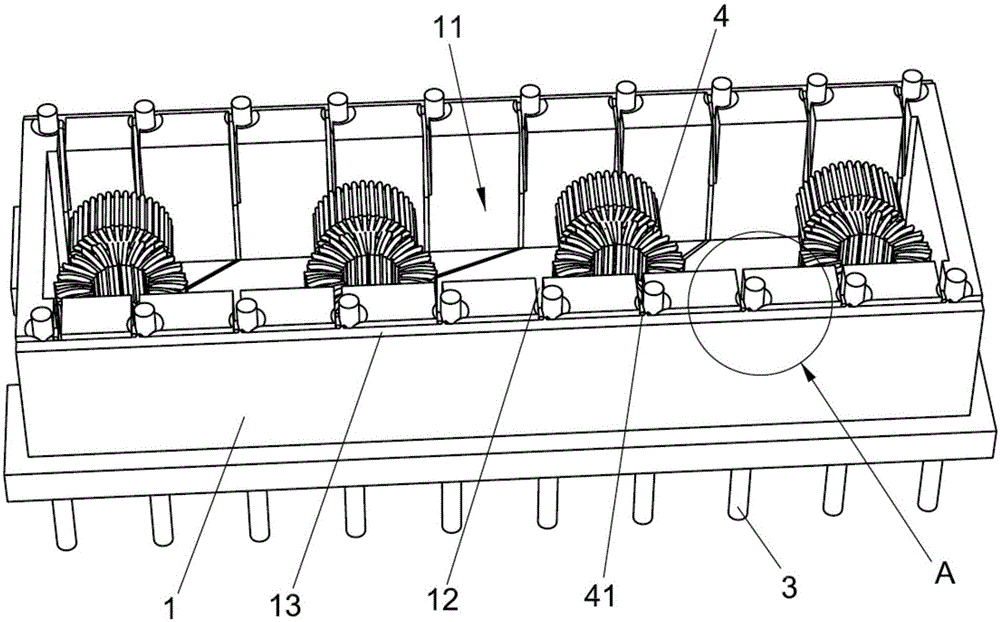

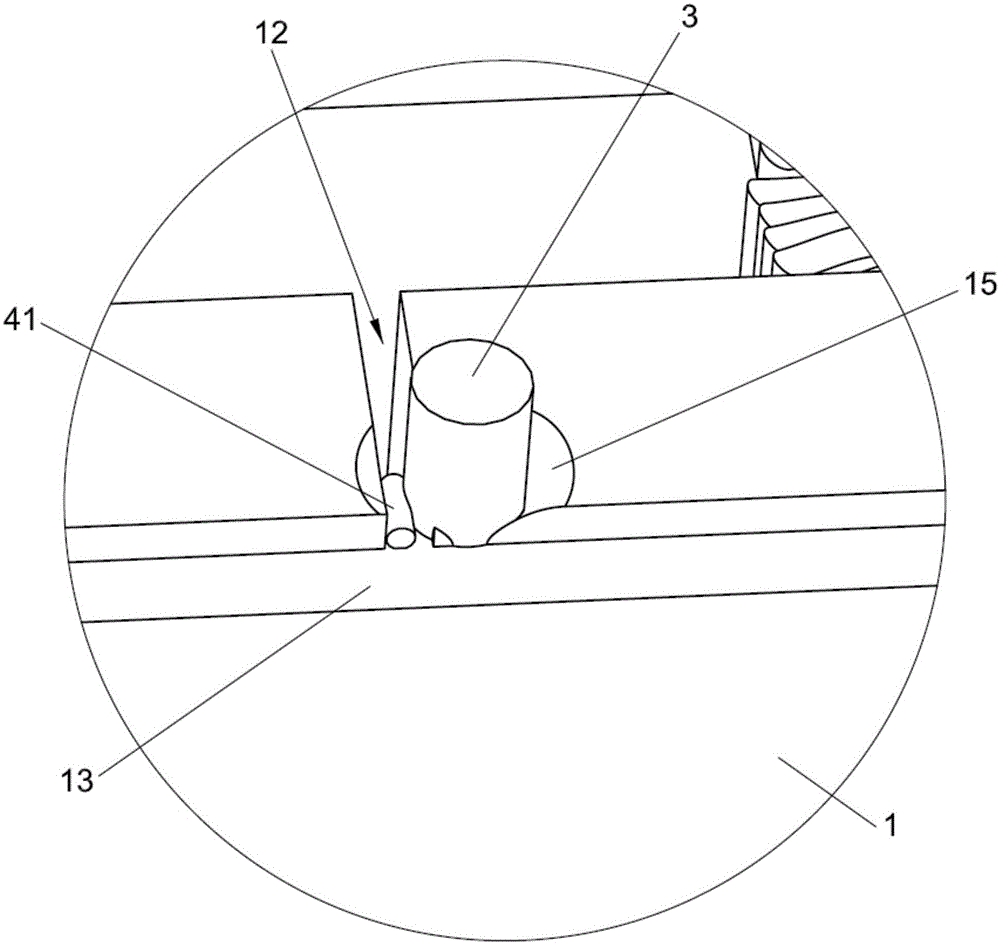

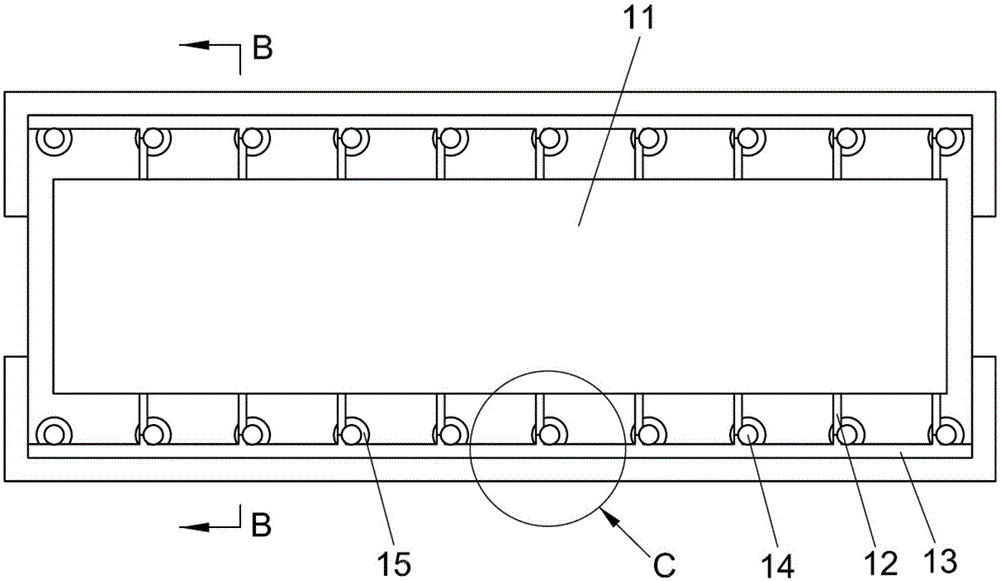

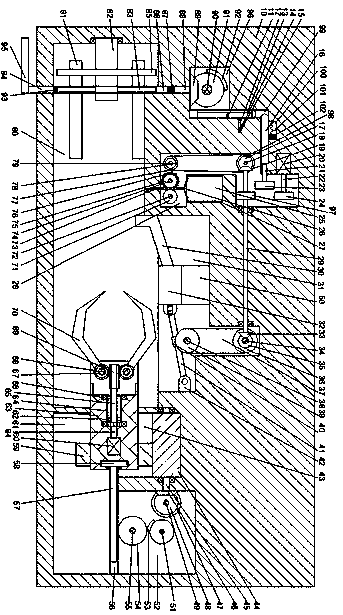

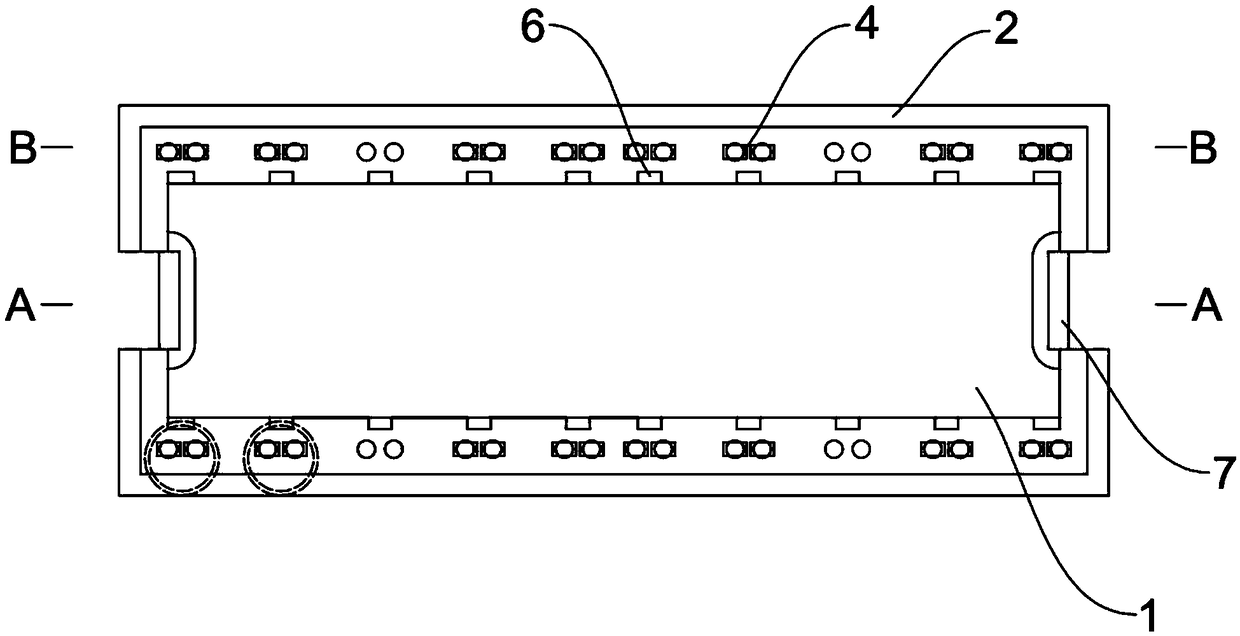

Network filter

ActiveCN105070488AShorten the lengthSave solderTransformers/inductances coils/windings/connectionsFixed signal inductancesWire cuttingElectrical performance

The invention discloses a network filter. The network filter comprises a shell, PINs and induction coils, a grooves is formed in the shell, the induction coils are arranged in the groove, multiple wire clamping grooves communicated with the groove are formed in the parts, at the two sides of the groove, of the shell, and coil lead wires of the induction coils are arranged in the wire clamping grooves. Multiple installation through holes are formed in the edge of each wire clamping groove, and the PINs are fixedly connected in the installation through holes. The ends of the coil lead wires are pressed tightly and fixed through the PINs and the inner walls of the wire clamping grooves, and the PINs and the coil lead wires are connected by way of soldering. A wire cutting step used for cutting away unnecessary coil lead wires is arranged at the edge of the shell. According to the network filter, the connection mode that the ends of the coil lead wires are pressed tightly and fixed through the PINs and the inner walls of the wire clamping grooves is adopted, the conventional wire winding connection mode is substituted, the process becomes simple, manpower and processing cost are saved, problems that originally, tweezers are used, so that surface paint on coil lead wires is prone to being damaged, and the coil lead wires are prone to being broken due to clamping are avoided, the electrical performance is improved, and the product qualified rate is raised.

Owner:MIANYANG HI TECH ZONE HONGQIANG TECH

Welding joint and use method thereof

InactiveCN109290693AEnsure safetySimple structureWelding/cutting auxillary devicesAuxillary welding devicesFixed frameEngineering

The invention relates to a welding joint and a use method thereof. The welding joint comprises a rack; the rack is internally provided with a machining cavity, an electric pole cavity communicating with the machining cavity is formed in the upper part of the machining cavity, a belt cavity communicating with the electric pole cavity is formed in the upper end wall of the electric pole cavity, therack is internally provided with a transmission cavity located on the left side of the electric pole cavity, a sliding cavity communicating with the transmission cavity is formed in the left side of the transmission cavity, a first gear cavity is formed in the left side of the sliding cavity, the rack is internally provided with a clamping claw cavity in the right side of the machining cavity, a third gear cavity is formed in the upper end face of the clamping claw cavity, a second gear cavity is formed in the right side of the third gear cavity, a rotating handle is rotatably arranged on thelower end wall of the machining cavity, a grip handle is fixedly arranged on the lower part of the rotating handle, a magnet is fixedly arranged at the top end of the rotating handle, the machining cavity is internally provided with a clamping block, and a fixing frame is rotatably arranged on the left end wall of the machining cavity.

Owner:杭州西非电子信息技术有限公司

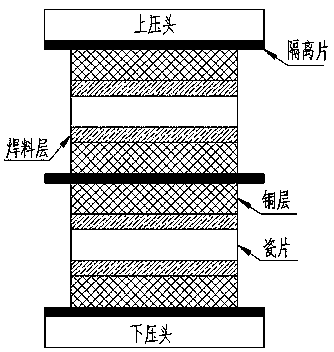

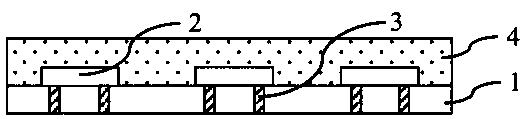

Method for preparing ceramic copper-clad plate by hot-pressing active brazing method

InactiveCN110064808AReduce void rateImprove pullout forceWelding/cutting media/materialsSoldering mediaVoid ratioAdditive ingredient

The invention discloses a method for preparing a ceramic copper-clad plate by a hot-pressing active brazing method. The method comprises the following steps that 1, a ceramic chip is ultrasonically cleaned with pure water under the condition of 70 DEG C for 1-10min and then dried in a drying oven at the temperature of 100 DEG C; 2, the two faces of the dried ceramic chip are evenly coated with silver-copper welding flux containing active metal ingredients and dried in the drying oven at the temperature of 60-90 DEG C; 3, the two faces, coated with the welding flux, of the ceramic chip are in fit with copper sheets to form a set A; 4, multiple sets A are stacked, and every two adjacent sets A are isolated through an isolation sheet; 5, the structure of the multiple stacked sets A is placedinto a hot pressing furnace, and 0-30 MPa pressure is applied to the two ends of the structure; 6, heating along with the furnace is started when vacuum is pumped to 10<-3>Pa, heat preservation is carried out for 30-90min at the temperature of 400-500 DEG C, then, glue discharge is carried out, and heat preservation is carried out for 10-60min at the temperature of 800-950 DEG C for brazing. By adopting vacuum hot-pressing active brazing, the prepared ceramic copper-clad plate has the characteristics of extremely low void ratio, high drawing force, solder saving, high production efficiency, simple operation in the preparation process and the like.

Owner:WUXI TIANYANG ELECTRONICS

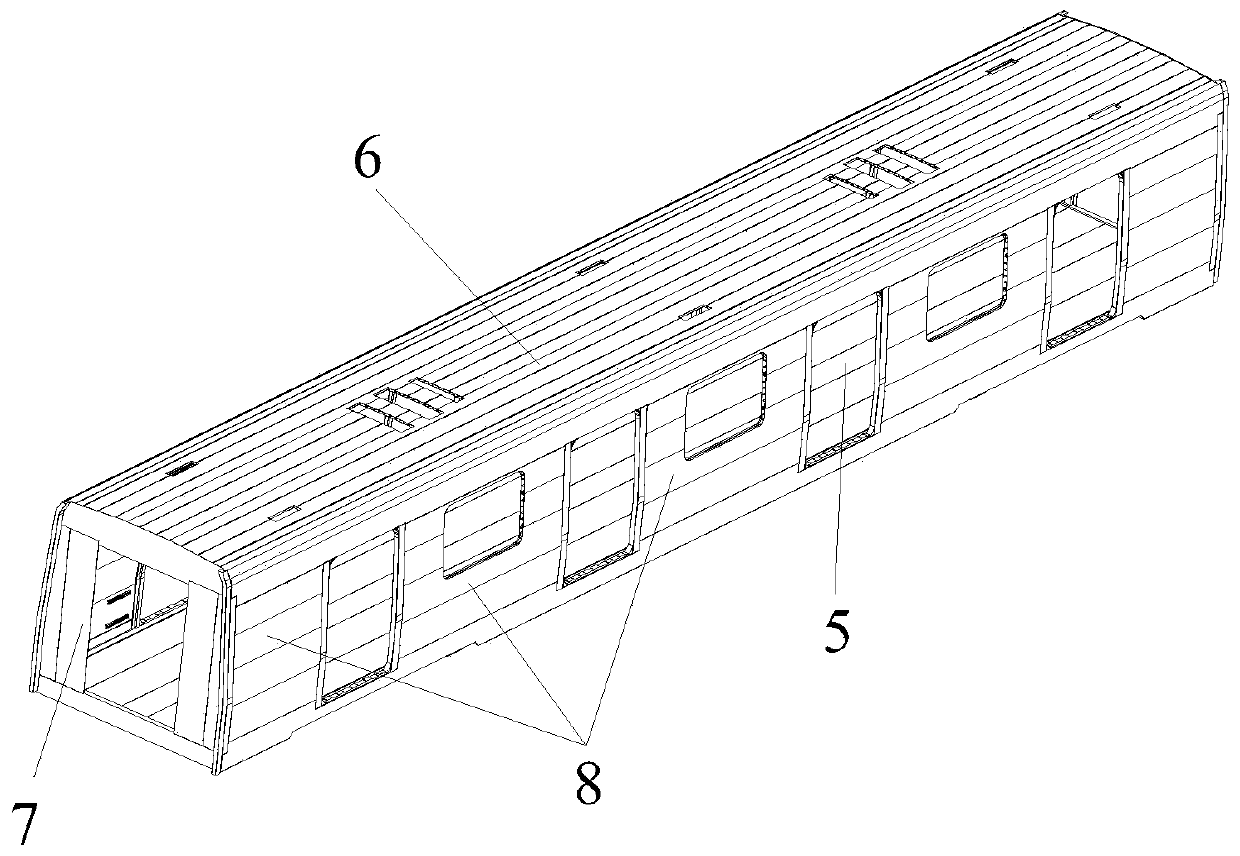

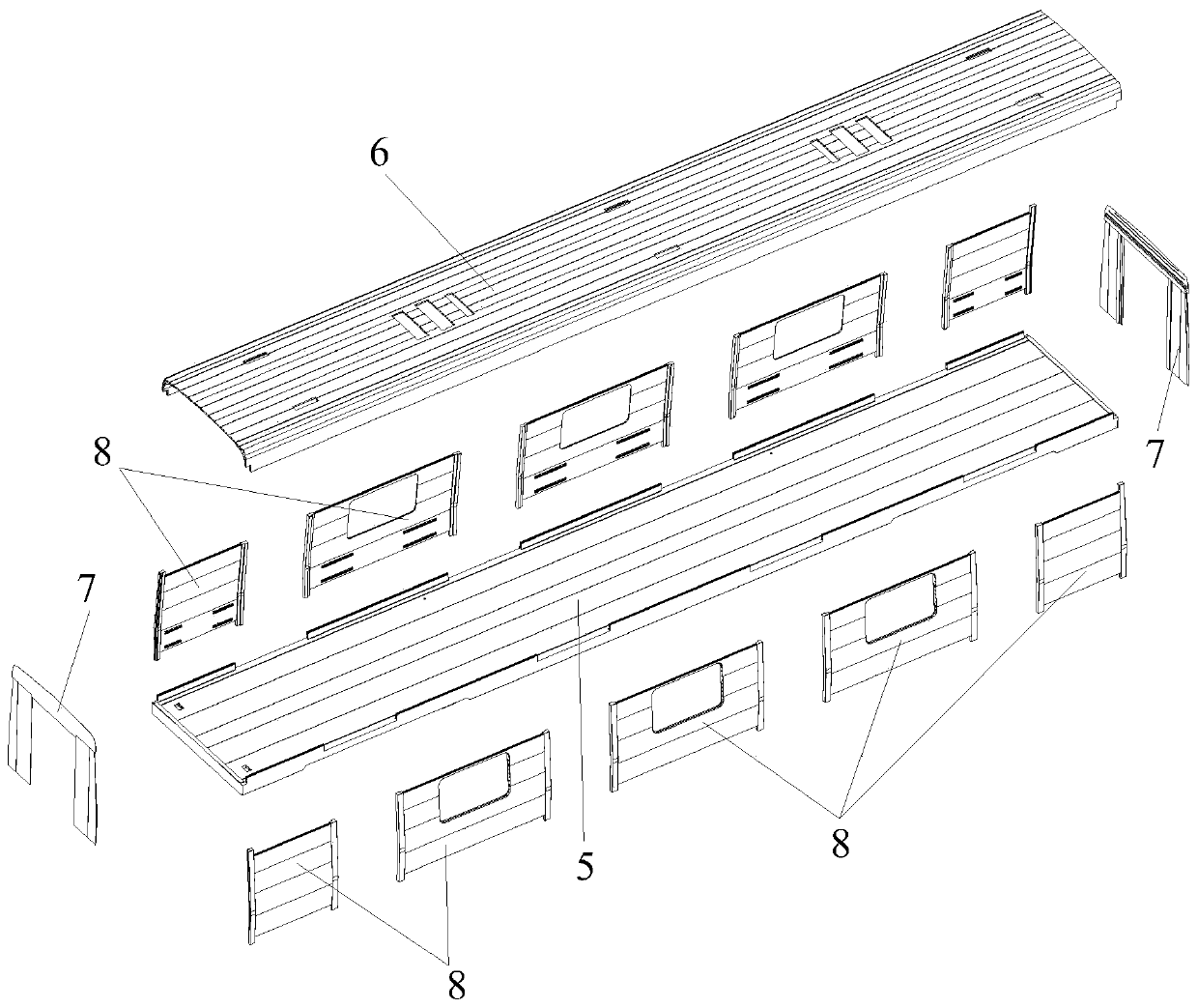

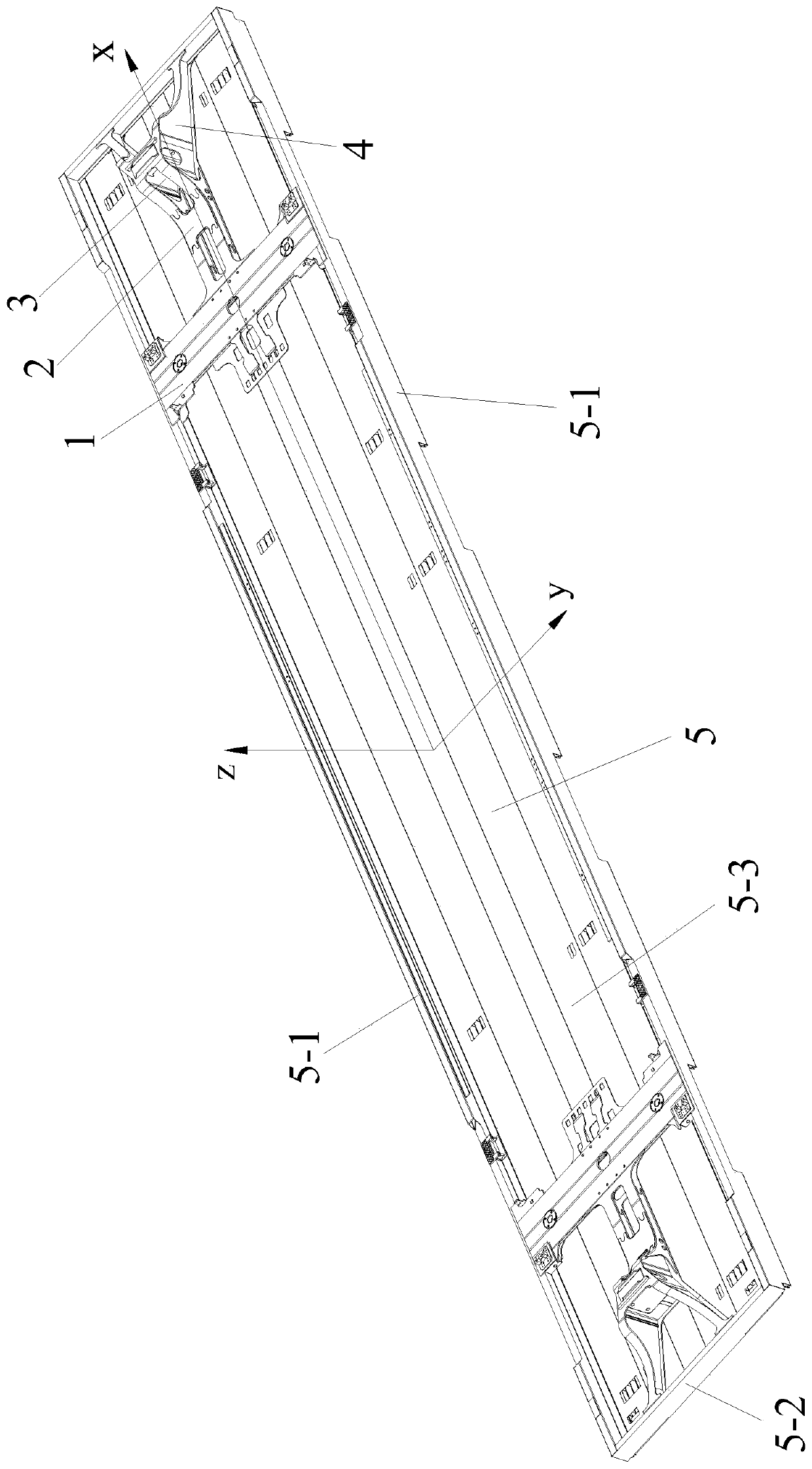

Lightweight subway car body with new tension pillow structure

ActiveCN107856688BGood workmanshipImprove accessibilityRailway roofsUnderframesEngineeringUltimate tensile strength

The invention provides a light-weight metro vehicle body with a novel traction sleeper buffer structure and belongs to the field of full-aluminum product metro vehicle body devices. The light-weight metro vehicle body comprises a chassis, a vehicle roof, two end walls, multiple side wall boards and a full-aluminum product traction sleeper buffer device. The chassis comprises a rectangular floor frame jointly defined by two side beams and two end beams and a floor located in the floor frame. The traction sleeper buffer device comprises a sleeper beam, a traction beam, a draw gear installation seat and two buffer beams. A traction beam lower cover plate and a buffer beam lower cover plate of the full-aluminum product traction sleeper buffer device of the light-weight metro vehicle body are both made of a profile aluminum plate material which is low in density, light in weight and good in bending performance, the draw gear installation seat is made from aluminum plates high in yield stress, other straight plate structures are all made of an aluminum plate material high in yield stress, overall selected materials of the traction sleeper buffer device meet the strength standard, and theprocessing property of welding and manufacturing of the traction sleeper buffer device is the best; and all lightening holes can be simultaneously used as auxiliary holes in the inner cavity weldingoperation process, so that the accessibility and welding quality of inner cavity welding joints are improved.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

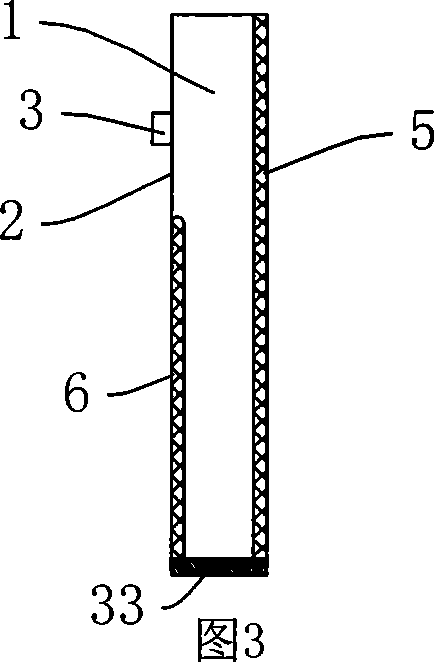

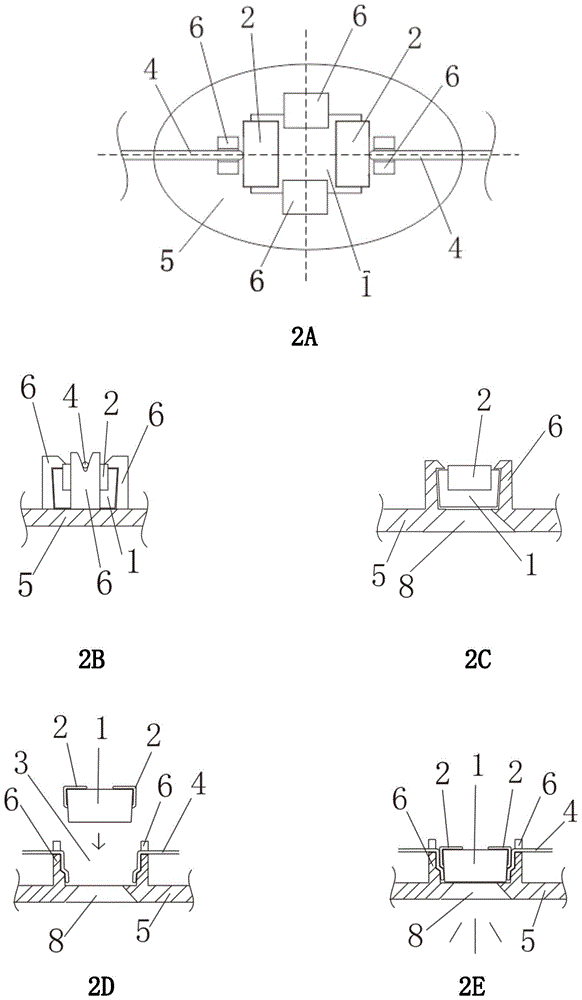

Weld-free type surface mounted device light-emitting diode (LED) lamp structure

ActiveCN103912805AEasy to installImprove cooling effectPoint-like light sourceLighting heating/cooling arrangementsSurface mountingEffect light

The invention relates to a weld-free type surface mounted device light-emitting diode (LED) lamp structure which is an enhancement and an improvement of an existing LED lamp and belongs to the field of LED decorative lighting. By means of the simple and novel LED lamp structure, a weld-free process of LED beads can be completely achieved, material costs are saved, and meanwhile, several manufacturing procedures are also saved in production manufacture links, so that the whole costs of the lamp structure are reduced, and a reject ratio of the LED beads during a high-temperature welding process of products is greatly reduced; meanwhile, by means of the special structure, LED application fields can be more flexible and broad, and later maintenance of a weld-free LED lamp can be achieved only by a simple manner of replacing broken LED beads, so that production and application links of the LED lamp can be more environmental friendly at the greatest extent.

Owner:马飞

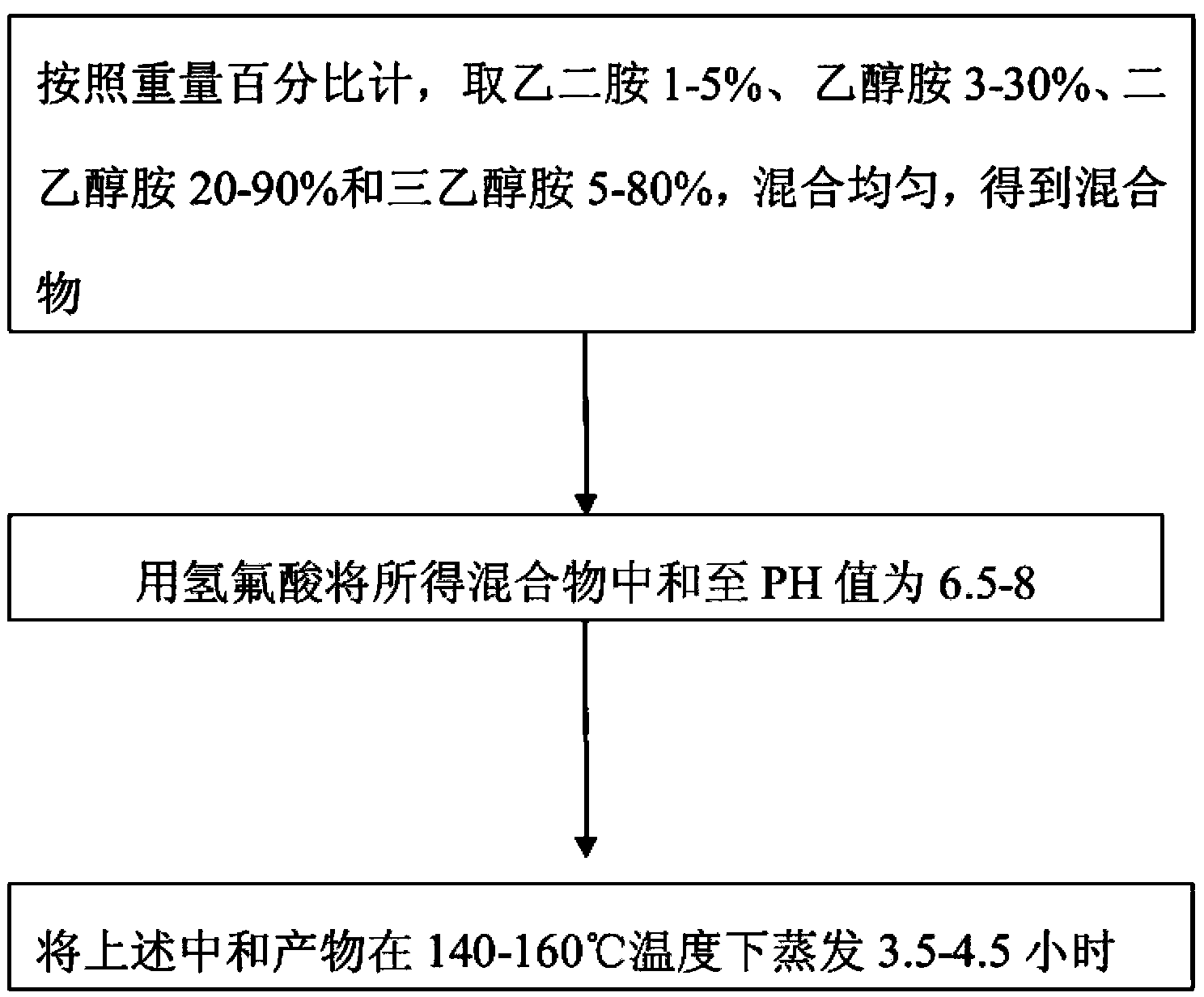

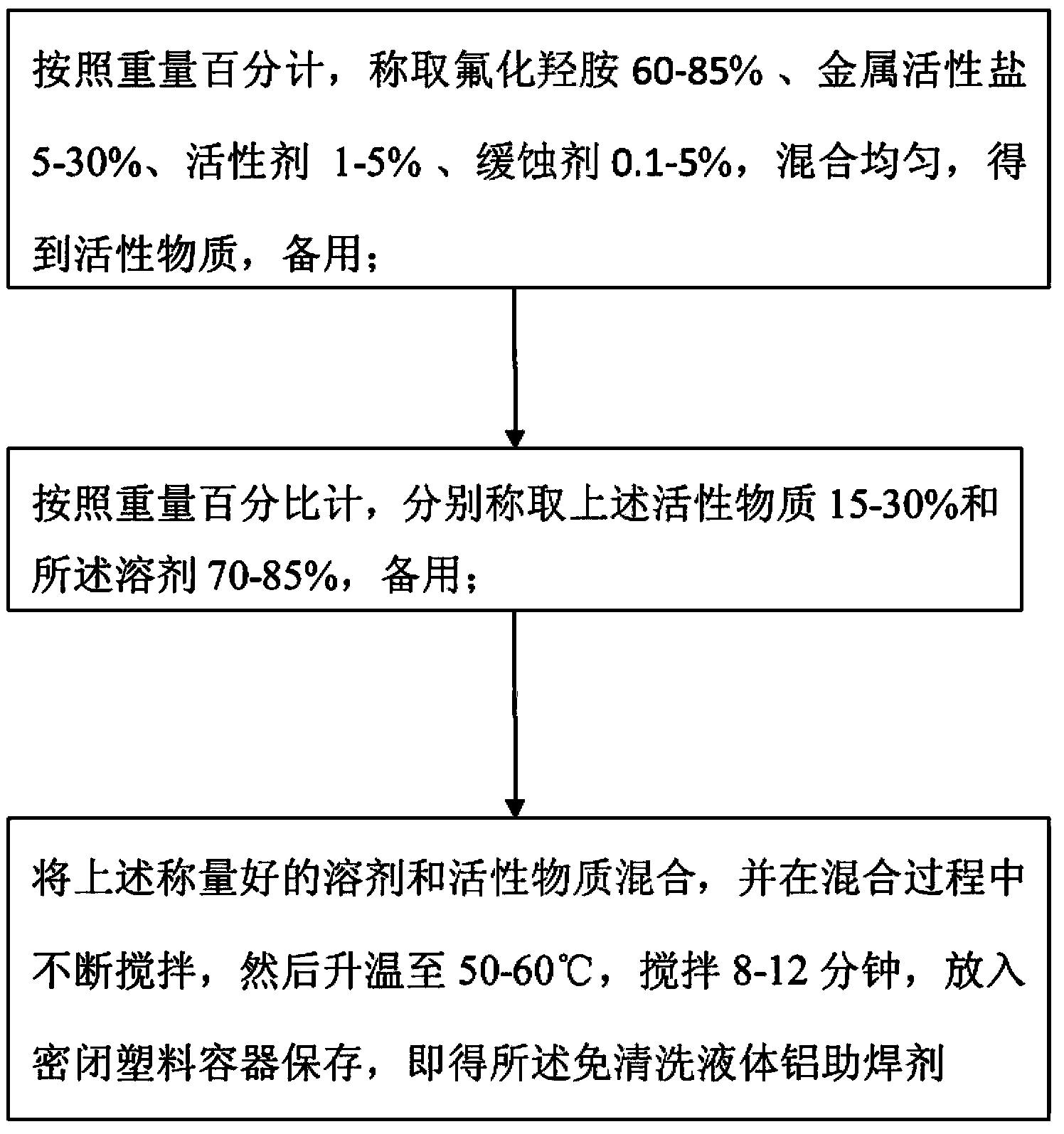

A kind of no-cleaning liquid aluminum flux and preparation method thereof

ActiveCN102922178BImprove solderabilityImprove welding efficiencyWelding/cutting media/materialsSoldering mediaHydroxylamineActive agent

The invention relates to a no-cleaning liquid aluminum flux and a preparation method of the no-cleaning liquid aluminum flux. The preparation method comprises steps of: 1) weighing 60 to 85% of fluorate hydroxylamine, 5 to 30% of metal active salt, 1 to 5% of active agent, and 0.1 to 5% of corrosion inhibitor by weight, and uniformly mixing to obtain an active object for later use; 2) weighting 15 to 30% of active substance, and 70 to 85% of solvent by weight for later use; 3) mixing the weighed solvent and active substance along with continuous agitating, then heating to 50 to 60 DEG C, agitating for 8 to 12 minutes, and then transferring into a sealed plastic container for storing, so as to obtain no-cleaning liquid aluminum flux. The no-cleaning liquid aluminum flux provided by the invention is high in weldability and welding efficiency; less splash is generated during welding, and the welding is nearly free of splashing, so that the welding flux can be saved; and fewer residues are generated after welding, and the welding spots do not need to be cleaned, so that long service life can be ensured.

Owner:青岛英太克锡业科技有限公司

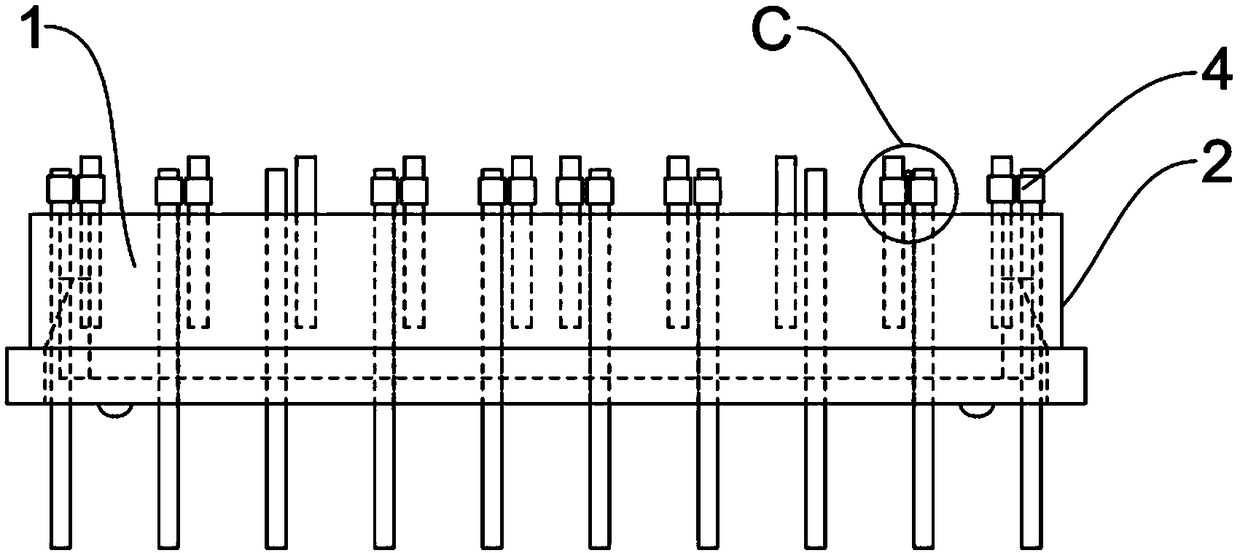

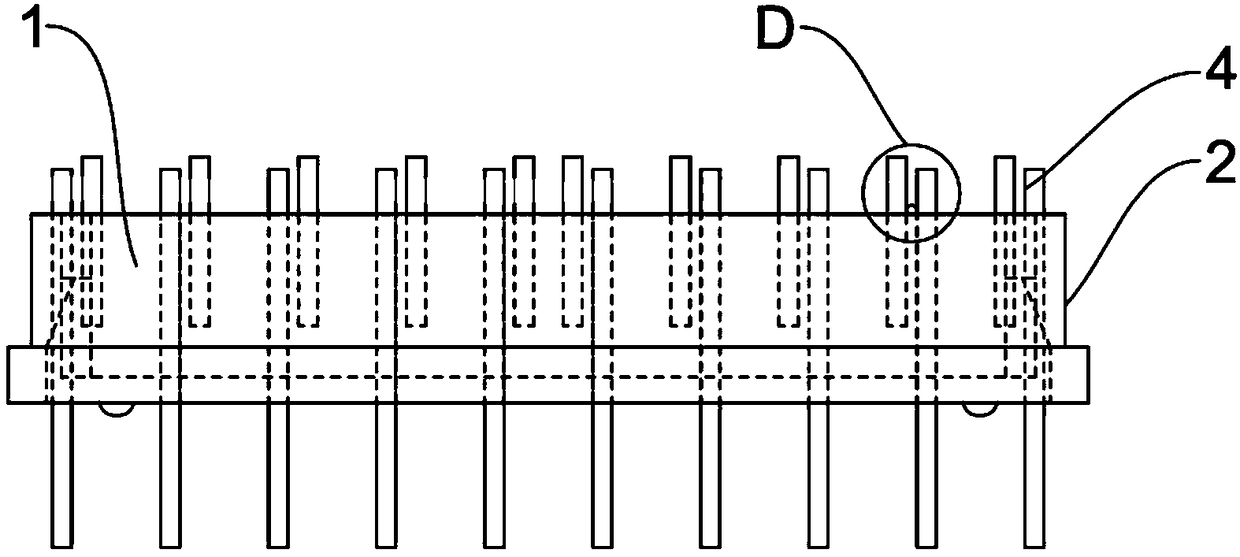

LED light-emitting panel and manufacturing method thereof

ActiveCN108682631AWon't hurtEasy to fixSolid-state devicesSemiconductor/solid-state device manufacturingOptoelectronicsTemperature difference

The invention provides an LED light-emitting panel and a manufacturing method thereof. Blind holes are formed in advance, then the blind holes are processed into through holes, so that the damage of apad is prevented; a metal pillar with a solder layer and a dielectric layer is used as a conductive terminal, which can enhance its adhesion to a metal substrate and save solder; in addition, the metal pillar and the metal substrate are made of the same material, the temperature difference due to the difference in thermal conductivity is prevented, and warpage can be prevented.

Owner:湖北维冠智显科技有限公司

Method for manufacturing powder metallurgy support

ActiveCN105436506AHigh precisionNo need to adjust the welding processTurbinesOther manufacturing equipments/toolsSurface finishManganese

A method for manufacturing a powder metallurgy support comprises the steps that iron, chrome, molybdenum, manganese, nickel, carbon and copper are mixed into mixed powder according to the mass percent; the mixed powder is compressed into a support green body with the density being 6.2-7.2 g / cm<3> by a press; the support green body is sintered under the temperature of 1000-1350 DEG C, the sintering time is 5-180 minutes, and annealing is conducted in a non-oxidizing atmosphere; extrusion is conducted by the press formed by modifying an extrusion moulding machine or a finishing press, and the extrusion deformation degree is larger than or equal to 2% in the diameter direction; selective processing is conducted according to dimension requirements, and steam treatment is conducted. The method for manufacturing the powder metallurgy support has the advantages that the manufacturing process is simple, the precision is high, the surface smoothness is good, and the problem that a mould is likely to fracture due to the fact that the forging process is conducted under high temperatures is effectively solved, so that the production cost is lowered and the production efficiency is improved. Compared with a traditional powder metallurgy process, the density of products is higher, and surface densification is basically achieved.

Owner:NBTM NEW MATERIALS GRP

Terminal and electric connector equipped with same

ActiveCN108365357AStop the spreadCause short circuitElectric discharge tubesSoldered/welded conductive connectionsResistElectricity

Disclosed is an electric connector for electrically connecting a chip module to a circuit board. The electric connector comprises an insulation body and at least one terminal, wherein at least one accommodating hole which runs through up and down is formed in the insulation body; each accommodating hole correspondingly accommodates one terminal; each terminal has a contact part at the upper end and a welding part at the lower end; the welding part extends downwardly out of the corresponding accommodating hole; the welding part has a welding surface and a solder resist layer for surrounding thewelding surface; the welding surface is used for combining a soldering flux; and the solder resist layer is used for blocking diffusion of the soldering flux on the solder resist layer.

Owner:DEYI PRECISION ELECTRONIC IND CO LTD PANYU

Welding process for inner exhaust coil pipe assembly

InactiveCN110170803AEasy to weldEasy to operateMetal working apparatusWelding apparatusNitrogenEngineering

The invention relates to a welding process for an inner exhaust coil pipe assembly. The welding process comprises the following steps of S1, preparing, wherein grinding and rusting are carried out onthe positions of two annular inner exhaust coil pipe welding openings before welding; S2, selecting, wherein a 70N rolling welding stick is selected; S3, spot welding, S4, adding of an inner filling material, wherein after cooling is carried out, circular inner tubes are plugged into the inner walls of the two annular inner exhaust coil pipe welding openings, and the diameter of the inner tubes issmaller than the diameter of inner exhaust coil pipes by 1 mm; S5, welding, wherein the two ends of each of the two inner exhaust coil pipes are clamped through external clamps, then rotation is carried out at the speed being 1 r / min, and electric welding is used for welding the welding openings; S6, cooling, wherein normal temperature nitrogen at 20 DEG C-30 DEG C is continuously introduced, cooling is carried out, and the inner filling material is taken out; S7, grinding, wherein a grinding machine is used for grinding the positions of the welding openings to make the welding positions smooth; and S8, anti-corrosion treatment, wherein the welding positions are plated with a metal chromium layer. The method is easy to operate, high in process adaptability and capable of conveniently welding the exhaust coil pipes.

Owner:TAIZHOU CHANGZHENG REFRIGERATOR PIPE FITTINGS

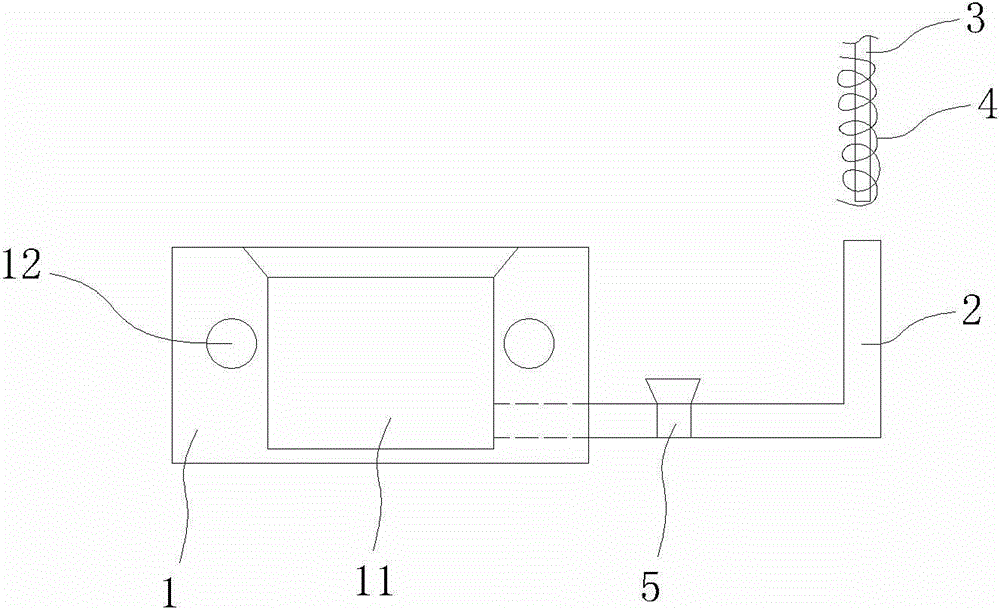

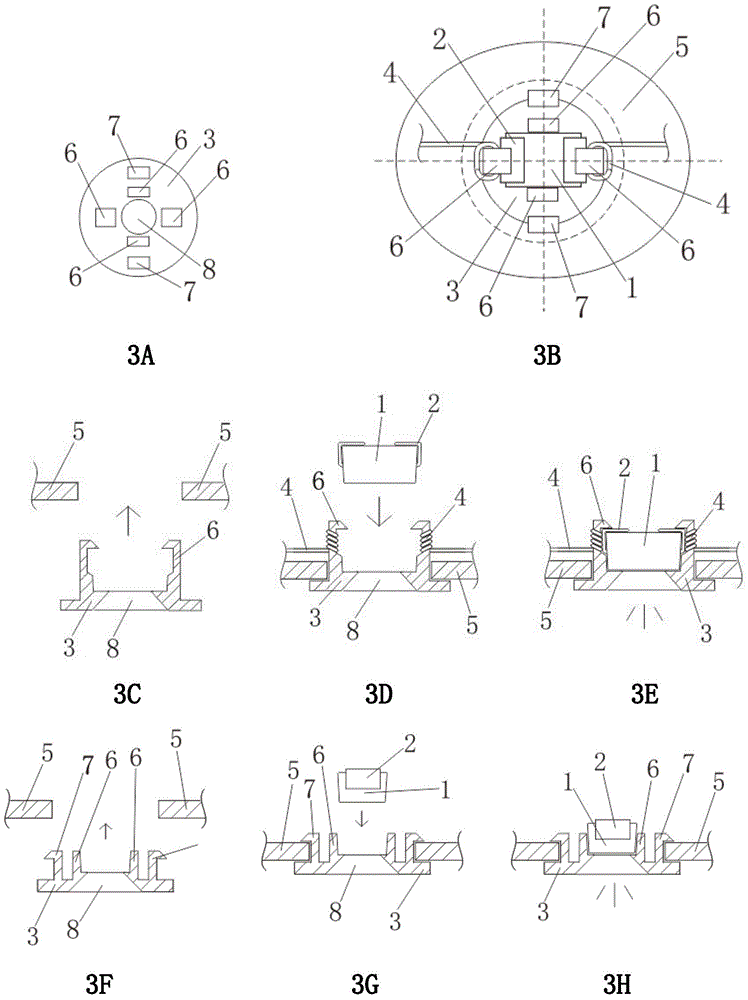

Installation method for inductor of duplexer

InactiveCN101471168AEliminate damageSave internal spaceTransformers/reacts mounting/support/suspensionState of artInductor

The invention relates to an installation method for inductor of duplexer, which comprises a cover board of duplexer, two through-hole screws, a block-shaped holding device, a metal wire, a hole filling screw, a spring washer, a metal wire pellet and a pellet fixing screw. The installation method comprises fixing the through hole screws on the cover board of duplexer, locating the block-shaped holding device between the two through hole screws, inserting both ends of the metal wire which has been shaped into two holes at the center of the two through hole screws, arranging the metal wire pellet on the block-shaped holding device, fixing the metal wire on the block-shaped holding device by the metal wire pellet, and jointing the through hole screws and the metal wire by soldering with tin solder. Compared with the prior art, the installation method for inductor of duplexer is characterized by uniform position of welding, which can relieve body harm to people, save inner space, and save tin solder.

Owner:ALLRIZON TONGGUANG COMM EQUIP SHANGHAI

No-clean liquid aluminum soldering flux and preparation method thereof

InactiveCN106808115AImprove solderabilityImprove welding efficiencyWelding/cutting media/materialsSoldering mediaHydroxylamineActive agent

The invention relates to a no-cleaning liquid aluminum flux and a preparation method thereof, comprising the following steps: 1) weighing 60-85% of hydroxylamine fluoride, 5-30% of a metal active salt, 1- 5%, 0.1-5% of the corrosion inhibitor, mix evenly to obtain the active substance, and set aside; 2) According to weight percentage, weigh 15-30% of the above active substance and 70-85% of the solvent, set aside; 3) Mix the above-mentioned weighed solvent and active substance, and keep stirring during the mixing process, then raise the temperature to 50-60°C, stir for 8-12 minutes, put them in a closed plastic container for storage, and obtain the no-cleaning liquid aluminum auxiliary flux. The no-cleaning liquid aluminum flux of the invention has good solderability and high welding efficiency; it has little spatter during welding and almost no spatter, saving solder; there is very little residue after welding, no need to clean solder joints, and it has a long service life.

Owner:QINGDAO SENMEIKE CHEM TECH CO LTD

Network transformer and line hanging method of network transformer

PendingCN108735466AReduce breakage rateReduce the difficulty of operationTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresTransformerEngineering

The invention discloses a network transformer. The network transformer comprises a shell base, a shell upper cover and dual rows of pins, wherein an accommodating groove is formed in the shell base and is used for accommodating a magnetic ring coil, the shell upper cover can cover the shell base, the dual rows of pins are arranged on the shell base, and a U-shaped clamping groove is formed in oneend, near to an opening of the accommodating groove, of each of dual rows of pins and is used for accommodating a lead of the magnetic ring coil. A line hanging method of the network transformer comprises the following steps of (a) placing the magnetic ring coil in the accommodating groove, allowing the lead of the magnetic ring coil to penetrate through a line through groove, and clamping the lead of the magnetic ring coil into the U-shaped clamping groove; (b) welding the lead arranged in the U-shaped clamping groove in the step (a) so that the lead is fixed in the U-shaped clamping groove and electrically communicates with the dual rows of pins; and (c) covering the shell upper cover and fixing the shell upper cover at the shell base.

Owner:MIANYANG HIGHLY TECH JINGWEIDA SCI

LED lighting device and manufacture method thereof

ActiveCN108807357AImprove fixationSave solderSolid-state devicesSemiconductor devicesMetallurgyLed illumination

The invention provides an LED lighting device and a manufacture method thereof. Blind holes are pre-formed and made into through holes, so that no damage is caused to a pad; ceramic posts with a solder layer are used as conductive terminals, so that fixation to a ceramic substrate can be enhanced, and solder can be saved. In addition, the ceramic posts and the ceramic substrate are of same material, and therefore, temperature differences due to different heat conductivity coefficients can be prevented, and warping can be prevented.

Owner:JIANGSU FURUIDE OPTICAL

Double-wave crest generator with electromagnetic pump

ActiveCN104125723AIncrease powerAchieve independent controlPrinted circuit assemblingSoldering apparatusSlag (welding)Electromagnetic pump

The invention relates to a double-wave crest generator with an electromagnetic pump, belongs to the field of microelectronic lead-free welding and aims at overcoming the disadvantages that the existing lead-free wave crest generator is prone to form oxidizing slag, the welding quality is difficult to guarantee and the like. The electromagnetic pump comprises an upper iron core and a winding thereof, and a lower iron core and a winding thereof; an upper pump ditch is arranged under the upper iron core, while a lower pump ditch is arranged under the lower iron core, and the upper iron core is shorter than or as long as the lower iron core; the upper pump ditch is connected with a turbulent wave generator by use of a turbulent wave generation pipeline, while the lower pump ditch is connected with a wide plane wave generator by use of a wide plane wave generation pipeline. The wave crest generator is capable of performing respective control on the crest heights of the turbulent wave and the wide plane wave and realizing the design concept of dual driving with one pump by taking a three-phase asynchronous inductive electromagnetic pump as the power source, and thus is applicable to the welding production of different PCBs (Printed Circuit Boards). Meanwhile, due to rigorous design, the solder-air contact area and the dosage of the solder are greatly reduced, and the formation of the lead-free solder oxidizing slag is effectively controlled.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

Combined inserted die used for production of sector gear shaft

InactiveCN111014561AReduce maintenance costsEasy maintenanceForging/hammering/pressing machinesEngine componentsMechanical engineeringIndustrial engineering

The invention discloses a combined inserted die used for production of a sector gear shaft. The combined inserted die comprises a lower die bottom plate, a lower die assembly, a middle die assembly, an upper die bottom plate and an upper die assembly; the interior of a lower die cavity is in a detachable fit with a lower die insert; the interior of a middle die cavity is in a detachable fit with amiddle die insert; and the interior of an upper die cavity is in a detachable fit with an upper die insert. By installing the detachable lower die insert, middle die insert and upper die insert, notonly can mold cavities be defined for processing and forging the sector gear shaft, but also any insert can be rapidly replaced at low cost after being damaged, so that not only is a large amount of solder saved, is the maintenance cost of the combined inserted die reduced, and are the labor strength and the workload of a maintenance worker greatly reduced, but also the maintenance efficiency canbe promoted, the maintenance time is shortened, and the lost labor behavior caused by die maintenance can be further reduced; and moreover, since the combined inserted die is convenient to maintain, alarge number of standby dies do not need to be prepared in a manufacturing shop.

Owner:SHANDONG JINMA INDAL GROUP

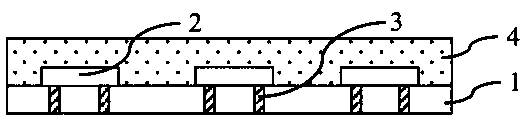

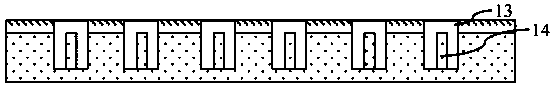

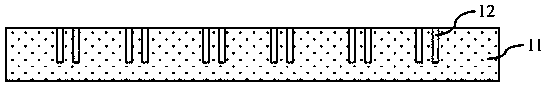

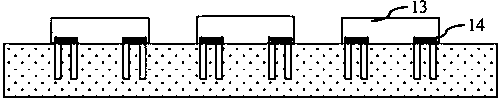

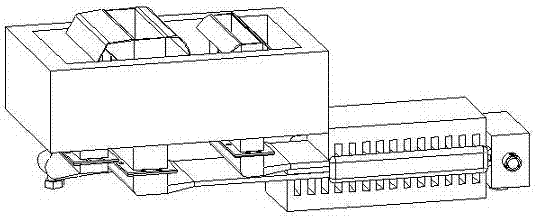

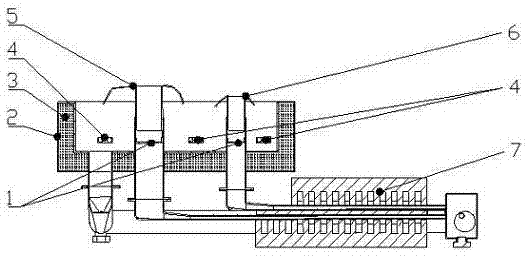

Bayonet type socket

InactiveCN101399159AGood electrical contactReduce manufacturing costElectric discharge tubesElectric discharge lampsEngineering

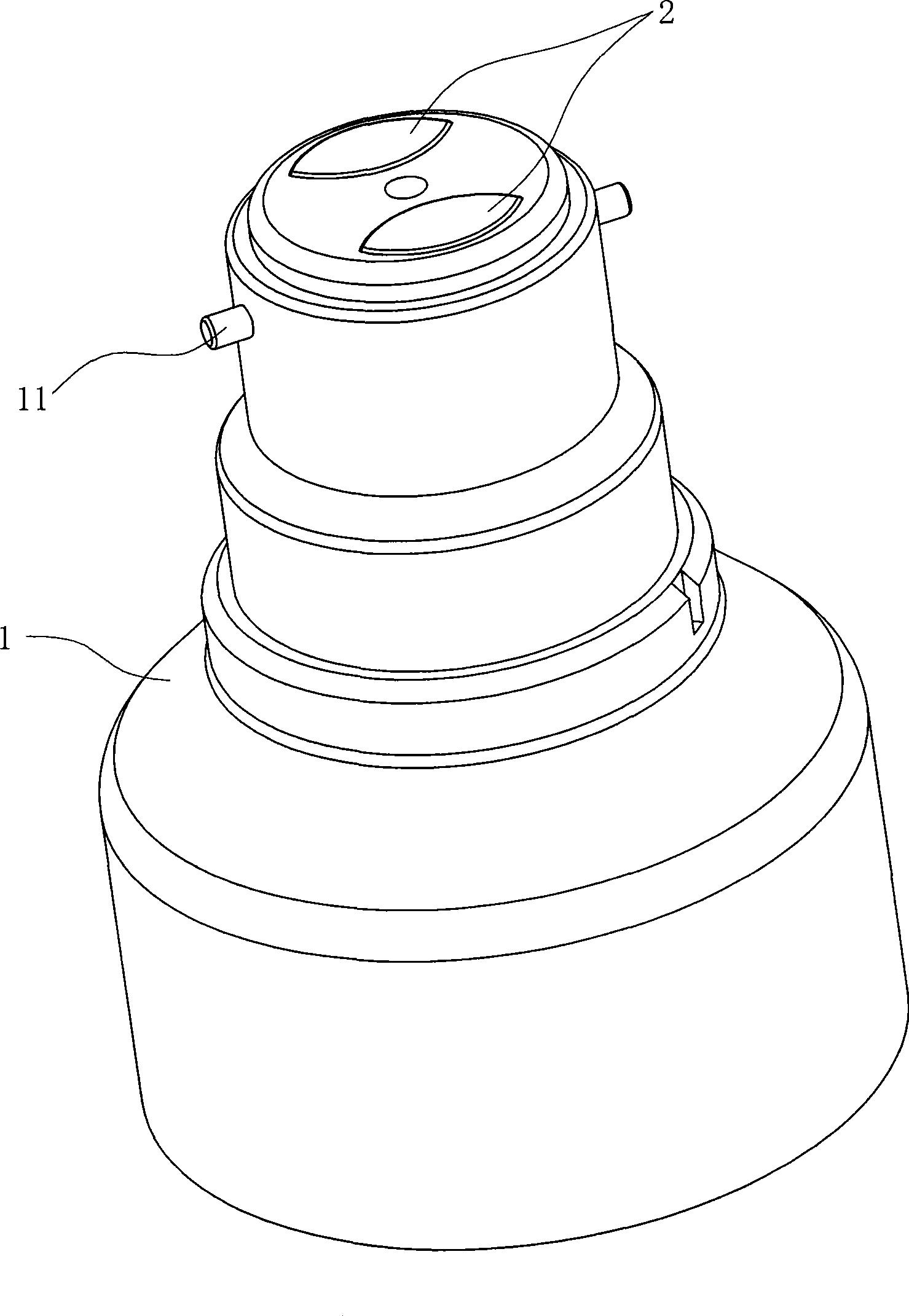

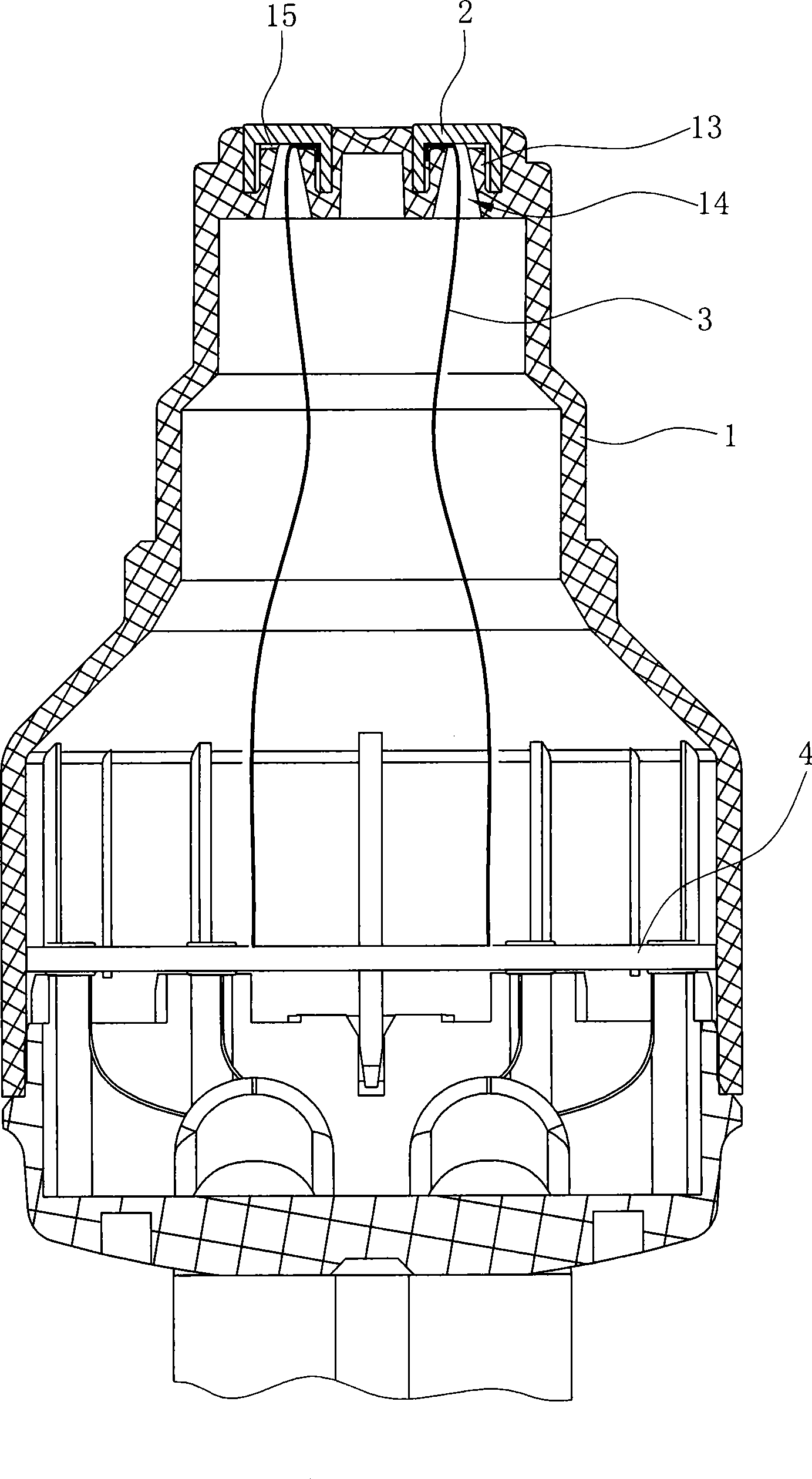

The invention discloses a bayonet lamp cap which comprises a lamp cap body (1) made from insulating material and two conductive contacts (2) arranged at the top of the lamp cap body (1), wherein, the lamp cap body (1) is provided with a couple of bayonet pins (11); the section of the conductive contacts (2) is of reversed U shape; the top of the lamp cap body (1) is provided with two grooves (12) which can be embedded with corresponding conductive contacts (2); the inside of each groove (12) is provided with a lug boss (13) which is matched with the inner lateral wall (21) of the conductive contact (2); and each lug boss (13) is provided with a through hole (14) along the axial direction of the lamp cap body (1). Compared with the prior art, the basic frame structure of the lamp cap body of the bayonet lamp cap is not changed; the whole lamp cap body can be made from plastics, thereby reducing the production cost greatly and being convenient for manufacturing; at the same time, the electric connection assembly can be finished just by plugging the conductive contacts at the top of the lamp cap body; the assembly working procedure is very simple; and the invention can ensure good electric connection between a line conductor and the conductive contacts.

Owner:NINGBO DONGXING ELECTRIC

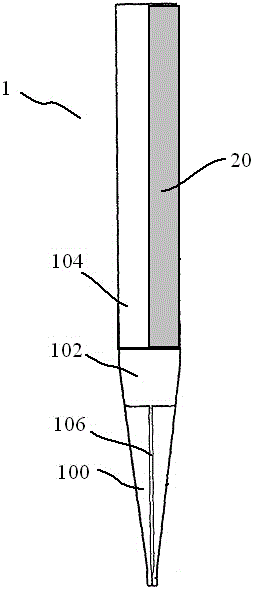

Welding flux welding head

InactiveCN104625460AEasy to operateSave solderWelding/cutting media/materialsSoldering mediaEngineeringMechanical engineering

The invention provides a welding flux welding head. The welding flux welding head is characterized in that the welding flux welding head at least comprises a welding head body which is used for welding a first workpiece to a to-be-welded part of a second workpiece and a welding flux body which is detachably arranged on the welding head body and used for providing welding flux when welding. Compared with the prior art, the welding flux welding head has the advantages of being convenient to operate, and capable of saving the welding flux.

Owner:SUZHOU AOPENG MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com