Urinal cartridge with improved performance

a technology of urinal cartridges and urinals, applied in water installations, construction, domestic applications, etc., can solve the problems of reducing the life of the cartridge, relating to the loss of sealant,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

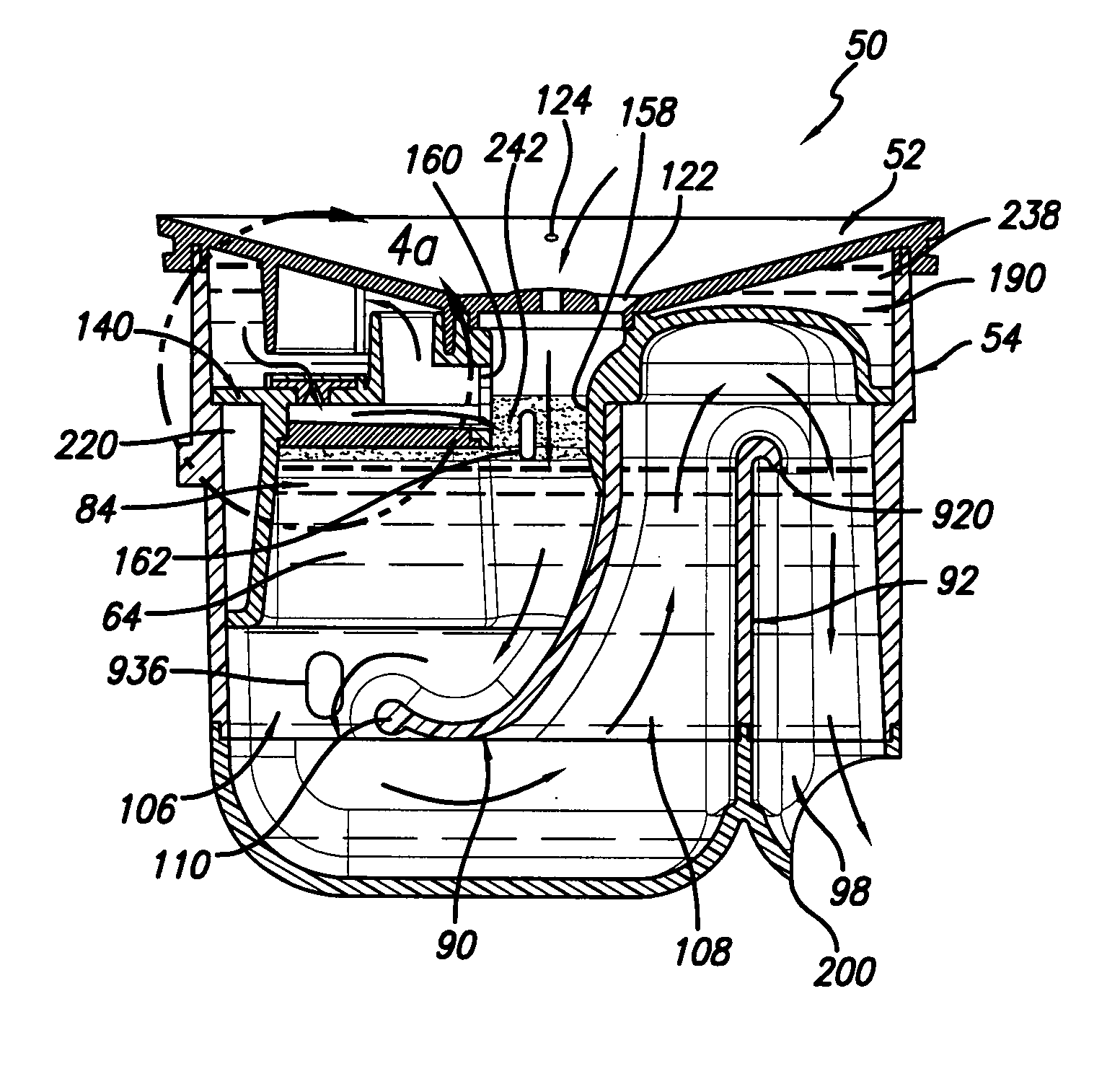

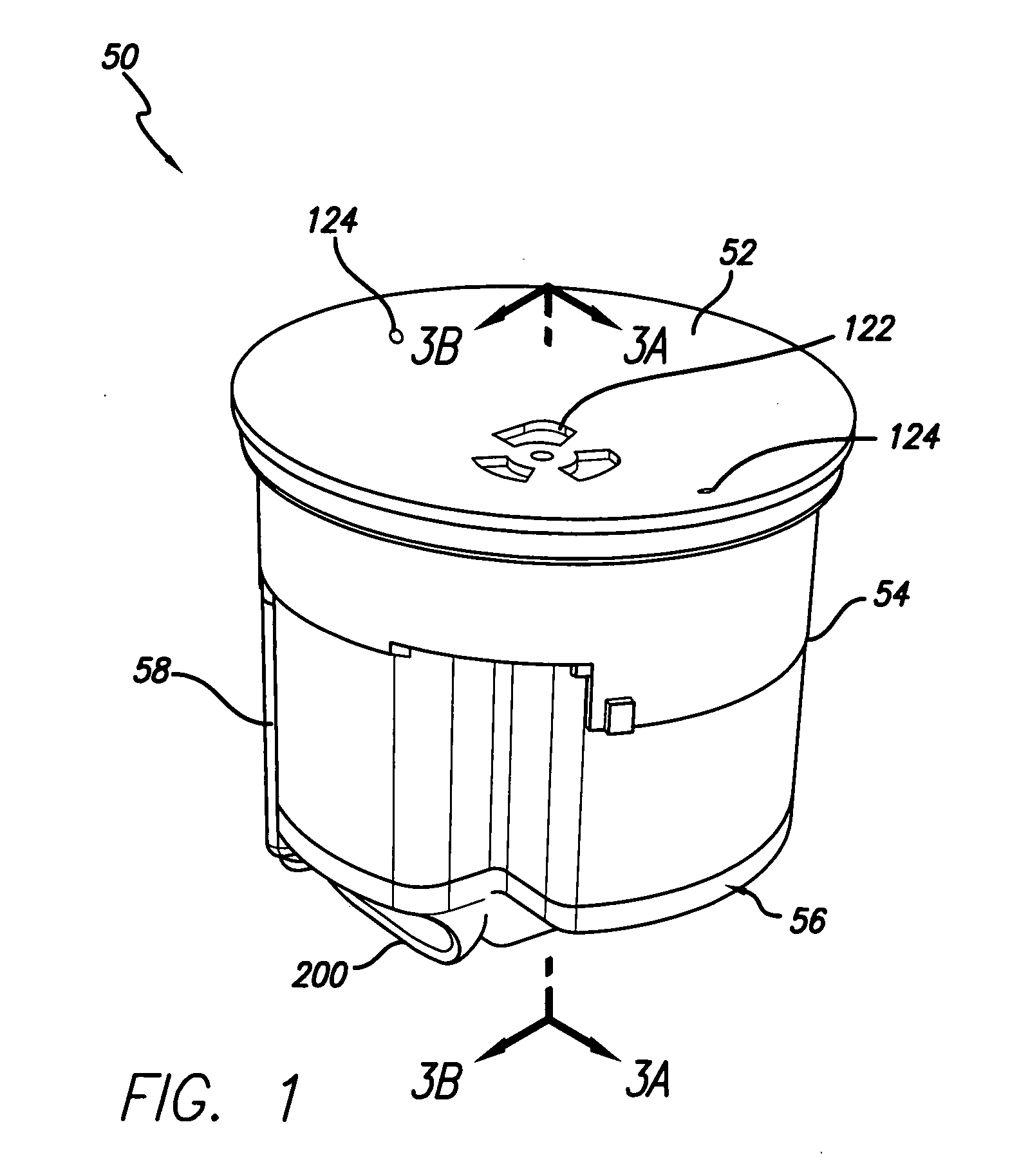

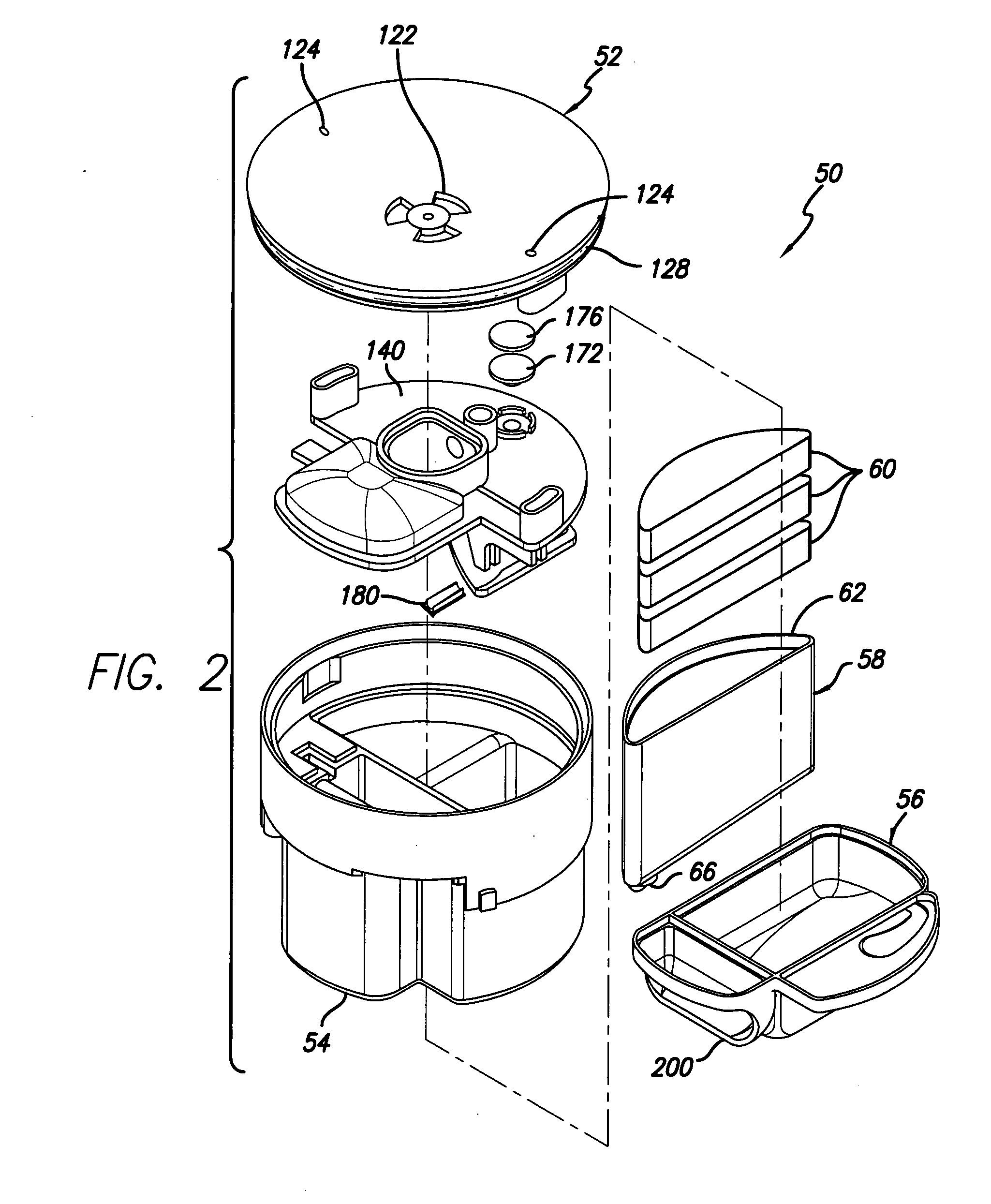

[0074] In the following exposition, a first embodiment has openings to a secondary reservoir or chamber for holding sealant and any wastewater that may accompany it. The second embodiment has a modification of the first embodiment in which such openings are not employed and, therefore, do not utilize the secondary reservoir or chamber. The third embodiment utilizes a water reservoir. Consistent therewith, the figure numbering and indicia attendant to the components depicted in the figures relevant to the second embodiment modification use numerals and the letter “M” and, for the third embodiment, indicia using the letter “x”; otherwise, there are no other distinguishing features made among the three embodiments. The three preferred embodiments can be used individually or in combination

[0075] Accordingly, as shown in FIGS. 1-4, 4A and 4M, a cartridge 50 for placement in a urinal includes a top portion 52, an intermediate portion 54 / 54M and a bottom portion 56. A compartment 58, cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com