Automatic feeding device for free-range chickens

An automatic feeding and free-range chicken technology, applied in animal taming devices, poultry industry, applications, etc., can solve the problems of short slaughtering time, slow artificial feeding speed, single function, etc., to ensure effective management, save manpower, The effect of improving meat quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

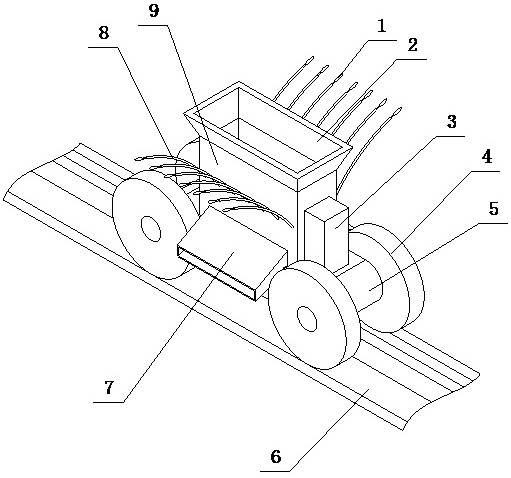

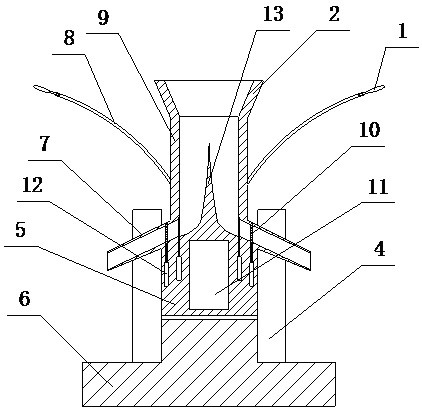

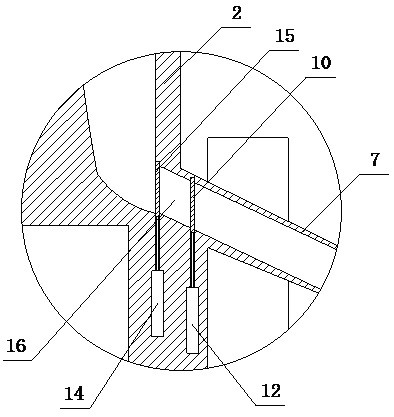

[0017] An automatic feeding device for free-range chickens of the present invention is realized in the following way: an automatic feeding device for free-range chickens of the present invention includes a feeder (17) and a track (6), and the feeder (17) is placed on a predetermined track (6) ) upper cycle movement, using the food-by-eating instinct of free-range chickens, can drive free-range chickens to move continuously and improve the quality of free-range chickens. Box (3), walking wheel (4), power box (5), feeding trough (7), guide leather cover (8), storage box (9), No. 1 baffle (10), battery pack (11 ), the No. 1 cylinder (12), the splitter plate (13), the No. 2 cylinder (14), the No. 2 baffle (15) and the quantitative cavity (16), and the storage box (9) is located directly above the track (6) , the two ends of the storage box (9) are respectively equipped with a power box (5) near the bottom, and the two ends of the power box (5) are respectively equipped with road w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com