Method for manufacturing powder metallurgy support

A manufacturing method, powder metallurgy technology, applied to other manufacturing equipment/tools, turbines, engine components, etc., can solve the problems of increased cost and no competitive advantage, and achieve reduction of solder, elimination of excessive laser welding parts, and high precision of parts Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

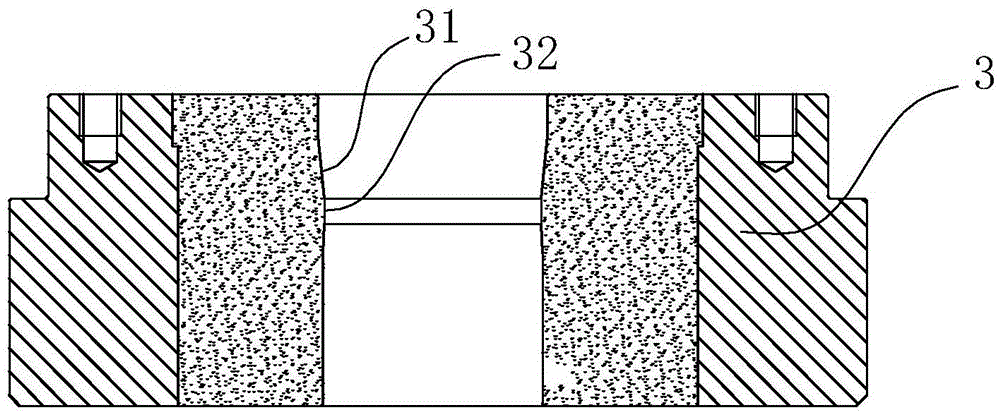

Examples

Embodiment 1

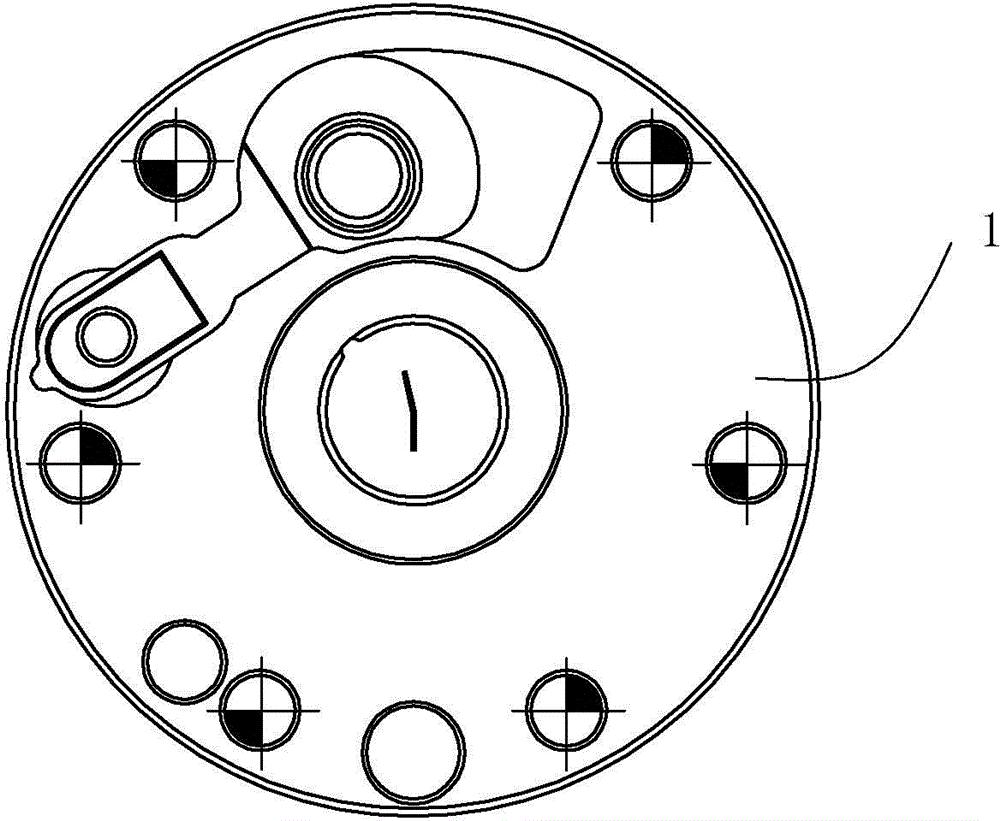

[0029] Embodiment one: (support with vent hole)

[0030] ①. Prepare the raw materials, that is, the mixed powder of iron, chromium, molybdenum and carbon. The ratio is: iron alloy (3.0% for chromium, 0.5% for molybdenum, other unavoidable substances, less than 1%, iron as the balance) is 99.0 %; carbon is 0.40%, and then add lubricant with a content of 0.60%;

[0031] Among them, chromium and molybdenum are added in the form of iron alloy or master alloy or element powder, carbon is added in the form of graphite, and then lubricant is added; lubricant and graphite are added by bonding;

[0032] ②. Press the above mixed powder under a pressure of 600MPa to a density of 6.65g / cm 3 The support blank;

[0033] ③, sintering, the support part is sintered at a temperature of 1200 ° C, the sintering time is 20 minutes, and the sintering is carried out in a vacuum sintering furnace;

[0034] ④ Annealing: the annealing temperature is 850°C; the atmosphere is nitrogen, the annealing h...

Embodiment 2

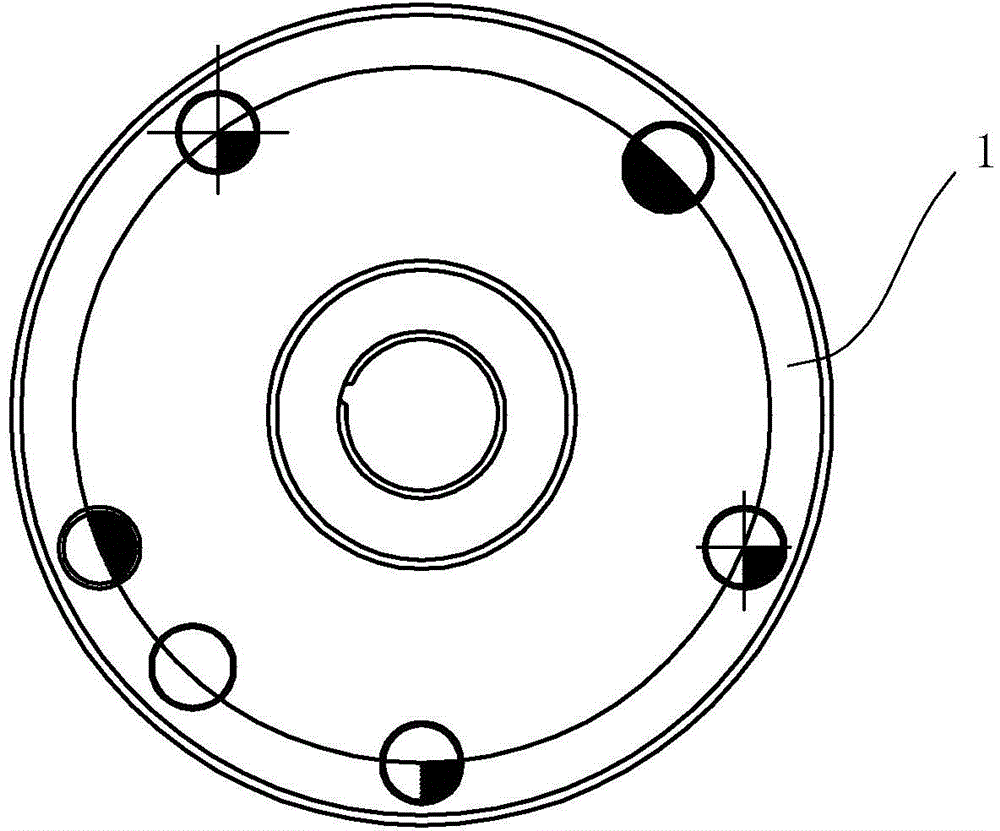

[0040] Embodiment two: (without vent support)

[0041] ① Prepare the raw materials, that is, the mixed powder of iron, chromium, molybdenum and carbon. The ratio is: iron alloy powder (chromium is 3.0%, molybdenum is 0.5%, other unavoidable substances, less than 1%, iron is the balance) is 50 %, pure iron powder is 49.3%; carbon is 0.3%, and then add a lubricant with a content of 0.4%;

[0042] Among them, chromium and molybdenum are added in the form of iron alloy or master alloy or element powder, carbon is added in the form of graphite, and then lubricant is added; lubricant and graphite are added by bonding;

[0043] ②Compress the above mixed powder under a pressure of 600MPa to a density of 6.8g / cm 3 The support blank;

[0044] ③Sintering, the support part is sintered at a temperature of 1120°C, the sintering time is 20 minutes, and the sintering is carried out in a sintering furnace based on nitrogen and the proportion of hydrogen is 10vol%;

[0045]④ Extrusion (finis...

Embodiment 3

[0049] ① Prepare the raw material, that is, the mixed powder of iron and carbon: iron powder (unavoidable other substances are less than 1%, iron is the balance) is 99.0%; carbon is 0.5%, and then add a lubricant with a content of 0.5%;

[0050] Carbon is added in the form of graphite, and then lubricant is added; lubricant and graphite are added by bonding;

[0051] ② Warm press the above mixed powder under a pressure of 600MPa to a density of 7.10g / cm 3 The support is green; the pressing is formed by warm pressing;

[0052] ③Sintering, sintering the support part at a temperature of 1120°C, and the holding time for sintering is 30 minutes;

[0053] ④ Extrusion (finishing): Extrusion is performed on a press modified by an extrusion molding machine or a finishing press, and the extrusion deformation is greater than 4% in the diameter direction, that is (Φ1 挤压件 -Φ1 烧结件 ) / Φ1 烧结件 ×100%≥4%, Φ1 烧结件 is the outer diameter of the sintered state, Φ1 挤压件 is the outer diameter of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com