Cast-welding method for lead-acid storage battery tabs

A lead-acid battery and battery technology, applied in the field of lead-acid battery pole lug casting and welding, can solve problems such as unenvironmental protection, lead liquid spillage, waste, etc., and achieve the effect of environmentally friendly solder and saving solder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

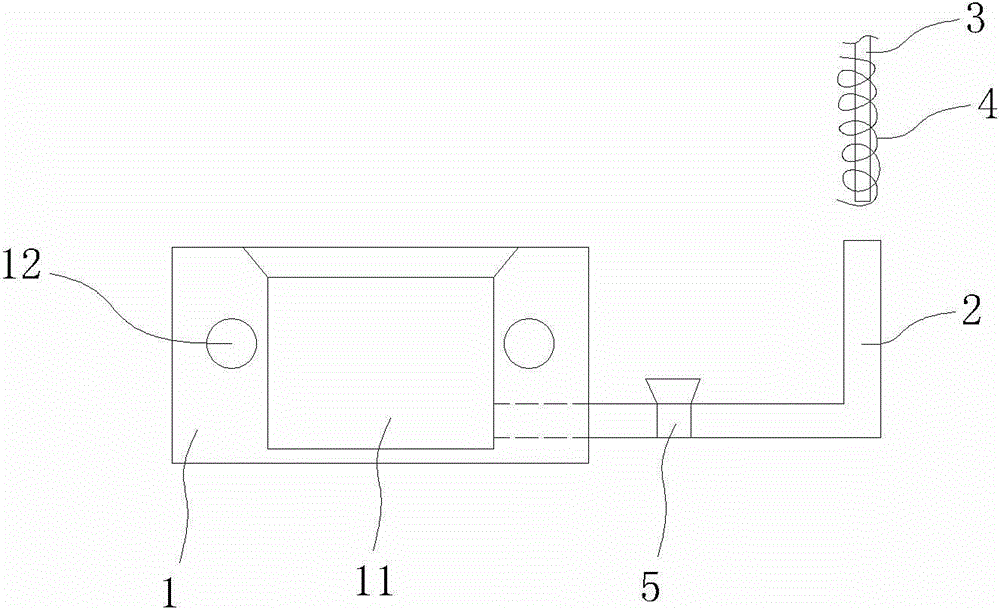

[0015] Example: see figure 1 , a lead-acid battery lug casting method, comprising the steps of: placing the battery pole plate on a casting mold 1, the mold is provided with at least one casting mold cavity 11, the side or bottom of the casting mold cavity passes through the connecting pipe 2 Inject a certain amount of molten lead liquid of V, the amount of lead liquid V is calculated in advance the amount of lead liquid required for welding the lugs of the cast welding mold, the entrance of the connecting pipe 2 is provided with a lead rod 3 and an induction heating device 4, and the induction heating The device quickly heats a section of lead rod 3 to form a lead liquid that drops into the connecting pipe and injects it into the cavity of the casting mold to achieve a certain amount of V, and then performs the lug casting operation. The casting mold cavity, the communicating pipe and the entrance of the communicating pipe of the casting and welding mold of the present invent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com