Method and special device for preplacing adhesive tape brazing filler metal for honeycombs

A special device and honeycomb technology, which is applied in the field of engine honeycomb structure manufacturing and repair, can solve the problems of bad influence of brazing quality, uneven thickness of brazing filler metal, easy contamination of brazing filler metal, etc., and achieve stable brazing quality, consistent thickness, The effect of saving solder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

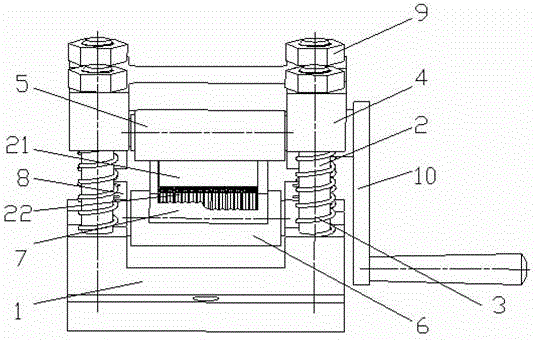

[0036] A method for pre-setting the honeycomb adhesive tape solder: using a rolling method and using a special device to press the adhesive tape solder 21 placed on the honeycomb base surface into the honeycomb core grid;

[0037] The special device (see attached Figure 1-6 ) consists of a base 1, a guide post 2, 4 springs 3, a pressure plate 4, an upper roller 5, a lower roller 6, a supporting plate 7, 4 locking plates 8, 4 compression nuts 9, and a rocker arm 10; Wherein: there are four guide posts 2, all of which are parallel to each other and vertically fixedly arranged on the base 1; the four guide posts 2 in the device are installed and fixed at the four corners of the base 1, and the upper ends of each guide post 2 are processed with threads Each guide post 2 is respectively covered with a spring 3 from bottom to top and a pressure plate 4 is installed, and a compression nut 9 is respectively arranged on the upper end of the guide post 2 above the pressure plate 4;

...

Embodiment 2

[0048] A special device for presetting honeycomb adhesive tape solder (see attached Figure 1-6 ), using it to use the rolling method to press the adhesive tape solder 21 placed on the honeycomb base surface into the honeycomb core grid; Roller 5, lower roller 6, supporting plate 7, 4 locking plates 8, 4 compression nuts 9, and rocker arm 10; wherein: there are 4 guide posts 2, all of which are parallel to each other and vertically fixed on the On the base 1; the four guide posts 2 in the device are installed and fixed at the four corners of the base 1, and the upper end of each guide post 2 is threaded, and each guide post 2 is respectively sleeved with one guide post 2 from bottom to top. The spring 3 is also equipped with a pressure plate 4, and the upper end of the guide post 2 above the pressure plate 4 is also respectively arranged with a compression nut 9;

[0049] Four locking plates 8 are installed in the middle part above the base 1, and the two ends of the lower ro...

Embodiment 3

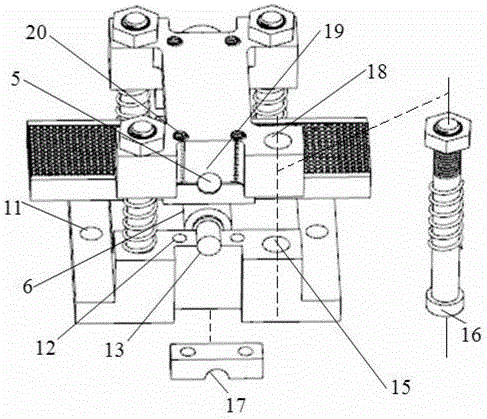

[0058] Such as Figure 1 to Figure 5 The shown method and its device are suitable for the presetting of fan-shaped honeycomb adhesive tape solder. In the device, the base (1) is made of ordinary steel, and its outer dimension is 156×140×45 (mm). There are 4 guide posts (2) mounting holes (15) and 2 symmetrical lower rollers processed on it. (6) semicircular slot A (13), 2 symmetrical mounting holes A (11) and 4 threaded holes A (12) for fixing the lock plate (8). It is mainly used for the installation and fixing of the whole device and the fixing of the guide post (2) and the lower roller (6).

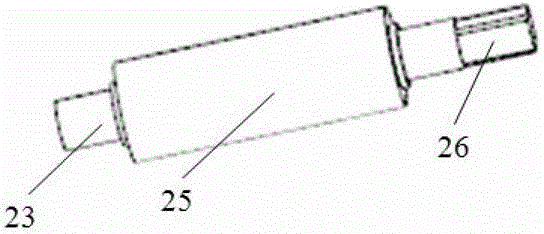

[0059] The guide post (2) is made of high-quality steel, and its size is φ16 × 130 (mm)_____. Its one end is processed with threads, and the other end is processed with bosses (16). The boss 16 of each guide post 2 has an interference fit with the guide post (2) installation hole B (15) on the base (1), which is used for fixing the spring (3), guiding the pressure plate (4), and conn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com