Method for siphon prevention of the terminal and the terminal made by this method

An anti-siphon and terminal technology, applied in contact manufacturing, contact parts, electrical components, etc., can solve problems affecting the electrical connection between conductive terminals and circuit boards, solder loss, empty soldering, etc., to prevent empty soldering and save solder. , to ensure the effect of welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

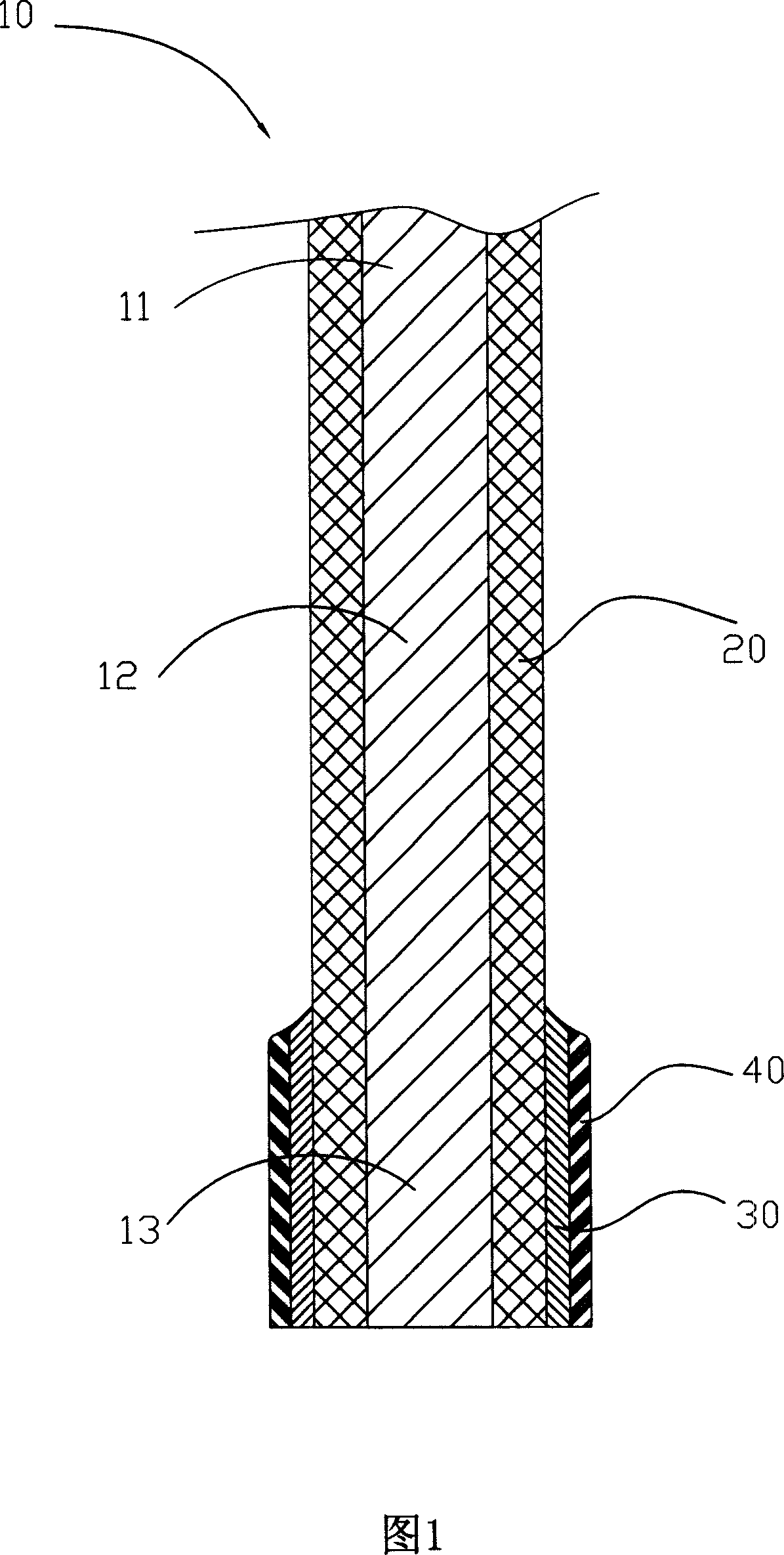

[0010] The method for making the terminal anti-siphon and the terminal manufactured by using the method of the present invention will be further described below in conjunction with the accompanying drawings.

[0011] Please refer to FIG. 1. FIG. 1 is a partial schematic diagram of a terminal with anti-siphon in the present invention. The method for making the terminal anti-siphon includes that the terminal 10 is welded with an external component (such as a circuit board) through solder (not shown). The connecting portion 13, and the connecting portion 12 extended from the connecting portion 13, of course, the connecting portion 12 can further extend the contact portion 11 (only a part of the contact portion 11 is shown in the figure), the contact portion 11 can be The chip module (not shown) or the adapter card (not shown) or other electronic components (not shown) are electrically connected to the circuit board (not shown), and the surface of the connecting part 12 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com