Submersible electrical power generating plant

a technology of submerged electrical power and generating plant, which is applied in the direction of electric generator control, machines/engines, mechanical equipment, etc., can solve the problems of devastating impact, few are aware of the seriousness of the problem, and operate at quite the same high capacity factor in that current, and achieve the effect of reducing the risk of accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

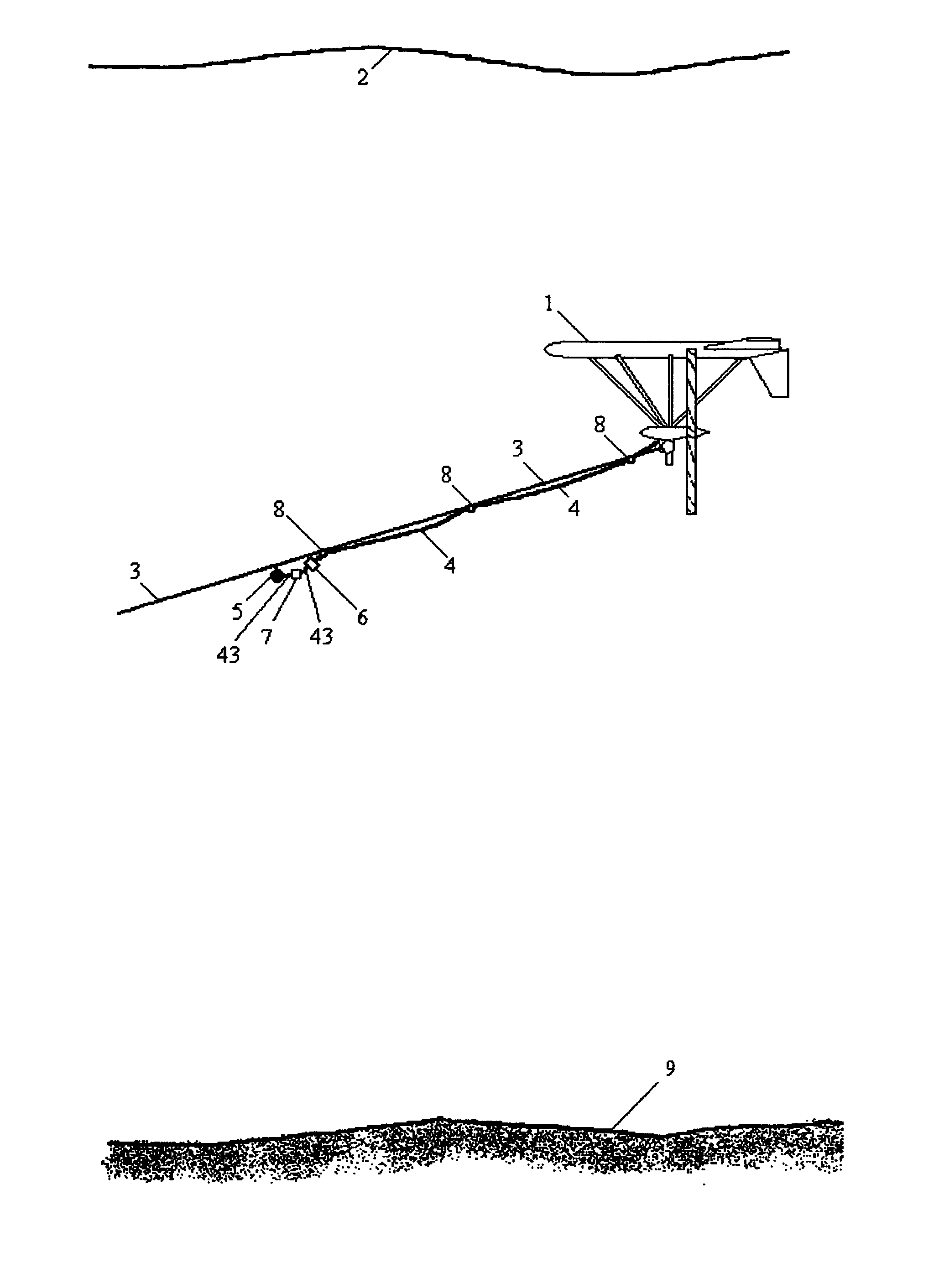

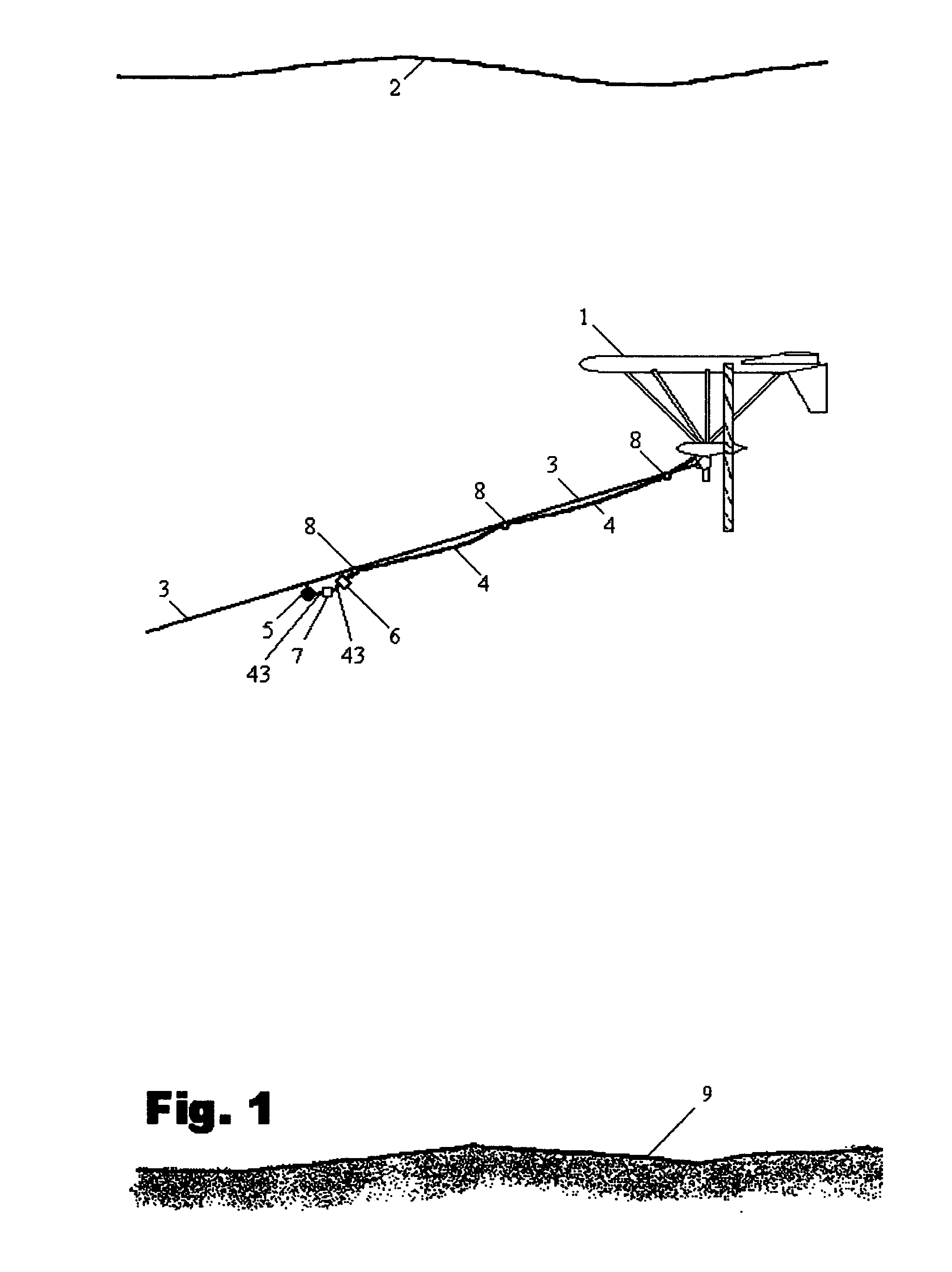

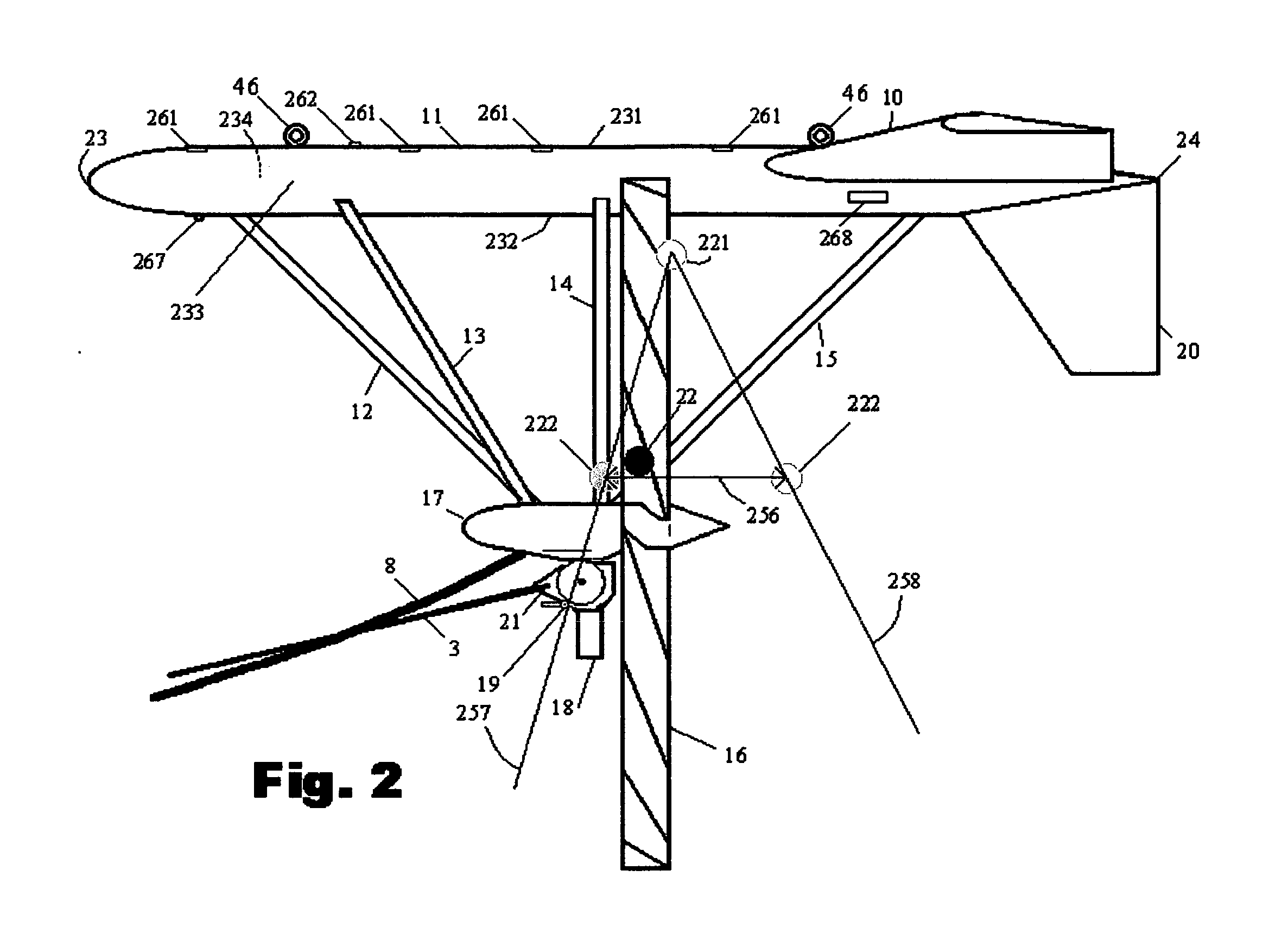

[0068] Referring now to the drawings, the present invention concerns a submersible electrical power generating plant for generating electrical power with no fuel costs from the flow of ocean current. The invention discloses a new and improved apparatus to capture the kinetic energy from the faster moving water that is near the surface of those steady currents that are the result of the Coriolis force produced by the Earth's eastward rotation acting on those currents produced by the trade winds. Instead of building giant structures that rest on the sea floor, the invention utilizes the forces produced by buoyancy, hydrodynamics, kinetic energy, leverage, weight to keep the submerged generators aligned to the current and stable at the desired depth. The invention consists of two counter-rotating, water turbines with a plurality of rotor blades extending radially outward from two separate horizontal axis that convey the kinetic energy from the two side-by-side rear-facing turbine rotor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com