VOCs pre-collecting treatment system with water seal and treatment method of VOCs pre-collecting treatment system

A treatment system and pre-collector technology, applied in the direction of combustion methods, lighting and heating equipment, combustion types, etc., can solve problems such as complex components, false alarms, inability to provide early warning and reduce VOCs, etc., to enhance the ability to change working conditions , prevent explosion accidents, and the overall structure is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

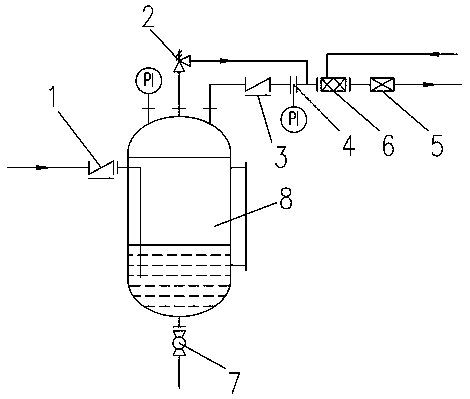

[0031] Example: VOCs waste gas released by the vent valve of the reactor or the breather valve of the storage tank (the main components are: toluene, xylene, ethyl acetate, Q=0.18m 3 / h, P=0.3MPa), through the exhaust gas main pipe (DN100), through a back pressure valve (BY-S100 / 0.5) into the pre-collection device 8 (working pressure 0.5MPa, volume 2m 3 ), with safety valve 2 (A62H5H), which is discharged after passing through the water seal, through the check valve 3 (H61H-3R), through the flow limiting orifice 4 (single-hole veneer, d=0.06m) to regulate the stable exhaust gas flow, and enter In the gas mixer 6, inert gas (Q=1.2m) is passed into the gas mixer 6 (SH L / D=6) 3 / h) mixed with exhaust gas to ensure that the concentration of exhaust gas is lower than 25% of the lower explosion limit, and the mixture of inert gas and exhaust gas passes through the flame arrester 5 continuously and stably before entering the RTO device.

[0032] The purpose of the present invention ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com