Patents

Literature

48results about How to "Prevent siphon" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

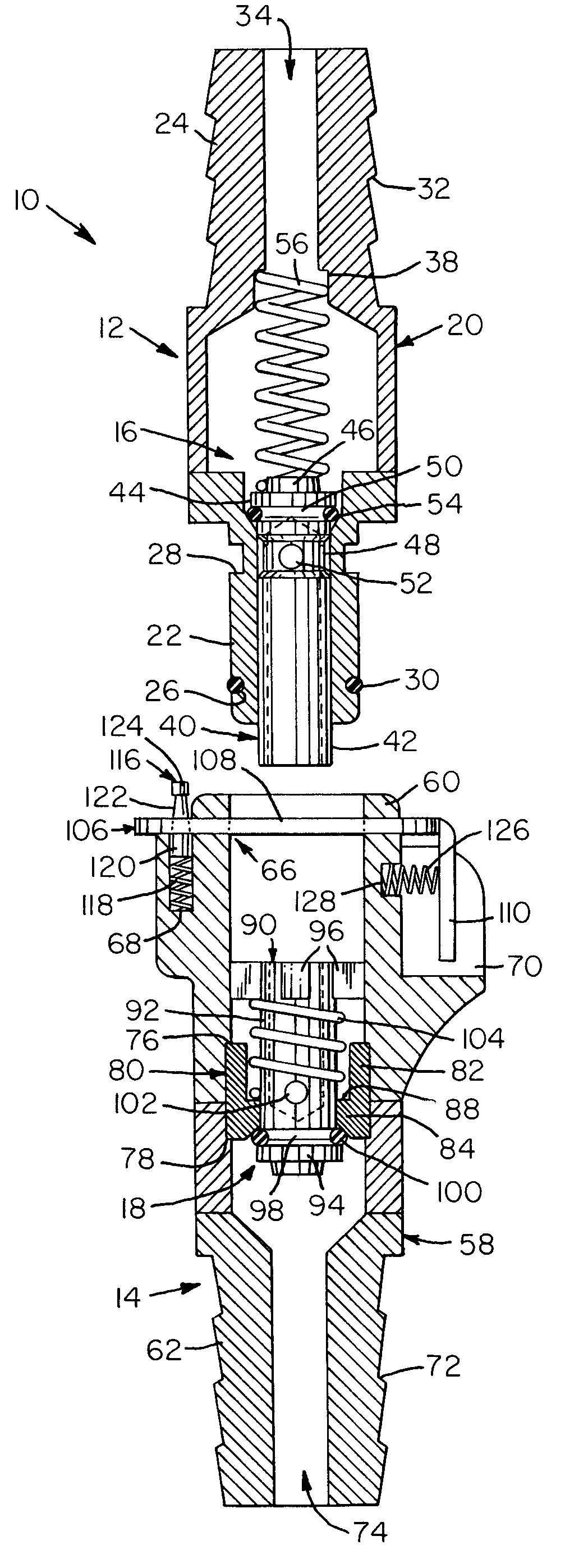

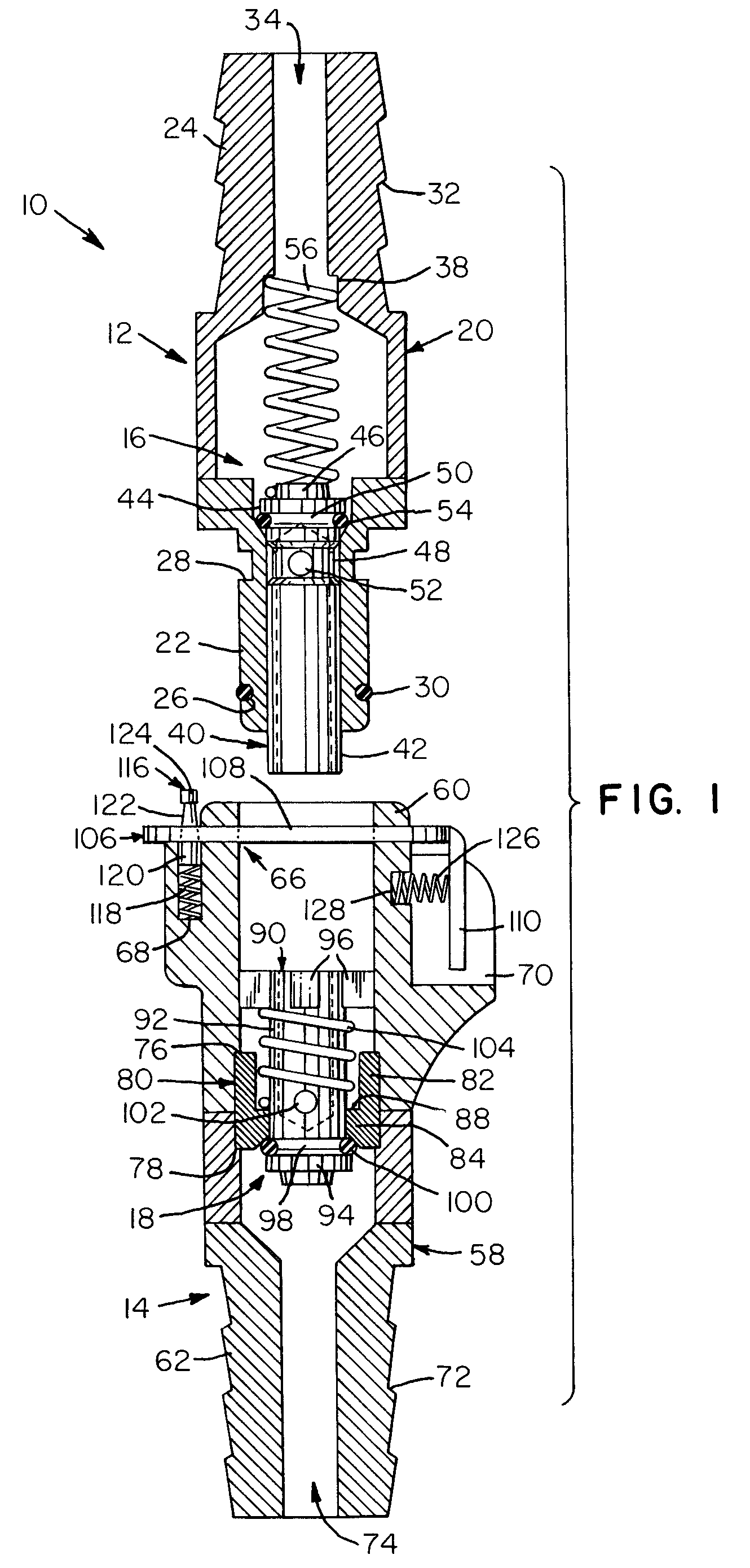

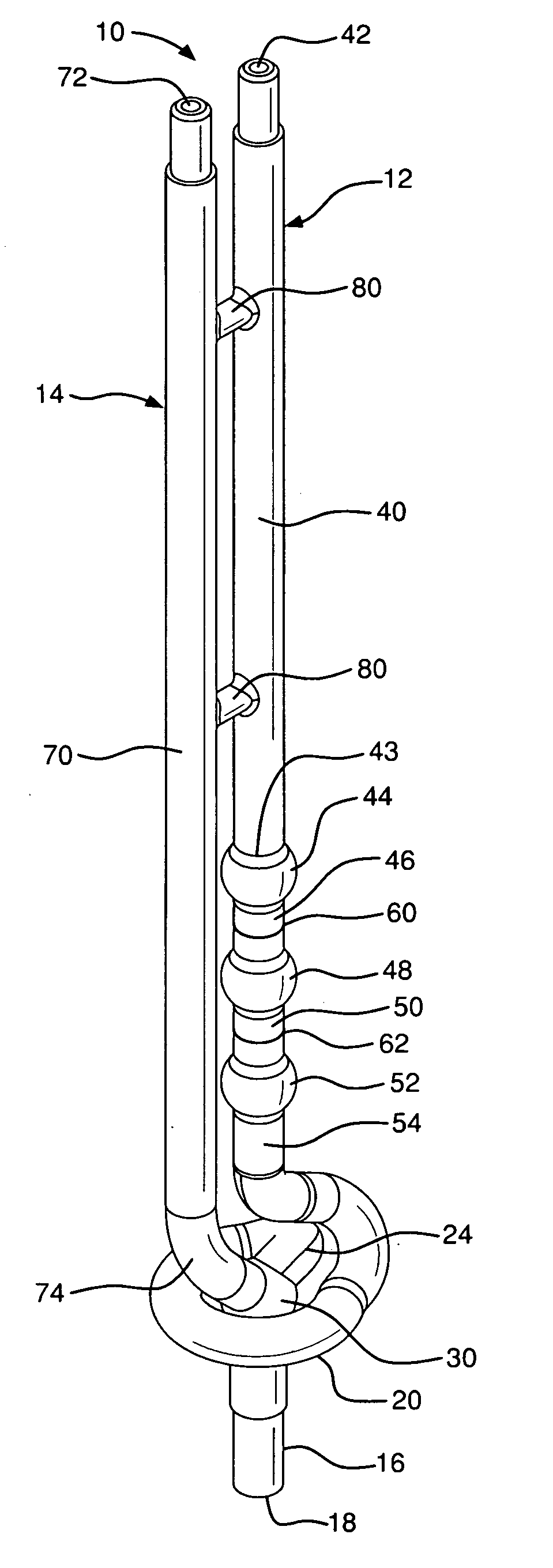

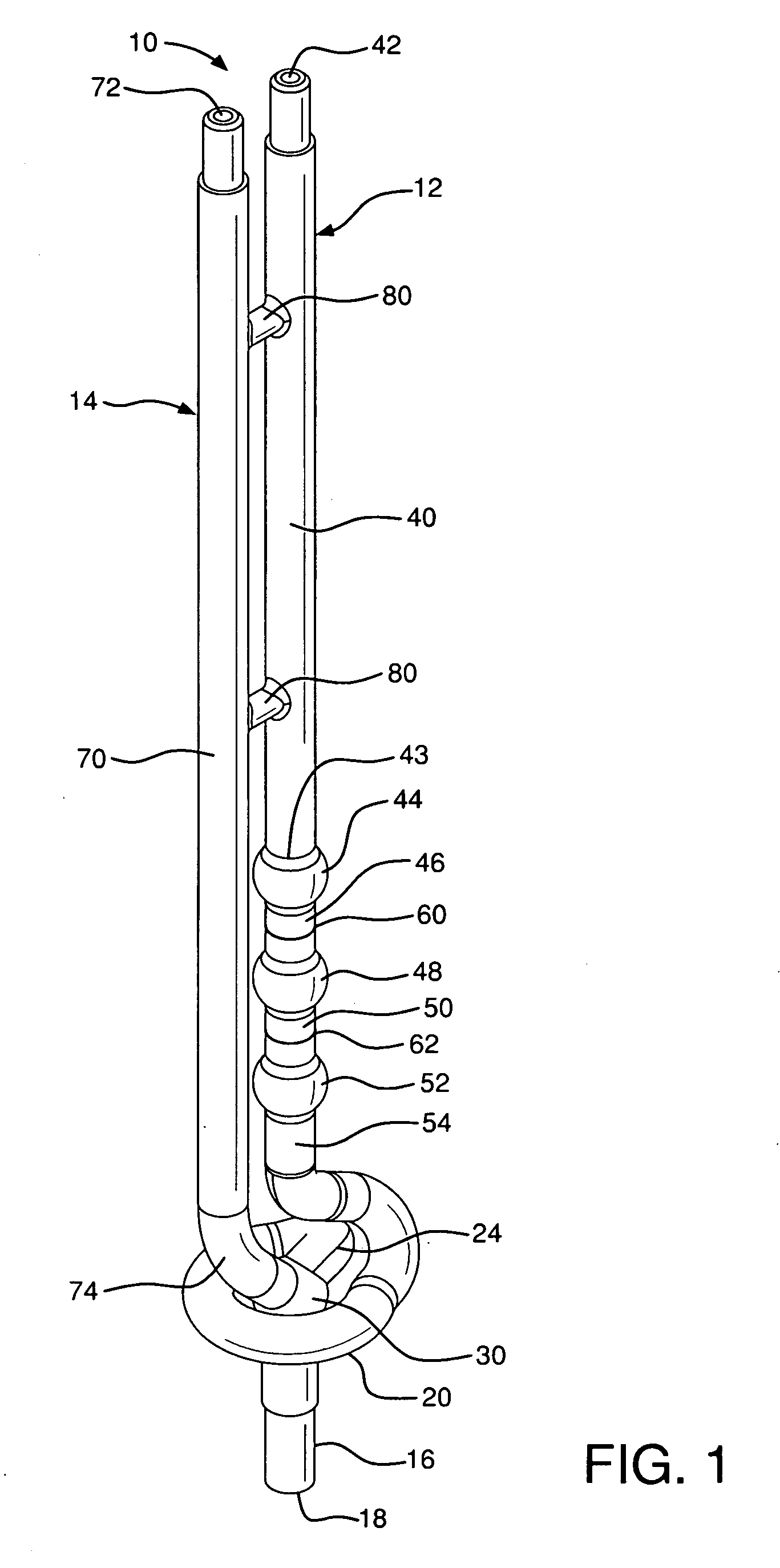

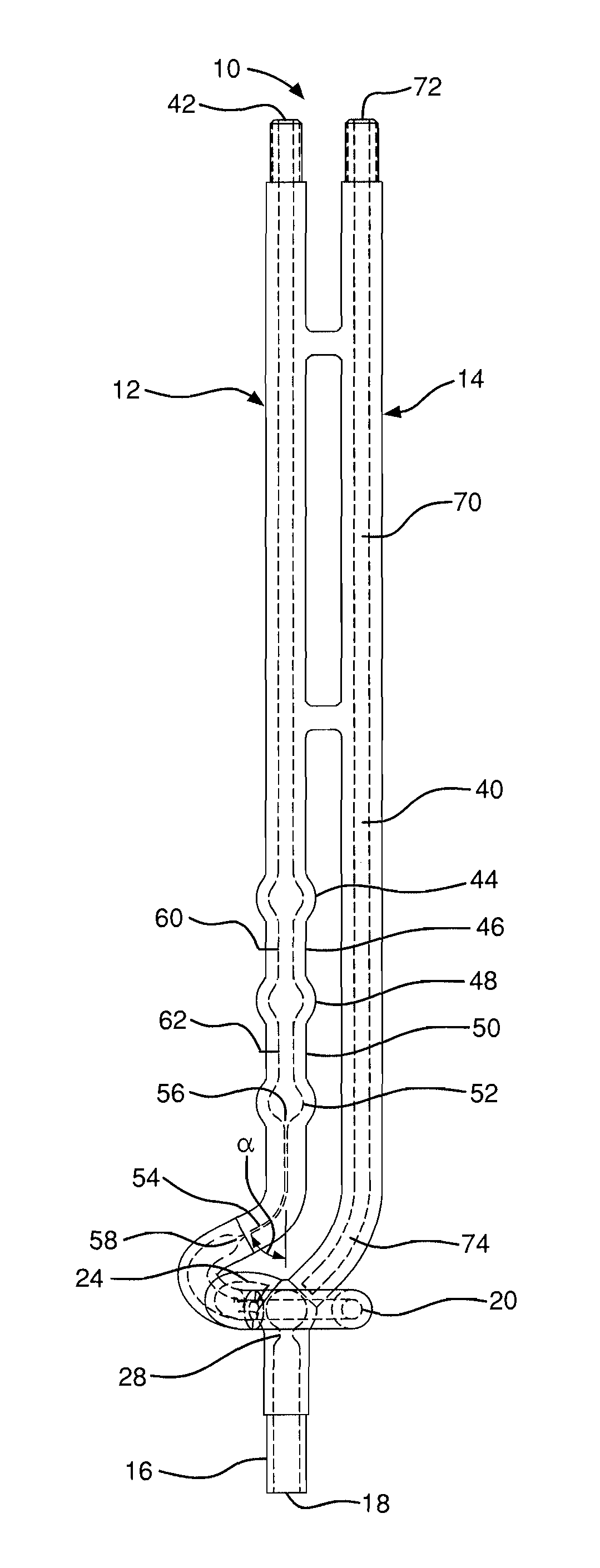

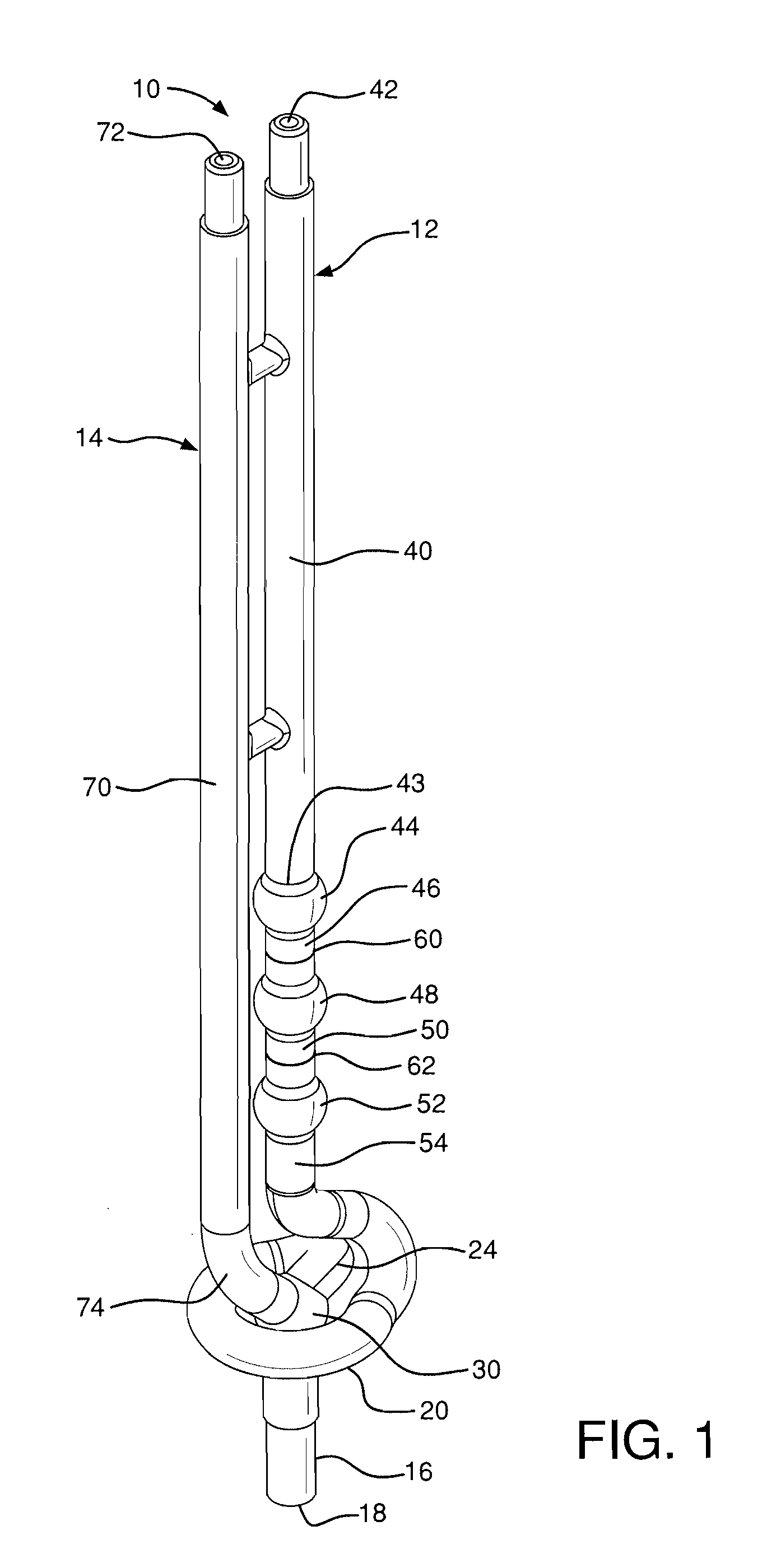

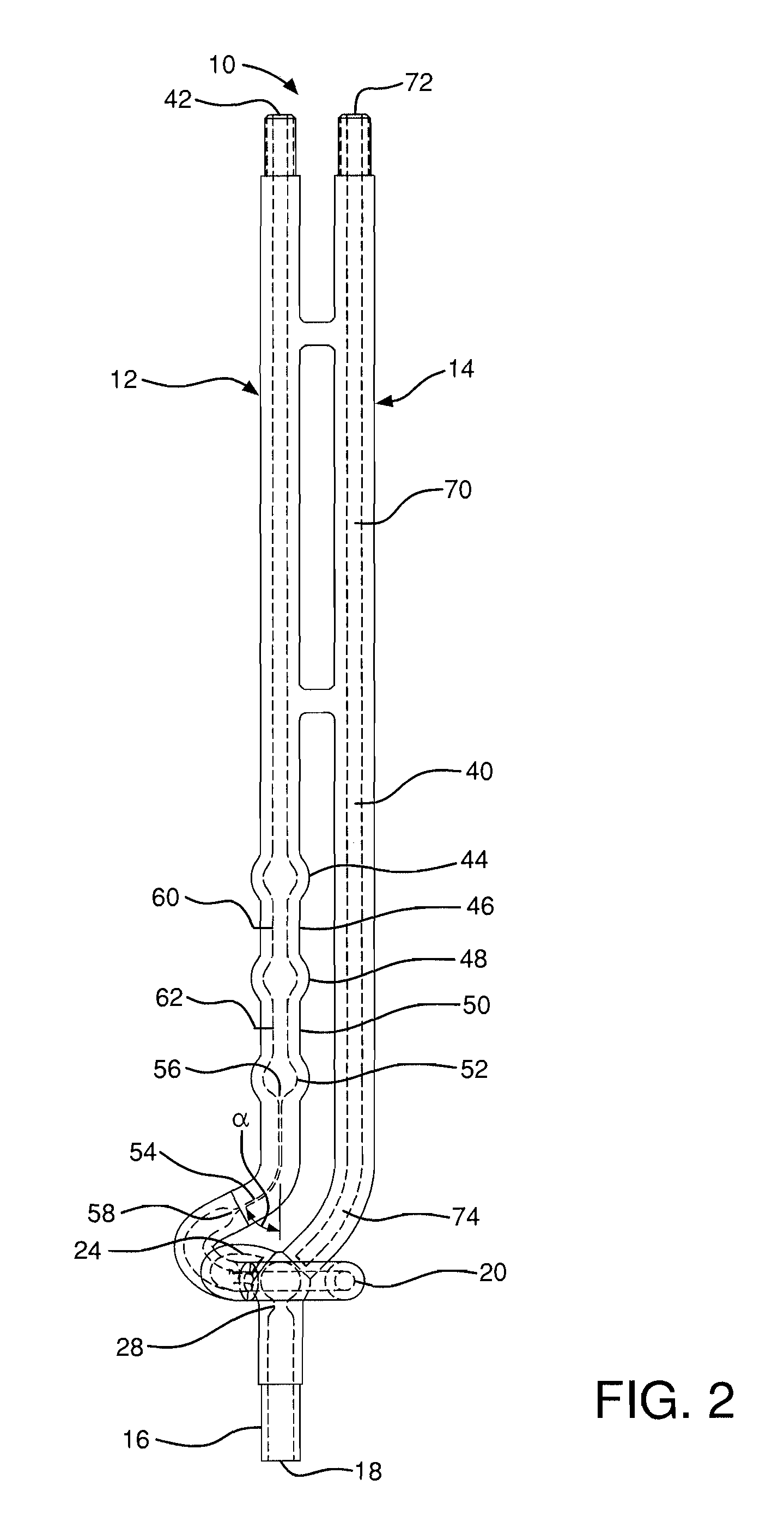

Multi-cycle dump valve

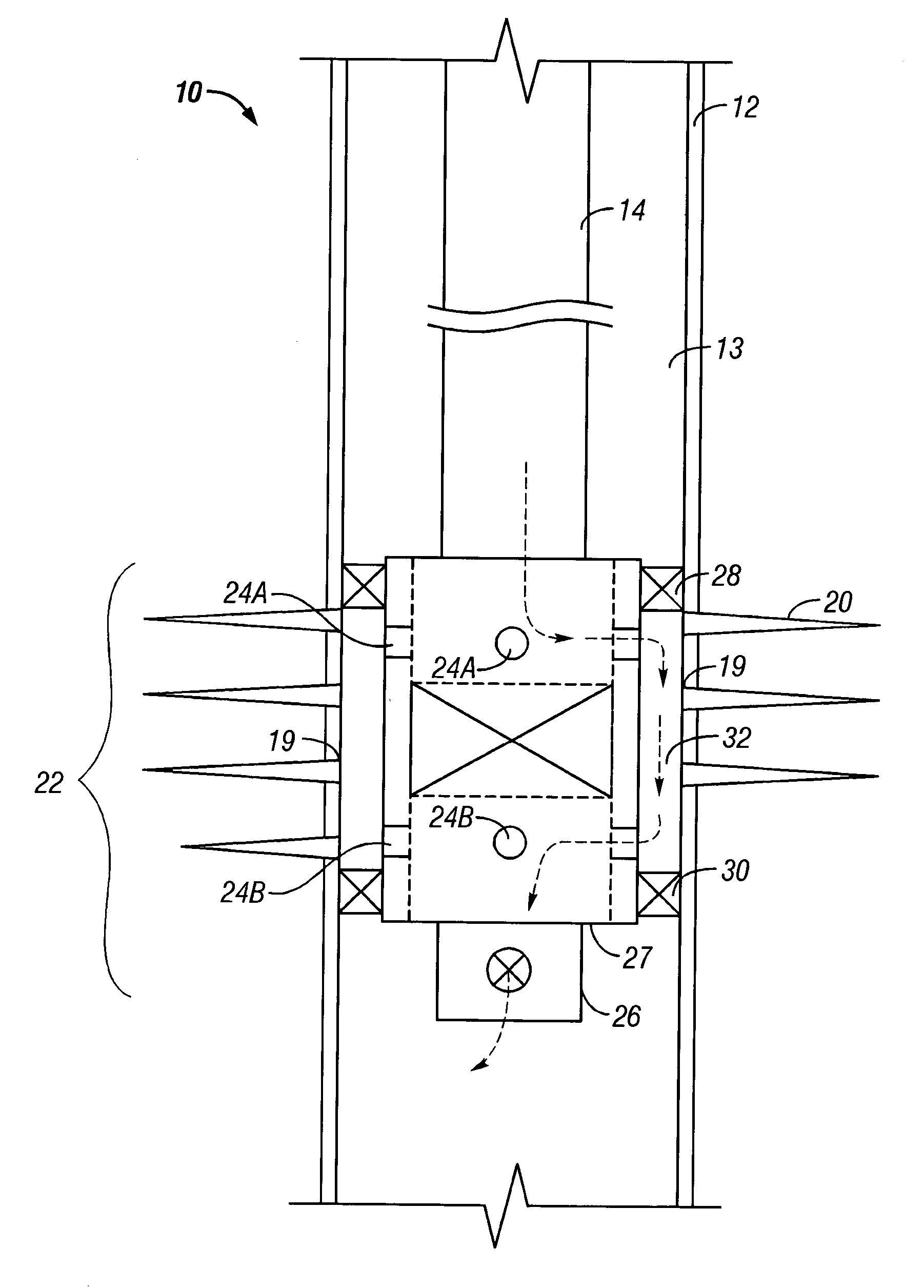

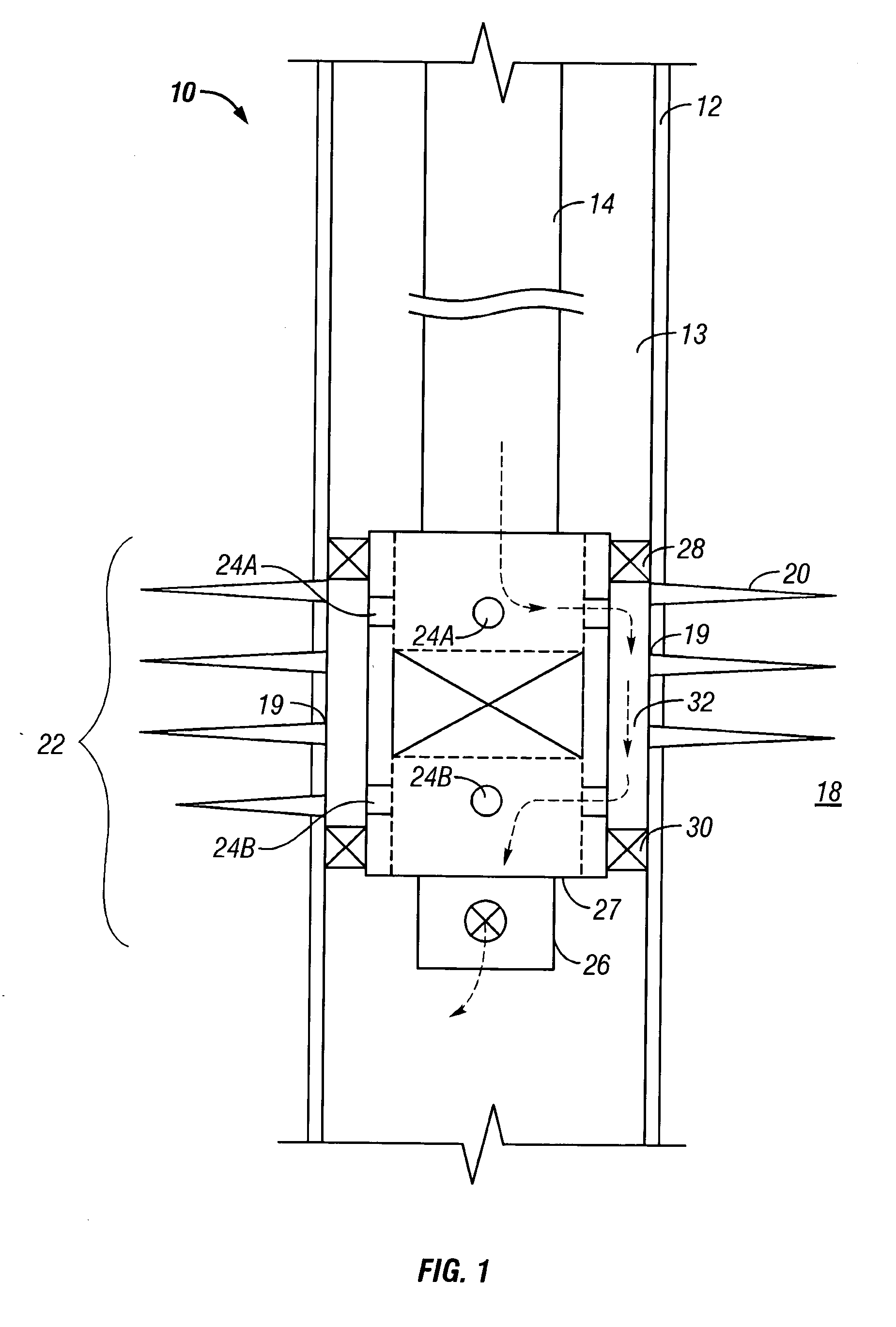

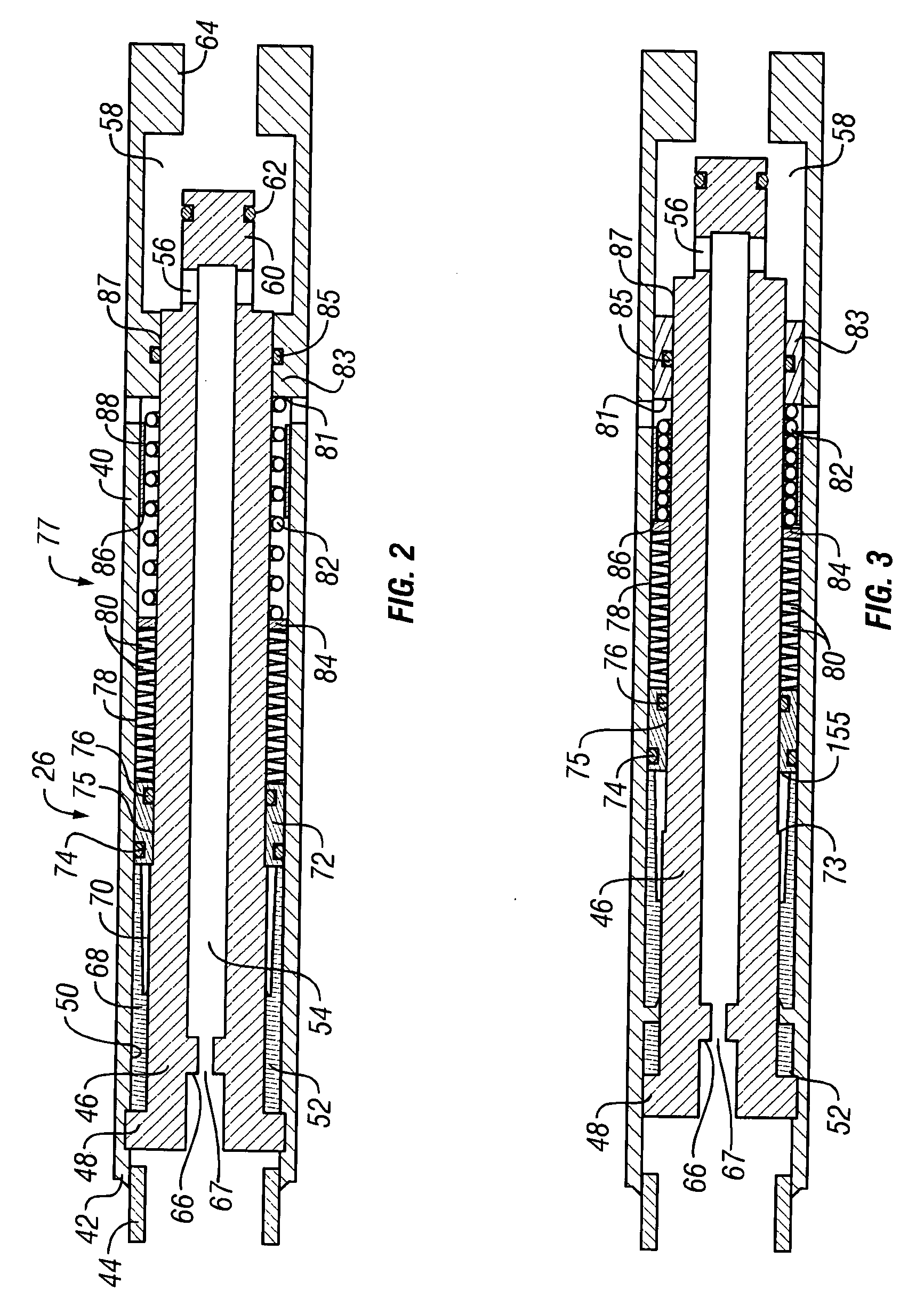

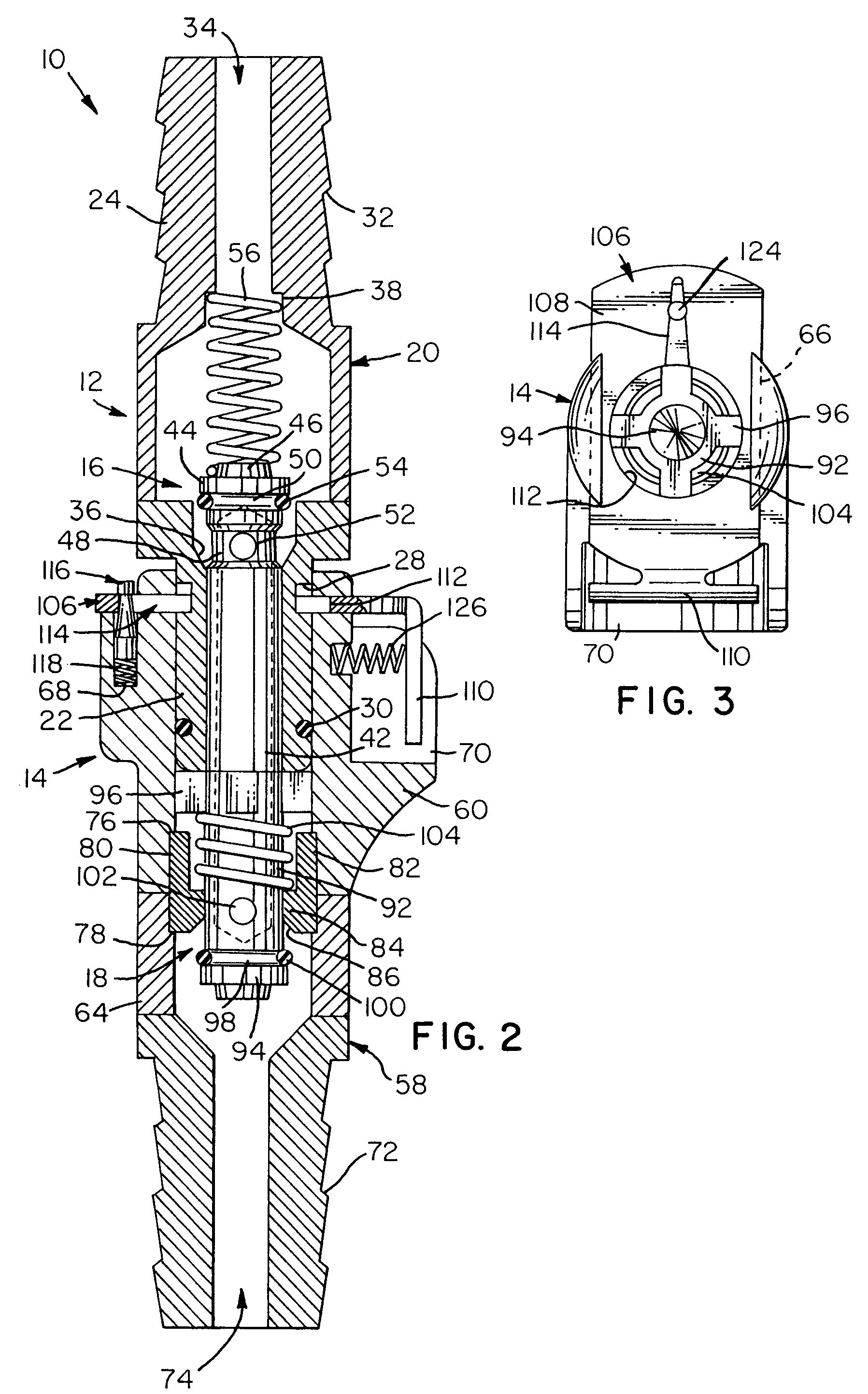

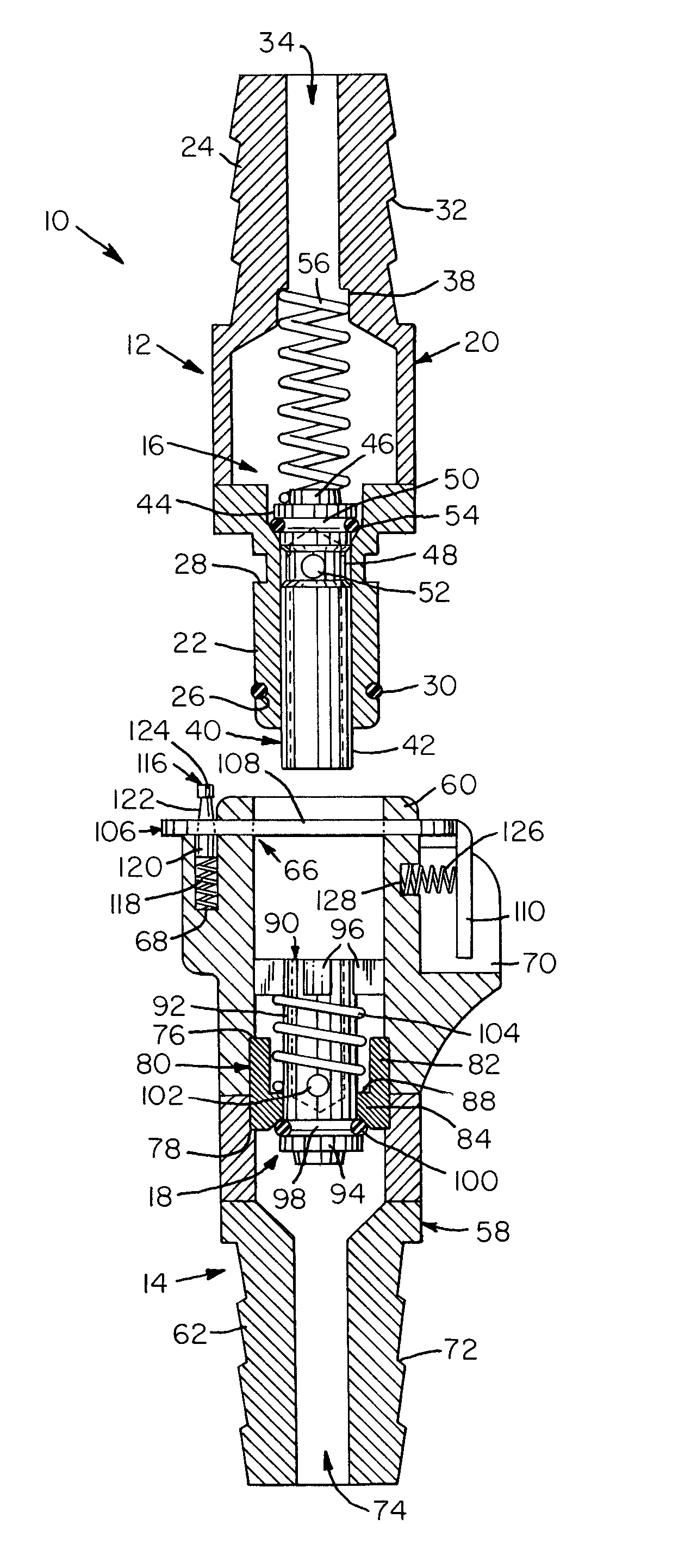

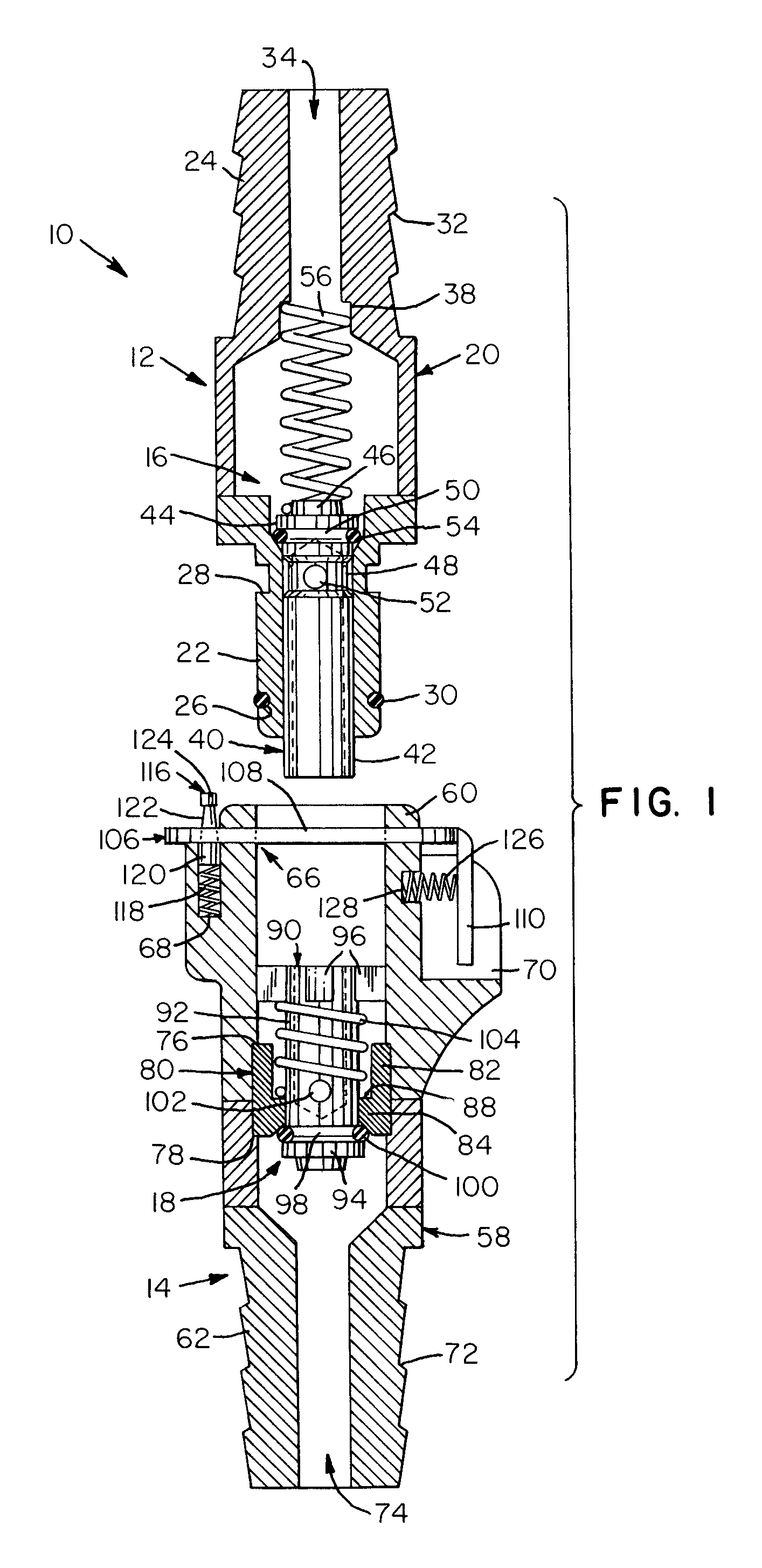

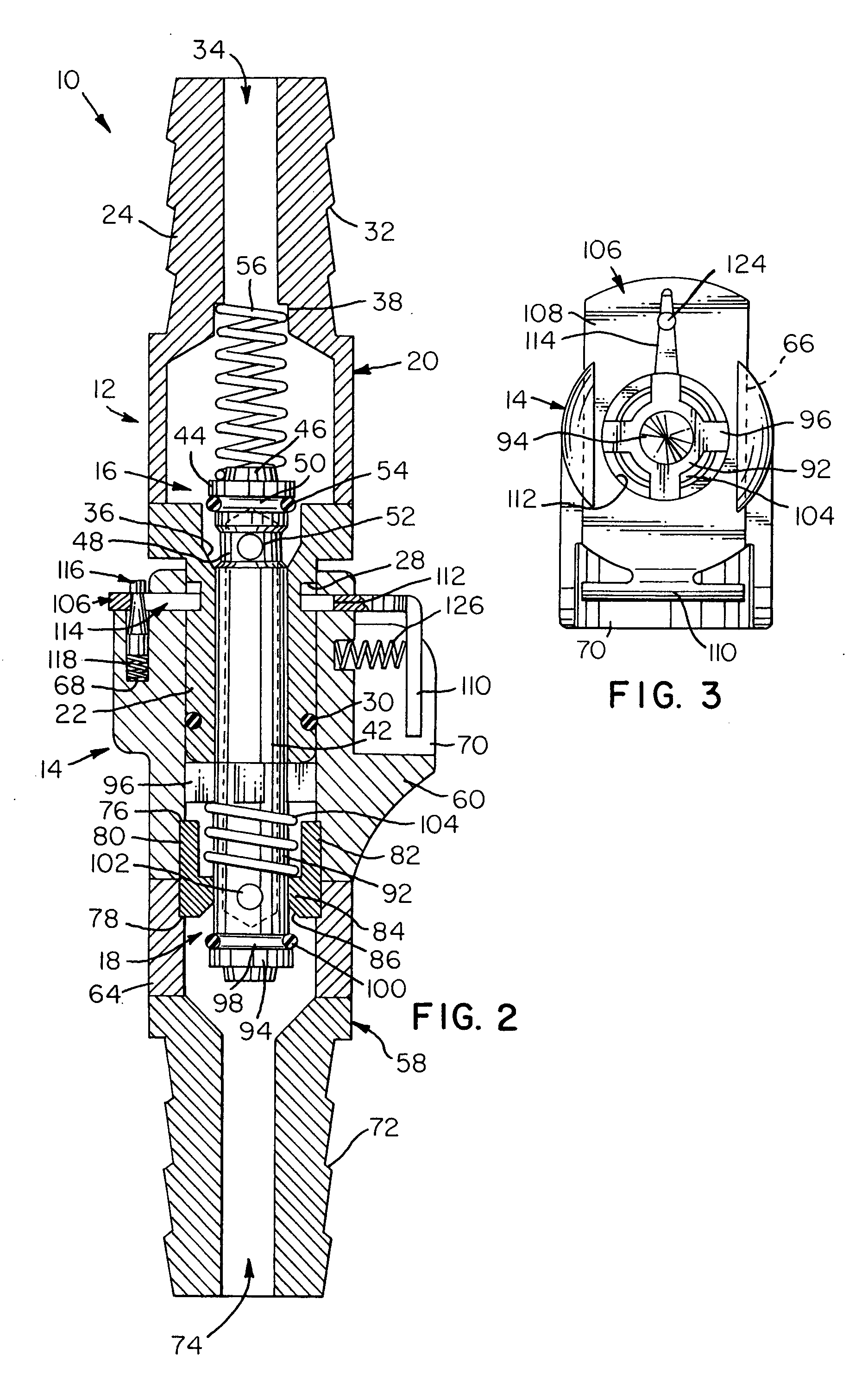

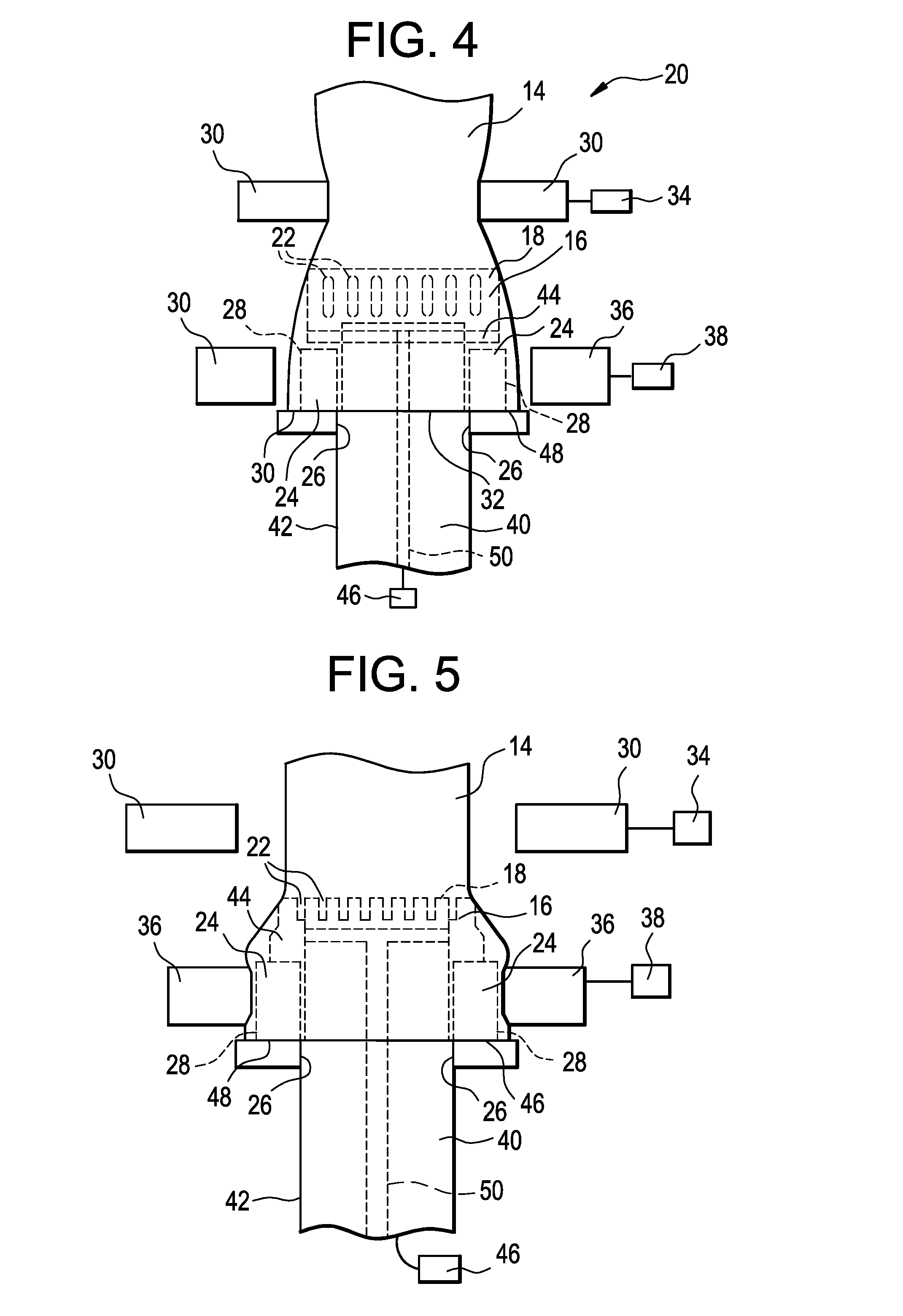

InactiveUS20040084190A1Less timePrevent siphonFluid removalWell/borehole valve arrangementsControl flowFree falling

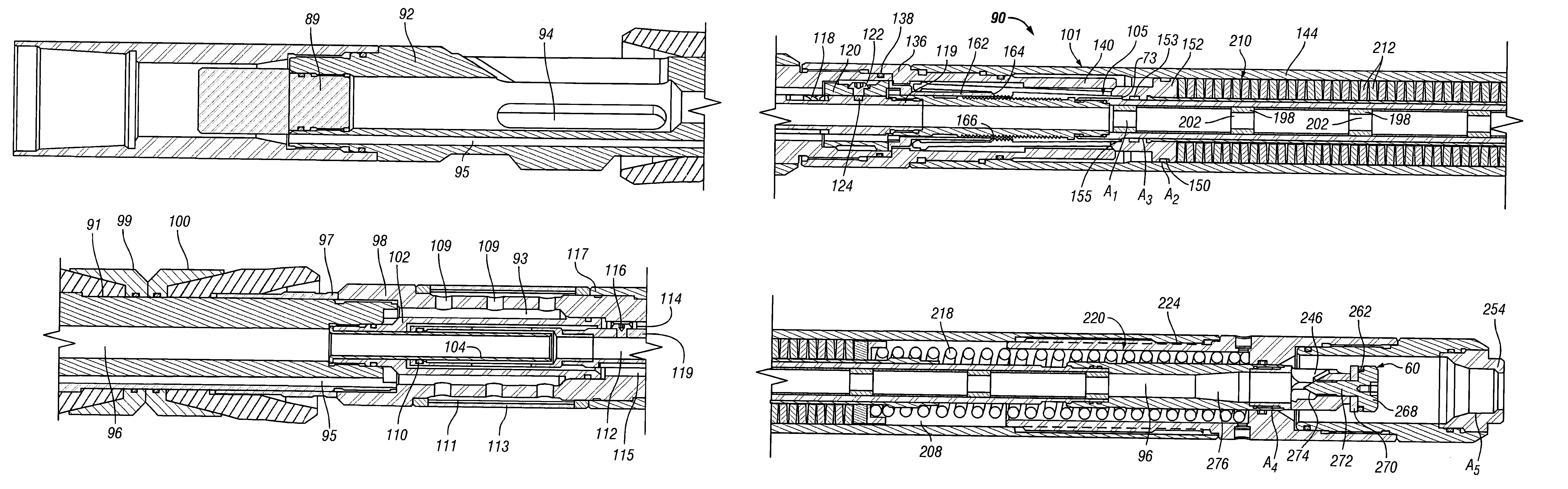

A flow responsive dump valve mechanism for a straddle packer tool and has a valve controlled flow passage from which underflushed fluid, typically well treatment slurry, in a conveyance and fluid supplying tubing string can be dumped into a well casing. The dump valve mechanism incorporates a ratcheting power piston, an indexing mechanism and high and low load energy storage systems to accomplish open, closed and intermediate dump valve positions. The intermediate position increases the functionality of the tool by preventing accidental closure either due to the free fall of fluid through the coiled tubing or during flushing of the tool and permits the flow rate to be increased for thorough cleaning of the straddle tool and coiled tubing. For energy storage, a light compression spring provides power to cycle the indexing mechanism. Heavier load disc springs (Bellville Washers) are used to provide power for the ratcheting power piston to open the valve.

Owner:SCHLUMBERGER TECH CORP

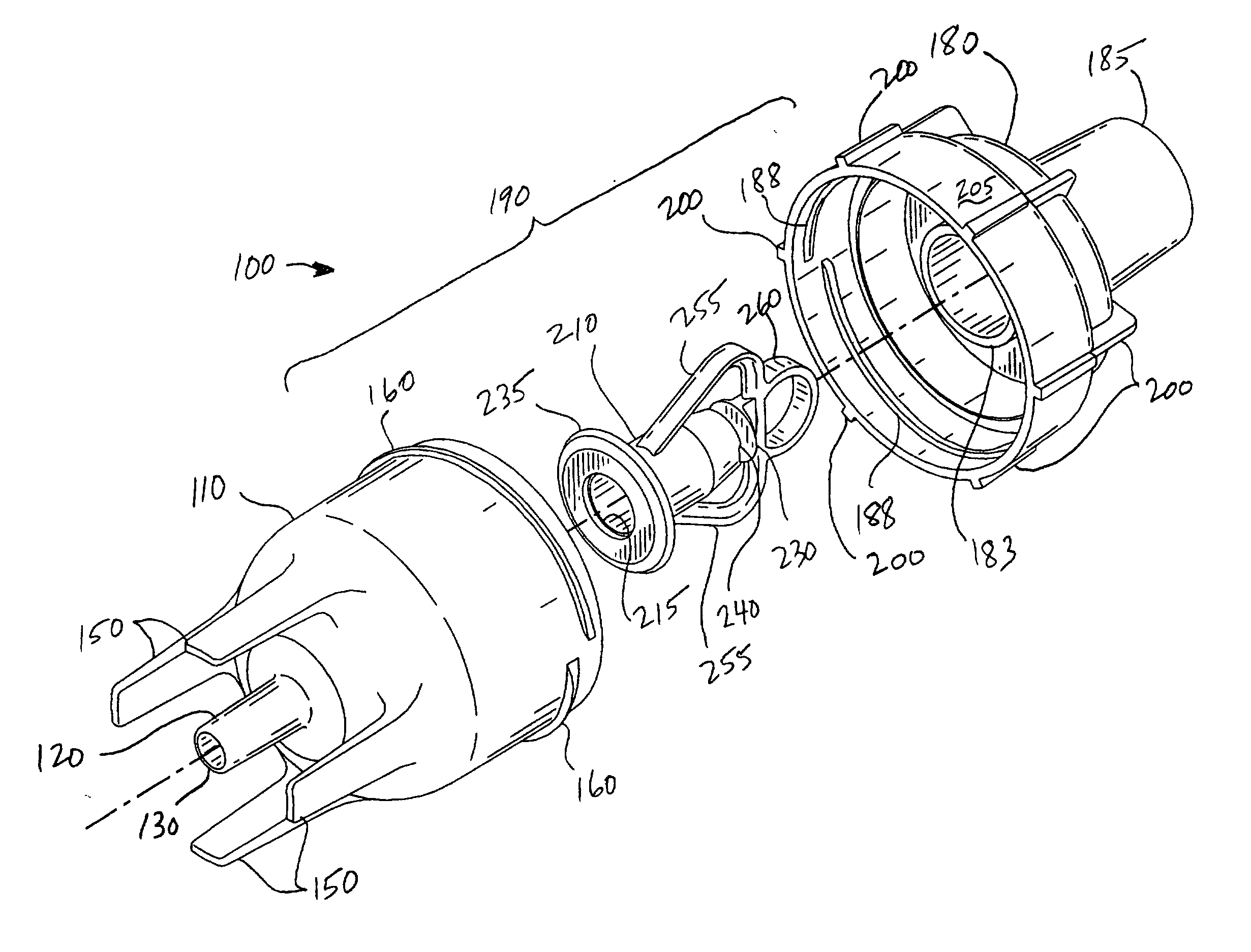

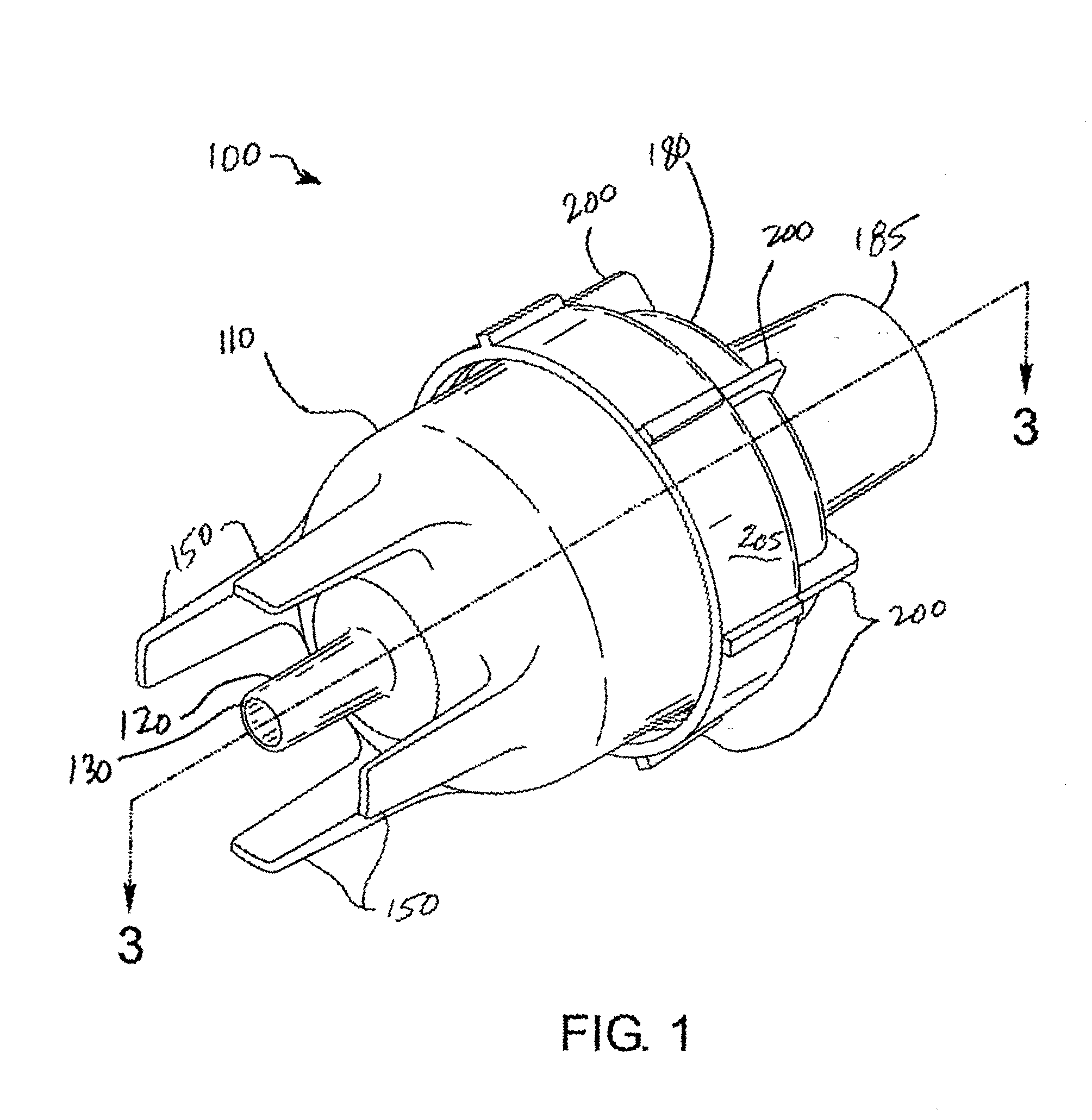

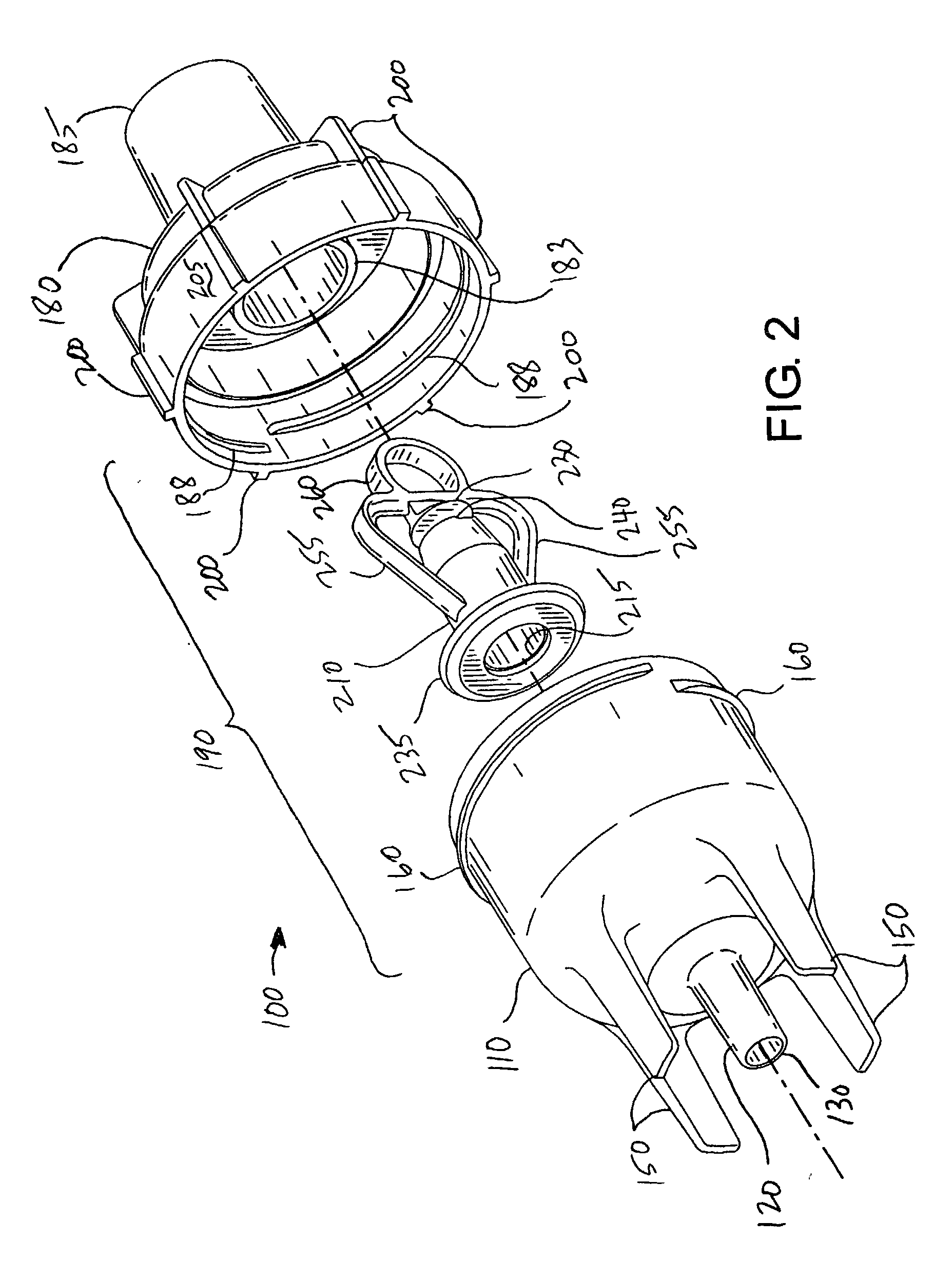

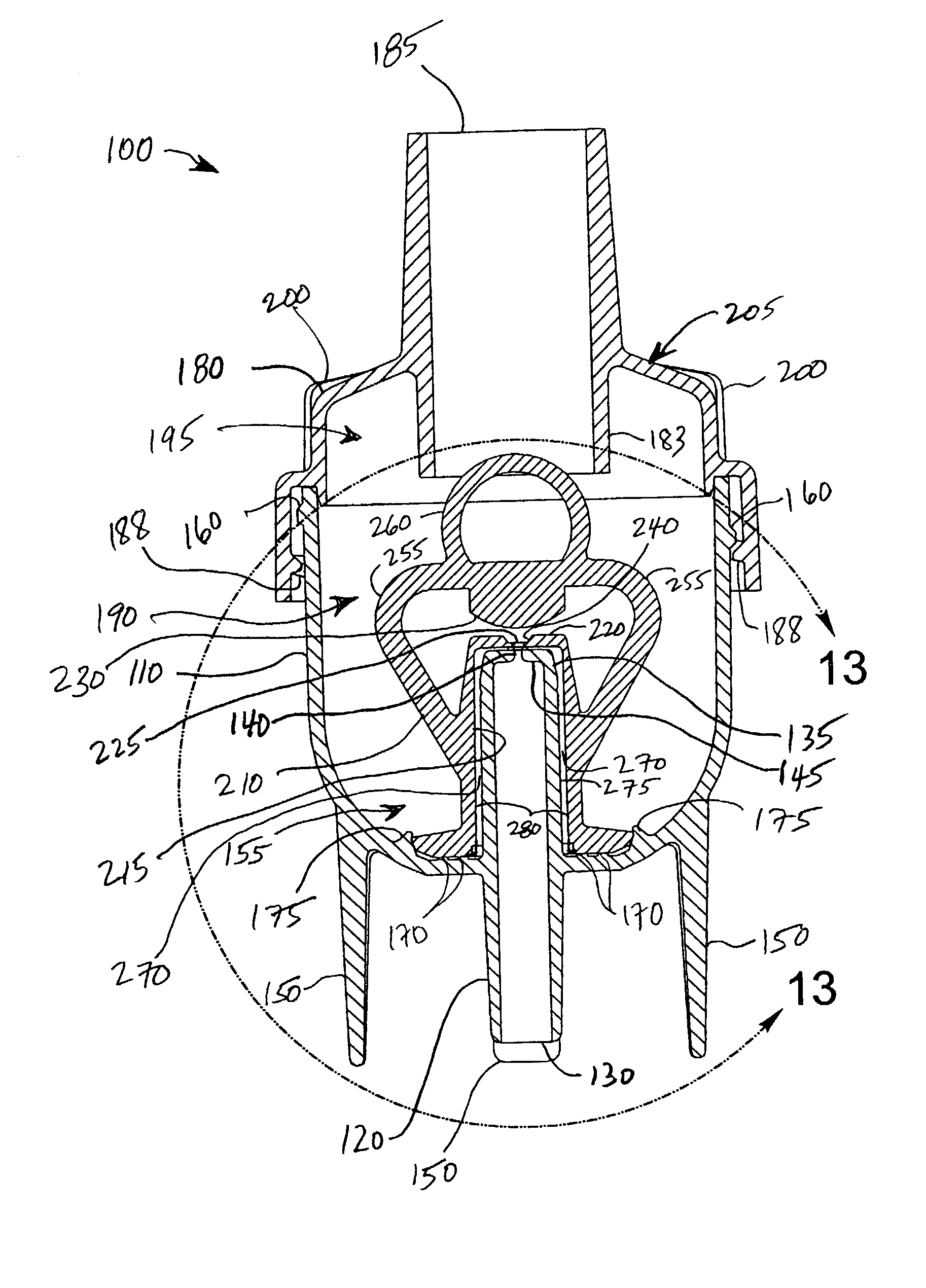

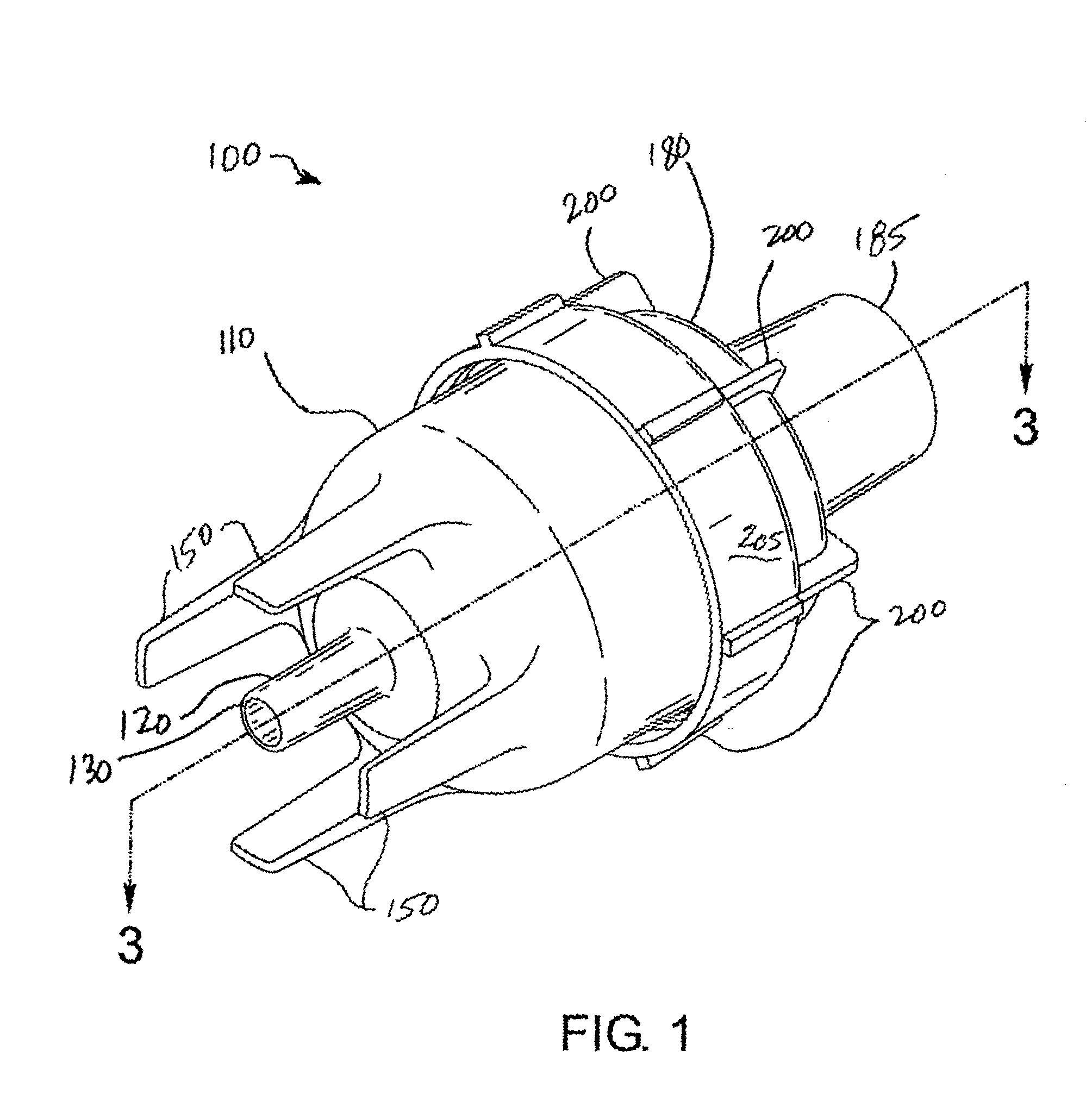

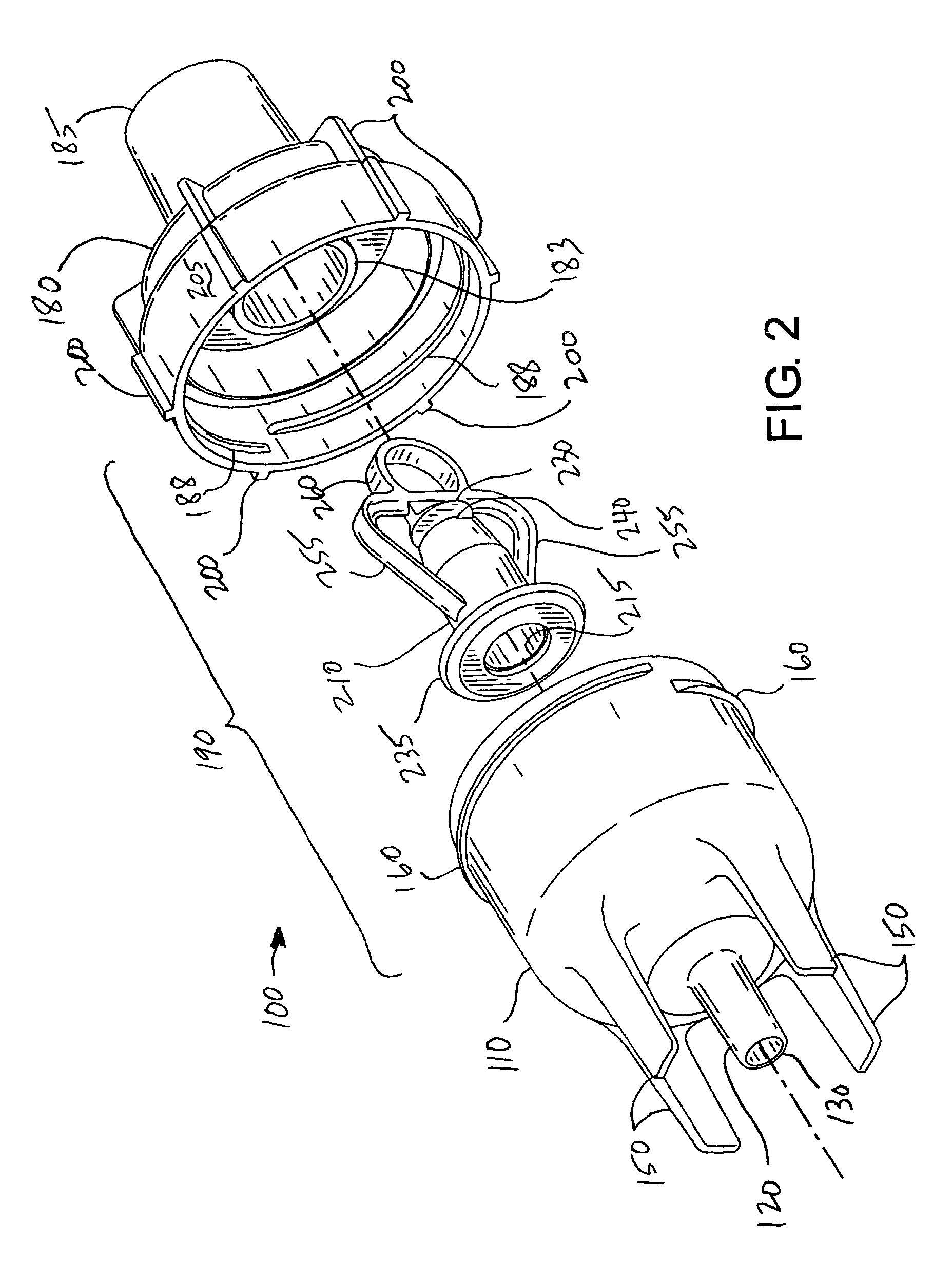

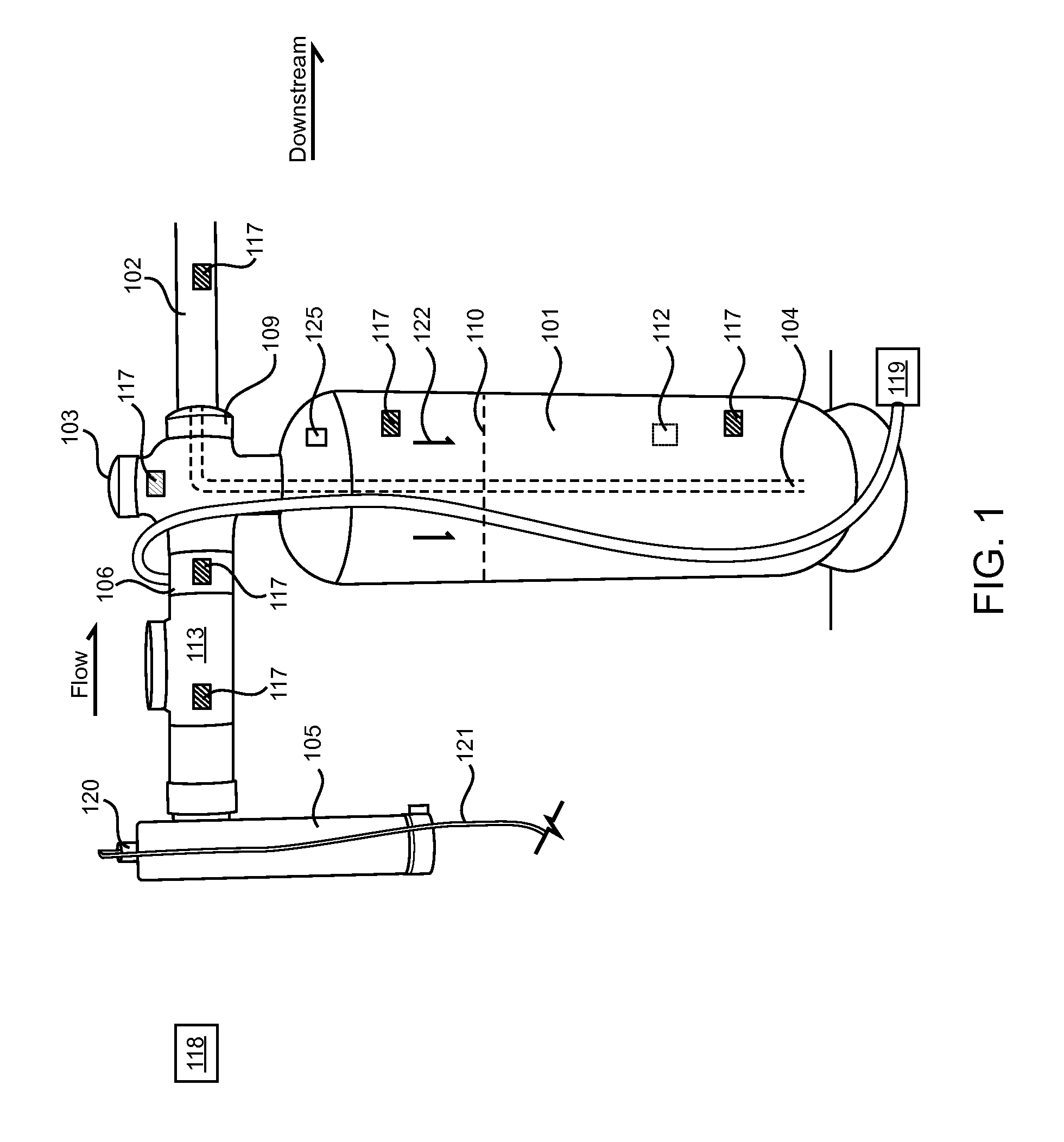

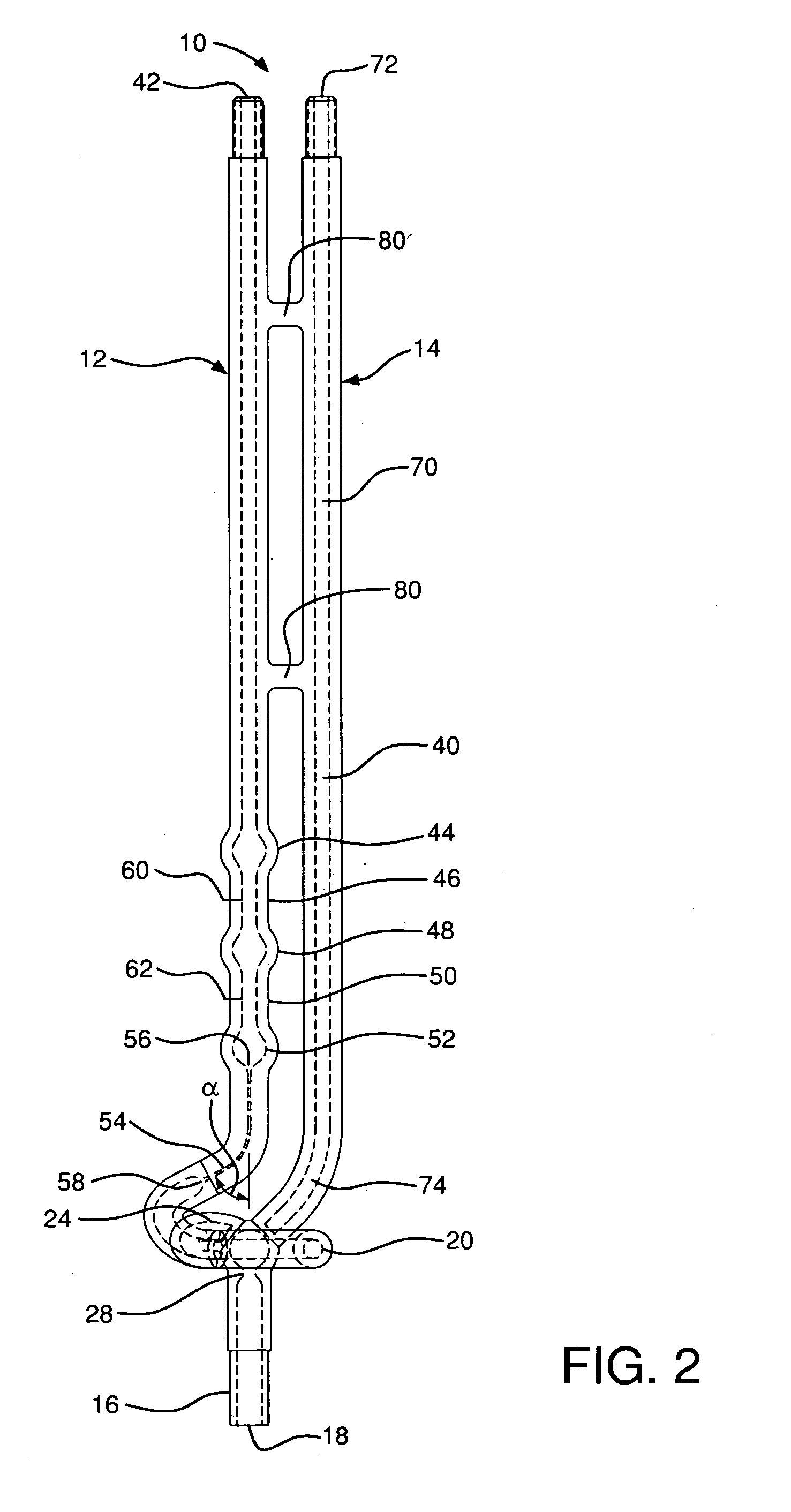

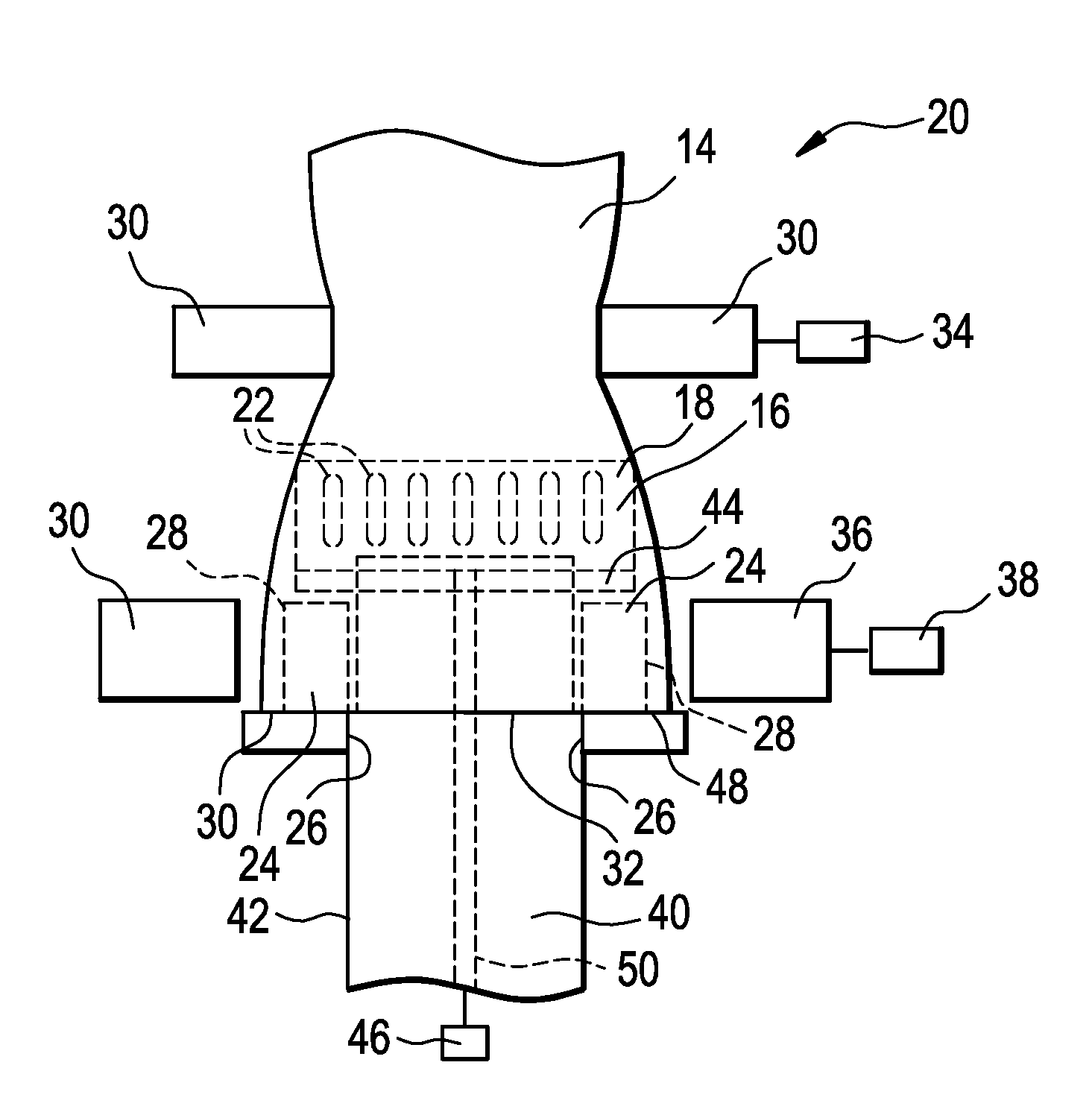

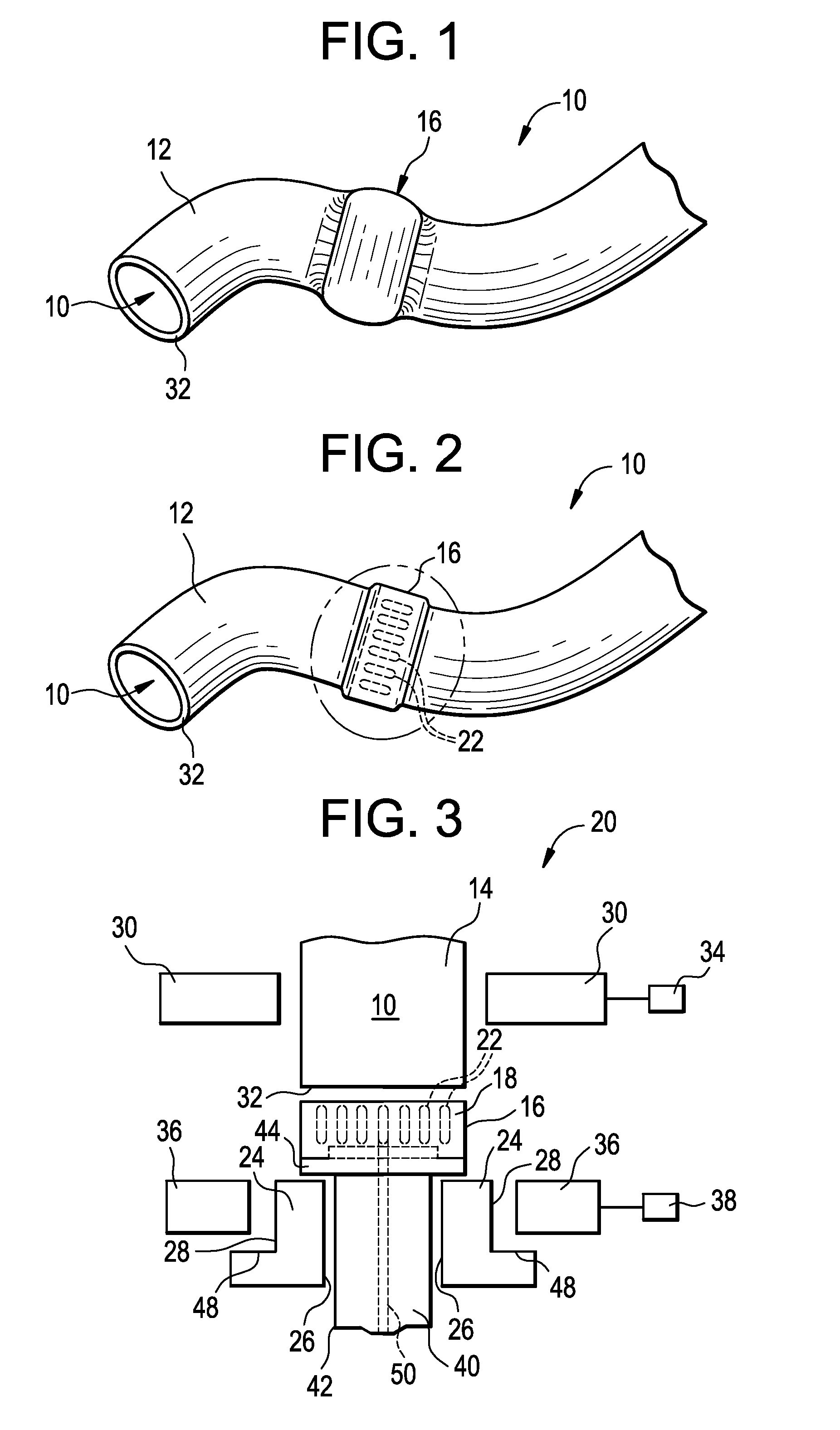

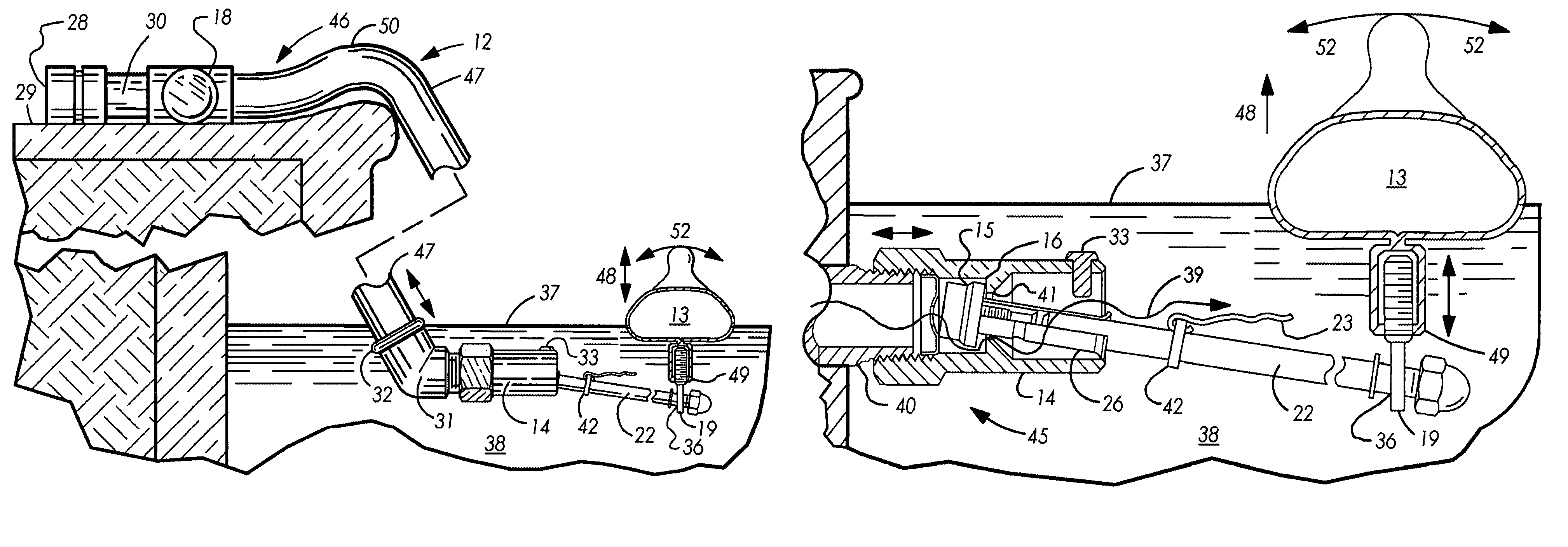

Small volume nebulizer

ActiveUS20040031485A1Minimize energy lossMinimize decelerationRespiratorsSpray nozzlesNebulizerProximate

An atomizing nebulizer for dispensing a substance or medicament is described. The nebulizer is formed with a reservoir base releasably secured to an effluent vent cap that together capture a diffuser and integral dispersing baffle that are further formed with an uptake lumen or channel terminating with a nozzle jet. The diffuser dispersing baffle is positioned relative to the jet nozzle to optimize atomization of any of a number of such substances so as to maximize disbursement of the substance. The reservoir base also incorporates a pressurized fluid-accelerating inlet tube terminated with a metering orifice that cooperates with the nozzle jet when the inlet tube is received within the diffuser uptake lumen or channel. When so received, the nozzle jet axially registers proximate and superior to the orifice to establish a vacuum space that is in fluid communication with a capillary interstice established between the walls of the exterior of the inlet tube and the confronting interior surface of the diffuser lumen or channel. When a pressurized fluid is communicated through the lumen, the orifice, and into the vacuum space towards the nozzle jet, a vacuum develops in the vacuum space that, in combination with the capillary action of the interstice, draws the fluid proximate to the orifice and disperses it into droplets that are then entrained into a fluid stream to be further atomized upon impact with the baffle and then dispensed.

Owner:SUNMED GRP HLDG LLC

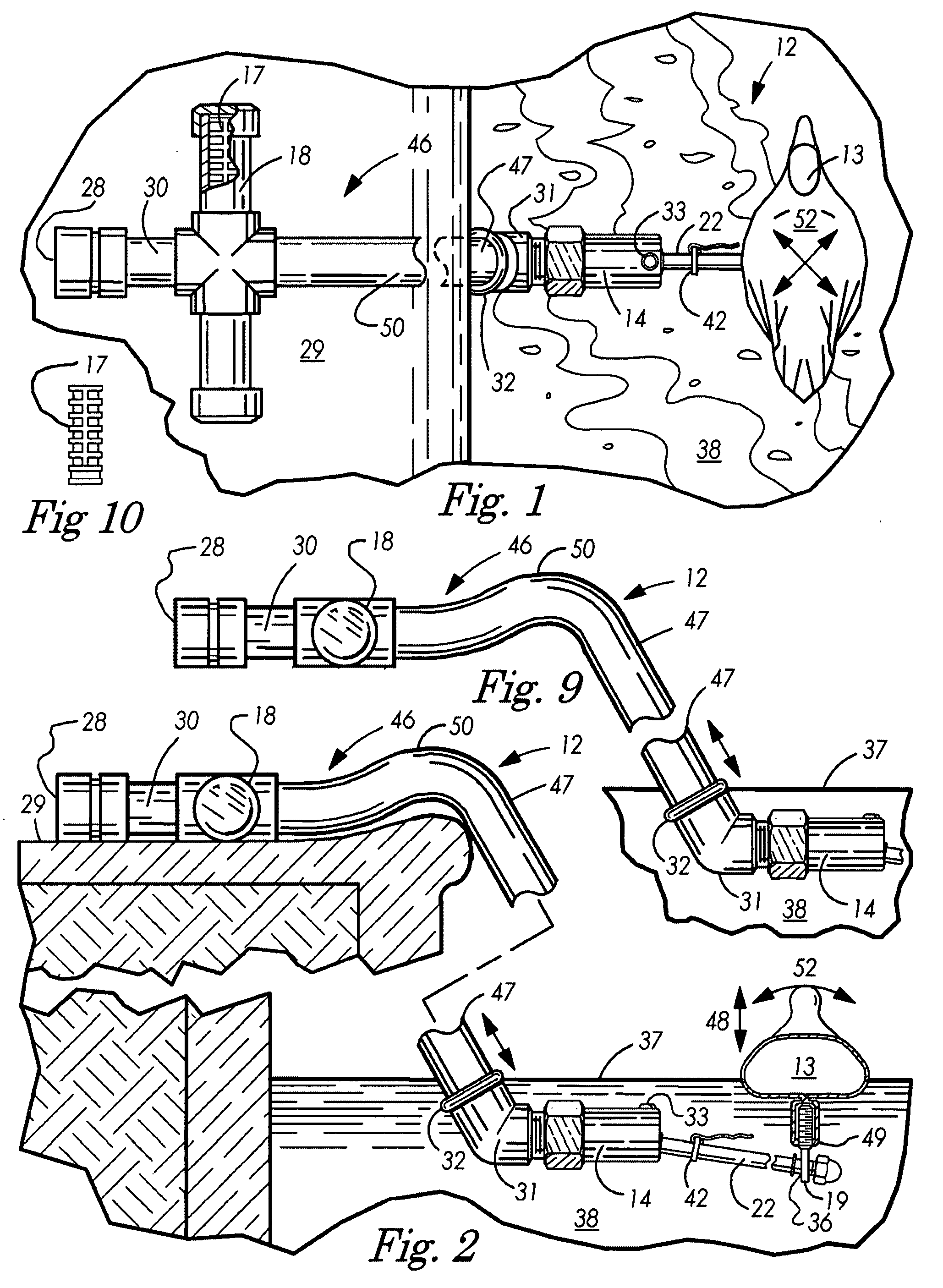

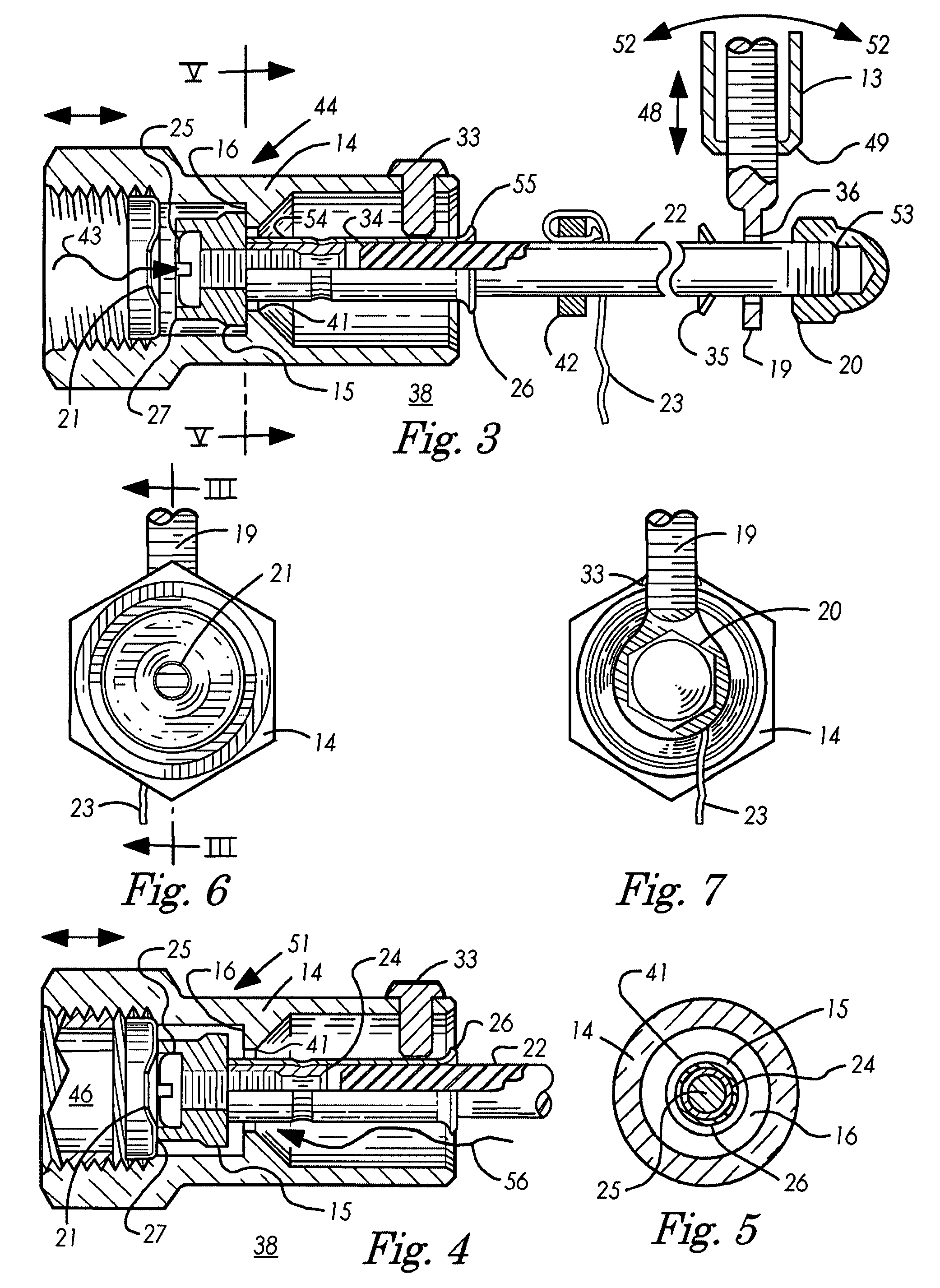

Releasable tubing connector

Owner:MITCHELL MARTIN S

Releasable tubing connector

InactiveUS20050101939A1Easy to operatePrevent siphonValve arrangementsWound drainsEngineeringVALVE PORT

Owner:MITCHELL MARTIN S

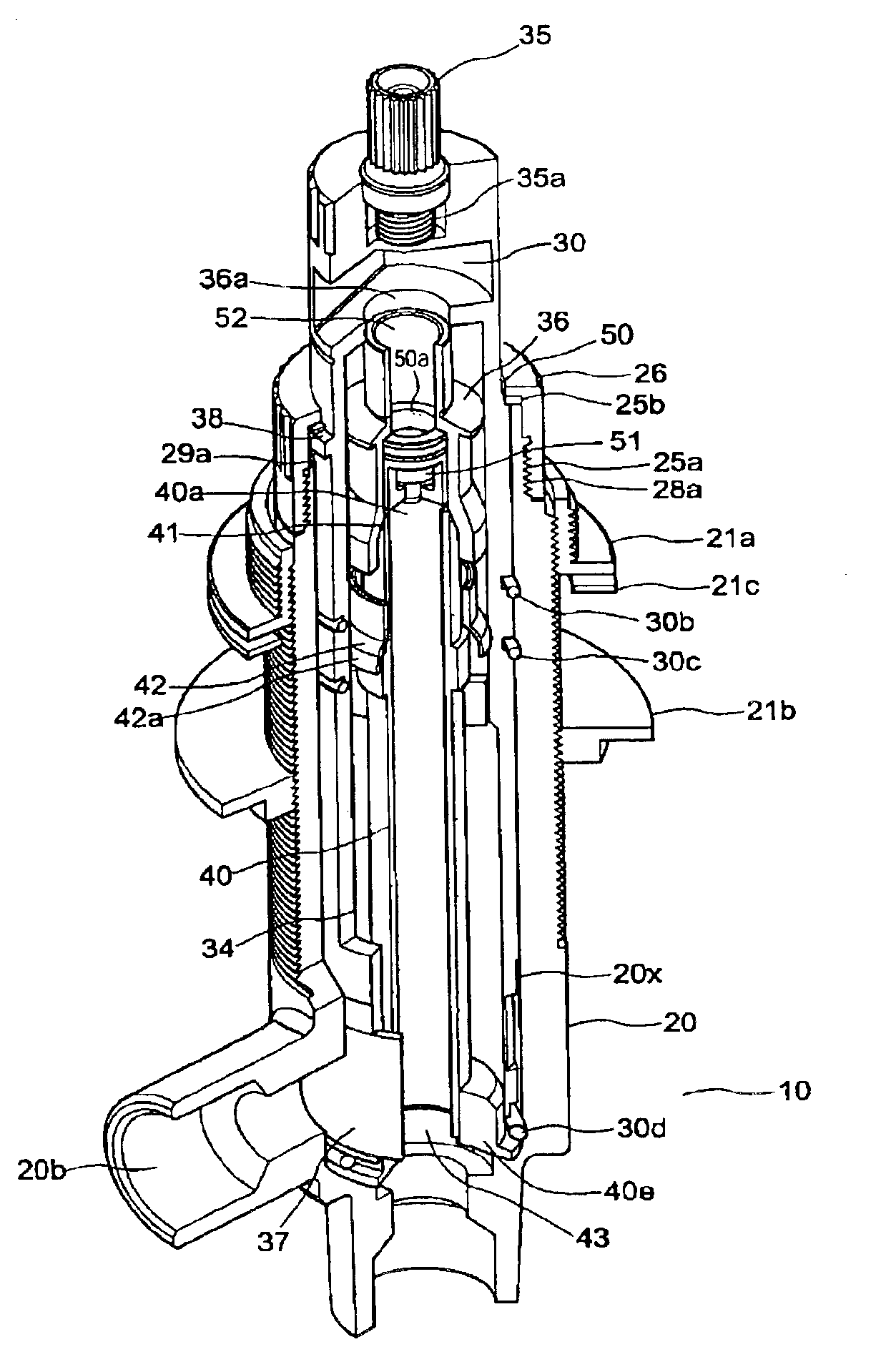

Multi-cycle dump valve

InactiveUS7090020B2Less timePrevent siphonFluid removalWell/borehole valve arrangementsControl flowFree falling

A flow responsive dump valve mechanism for a straddle packer tool and has a valve controlled flow passage from which underflushed fluid, typically well treatment slurry, in a conveyance and fluid supplying tubing string can be dumped into a well casing. The dump valve mechanism incorporates a ratcheting power piston, an indexing mechanism and high and low load energy storage systems to accomplish open, closed and intermediate dump valve positions. The intermediate position increases the functionality of the tool by preventing accidental closure either due to the free fall of fluid through the coiled tubing or during flushing of the tool and permits the flow rate to be increased for thorough cleaning of the straddle tool and coiled tubing. For energy storage, a light compression spring provides power to cycle the indexing mechanism. Heavier load disc springs (Bellville Washers) are used to provide power for the ratcheting power piston to open the valve.

Owner:SCHLUMBERGER TECH CORP

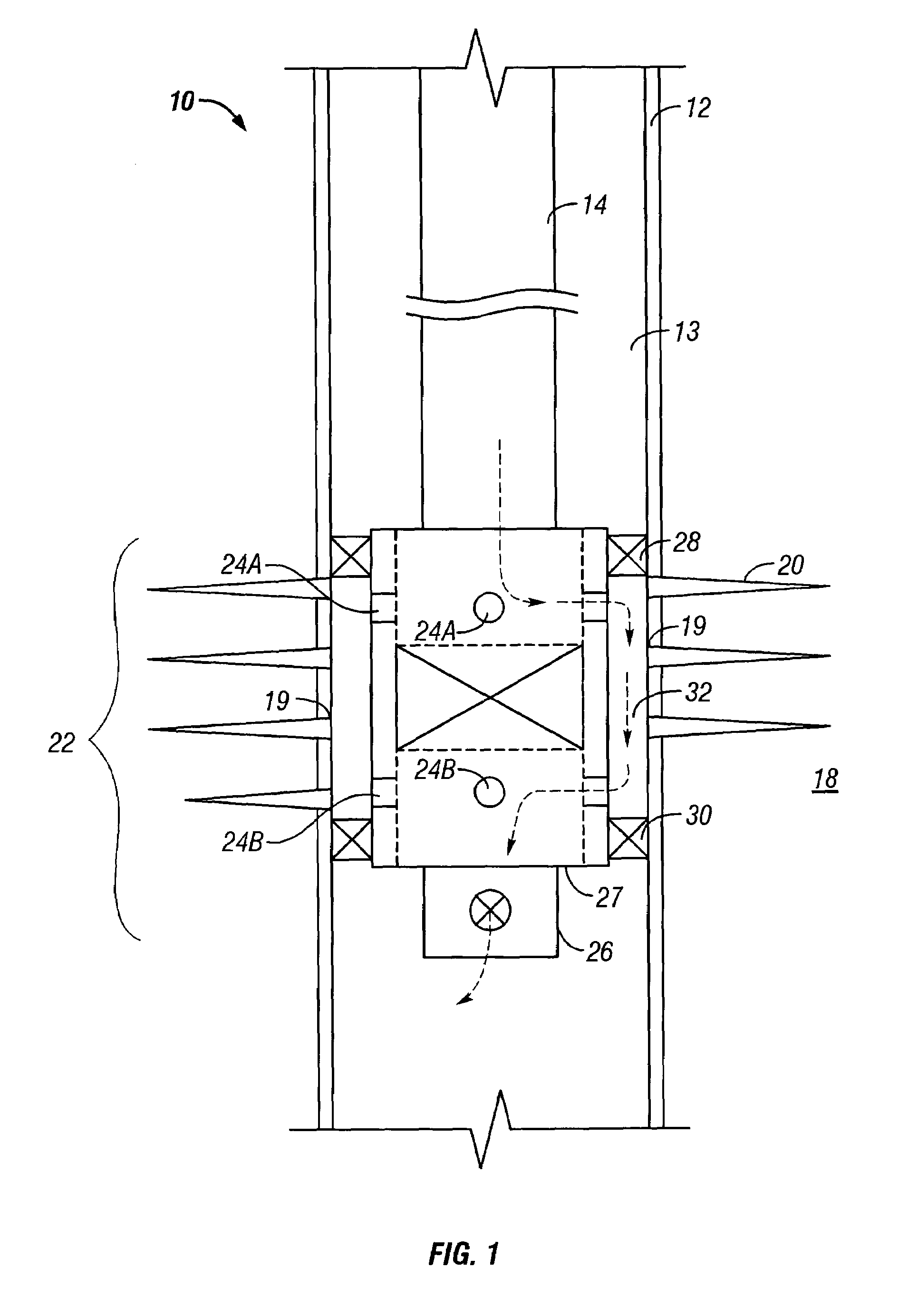

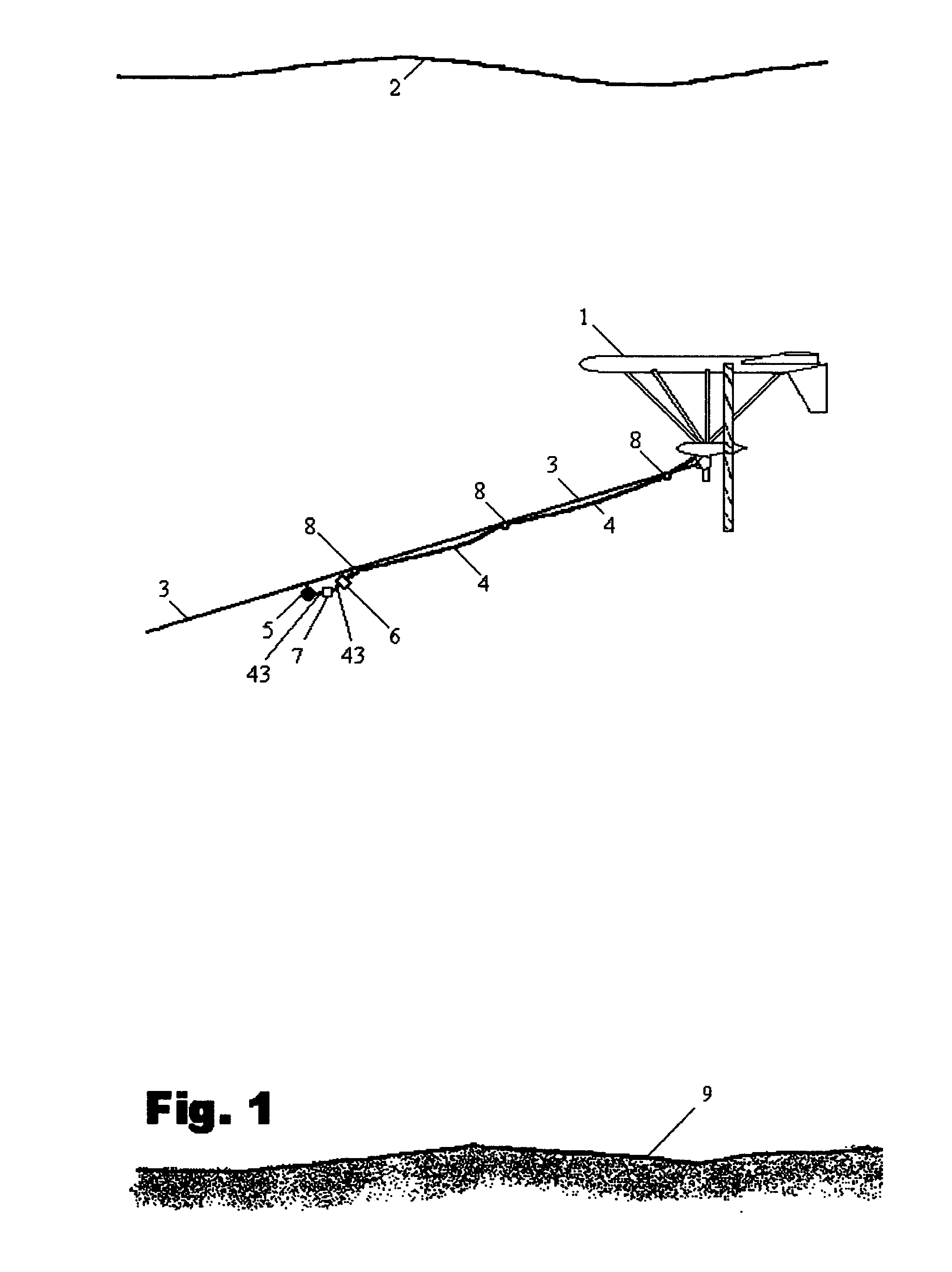

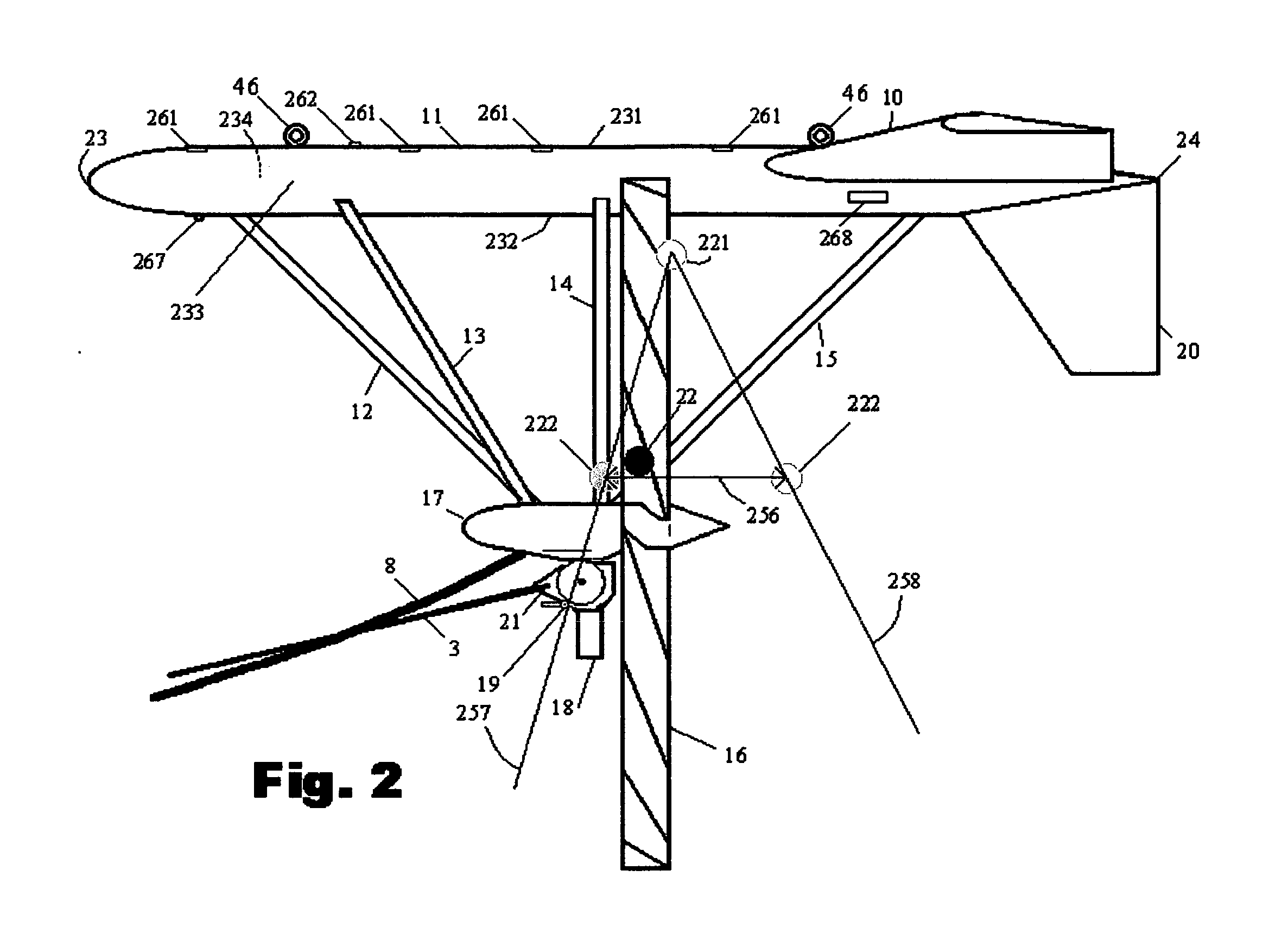

Submersible electrical power generating plant

InactiveUS20070257492A1Improved directional stabilitySuperior located center of buoyancyEnergy industryMachines/enginesNacelleHorizontal axis

Owner:ROBSON JOHN H

Small volume nebulizer

An atomizing nebulizer for dispensing a substance or medicament is described. The nebulizer is formed with a reservoir base releasably secured to an effluent vent cap that together capture a diffuser and integral dispersing baffle that are further formed with an uptake lumen or channel terminating with a nozzle jet. The diffuser dispersing baffle is positioned relative to the jet nozzle to optimize atomization of any of a number of such substances so as to maximize disbursement of the substance. The reservoir base also incorporates a pressurized fluid-accelerating inlet tube terminated with a metering orifice that cooperates with the nozzle jet when the inlet tube is received within the diffuser uptake lumen or channel. When so received, the nozzle jet axially registers proximate and superior to the orifice to establish a vacuum space that is in fluid communication with a capillary interstice established between the walls of the exterior of the inlet tube and the confronting interior surface of the diffuser lumen or channel. When a pressurized fluid is communicated through the lumen, the orifice, and into the vacuum space towards the nozzle jet, a vacuum develops in the vacuum space that, in combination with the capillary action of the interstice, draws the fluid proximate to the orifice and disperses it into droplets that are then entrained into a fluid stream to be further atomized upon impact with the baffle and then dispensed.

Owner:SUNMED GRP HLDG LLC

Urinal cartridge with improved performance

InactiveUS20080028504A1Prevent siphonSealant loss is minimizedBathroom accessoriesDomestic plumbingDraining tubeWastewater

A cartridge for placement in a urinal includes a chamber having an entry for receiving wastewater (e.g., urine), a quantity of sealant floatable on the wastewater in the chamber for functioning as a barrier to odors that may otherwise emanate from the wastewater in the chamber, a sealant reservoir coupled to the chamber for containing a supply of the sealant, and a closed path sealant dispenser for dispensing the sealant from the sealant reservoir to the chamber for maintaining the sealant modicum atop the wastewater. The sealant dispenser includes a cap having a U-shaped channel, and opening, and an orifice entering into a throat in which the sealant floats. An air vent avoids the buildup of suction in the primary reservoir. A secondary reservoir may be coupled to the sealant reservoir primarily for retaining additional sealant, in addition to any wastewater that might accompany the sealant for conserving sealant, and is particularly useful to avoid the deleterious effects of water being dumped into cartridge, particularly, sealant that is flushed out and into drain through the outlet-to-drain compartment, which flushing has a minimal effect on the sealant in the secondary reservoir. If desired, a water reservoir may be housed within the cartridge.

Owner:FALCON WATERLESS TECH INC

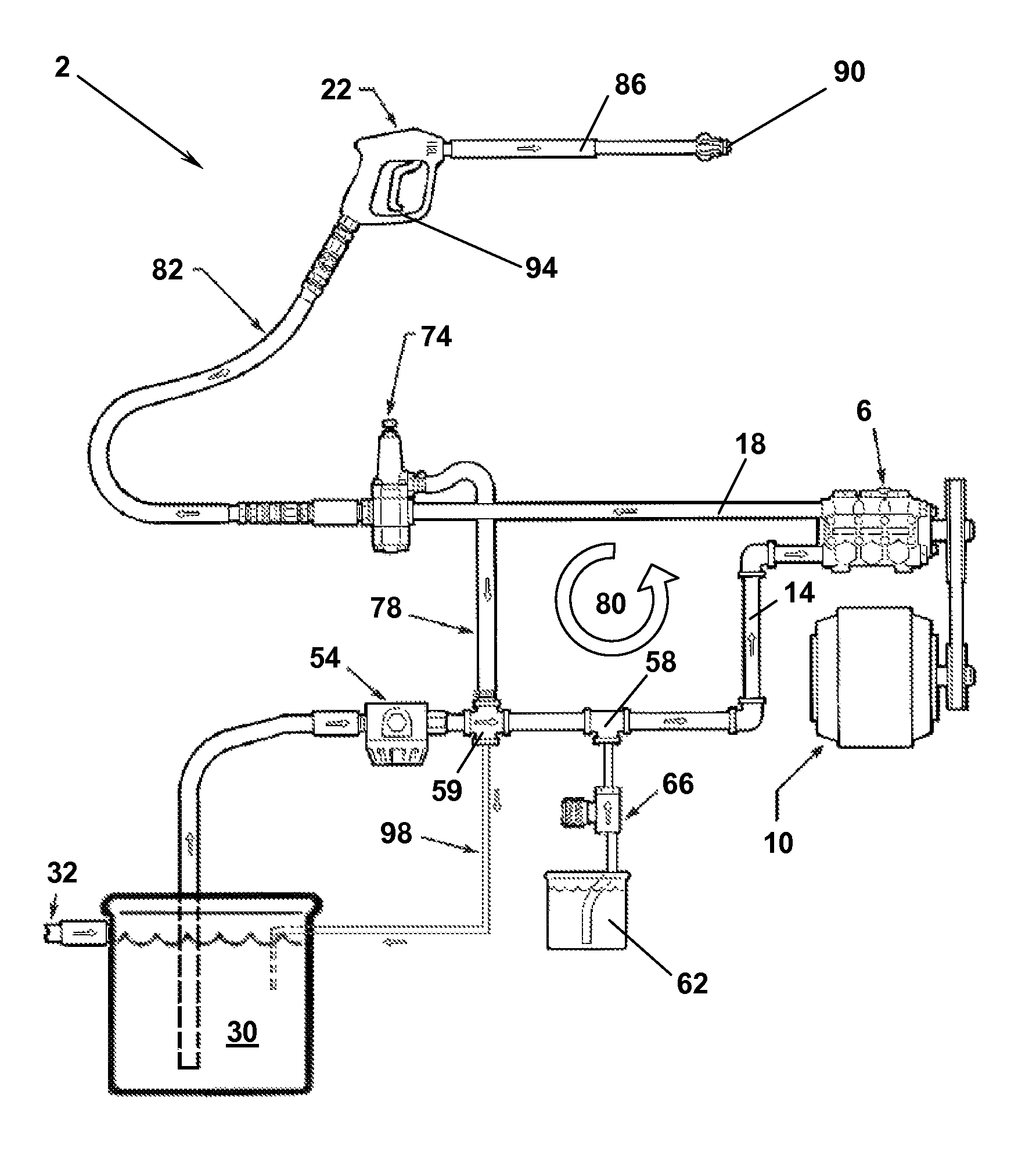

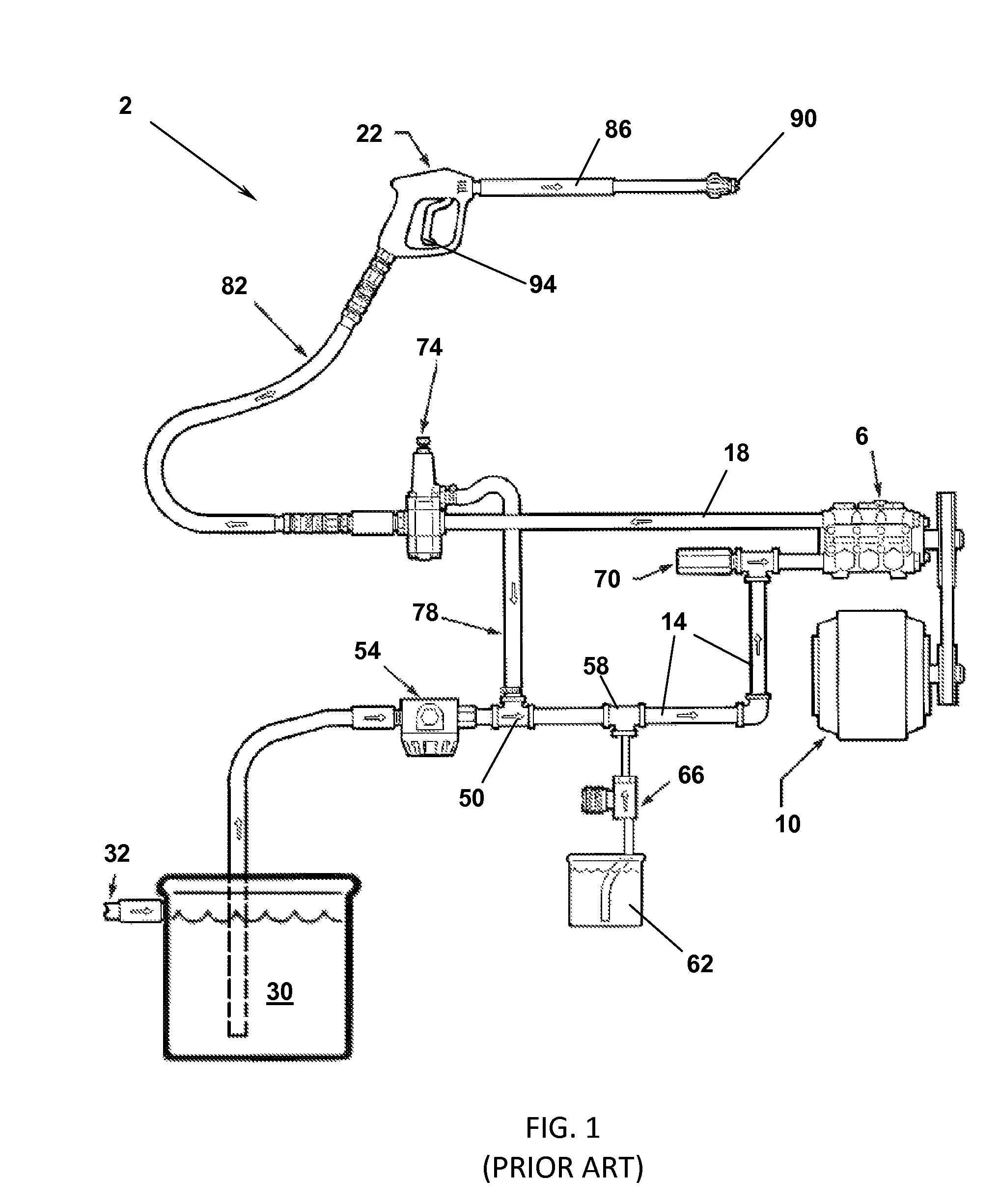

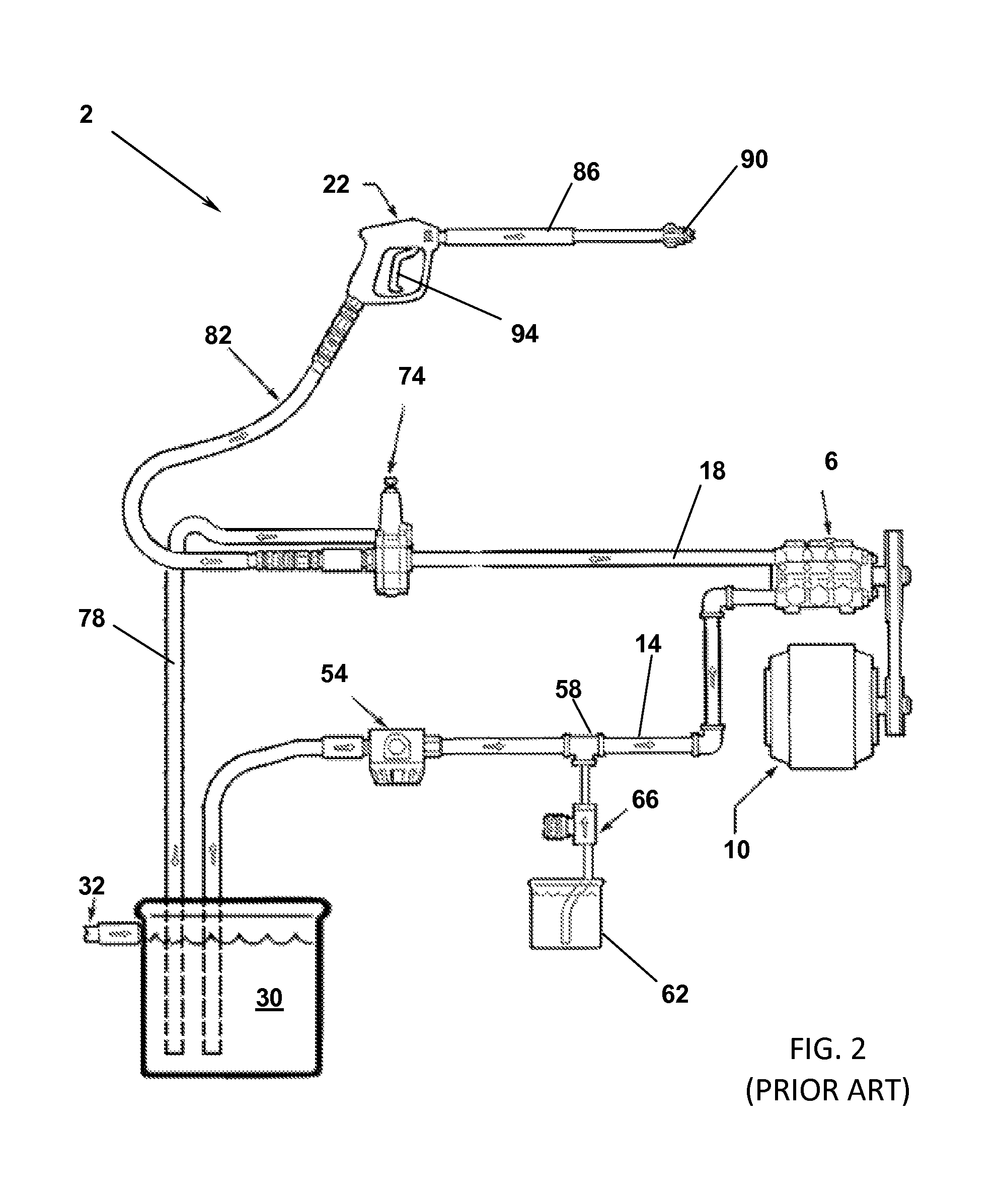

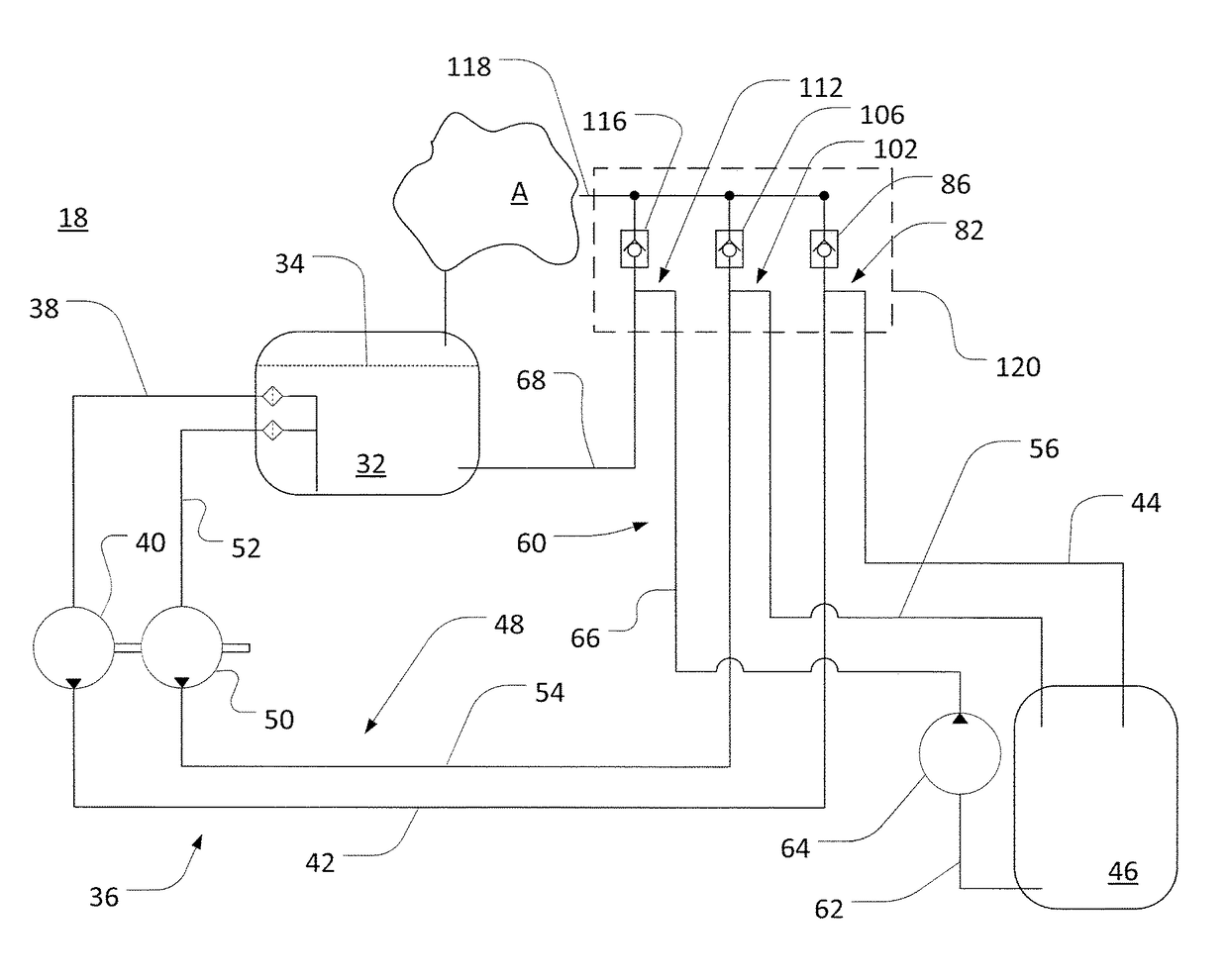

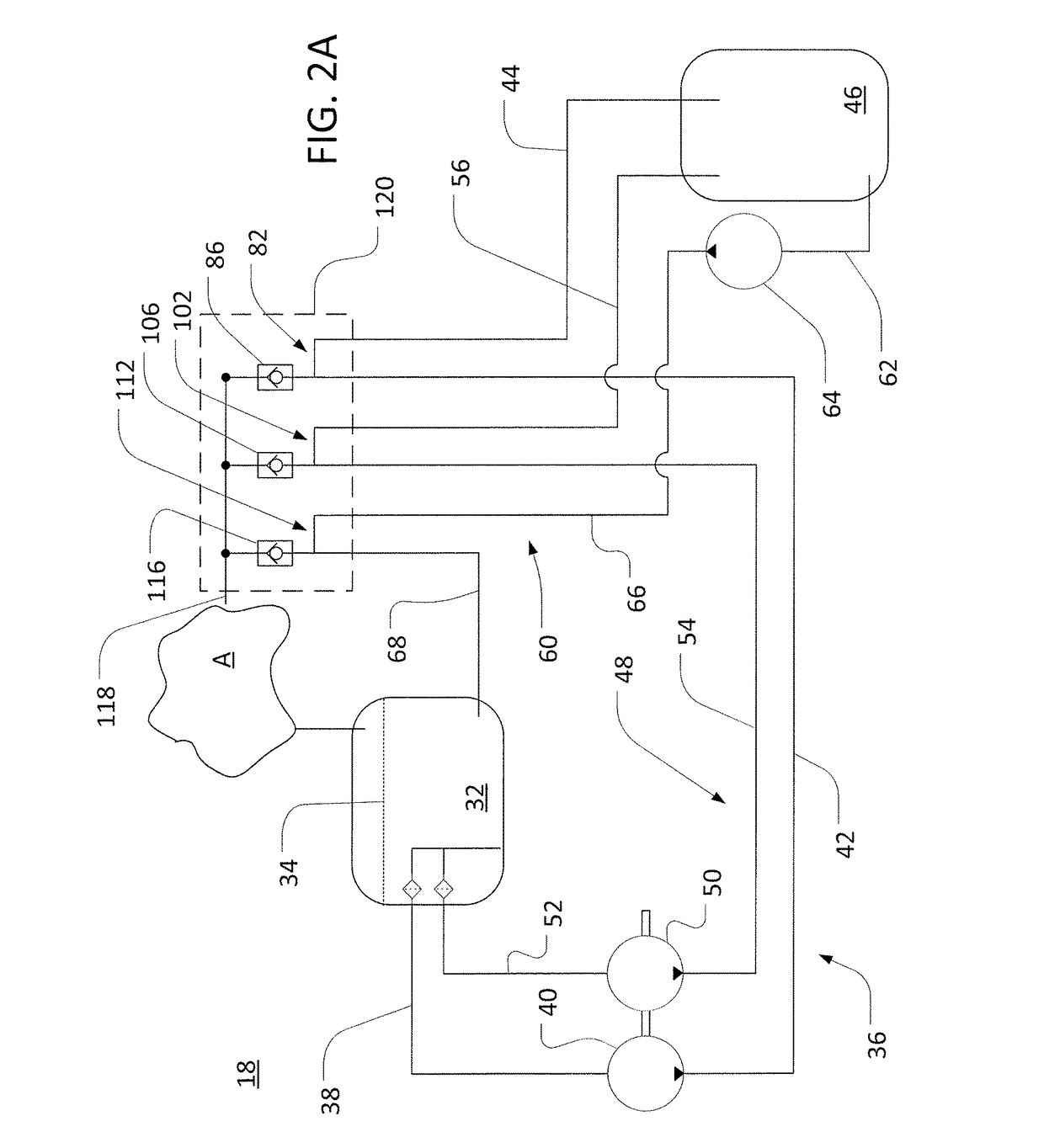

Pressure washer device employing a cool bypass

ActiveUS8496188B2Prevent siphonAvoid overall overheatingLiquid surface applicatorsSpray nozzlesThermal reliefWater storage tank

A pressure washer device is provided that employs an unloader bypass valve that directs a selective amount of fluid via a small diameter bypass line back to a water storage tank. The small amount of fluid allows for the pump to remain working and introduces cooler water into a bypass circuit, thereby allowing the thermal relief valve to be omitted. The diameter of the bypass line is of such a diameter to prevent siphonage of the detergent associated with the pressure washer system into the water storage tank as well.

Owner:KARCHER FLOOR CARE +1

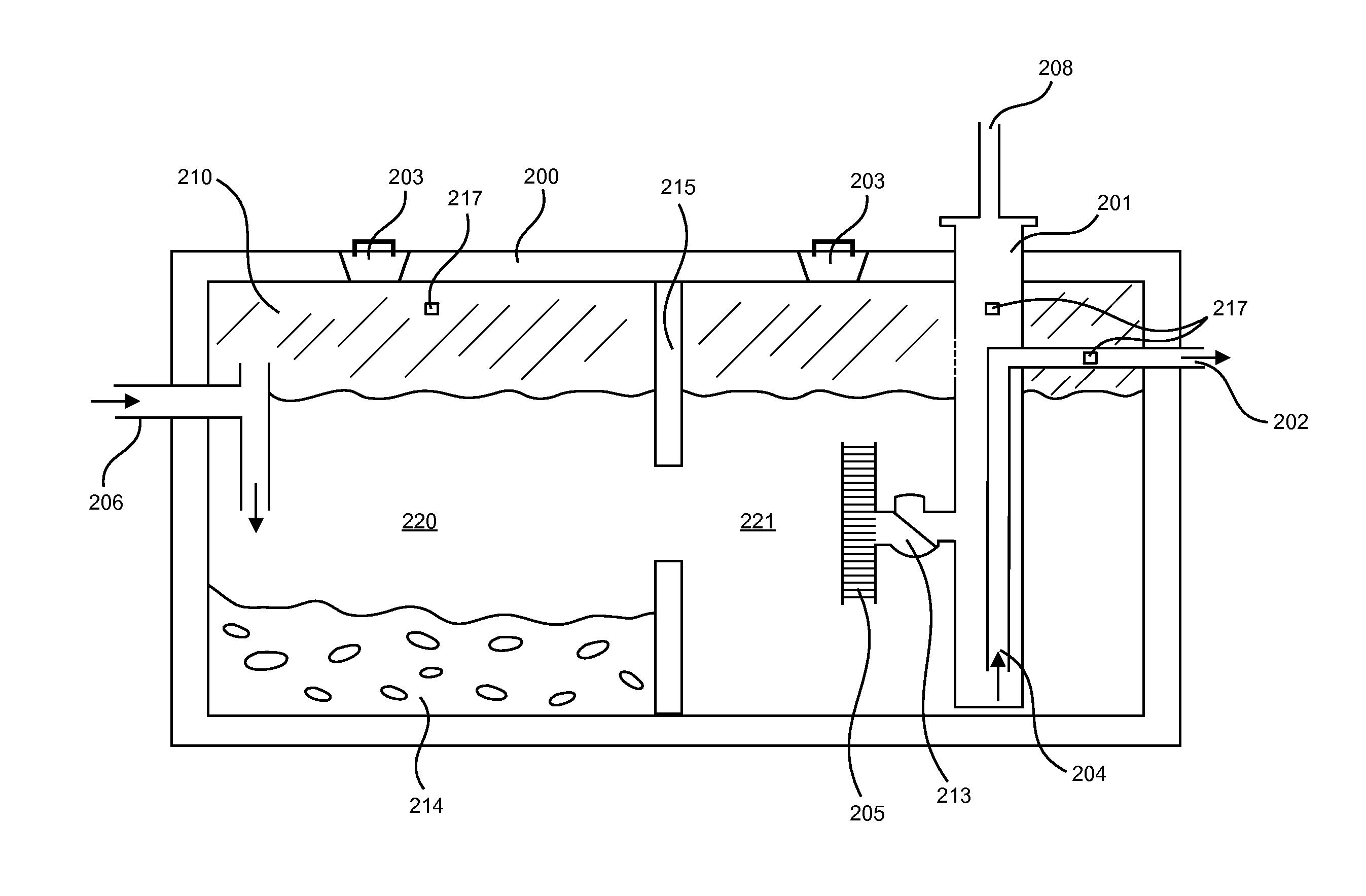

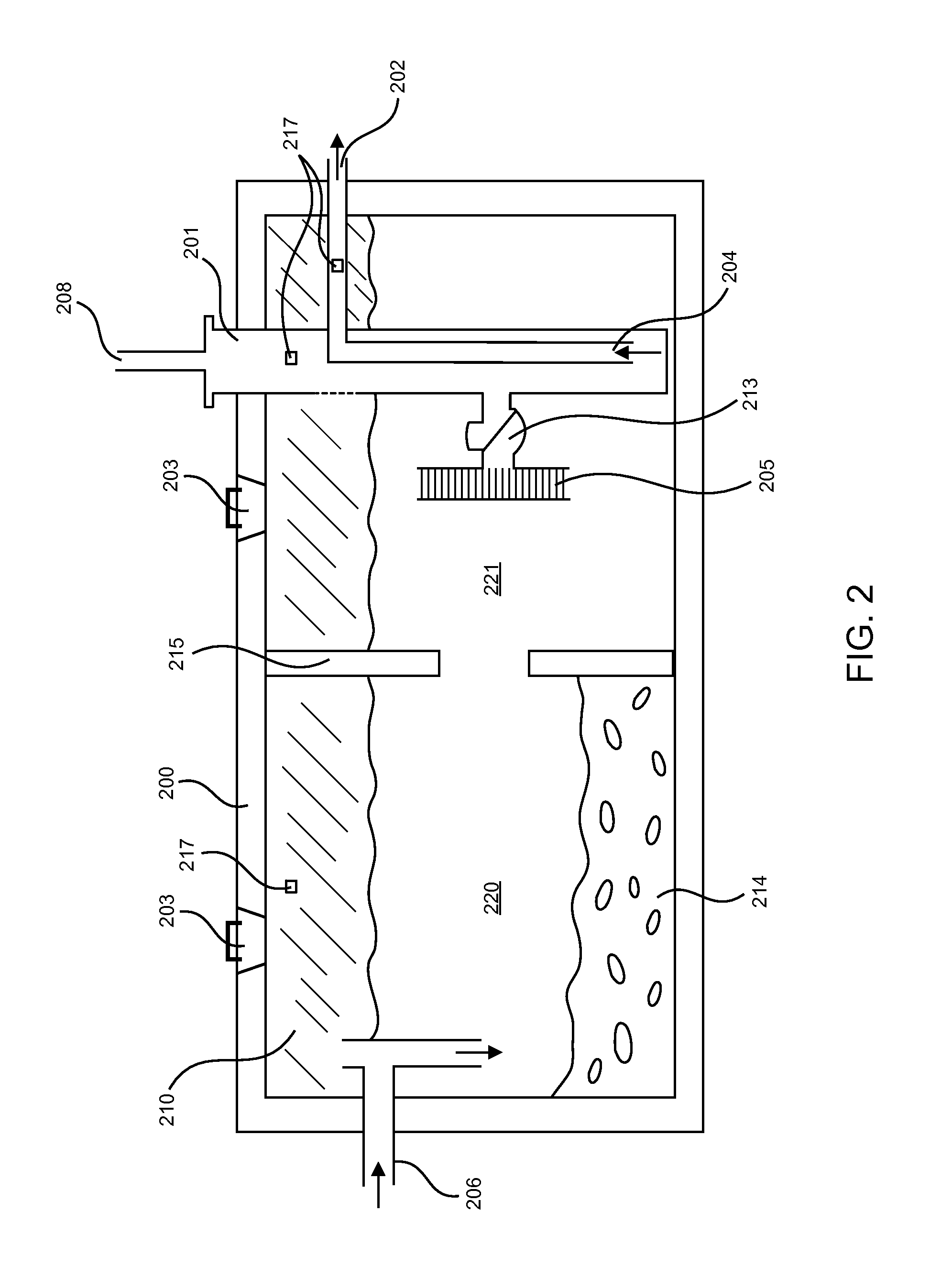

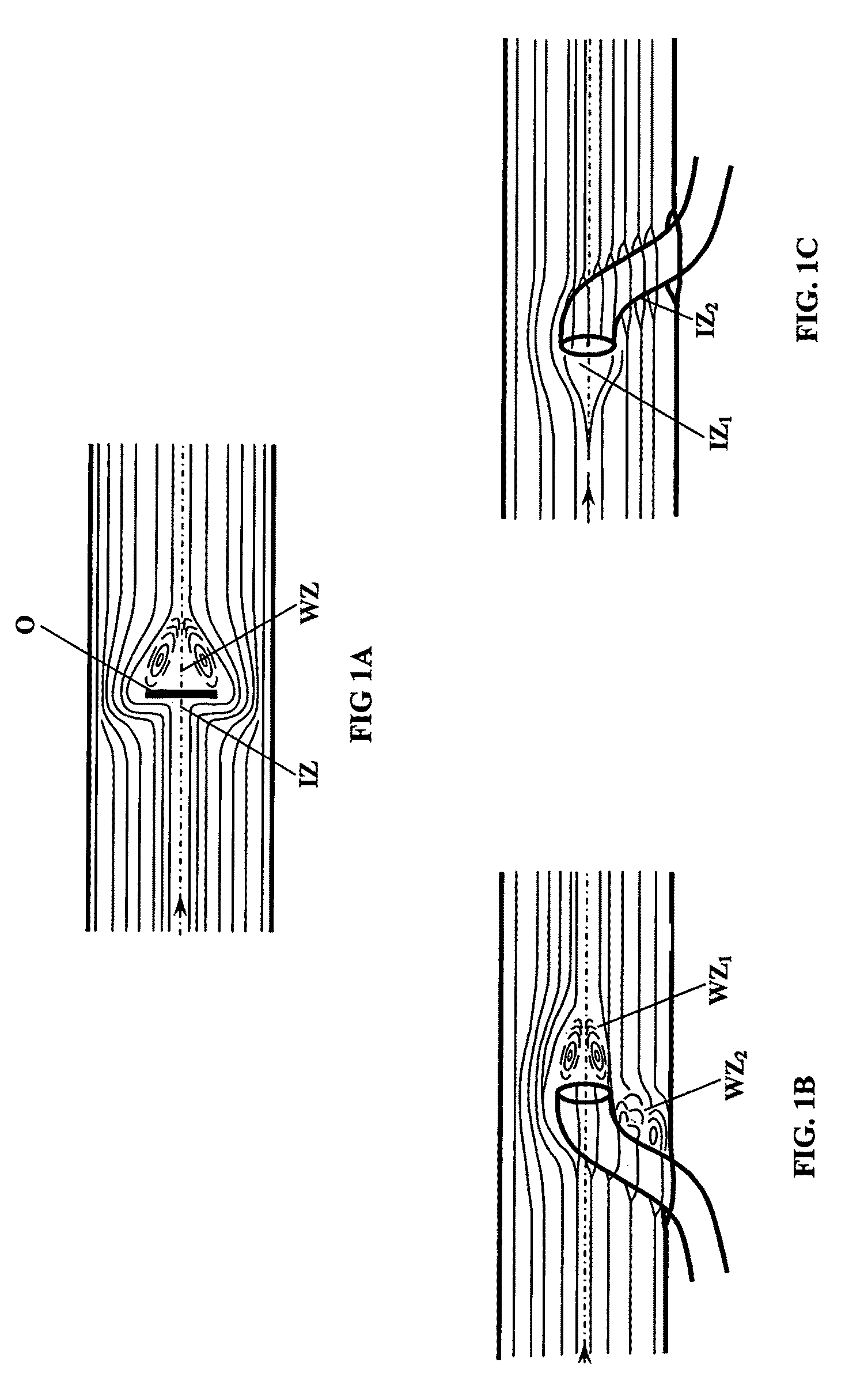

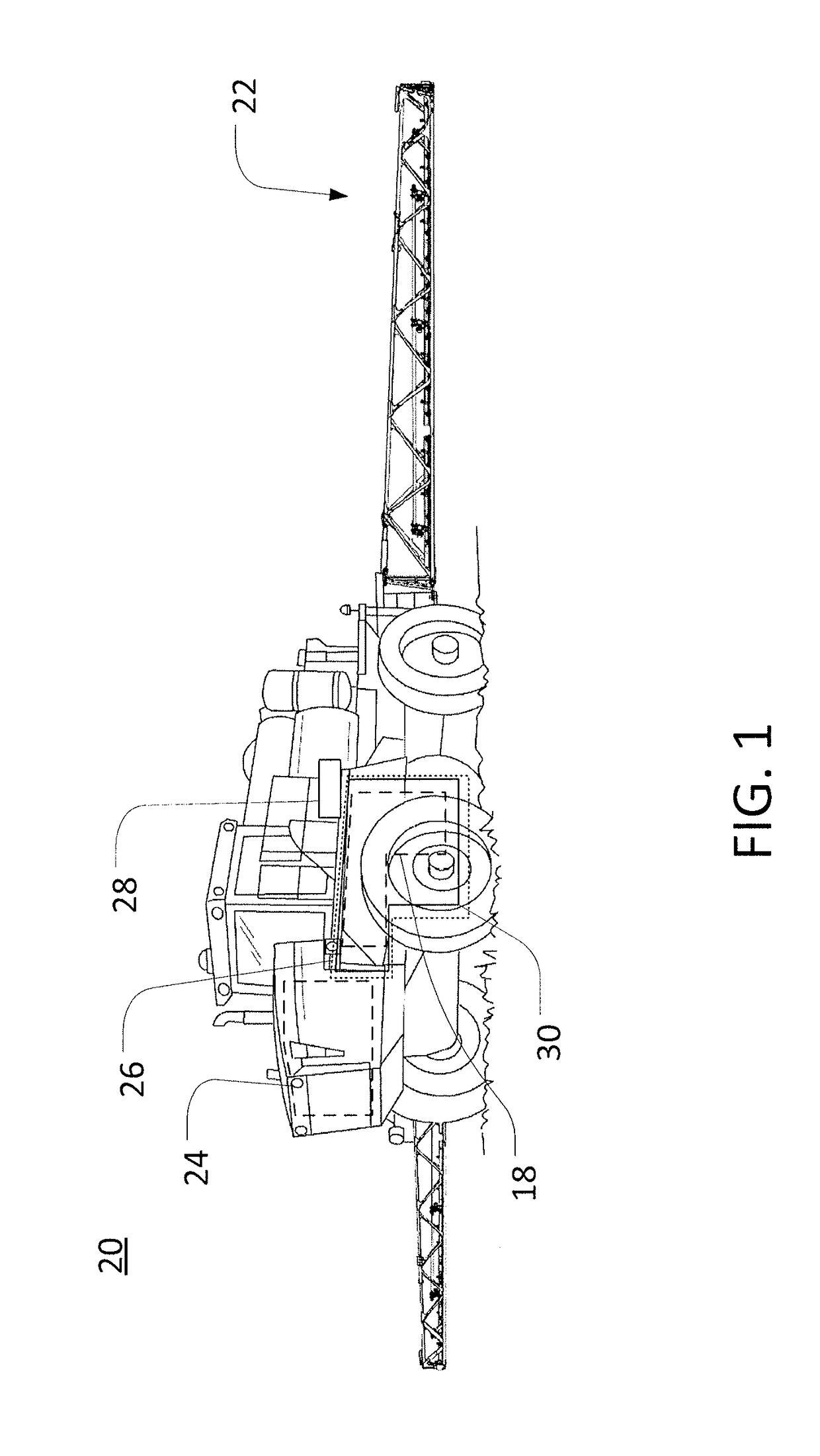

Pressurized Gas Lifting and Gas Rejuvenation

ActiveUS20130306572A1Prevent siphonMinimize freezingBiological treatment regulationPressure pumpsFluid interfaceWastewater

Devices, processes, systems, and articles of manufacture adapted to treat contaminated fluid, such as organic wastewater, are described. These are described to include lifting contaminated fluids, treating contaminated fluids, or both, through gas application. In certain designs, gas, such as pressurized air, may be used to lift contaminated fluids, such as organic wastewater (i.e., water having contaminating organics of some kind, e.g. residential septic wastewater). In certain designs, gas, such as pressurized air, may also be used to treat fluids interfacing with the gas.

Owner:POTTS DAVID A

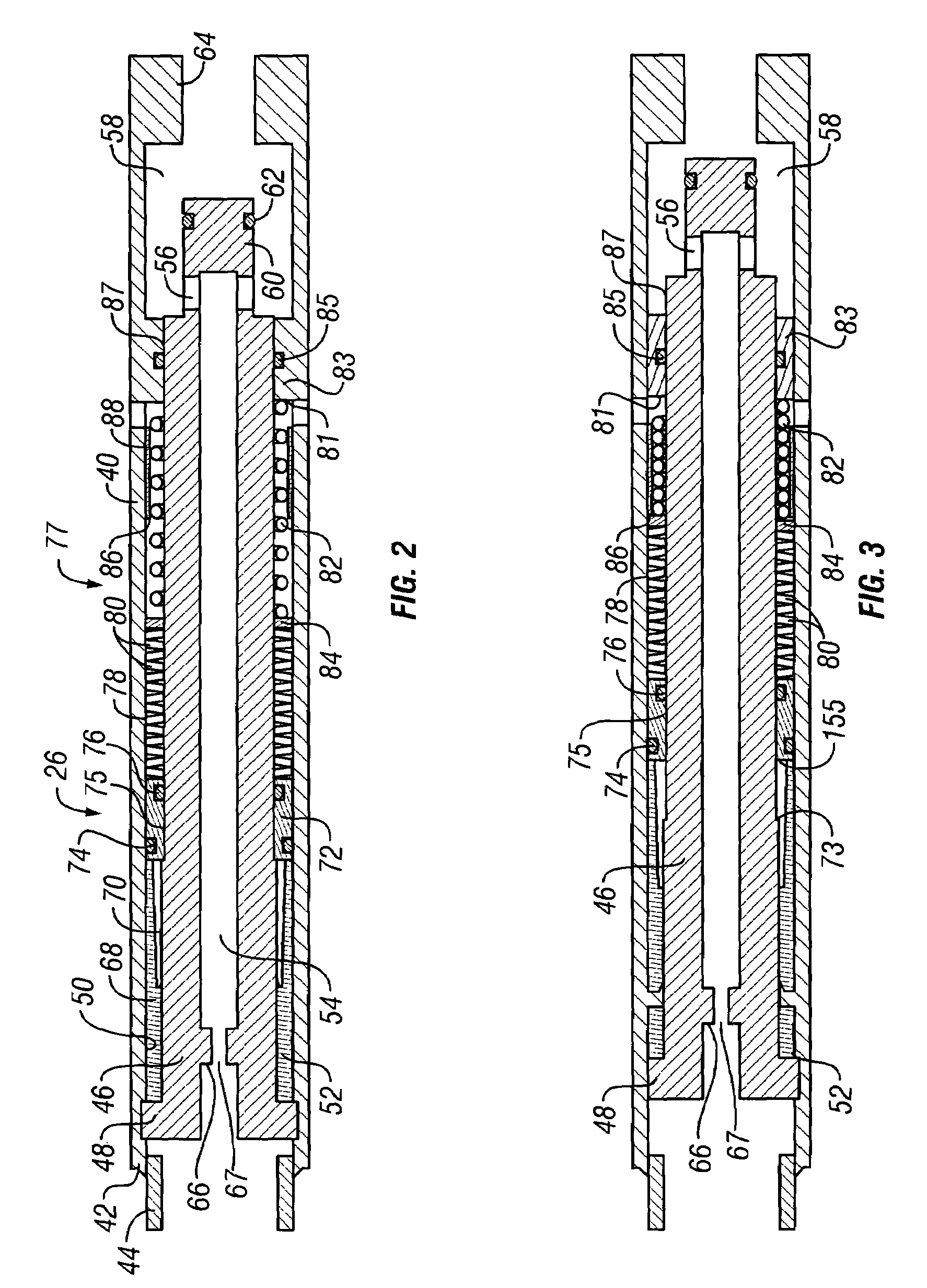

Liquid-solids applicator with valve means to permit cleaning

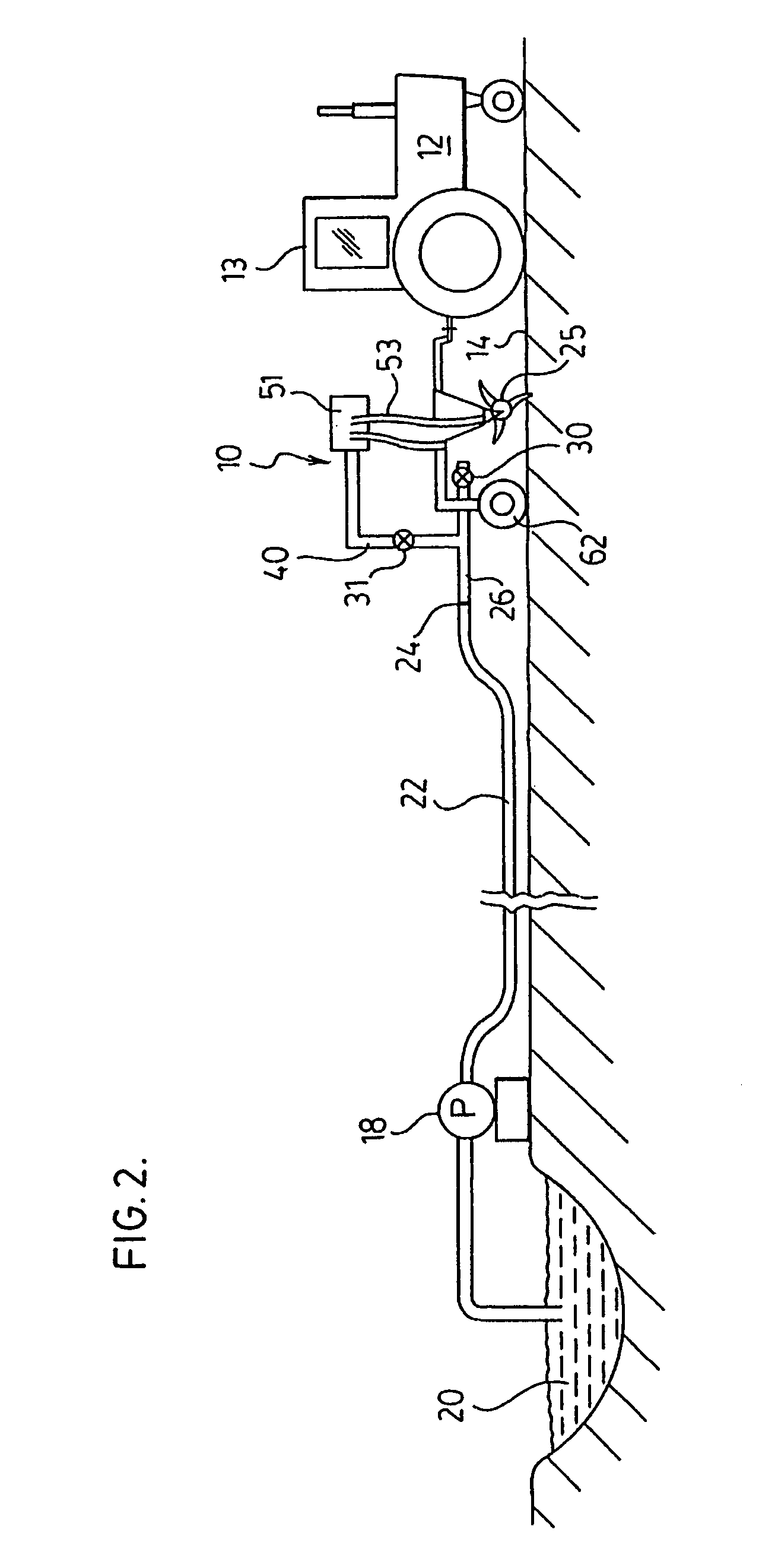

Apparatus for applying liquid-solid dispersions to soil. Valve means are provided which permit cleaning. An elongate conduit, with an aperture at one end, and a first valve proximate such aperture may be opened to permit passage of a pig member. An upwardly extending conduit is “T'ed” off the elongate conduit, and connects with a manifold and a plurality of supply tubes to direct the liquid-solid dispersions to the soil at various points along the frame of the applicator. A second valve may be provided on the upwardly extending conduit, which may be closed to prevent initial supply of the liquid-solid dispersion to the apparatus and instead flow to the aperture to prevent plugging during initial operation. The second valve, when closed, further serves as an anti-siphoning valve to prohibit further supply of liquid solid dispersion to the manifold. A method for cleaning such apparatus is further disclosed.

Owner:SALFORD GRP INC

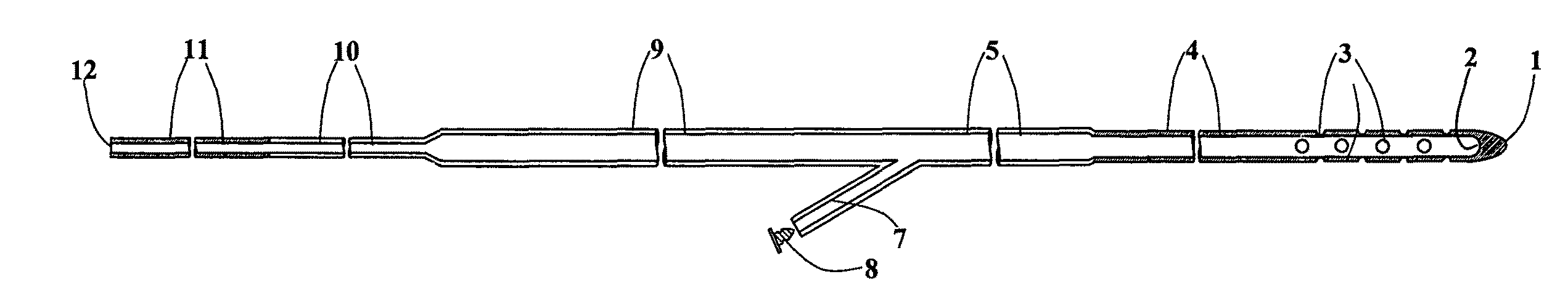

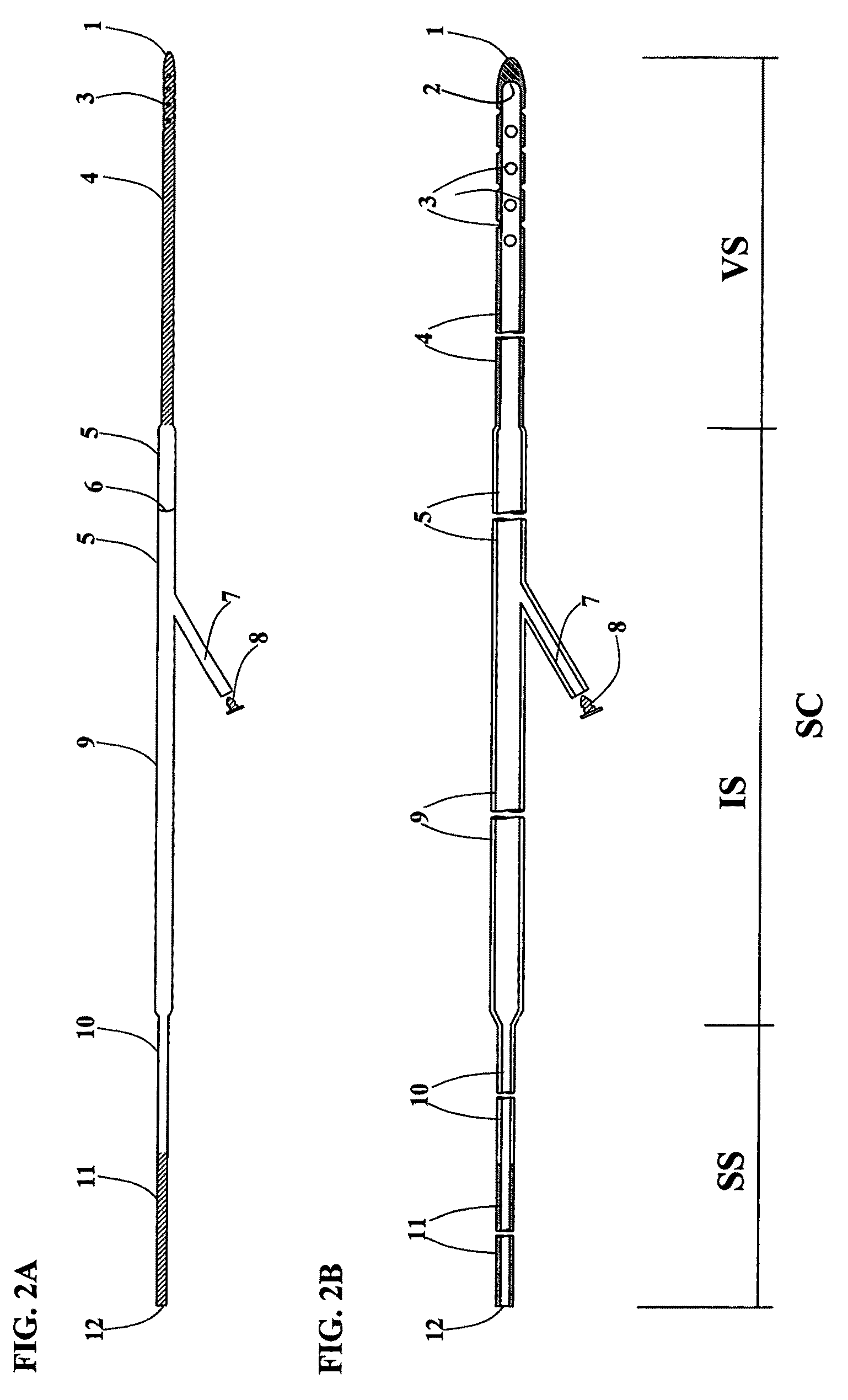

Device for implantation of retrograde ventriculo-sinus shunt

InactiveUS7998103B2Prevent siphonDiscourage stagnation and clottingWound drainsCatheterVeinIntraventricular pressure

A shunt system for implantation of retrograde ventriculo-sinus shunts to establish a water tight connection that drains excess cerebrospinal fluid from hydrocephalic brain ventricles and delivers it, against the direction of blood flow, in a dural sinus comprising a valveless shunting catheter and a styforator. Retrograde ventriculo-sinus shunts mimic natural drainage of cerebrospinal fluid; they utilize natural forces to regulate the intraventricular pressure and to maintain it more than the sinus pressure, to prevent regurgitation of blood in the shunting catheter as a result of changes in posture or intra-thoracic pressure, to maintain a steady flow of cerebrospinal fluid to the venous circulation at a rate equal to and dependent upon the rate of it's formation, to discourage stagnation and clotting of blood at the venous end of the connection and to prevent siphonage in the erect posture.

Owner:EL SHAFEI ISMAIL LOTFY +1

Mixed culture method for hippocampi and sea cucumbers

InactiveCN102657114APrevent siphonReduce wasteClimate change adaptationAnimal feeding stuffMixed cultureBiological property

The invention discloses a mixed culture method for hippocampi and sea cucumbers. According to the method, a culture draft is made according to the respectively biologic features of the hippocampi and the sea cucumbers, so the hippocampi and the sea cucumbers can be in mixed culture in the same region for forming a situation in spaces without mutual interference, meanwhile, bait and water body waste can be avoided, the culture complementation is formed, further, the culture cost is obviously reduced, and the culture efficiency is improved. The mixed culture method has the advantages that the operation is easy, and the controllability is high, and the method is suitable for large-scale business-like culture popularization.

Owner:SOUTH CHINA SEA INST OF OCEANOLOGY - CHINESE ACAD OF SCI

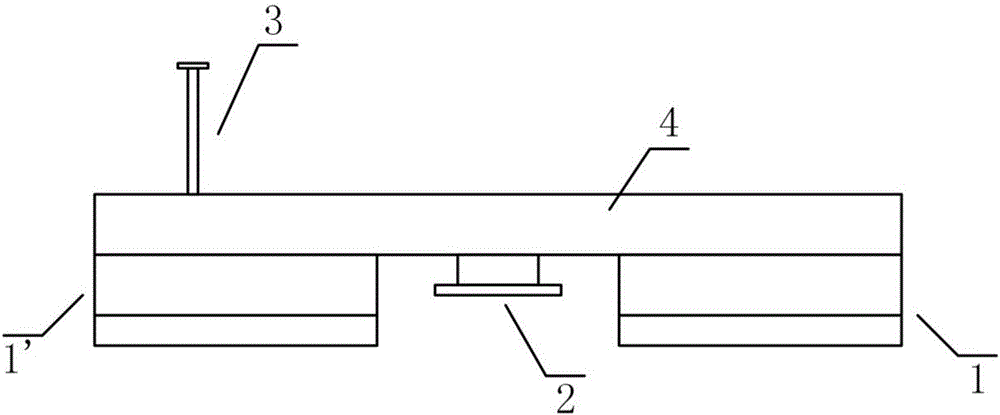

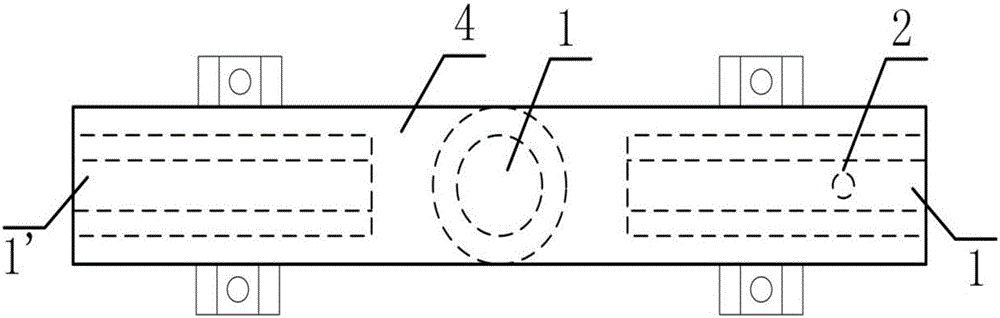

Method for siphon prevention of the terminal and the terminal made by this method

InactiveCN101009409APrevent siphonPrevent empty welding phenomenonContact member manufacturingElectrically conductive connectionsSiphonCopper oxide

The invention discloses an anti-siphonage method of ends, the ends includes guiding connection part which is welded with the outer element by solder, and connection part which is extended by the guiding connection part, the surface of the connection part is naked and made of copper, the copper is oxidized to form oxide. The ends of the invention includes connection part and guiding connection part, thereinto, the connection par extends to form the guiding connection part, the guiding connection part can be connected with outer element by solder, the connection part is made of copper which can be oxidized and naked. Because the invention comprises copper which can be oxidized and naked, the copper is oxidized to form oxide, the oxide such as copper-oxide can avoid the solder siphoned from the guiding connection part to the ends connection part during the welding, it can save the solder and avoid the phenomenon of empty welding, the quality of welding can be guaranteed and the cost is saved.

Owner:DEYI PRECISION ELECTRONIC IND CO LTD PANYU

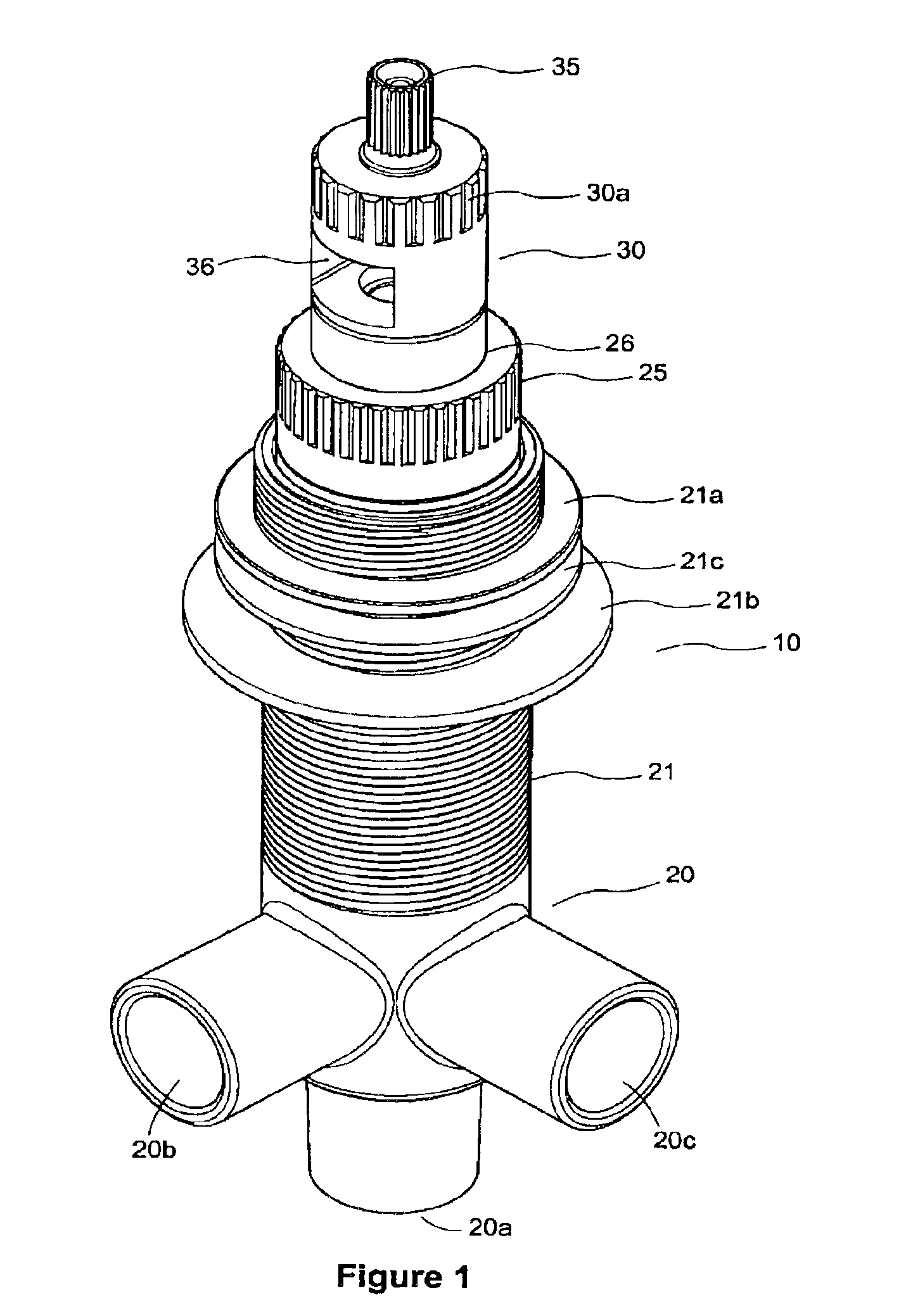

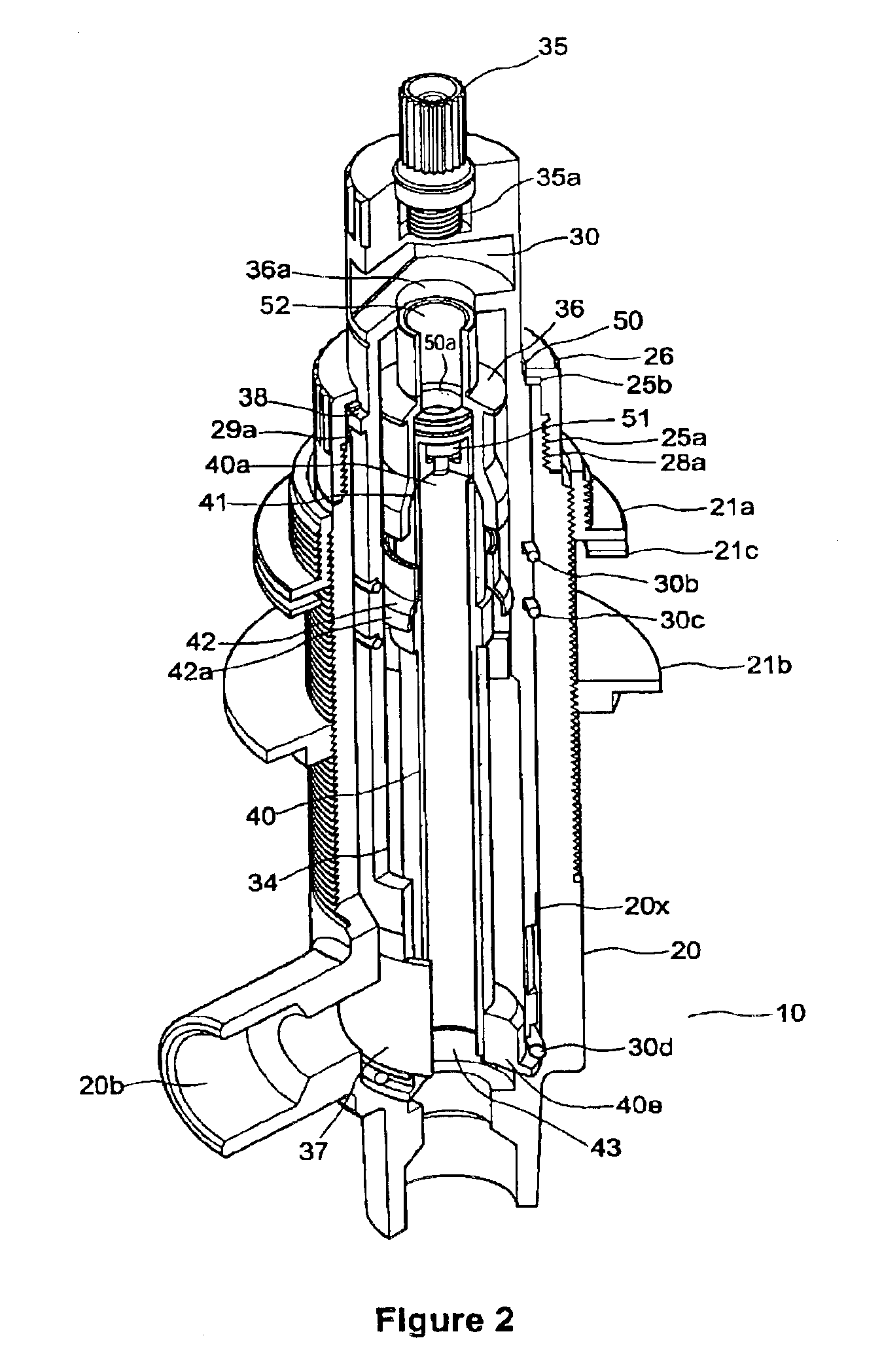

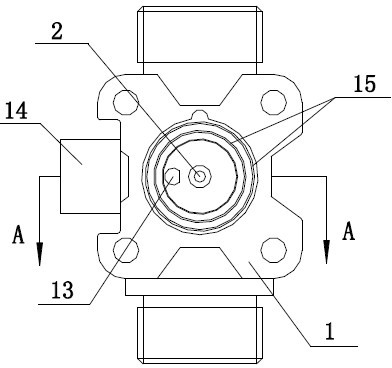

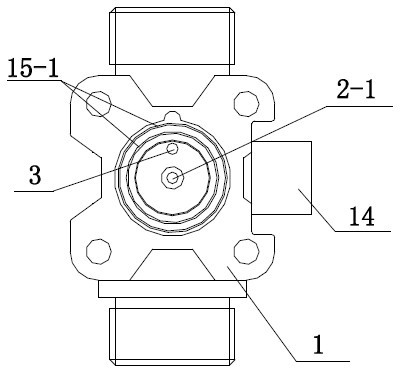

Diverter valve with removable cartridge including integral atmospheric type vacuum breaker and check

InactiveUS6913033B2Prevent backflowPrevent siphonDomestic plumbingVenting valvesCheck valveVacuum interrupter

A modular diverter valve with integral atmospheric type vacuum breaker has a housing and a replaceable rotatable cartridge is provided. The housing having a cartridge receiving chamber being surrounded by an internal housing wall. The housing also has an inlet port and laterally directed outlet ports. Each outlet port directs water for selective uses. The rotatable cartridge includes all working parts including a handle engaging portion, an inlet and an outlet for selective alignment with the housing ports. The cartridge has a hollow interior having an inlet tube in communication with the inlet of the cartridge and including a vented hollow space above the inlet tube, and including a float assembly to the vent the cartridge to the atmosphere. The float assembly has a resilient seal for sealing the open end of the inlet tube and a check valve to prevent siphoning to the inlet port.

Owner:BREDA SILVANO

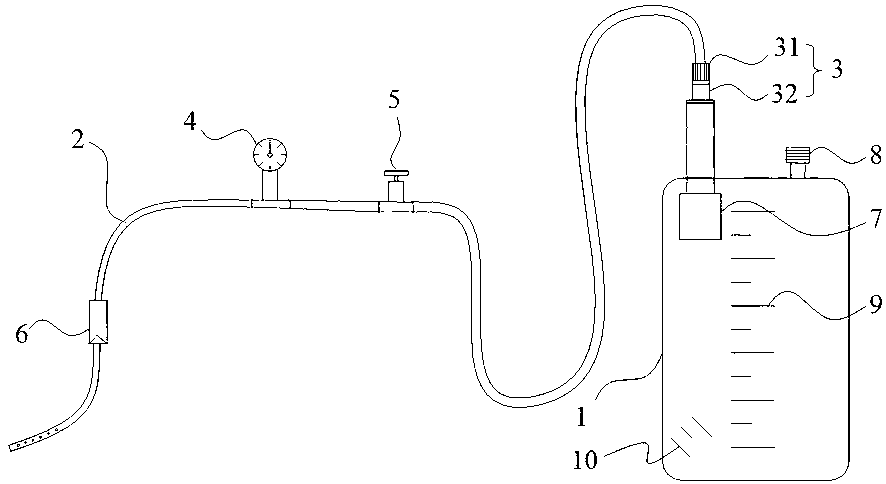

Negative pressure drainage device with adjustable pressure

The invention discloses a negative pressure drainage device with adjustable pressure and belongs to the field of medical equipment. The negative pressure drainage device comprises a liquid storage bottle, a drainage tube, a lock catch connector connecting an inner cavity of the liquid storage bottle and the drainage tube. The drainage tube is sequentially provided with a pressure gage and a pressure regulating valve along the liquid flowing direction. The drainage tube is further provided with a first reverse flow resistance device. A second reverse flow resistance device is disposed at the lock catch connector end in the liquid storage bottle. The liquid storage bottle is further provided with a vacuum indicator communicated with the inner cavity. By the aid of the negative pressure drainage device with adjustable pressure, the volume of liquid in the bottle can be measured precisely, the bottle body is small and light and easy to carry, and the problems of siphon or inadequate drainage caused by too high or too low a negative pressure value can be avoided when pressure is properly adjusted through a pressure adjusting valve. Meanwhile, pressure changes in the bottle can be directly observed through the vacuum indicator, and the risk of retrograde infection can be effectively removed under the action of the double reverse flow resistance devices.

Owner:NANJING SHUANGWEI BIOTECH

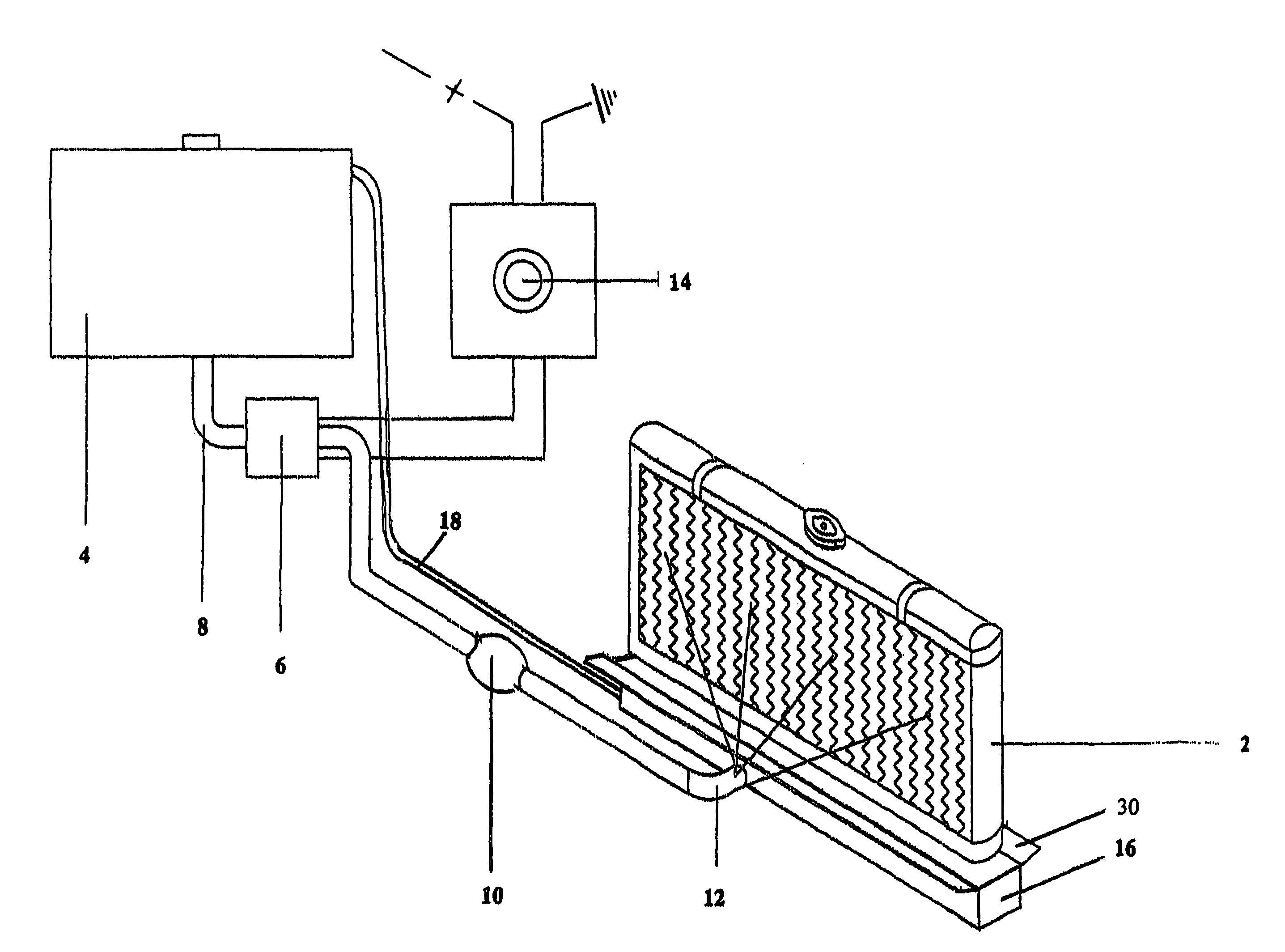

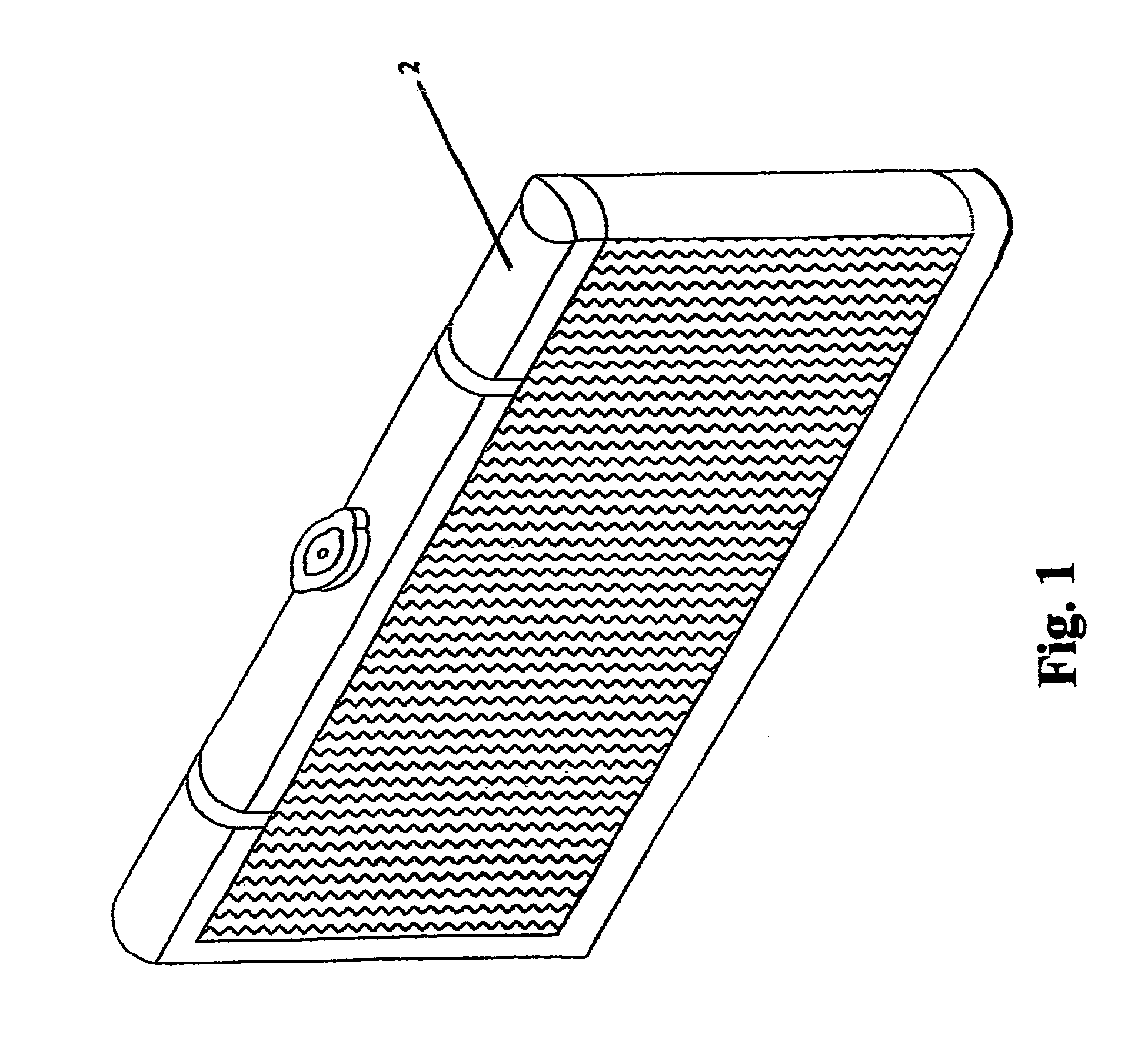

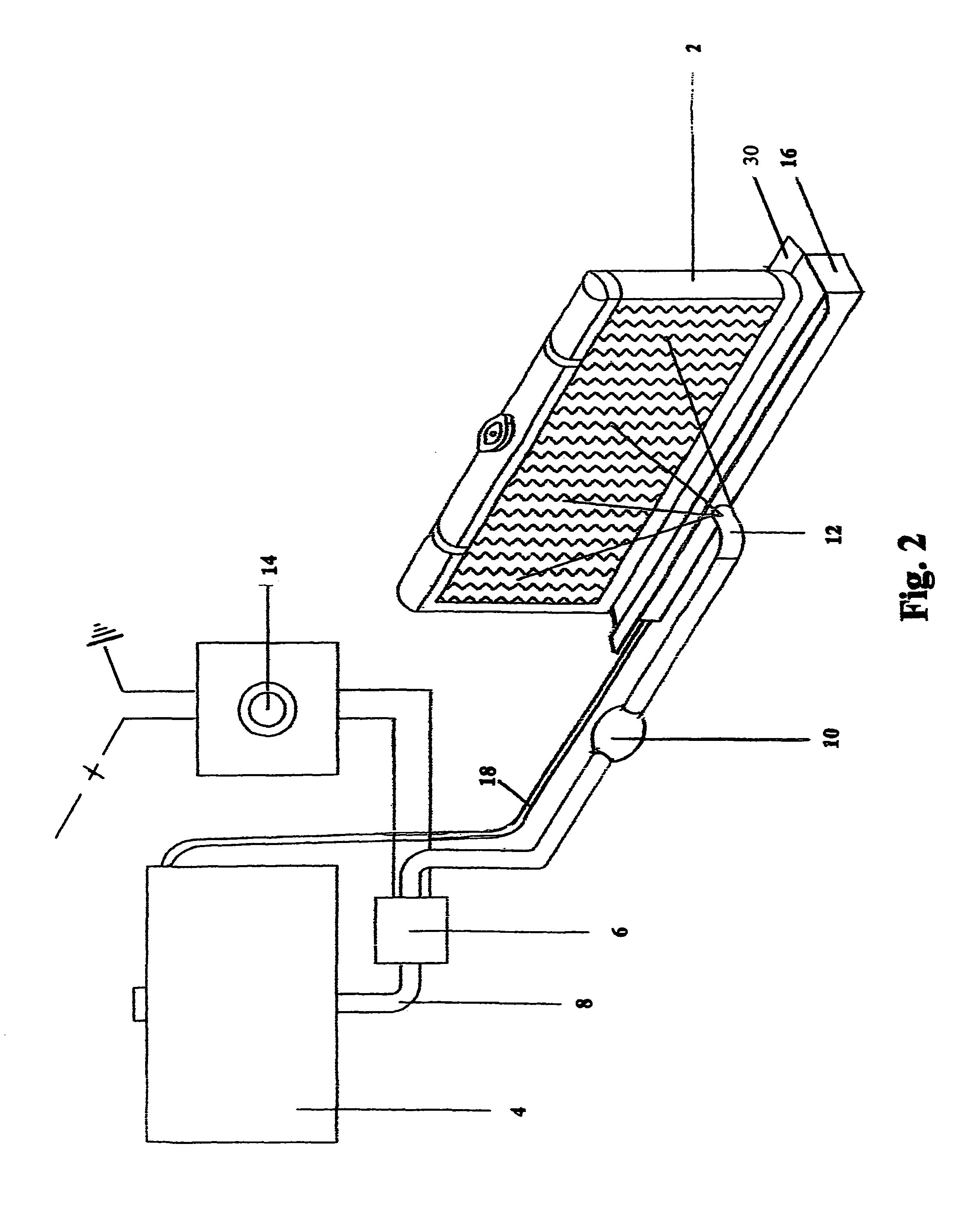

Radiator and air cooler mister

InactiveUS8596556B2Expand the scope of operationReducing routineCoolant flow controlExhaust apparatusSpray nozzleEngineering

The present invention provides additional cooling assistance for automotive heat exchanging systems used for the cooling of liquids or air needed for engine operations. This operating system utilizes a liquid reservoir, an electric pump, a liquid transfer hose housing a directional flow valve, a spray nozzle, a liquid recycling tray mounted below the heat exchanger, a recycling liquid return hose, an electrical timed pulse relay circuit incorporated into a remotely mounted electrical on and off switch assembly, or the system can be automated with the incorporation of an adjustable thermostatic control sensor circuit. Under extreme operating conditions, a vehicle's engine can reach undesirable operating temperatures and when providing a mist of liquid to the frontal area of the heat exchanger, helps to stabilize or drop the engine's operating temperatures.

Owner:VEHICLE ENHANCEMENT LABS

Viscometer with integral sample retention reservoir

ActiveUS20100058839A1Prevent siphonDirect flow property measurementEngineeringMechanical engineering

A viscometer having a substantially horizontal reservoir including a trap for retaining a sample indefinitely in the reservoir. A substantially vertical measuring tube disposed perpendicularly to the substantially horizontal reservoir and depends substantially upwardly from the reservoir. A junction interconnects the trap, a generally downwardly projecting fill tube, and a generally upwardly projecting vent tube.

Owner:CANNON INSTR

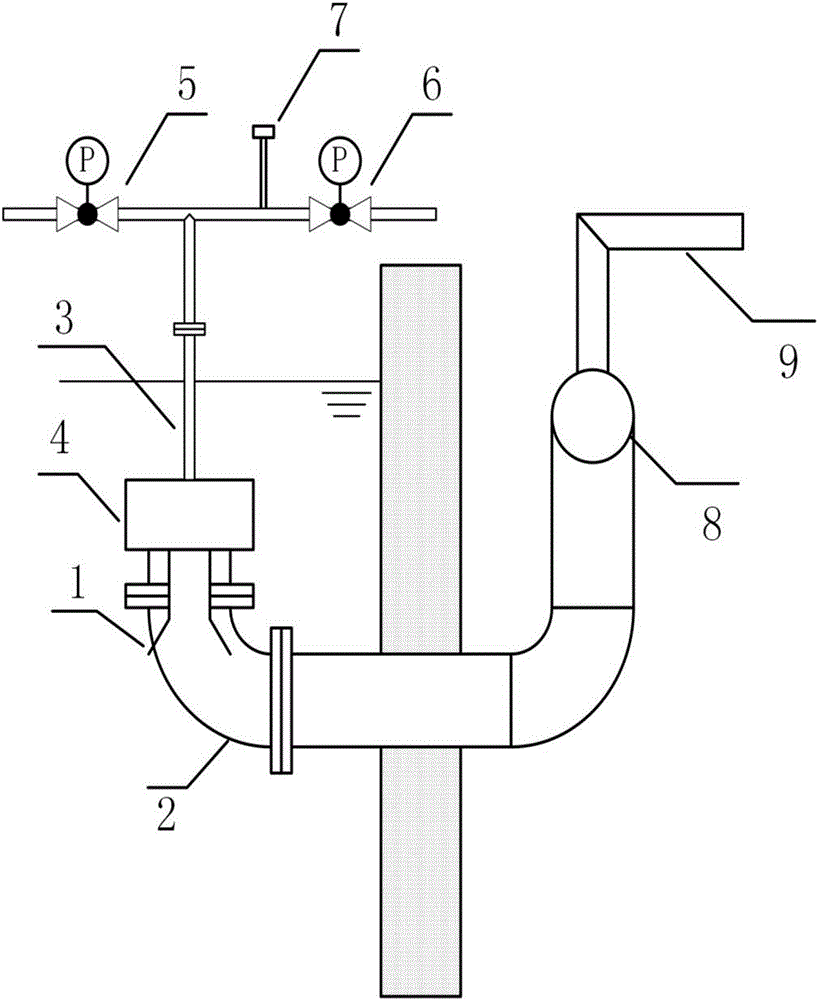

Drainage air weir system for constant-water-level sedimentation tank and use method of drainage air weir system

InactiveCN106422444APrevent outflowAvoid short flowWater treatment parameter controlTreatment using aerobic processesAutomatic controlControl system

The invention discloses a drainage air weir system for a constant-water-level sedimentation tank and particularly relates to an air weir for a sedimentation tank. The drainage air weir system comprises a water inlet, a water outlet pipe, an air weir air chamber, an air inlet and outlet pipe, an air inlet valve, an air outlet valve, a pressure transmitter, a water outlet main and an air duct. The drainage air weir system control intermittent water outlet of the water tank by means of air pressure change, and opening and closing of an air pipe valve are controlled by an automatic control system, so that drainage and drainage stopping are realized; the air weir adopts an under-liquid-level water outlet manner, is especially suitable for an aeration tank, prevents scum from flowing out with water flow and solves the problems of short flow and the like caused by poor construction of the traditional effluent weir, and an air hose is added to the water outlet main to effectively prevent siphoning.

Owner:安徽泓济环境科技有限公司

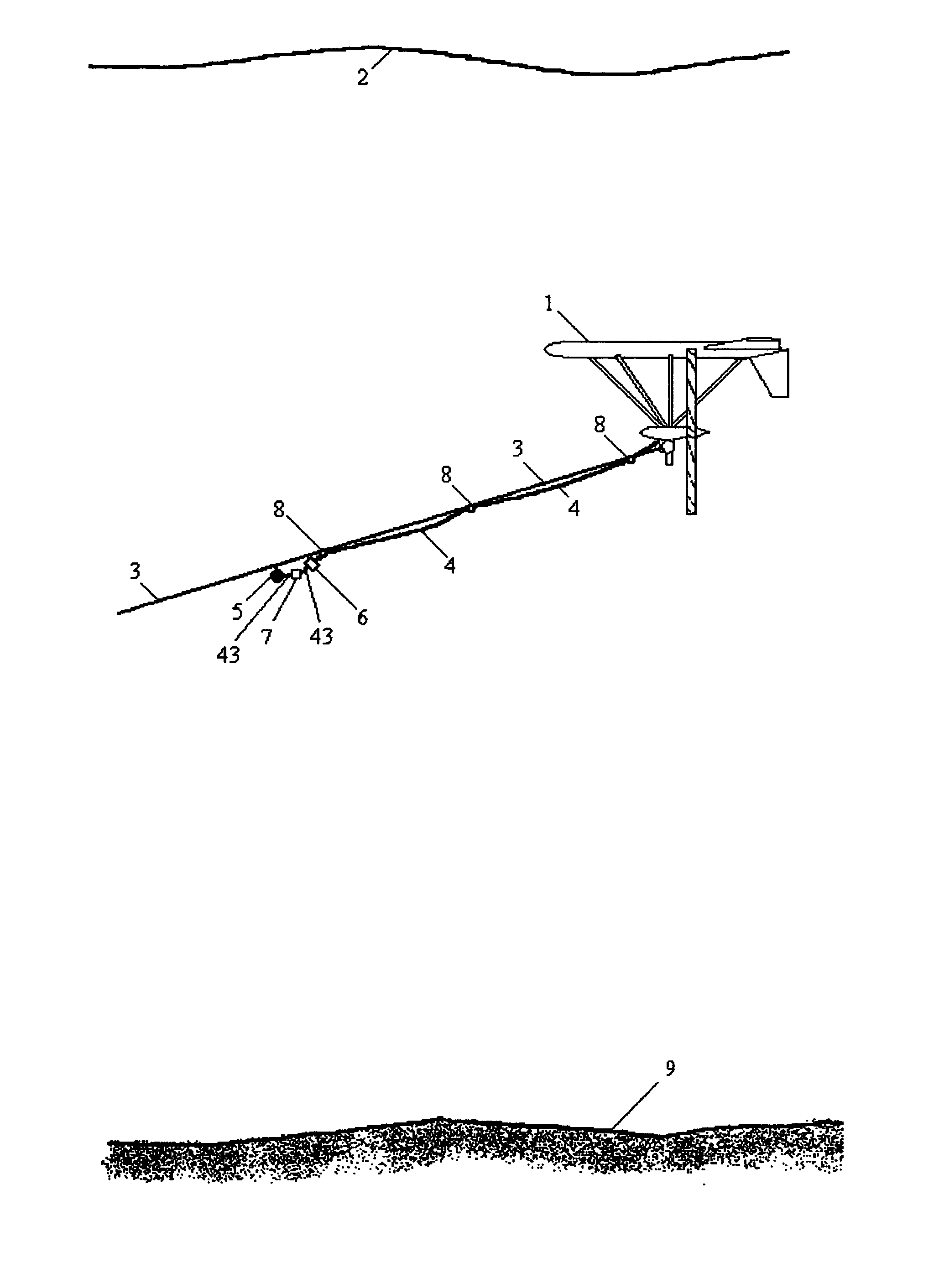

Method and appratus for insertion of an Anti-siphon grid into a hose

InactiveUS20080283124A1Eliminates undesirable shortcomingProvide protectionValve arrangementsPipe elementsSiphonAutomotive fuel

An apparatus for installing an anti-siphon device into an automotive fuel filler comprises; a cylindrical mandrel having an inner surface and an outer surface, the outer surface of the mandrel adapted to receive a proximal end of the hose; a first grasping means configured to grasp the hose at a predetermined distance from a proximal end of the hose, and to insert the proximal end of the hose onto the outer surface of the mandrel; a first actuating means for inducing the first grasping means to grasp the hose at the predetermined distance from the proximal end of the hose, and to insert the proximal end of the hose onto the outer surface of the mandrel; a second grasping means configured to grasp and hold the proximal end of the hose on the mandrel during installation of the anti-siphon device in the hose; a second activating means for inducing the second grasping means to grasp the proximal end of the hose on the mandrel, and hold the hose thereon during installation of the anti-siphon device into the hose; an anti-siphon device insertion means having an outer surface, the anti-siphon device insertion means disposed in the mandrel, wherein the outer surface of the anti-siphon device insertion means is adjacent the inner surface of the mandrel; an anti-siphon device fixture disposed on one end of the anti-siphon device insertion means, wherein the anti-siphon device fixture is adapted to receive the anti-siphon device thereon; and a third activating means for inserting the anti-siphon device inserting means having the anti-siphon device disposed thereon, into the hose and withdrawing the anti-siphon device inserting means to the mandrel upon installing the anti-siphon device in the hose. A method is also described.

Owner:FLUID ROUTING SOLUTIONS

Fluid level control toggle valve device and method

InactiveUS8091581B2Low costLimit turbulent water flow noiseOperating means/releasing devices for valvesGymnasiumEngineeringFluid level

A water level control device has connected tubular housings, one serving as a support for a hose connection and the other serving to support a valve housing assembly for operation of a toggle valve within the valve housing. An airtight float serves to raise the one extreme of a float rod when buoyed by sufficient water level admitted through apertures in the valve housing. The other extreme of the float rod is attached to a rod holder to hold the float rod. The rod holder passes through an outlet apertured valve seat wherein a valve washer attached to the rod holder within the toggle valve cavity is urged against the outlet valve seat by water pressure from a water hose.

Owner:BUCHTEL MICHAEL E

Viscometer with integral sample retention reservoir

A viscometer having a substantially horizontal reservoir including a trap for retaining a sample indefinitely in the reservoir. A substantially vertical measuring tube disposed perpendicularly to the substantially horizontal reservoir and depends substantially upwardly from the reservoir. A junction interconnects the trap, a generally downwardly projecting fill tube, and a generally upwardly projecting vent tube.

Owner:CANNON INSTR

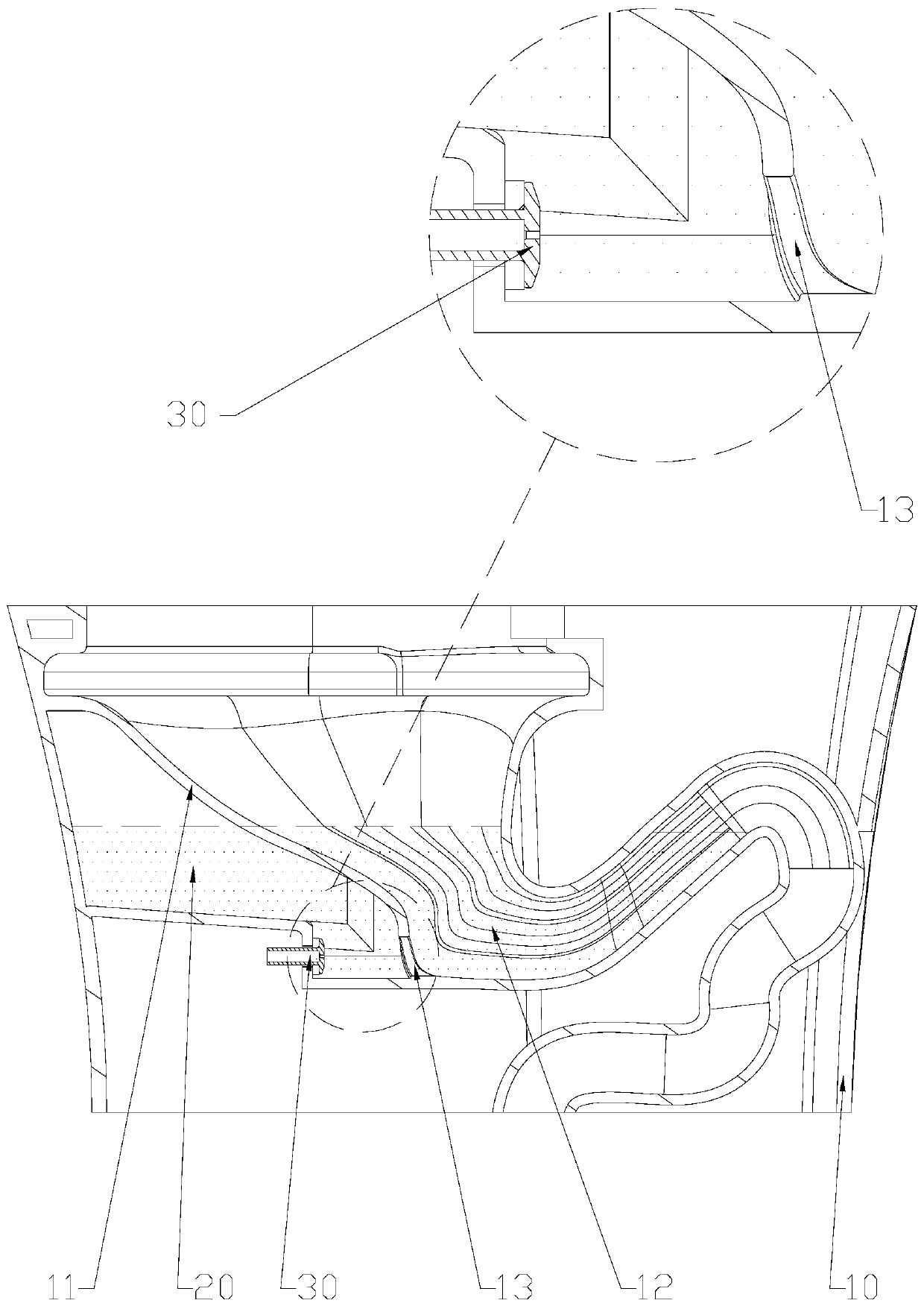

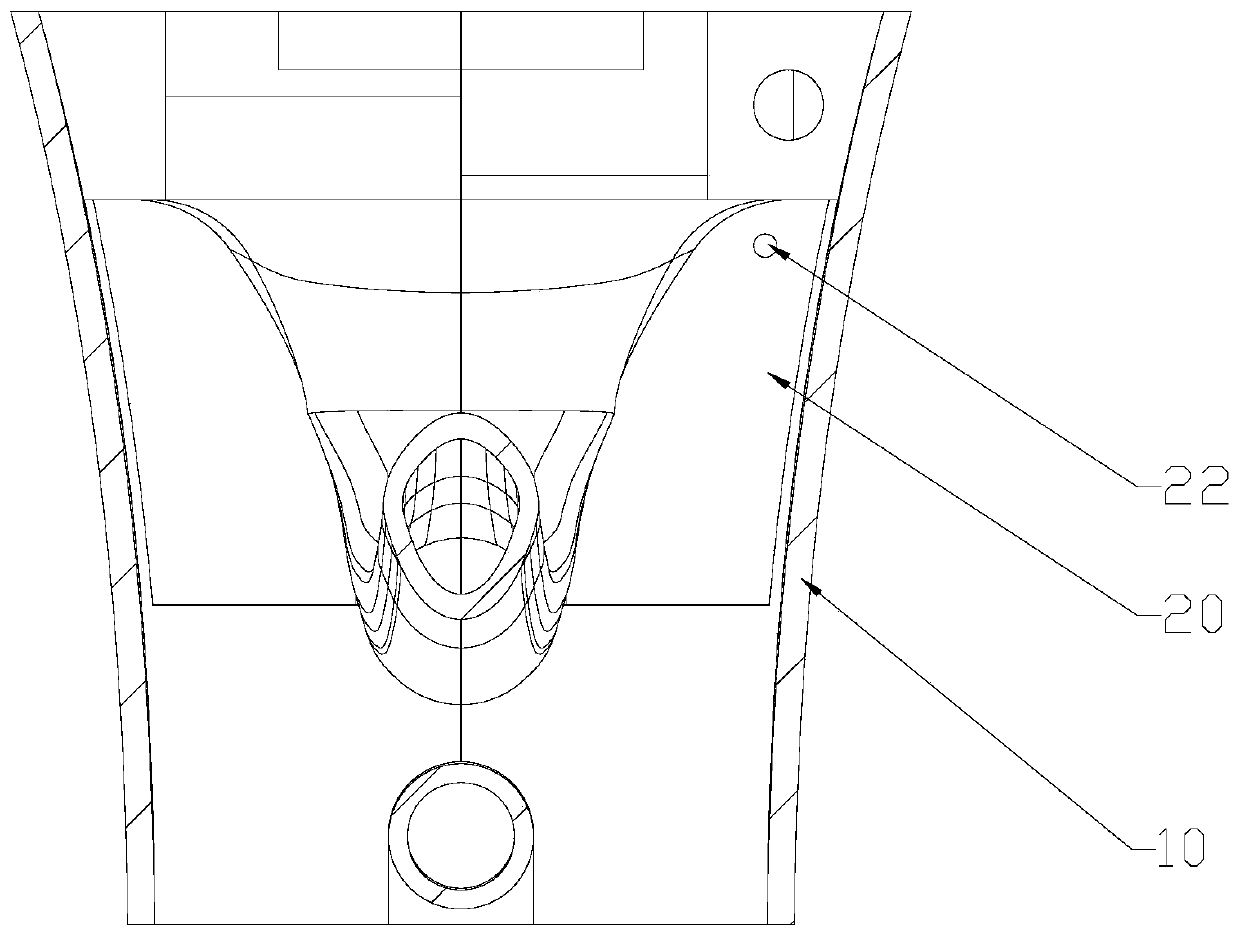

Toilet flushing device

PendingCN109797824ANovel design conceptSimple structureWater closetsFlushing devicesWater supplyToilet flushing

The invention discloses a toilet flushing device, comprising a toilet bowl with a pan. The bottom of the pan has sealing water which forms a water seal; the bottom of the pan is also provided with a spray hole; water in the spray hole is sprayed to the water seal. A water supply mechanism is also provided and can supplement water to the water seal when the toilet bowl performs siphoning. The toilet flushing device helps greatly improve flushing performance of a toilet bowl, flushing noise is greatly decreased, and the splashing problem is solved.

Owner:厦门派夫特卫浴科技有限公司

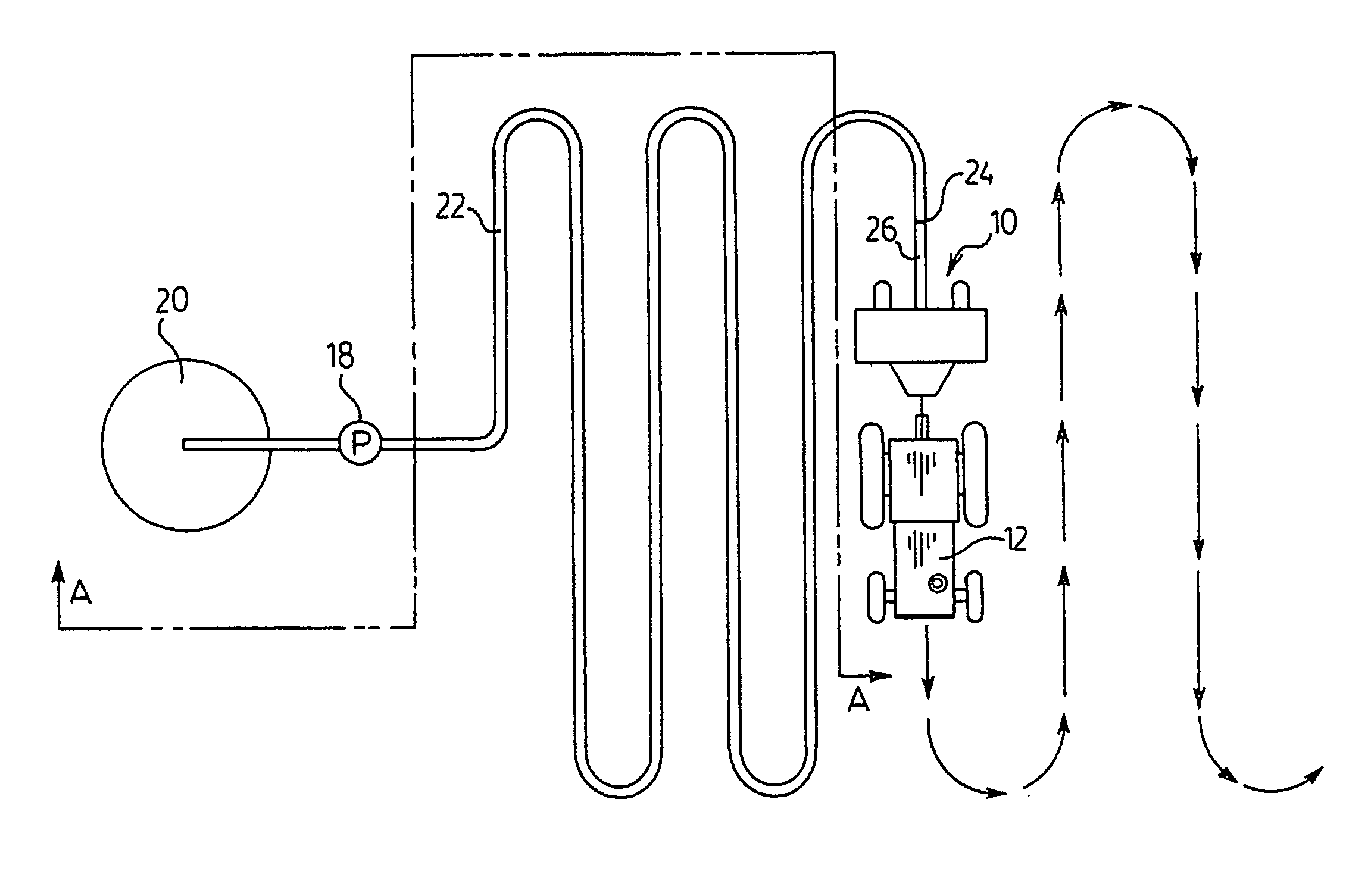

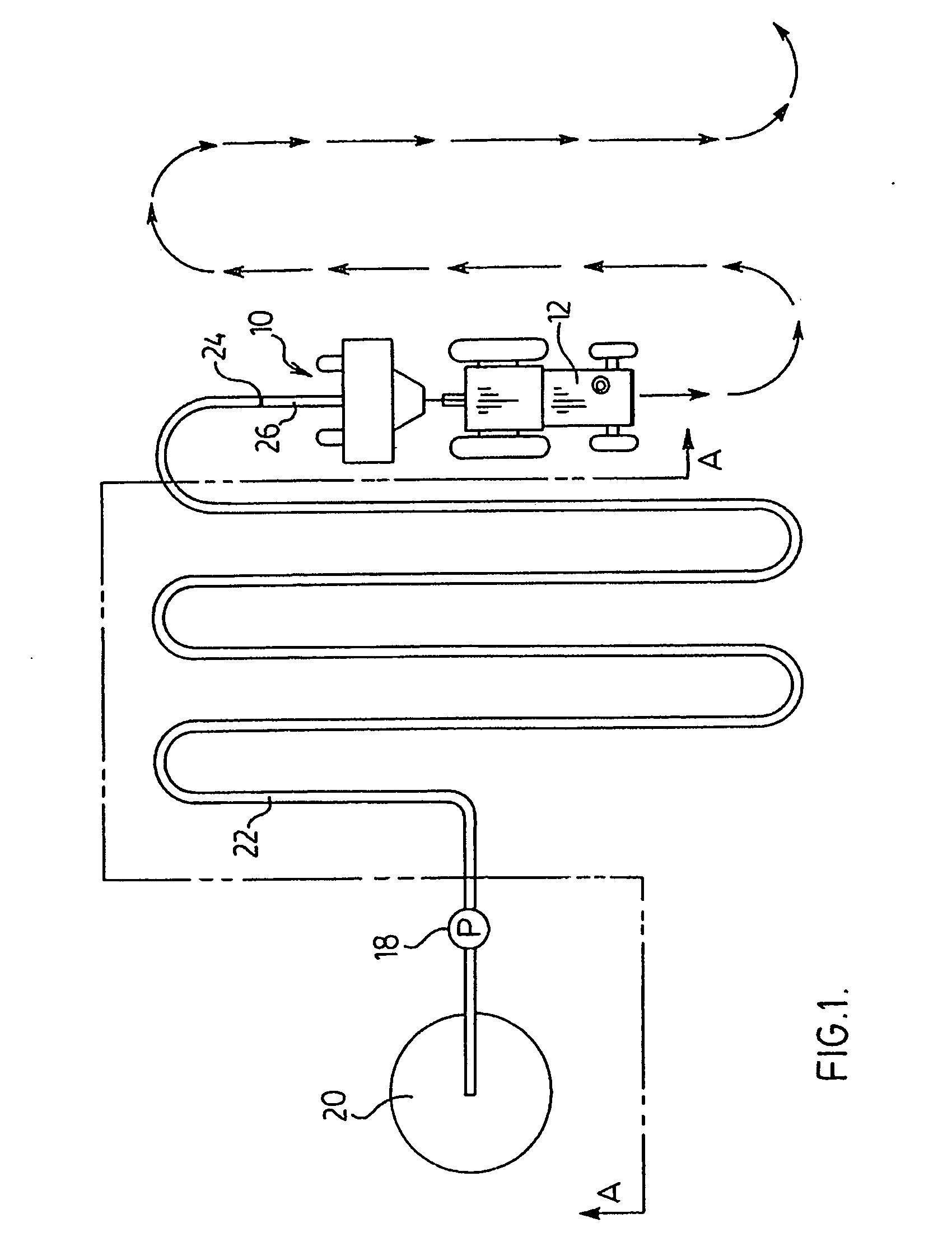

Anti-siphon arrangement for hydraulic systems

An anti-siphon arrangement for a hydraulic system with a reservoir includes first and second flow paths providing hydraulic communication between the reservoir and a lower area. Each flow path includes an anti-siphon portion extending at least partly above a fluid level of the reservoir. First and second valves are configured, when configured in open states, to allow gas to flow from a gas source to the anti-siphon portions of the first and second flow paths, respectively.

Owner:DEERE & CO

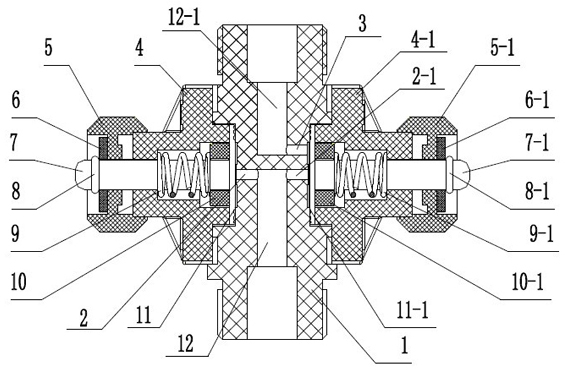

Four-functional valve

ActiveCN102052487APrevent backflowPrevent siphonMultiple way valvesValve housingsEngineeringHigh pressure

The invention relates to a valve, particular to a four-functional valve, wherein the body of the valve is provided with an upper blind hole and a lower blind hole; the lower blind hole is respectively connected to a first central hole arranged on an exhaust sampling valve and a second central hole arranged on a backpressure check valve; the upper blind hole is connected to a third central hole arranged on the backpressure check valve; the body of the valve is provided with a sampling port; the sampling port is connected to a drainage hole arranged on the exhaust sampling valve; the first central hole is connected to the sampling port 14 through a first sealing cavity formed by a first concentric annular boss and a first diaphragm; and the second central hole is connected to the third central hole through a second sealing cavity formed by a second concentric annular boss and a second diaphragm. In the invention, the safety valve, the sampling valve, the vent valve and the backpressure valve are integrated, which not only achieves the function required by a liquid-adding pipeline for user but also greatly relieves the difficulty of mounting and maintaining the pipeline. Besides, the four-functional valve is convenient and easy to operate, has low cost and is specially fit for high-pressure and low-flux liquid-medicine adding pipeline.

Owner:ZHEJIANG AILIPU TECH

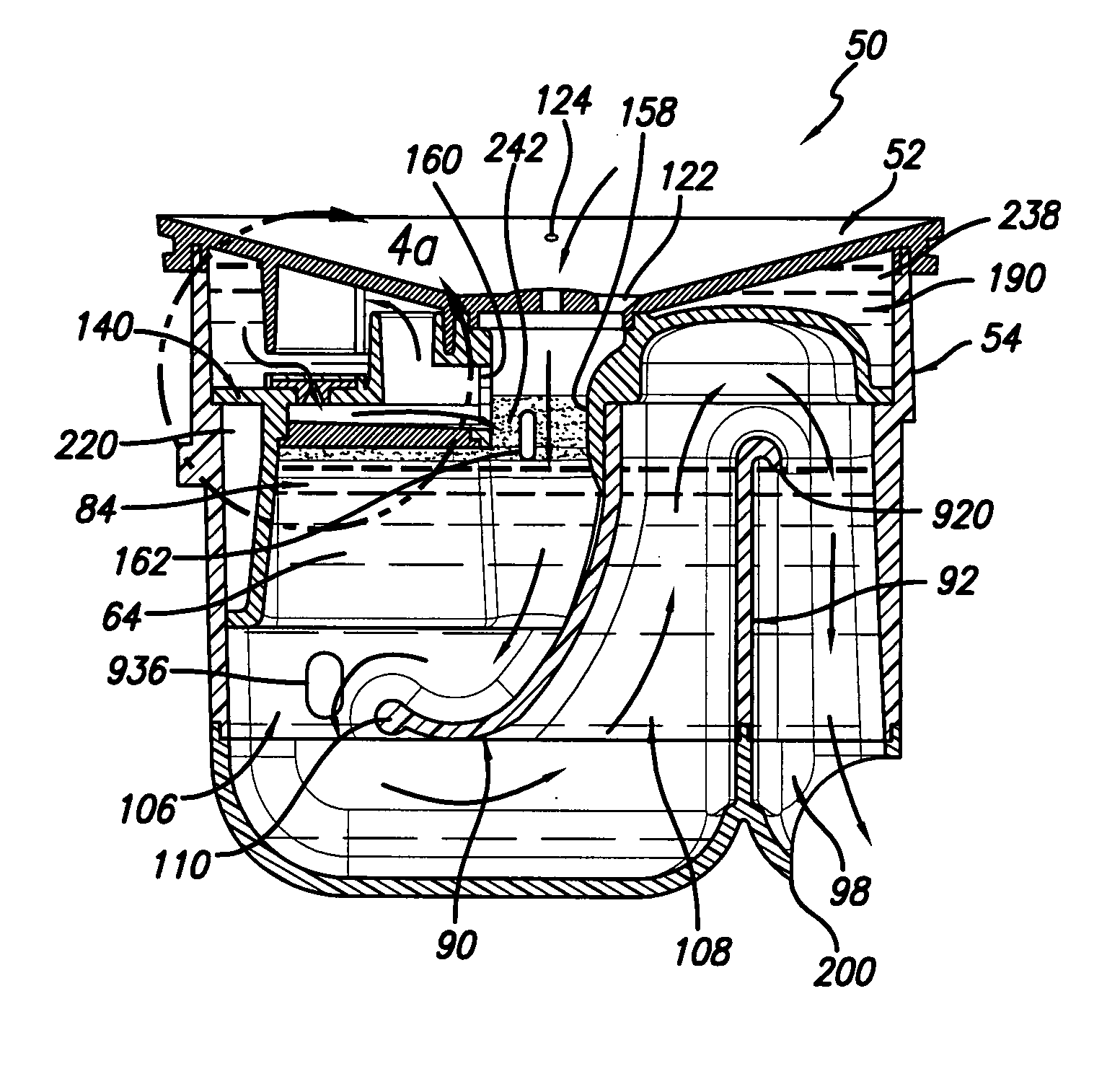

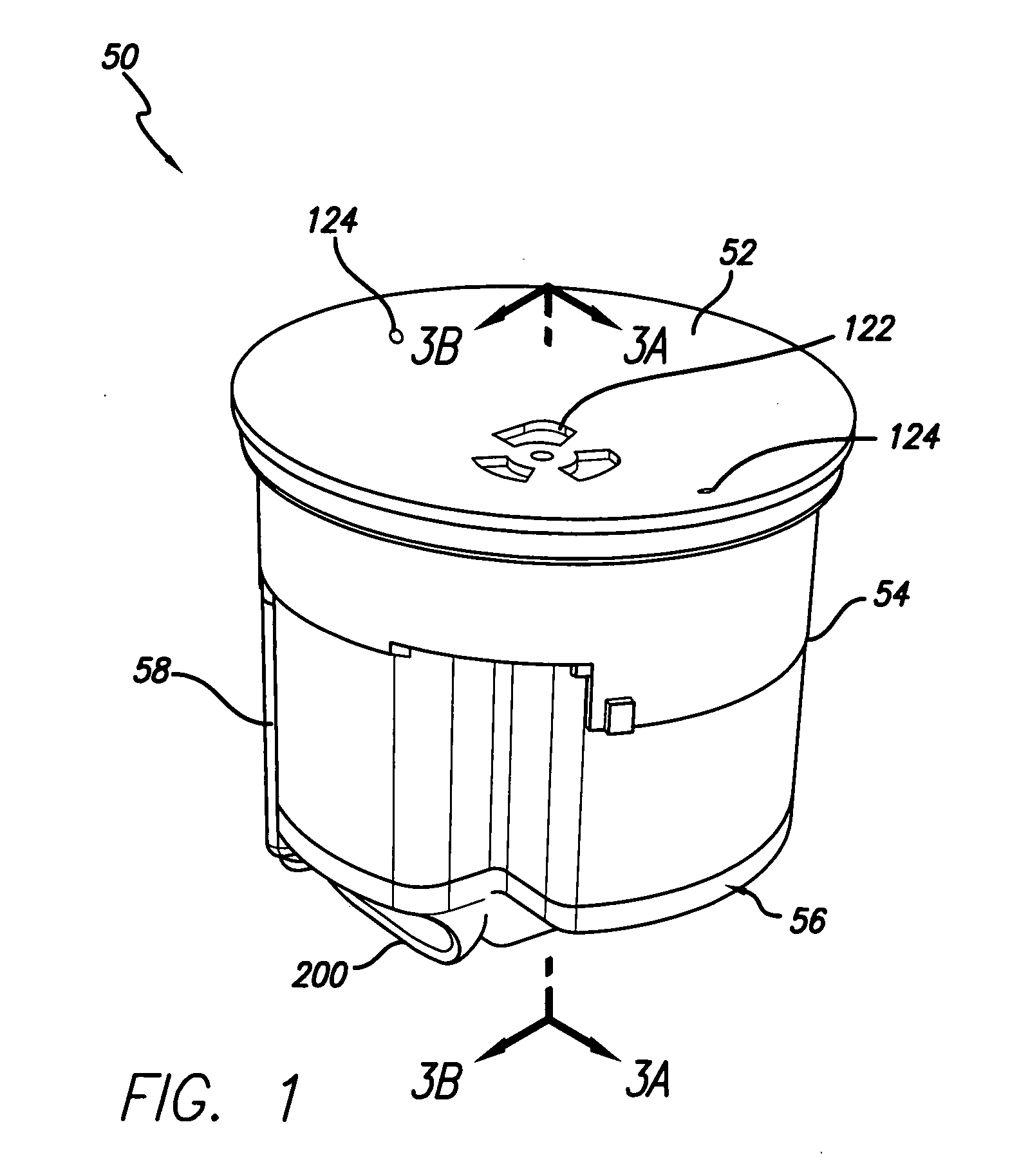

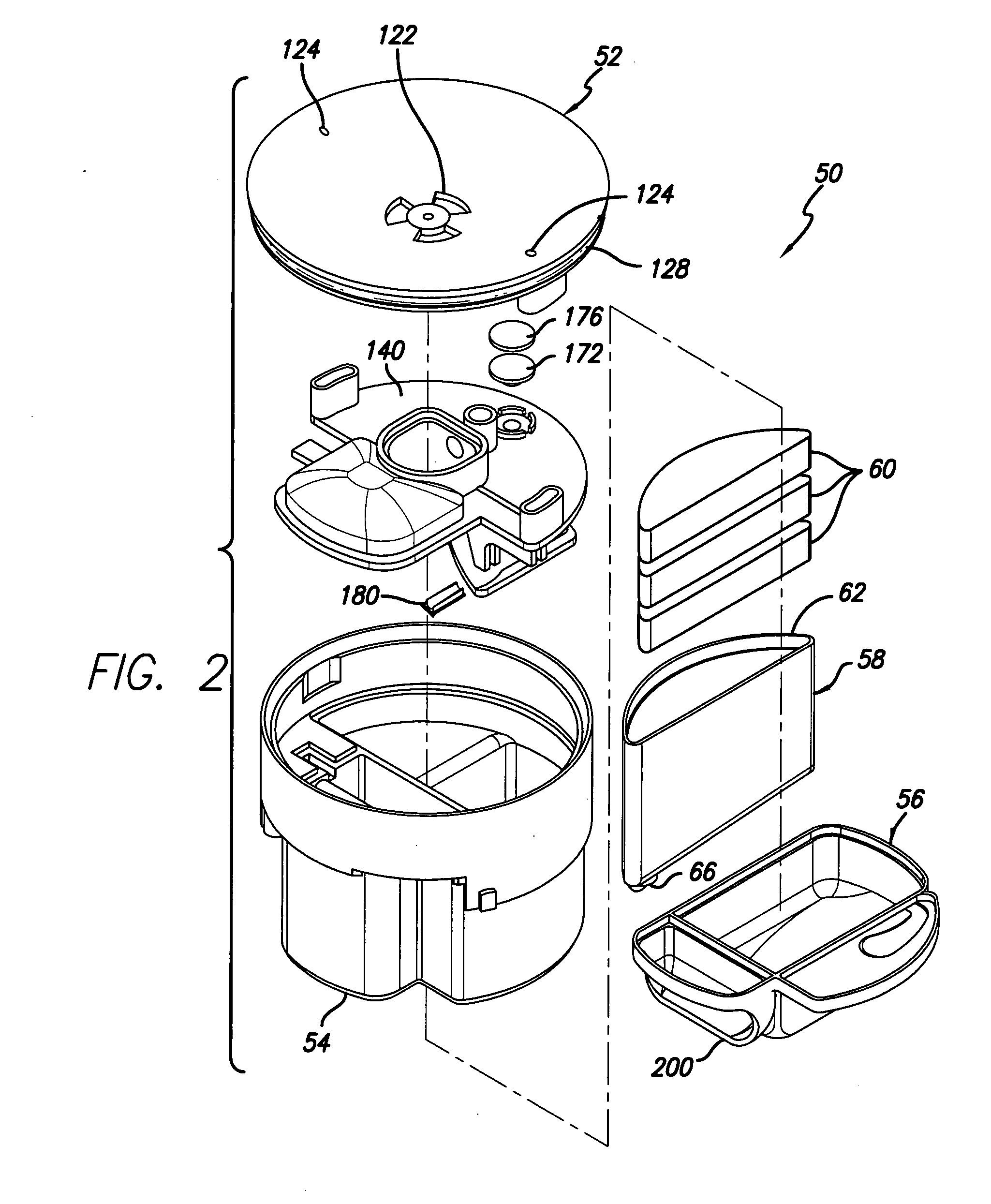

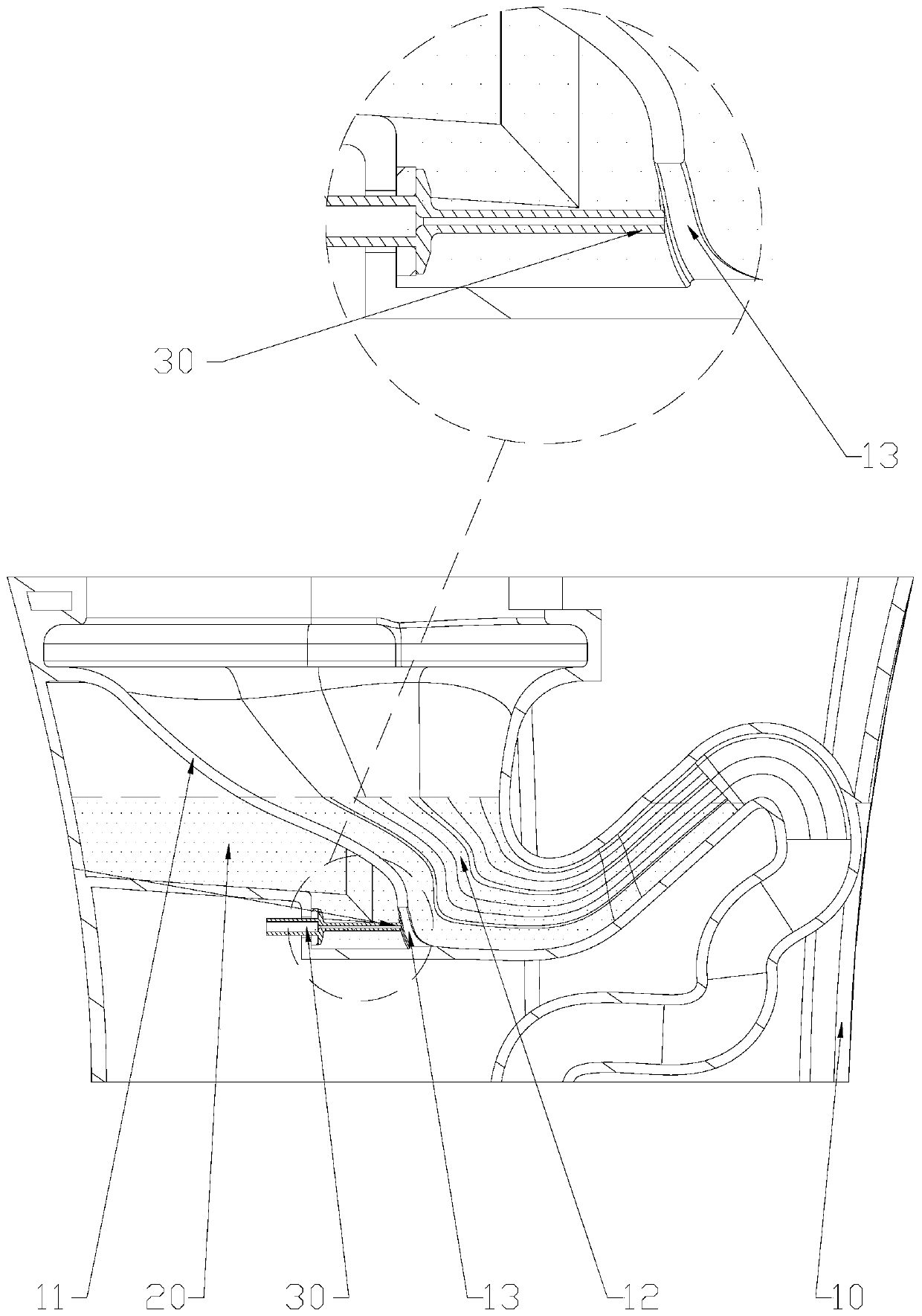

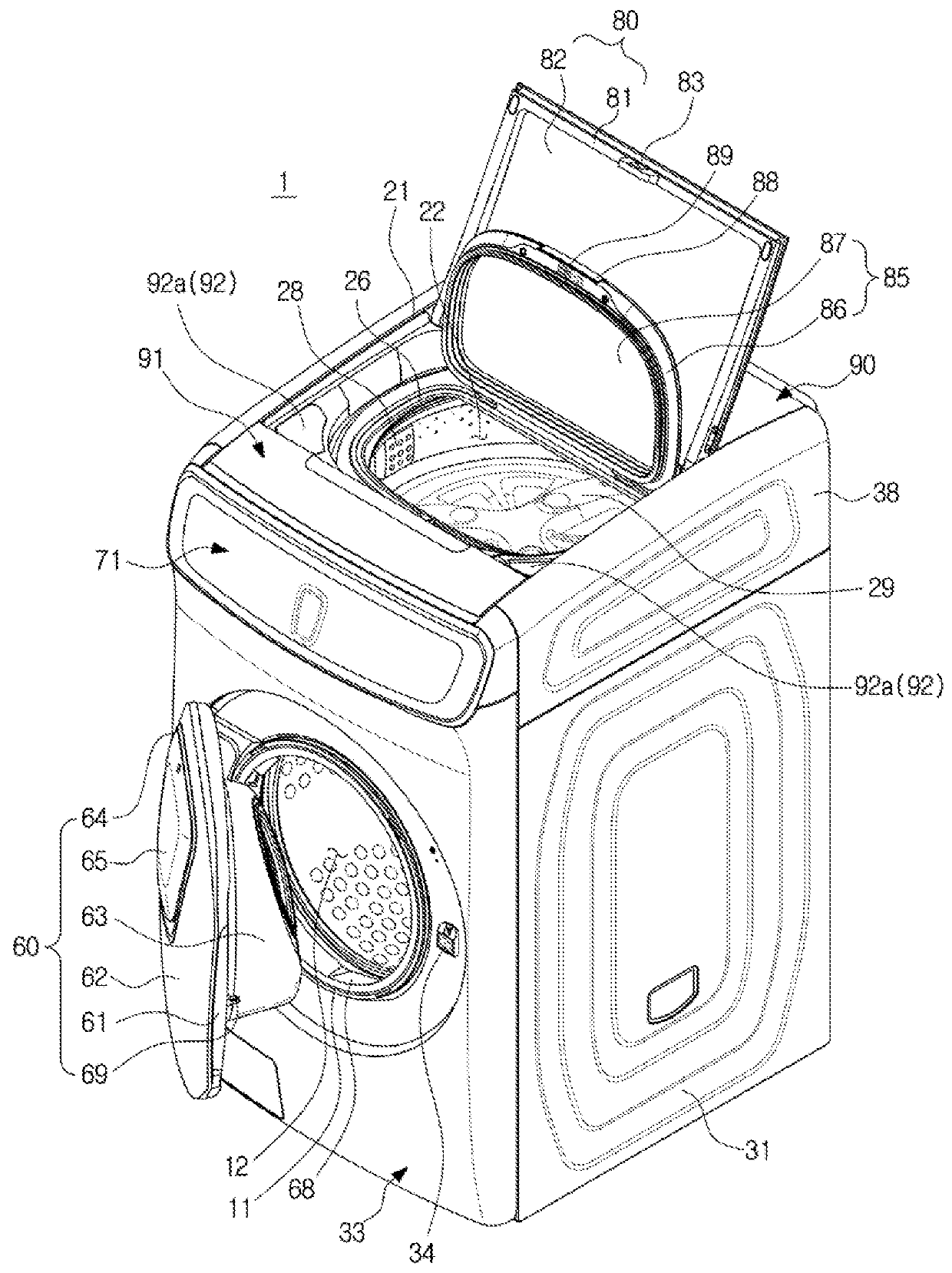

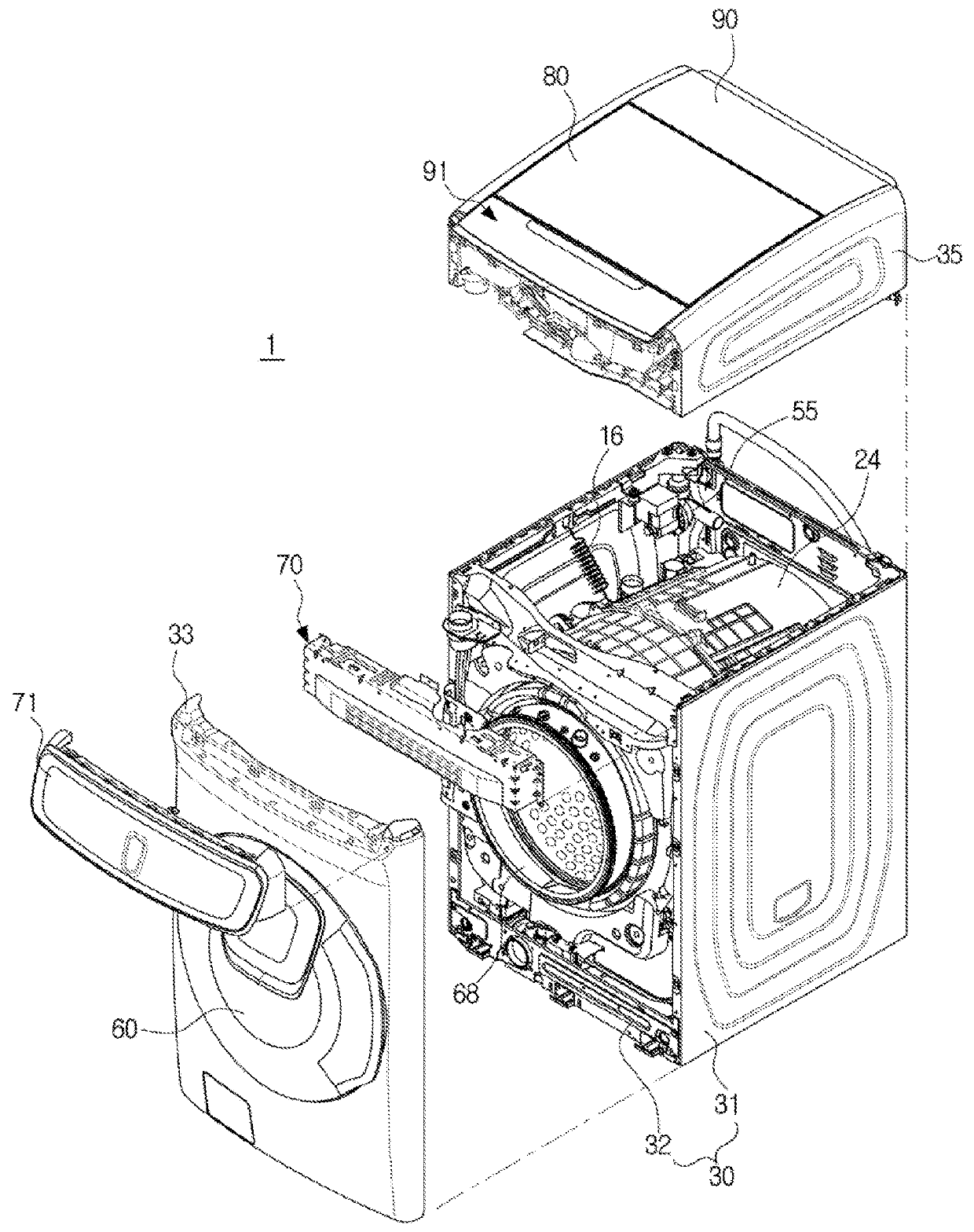

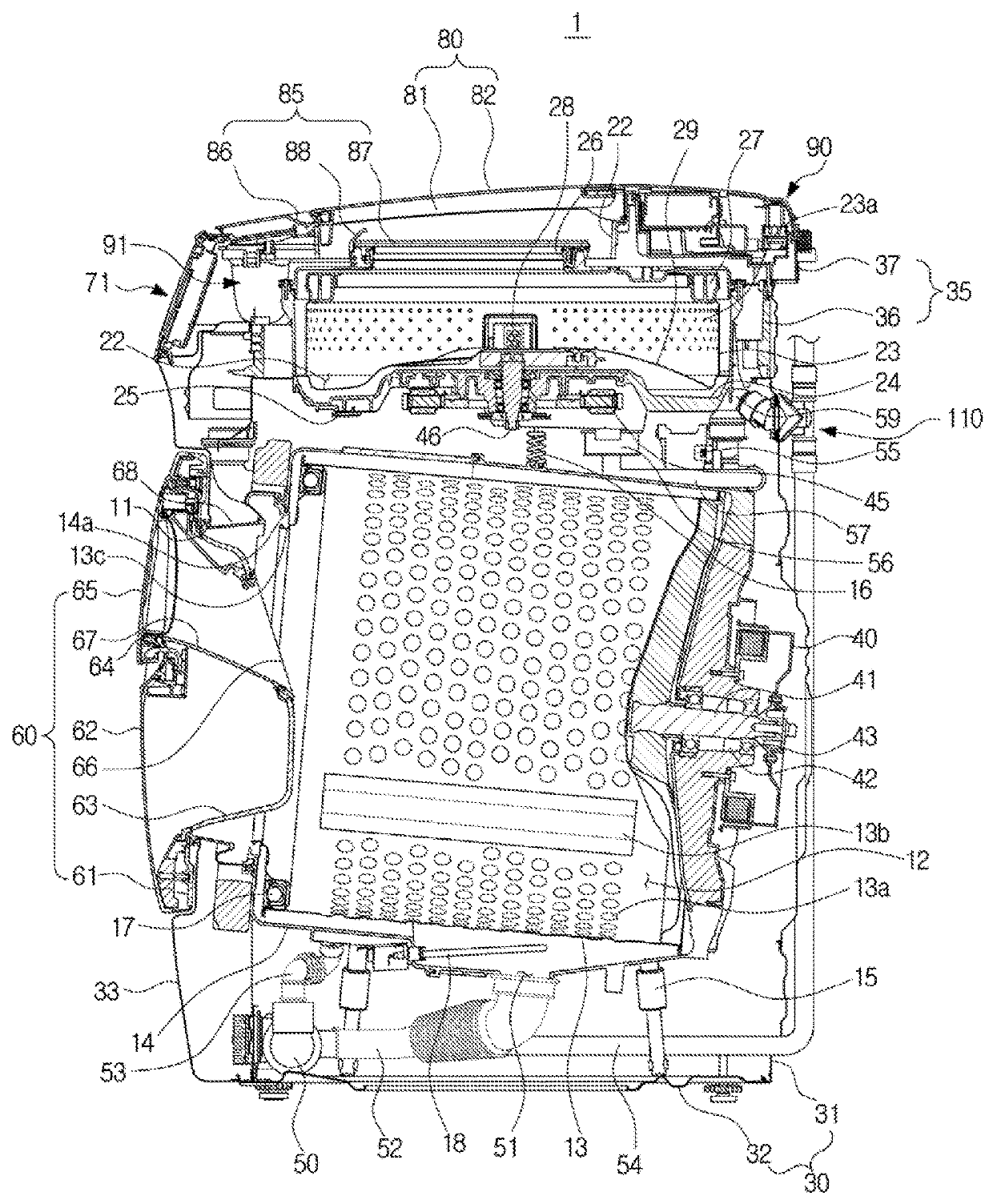

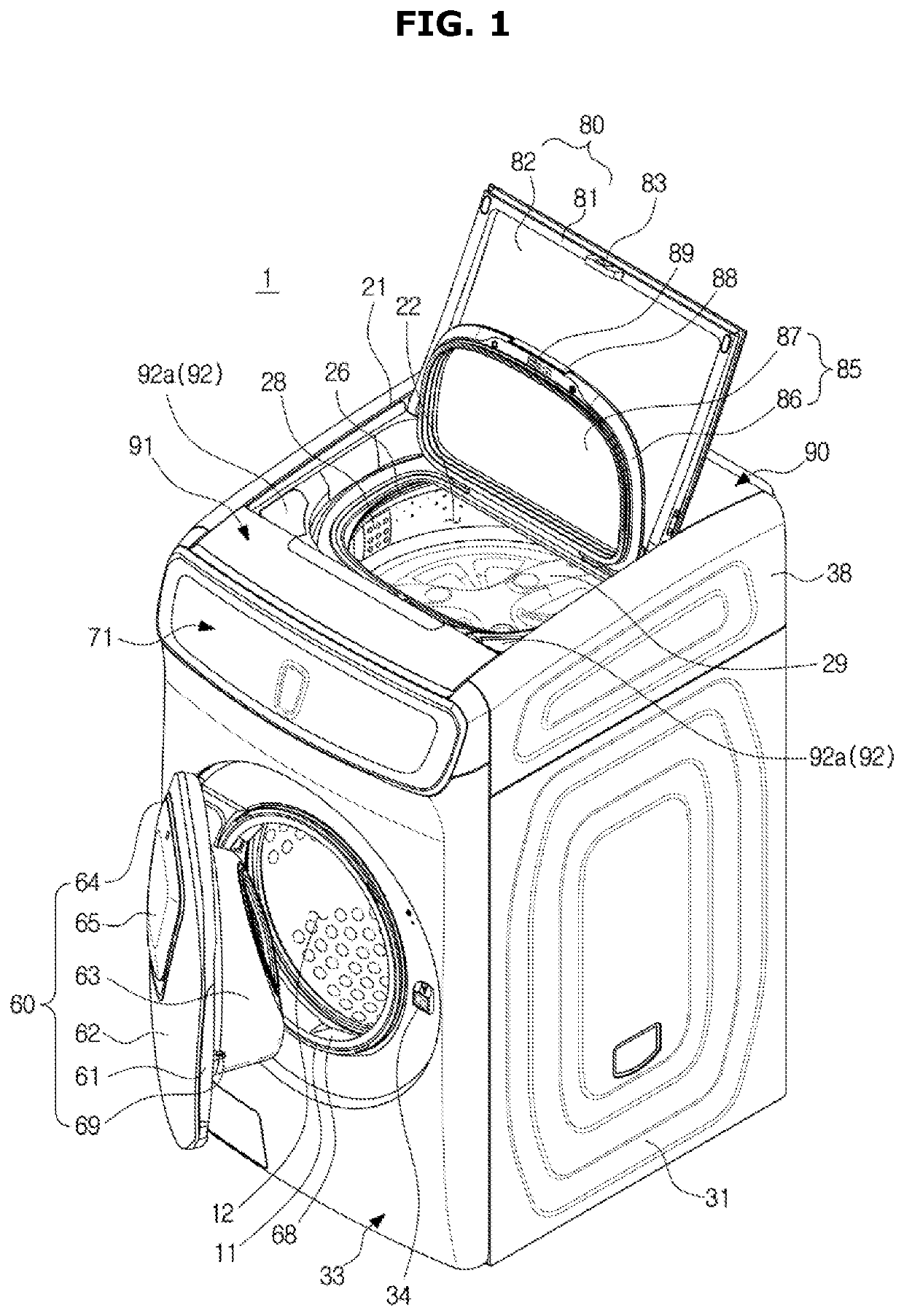

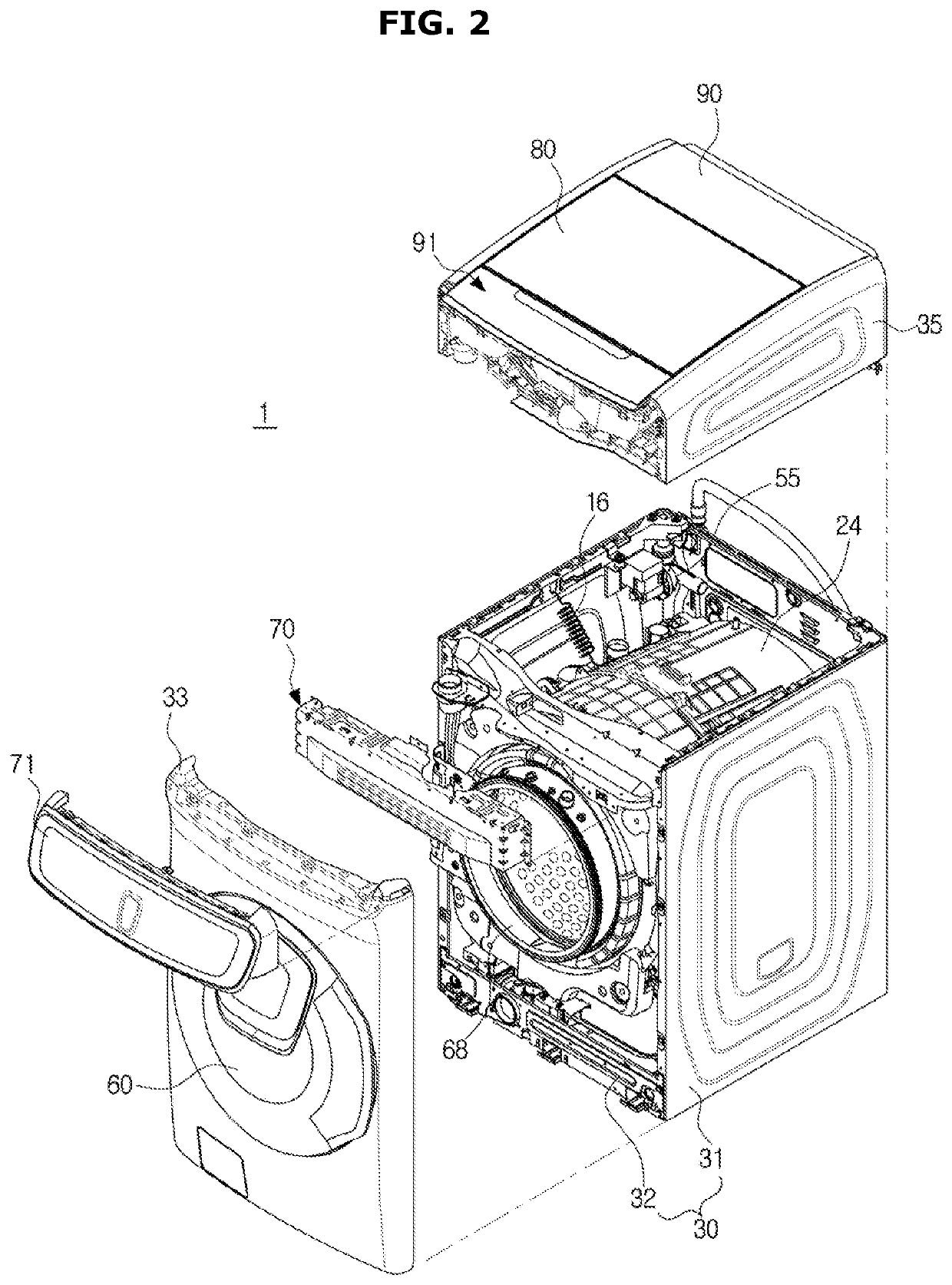

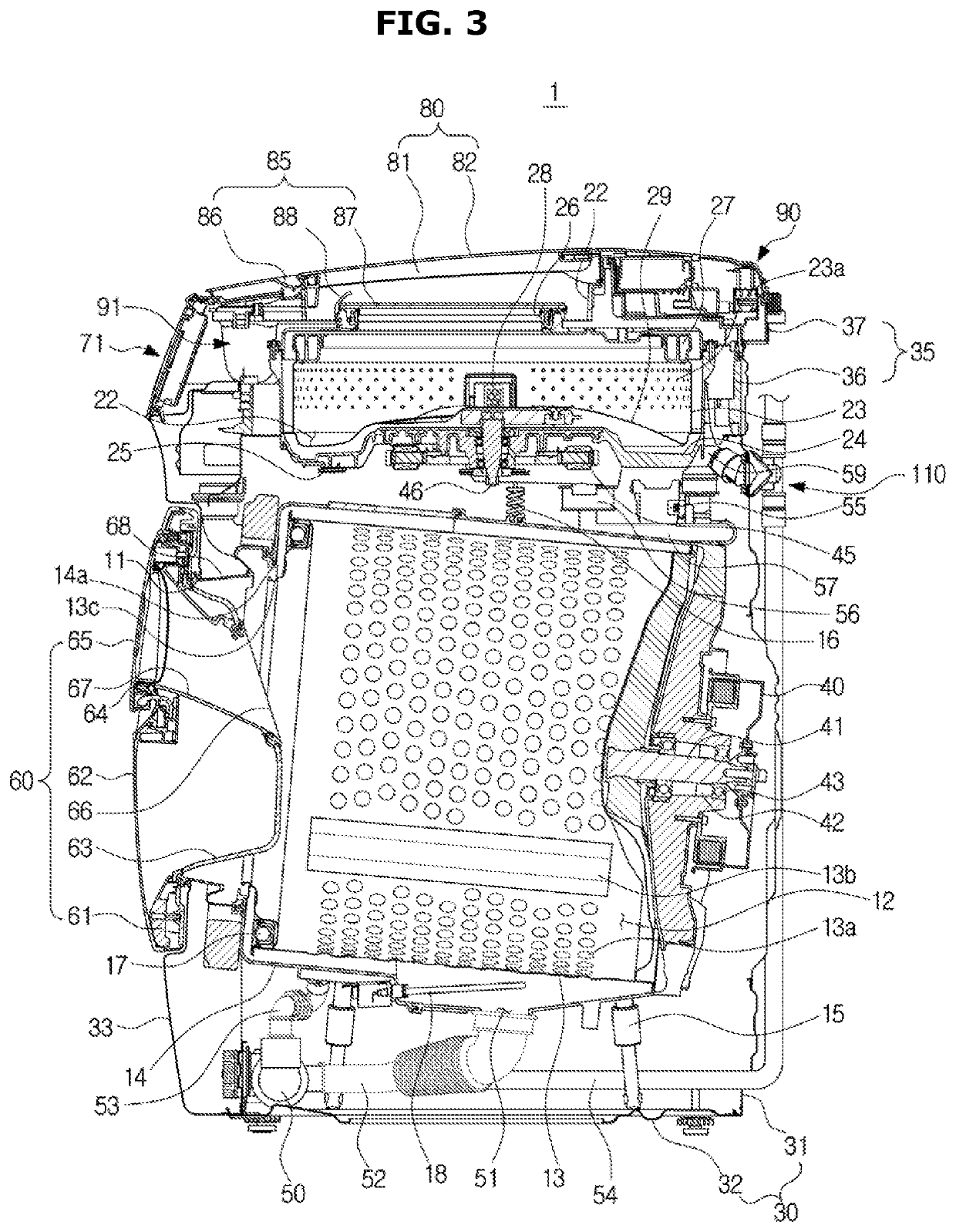

Washing machine

ActiveUS20180179682A1Prevent backflowReduce manufacturing costOther washing machinesWashing machine with receptaclesWater storageWash water

A washing machine is provided, The washing machine includes a first housing; a second housing disposed on the first housing; a first tub covered by the first housing and having a first opening formed at a front surface; a second tub covered by the second housing and having a second opening formed at an upper surface; a drain path provided to drain wash water of the first tub and wash water of the second tub and having at least one portion located at a position higher than a maximum water storage height of the second tub; and a connector coupled to the first housing and disposed at one portion of the drain path where wash water of the first tub and wash water of the second tub are joined.

Owner:SAMSUNG ELECTRONICS CO LTD

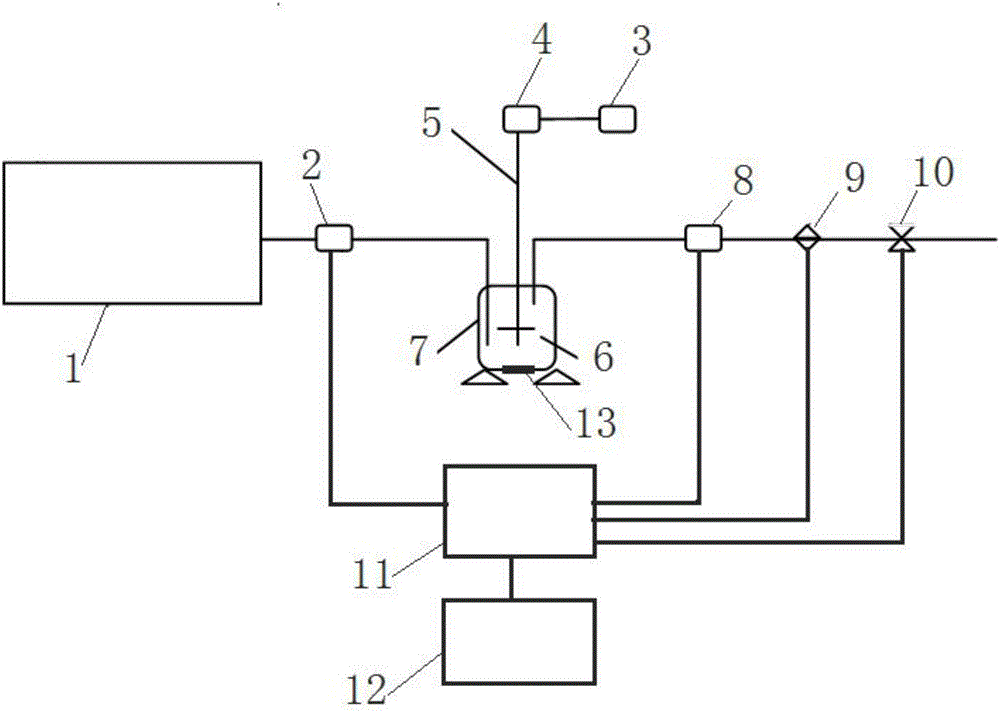

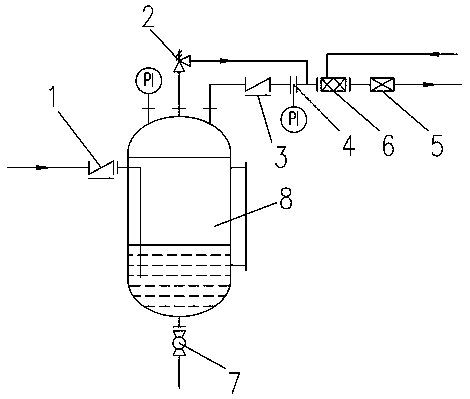

On-line calibration type automatic metering and blending system and method for liquid grinding aids

InactiveCN106140446AImprove continuityPrevent siphonCement productionGrain treatmentsSiphonMetering pump

The invention provides an on-line calibration type automatic metering and blending system for liquid grinding aids. The on-line calibration type automatic metering and blending system comprises a grinding aid storage tank, a transfer pump, a grinding aid weighing tank, a metering pump, a flow meter, an electromagnetic valve and a DCS control cabinet. An outlet of the grinding aid storage tank is connected with an inlet of the transfer pump through a pipeline. An outlet of the transfer pump is connected with an inlet of the grinding aid weighing tank through a pipeline. An outlet of the grinding aid weighing tank is connected with an inlet of the metering pump through a pipeline. An outlet of the metering pump is connected with an inlet of the flow meter through a pipeline. An outlet of the flow meter is connected with an inlet of the electromagnetic valve through a pipeline. An outlet of the electromagnetic valve is connected with a discharging point pipeline. The signal output end of the flow meter is connected with the signal input end of the DCS control cabinet. The signal output end of the DCS control cabinet is connected with the signal input end of the transfer pump, the signal input end of the metering pump and the signal input end of the electromagnetic valve. The DCS control cabinet is connected with an upper computer. By the adoption of the on-line calibration type automatic metering and blending system for the liquid grinding aids, the continuity, accuracy, calibration and siphon avoidance in cement blending can be improved.

Owner:襄阳海螺新材料科技有限公司

Washing machine

ActiveUS11001953B2Reduce manufacturing costPrevent siphonOther washing machinesWashing machine with receptaclesWater storageLaundry washing machine

A washing machine is provided. The washing machine includes a first housing; a second housing disposed on the first housing; a first tub covered by the first housing and having a first opening formed at a front surface; a second tub covered by the second housing and having a second opening formed at an upper surface; a drain path provided to drain wash water of the first tub and wash water of the second tub and having at least one portion located at a position higher than a maximum water storage height of the second tub; and a connector coupled to the first housing and disposed at one portion of the drain path where wash water of the first tub and wash water of the second tub are joined.

Owner:SAMSUNG ELECTRONICS CO LTD

VOCs pre-collecting treatment system with water seal and treatment method of VOCs pre-collecting treatment system

PendingCN110173702APrevent backfirePrevent siphonIncinerator apparatusAir quality improvementProduct gasEngineering

The invention discloses a VOCs pre-collecting treatment system with a water seal and a treatment method of the VOCs pre-collecting treatment system. A pre-collector, a waste gas main pipeline arrangedat one side position of the pre-collector, a first pipeline arranged at the bottom of the pre-collector, a second pipeline arranged on the top of the pre-collector, a third pipeline arranged on the top of the pre-collector and an RTO device arranged at the tail end of the third pipeline are included. The waste gas main pipeline is connected with the pre-collector and stretches to the position below the liquid level of the pre-collector. The second pipeline is provided with a safety valve, one end of the second pipeline is connected with the pre-collector, and the other end of the second pipeline is connected to the third pipeline. The third pipeline is provided with a check valve and a gas mixer, a flow limiting hole plate is arranged between the check valve and the gas mixer, the gas mixer is externally connected with a connecting pipeline, and inflation of inert gas is conducted through the connecting pipeline. The VOCs pre-collecting treatment system has the beneficial effects thatthe integral structure of the device is simple, safety and stability are achieved, RTO production explosion accidents are effectively prevented, and the variable work condition capability of the RTOdevice is enhanced.

Owner:CHINA NAT AIR SEPARATION ENG CO LTD

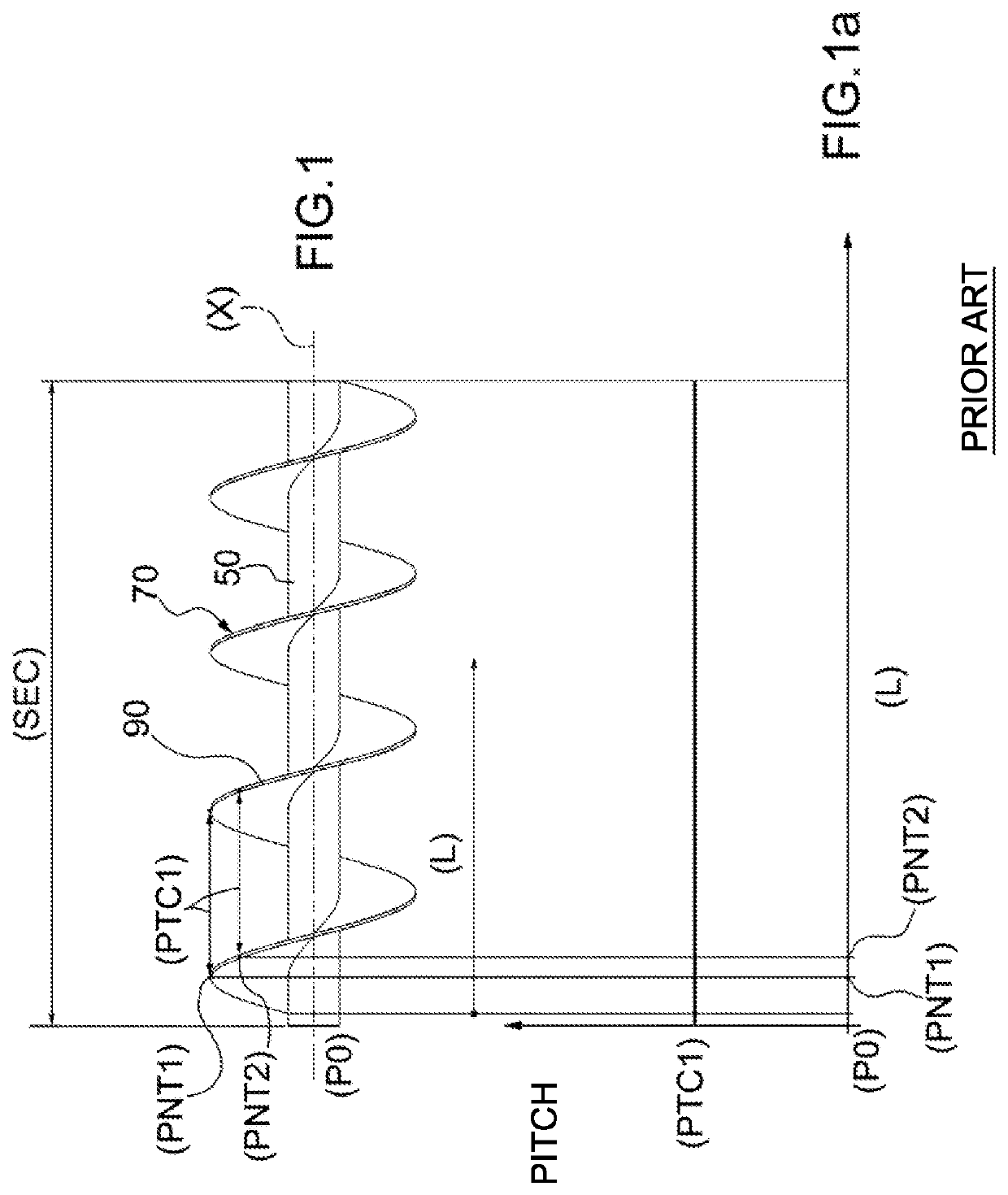

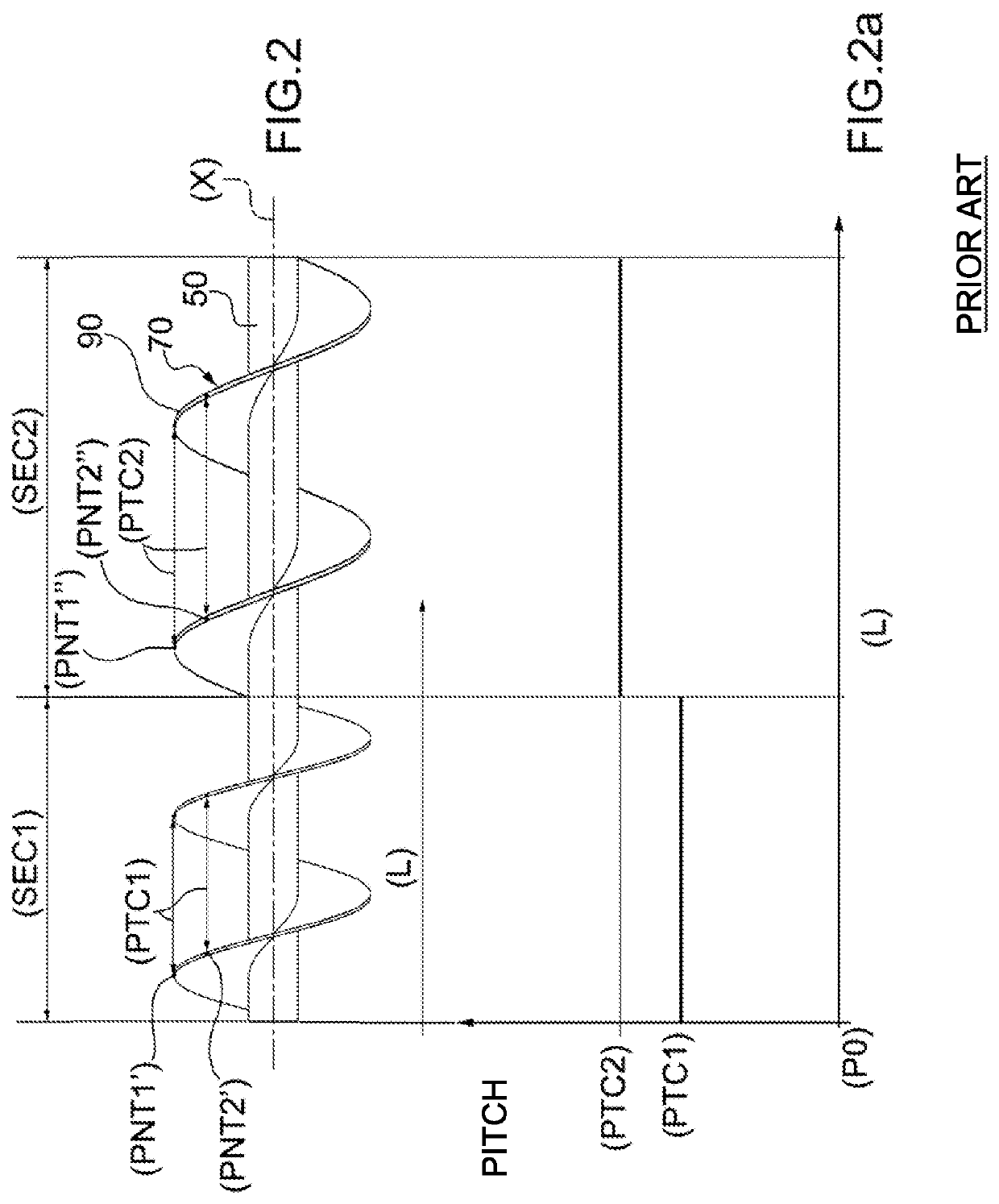

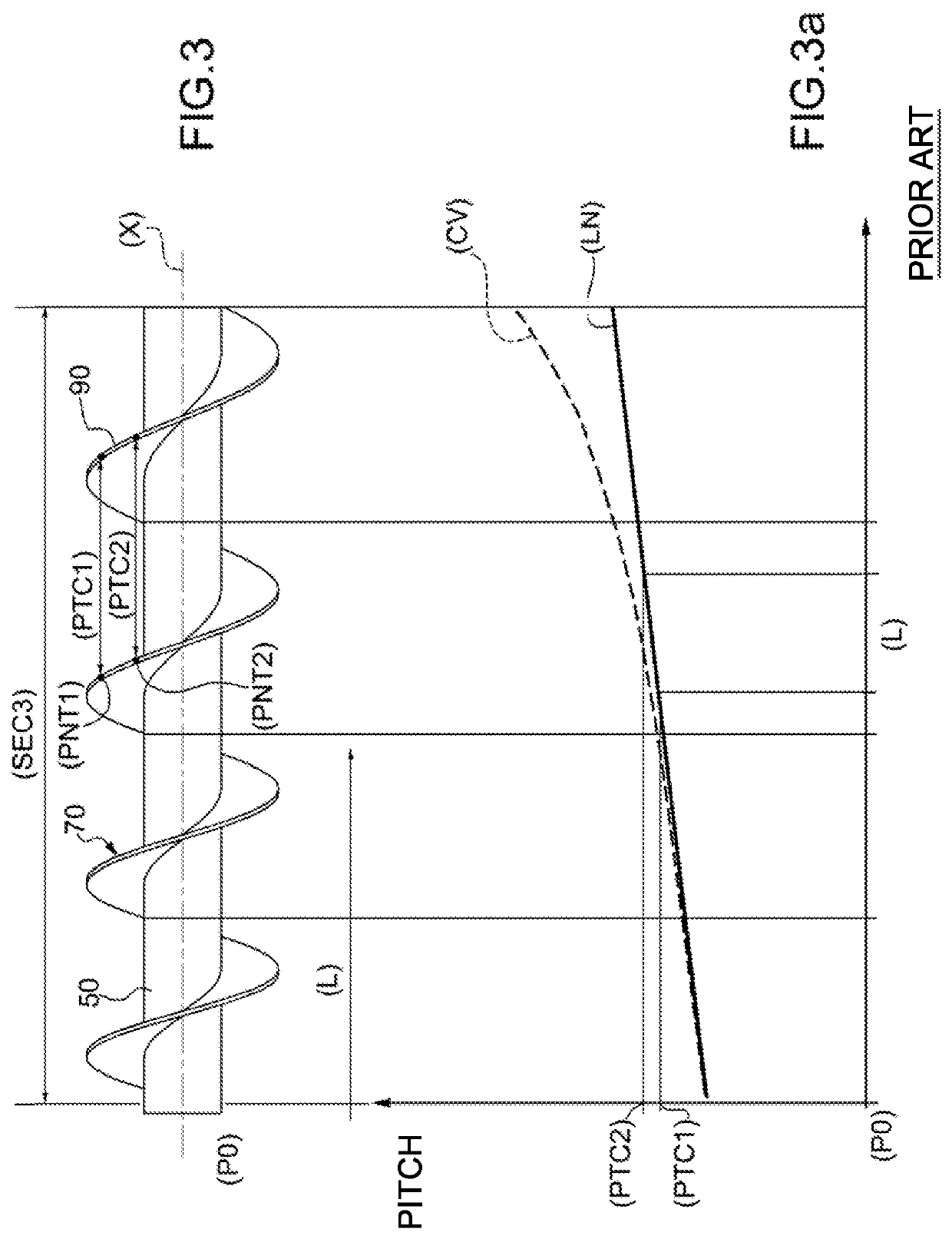

Screw conveyor to convey powdery material, in particular cement or the like

ActiveUS10759609B2Minimize wasteReduced forward resistanceBulk conveyorsPackagingThermodynamicsEngineering

A screw conveyor to convey powdery material, in particular cement. The screw conveyor comprises:a transfer screw; anda trough containing the transfer screw; the trough being provided with an inlet section and an outlet section of the powdery material.The screw conveyor is characterized in that the screw comprises:at least a first screw portion having a first law of continuous variation of the pitches of the screw, which can be graphically represented by means of a first function having in at least one stretch a first derivative other than zero; andat least a second screw portion having a second law of continuous variation of the pitches of the screw, which can be graphically represented by a second function having in at least one stretch a first derivative other than zero. The first law of continuous variation of the pitches is different from the second law of continuous variation of the pitches.

Owner:WAMGRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com