LED light-emitting panel and manufacturing method thereof

A technology for light-emitting panels and manufacturing methods, applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., can solve problems such as unfavorable packaging reliability, LED pad damage, etc., to save solder, prevent warping, To prevent the effect of temperature difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

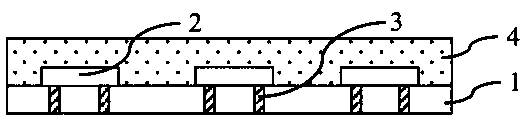

[0032] see Figure 2-8 , the manufacturing method of LED light-emitting panel of the present invention, comprises:

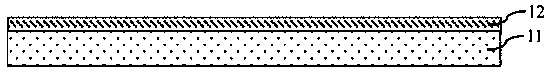

[0033] (1) Refer to figure 2 , providing a metal substrate 11, the metal substrate 11 has an opposite first surface and a second surface, and a first insulating layer 12 is formed on the first surface;

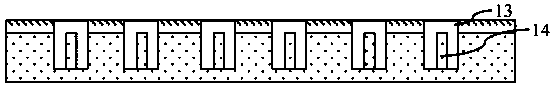

[0034] (2) Refer to image 3 , a plurality of annular blind holes 13 are formed in the metal substrate by laser slotting technology, the annular blind holes 13 penetrate the first insulating layer 12 and go deep into the metal substrate 11, the annular blind holes 13 surround A metal post 14, the first insulating layer 12 on the metal post 14 is removed at the same time;

[0035] (3) Refer to Figure 4 distributing a plurality of LED chips 15 on the first insulating layer 12 with their pads 16 facing the first insulating layer 12, the pads 16 corresponding to the annular blind holes 13 one by one, and The LED chip 15 completely covers the annular blind hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com