Drainage air weir system for constant-water-level sedimentation tank and use method of drainage air weir system

An air drainage weir and air weir technology, which is applied in the fields of flocculation/sedimentation water/sewage treatment, sedimentation separation, separation methods, etc., can solve the problems of inapplicability, high construction requirements, and inability to remove scum from the liquid surface, and prevent siphoning. , to avoid the effect of short flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

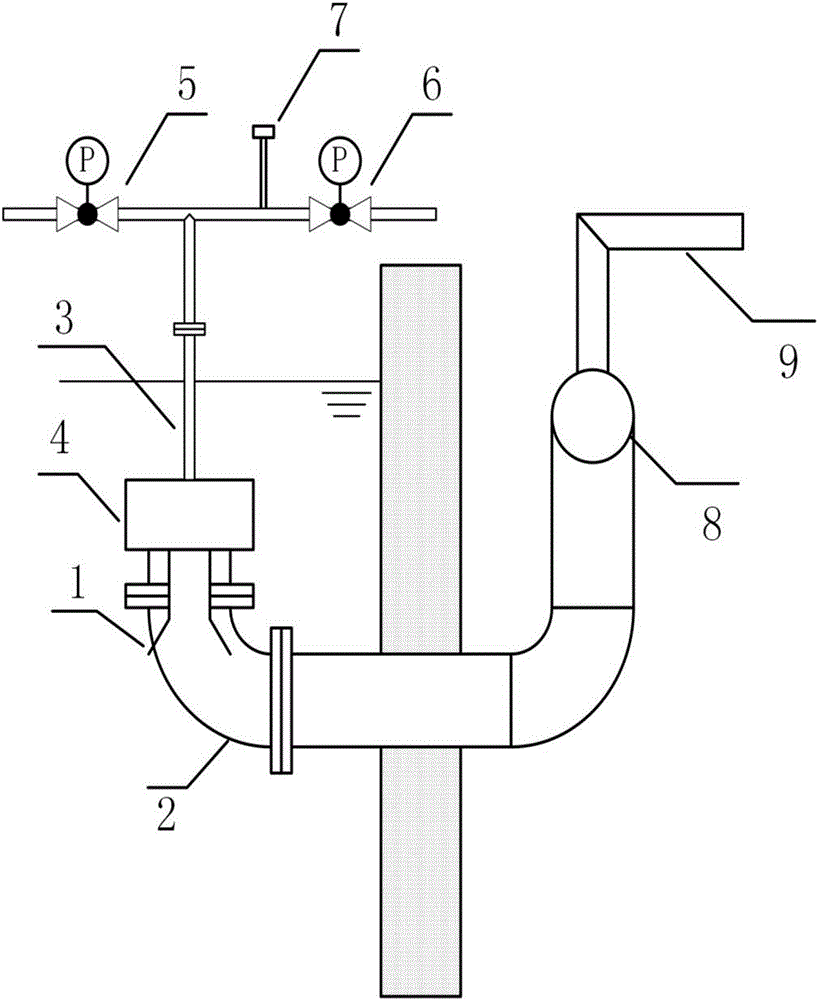

[0026] Implementation case one, the use method of the air drainage weir of the present invention, comprises the following steps:

[0027] 1) The constant water level sedimentation tank is filled with purified sewage, and the controlled sewage water level must be higher than the air weir chamber 3 and lower than the central elevation of the main outlet pipe 8;

[0028] 2) When the air weir is discharging water, close the intake valve 5 and open the exhaust valve 6, the air in the air weir chamber 3 is discharged into the atmosphere through the exhaust valve 5 under the action of water pressure, and the water level in the water inlet 1 gradually rises , and flow through the outlet pipe 2, when the water level rises above the central elevation of the outlet pipe 8, it starts to drain, and continues to drain until the set drainage time;

[0029] 3) After the drainage is finished, open the air weir intake valve 5 and close the air weir exhaust valve 3 at the same time, the air begi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com