Bayonet type socket

A bayonet type, lamp cap technology, applied in incandescent lamps, discharge lamps, incandescent lamp parts and other directions, can solve the problems of poor contact, cumbersome assembly process, easy to loosen, etc., to reduce production costs, simple assembly process, electrical contact good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

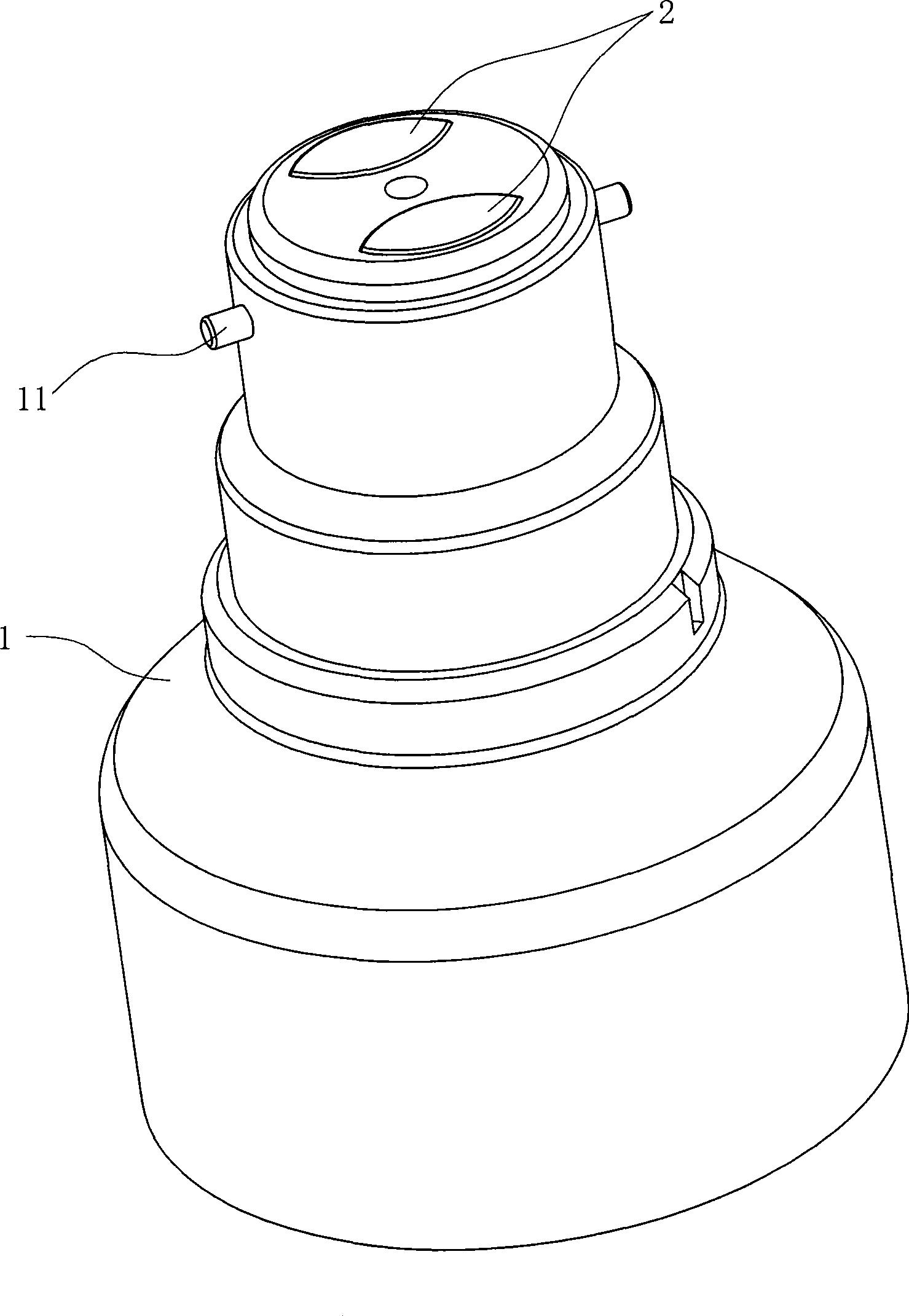

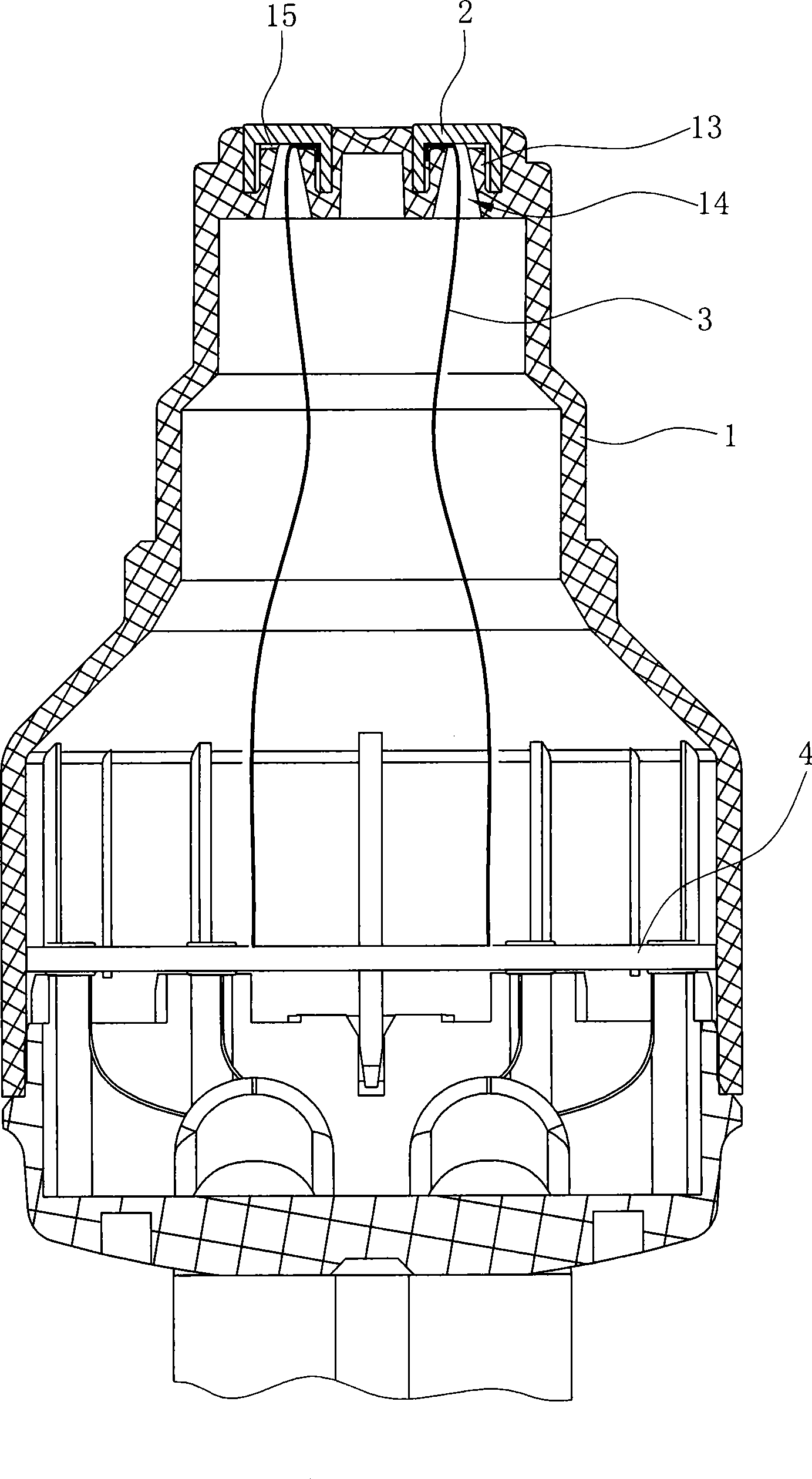

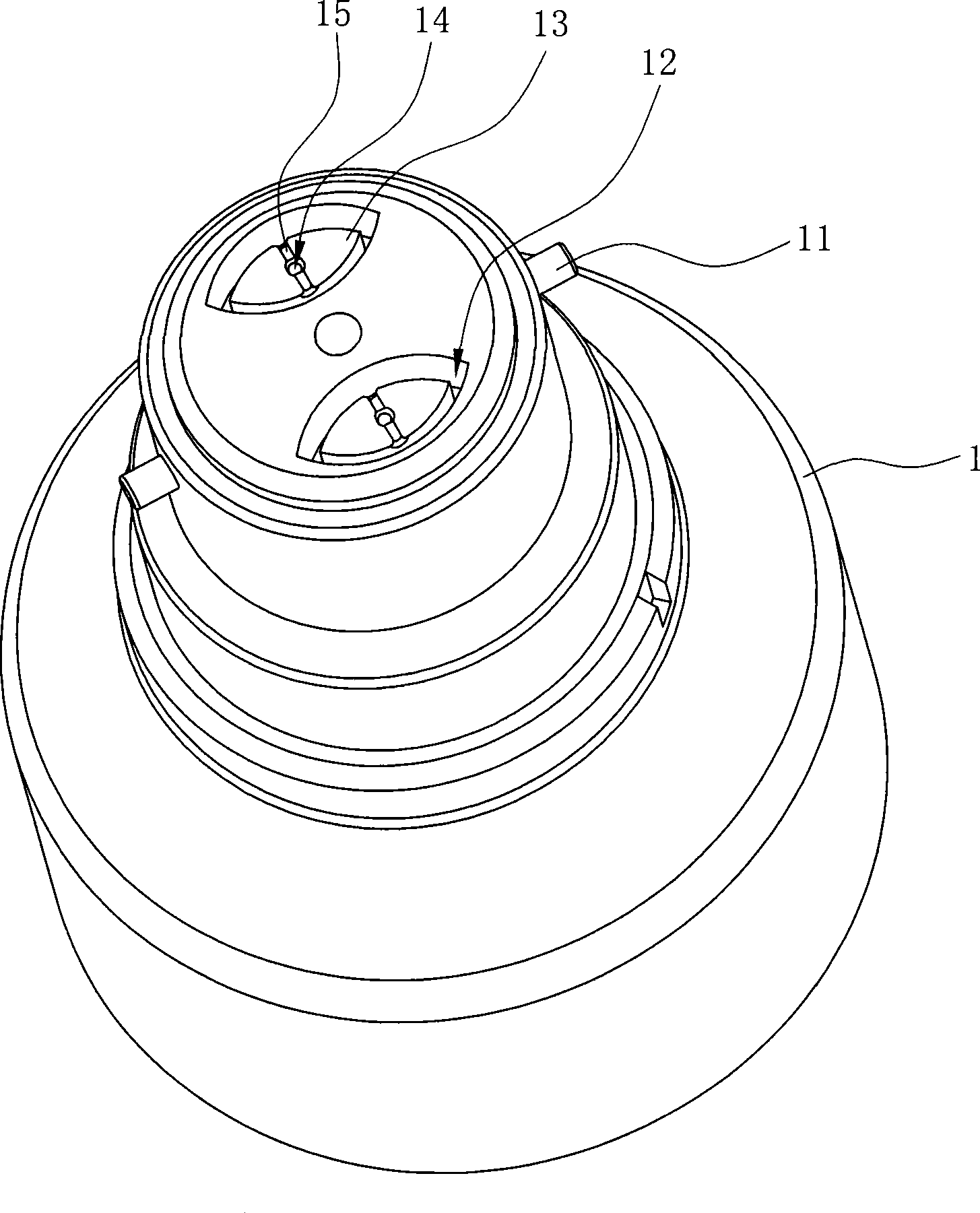

[0014] Such as Figure 1 to Figure 4 As shown, the bayonet type lamp cap includes a lamp cap body 1 made of insulating material and two conductive contacts 2 embedded in the top 1 of the lamp body;

[0015] Wherein, the section of the conductive contact 2 is inverted U-shaped, that is, the conductive contact 2 has a concave cavity inside;

[0016] A pair of bayonet pins 11 are provided on the outside of the lamp body 1, and two grooves 12 that can be embedded with corresponding conductive contacts 2 are provided on the top of the lamp body 1, and each groove 12 is provided with a conductive contact. The inner side wall 21 of 2 is adapted to the boss 13, and each boss 13 has a through hole 14 along the axial direction of the lamp body 1, and the through hole 14 passes through the top of the boss 13, so that the lamp body 1. The interior commu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com